Revolutionizing Aquatic Water Treatment: Advanced Industrial Electrolysis Solutions

Aquatic centers face a constant challenge: maintaining pristine water quality for swimmer safety and enjoyment, all while managing operational costs and environmental impact. Traditional chemical disinfection methods often fall short, introducing handling risks and generating undesirable byproducts. This isn't just a nuisance; it's a critical operational hurdle.

Industrial electrolysis emerges as the definitive solution. This isn't a minor upgrade; it's a transformative leap. We're talking about on-site disinfectant generation, precise control, and a significant enhancement to overall facility management. For commercial aquatic centers, public pools, and water parks globally, this technology is a game-changer for securing robust, efficient, and truly sustainable water disinfection.

Understanding Industrial Electrolysis for Superior Aquatic Facilities

The imperative for clean, safe water in aquatic centers isn't negotiable. Industrial electrolysis offers a robust, on-site mechanism for generating necessary disinfectants. This section lays the groundwork, detailing the mechanics and critical components that make this technology indispensable for high-demand aquatic environments.

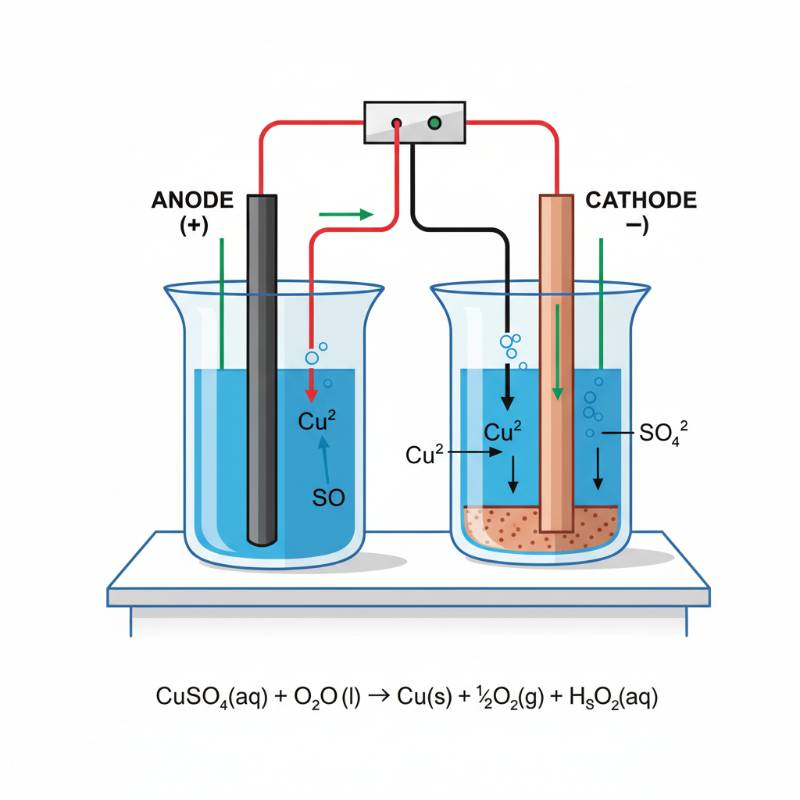

What is Industrial Electrolysis and How Does It Work?

Industrial electrolysis for aquatic centers is a process that converts a simple brine solution (saltwater) into hypochlorite solution, a potent disinfectant. This happens right at your facility. No hazardous chemical deliveries. No bulky storage. Just a reliable, continuous supply of disinfectant.

Industrial Electrolysis: An electrochemical process utilizing an electric current to drive non-spontaneous chemical reactions. In water treatment, this typically involves converting sodium chloride (salt) into sodium hypochlorite (a chlorine-based disinfectant) and other byproducts through an electrolytic cell.

The science is straightforward: an electric current passes through the brine, splitting water and salt molecules. This reaction produces sodium hypochlorite and hydrogen gas. The hypochlorite is then dosed into the pool water, actively disinfecting it. This on-demand generation ensures consistent water purity and minimizes the risks associated with traditional chlorine handling.

Key Components of a High-Performance Electrolysis System

A robust industrial electrolysis system relies on several core components, each engineered for durability and efficiency. At its heart are the electrolytic cells. These cells, often featuring advanced titanium electrodes, are where the magic happens. Titanium, specifically, offers unparalleled corrosion resistance and catalytic activity, crucial for longevity and performance.

Our experience dictates that high-quality electrode materials are not a luxury; they're a necessity. Beyond the cells, the system integrates intelligent power supply units (rectifiers), brine tanks, product storage tanks, and sophisticated control systems. These components work in concert to deliver a reliable and automated disinfection process. At China Titanium Factory, we specialize in the fabrication of these crucial electrolytic cell components, ensuring peak system performance.

Safety and Operational Considerations for Aquatic Environments

Safety is paramount in any aquatic facility. Industrial electrolysis inherently improves safety by eliminating the need to store and handle bulk hazardous chemicals like chlorine gas or concentrated liquid chlorine. The primary inputs are salt and water, significantly reducing risks for staff and patrons.

Operational best practices include regular system monitoring, adherence to manufacturer guidelines, and proper ventilation for the minimal hydrogen gas byproduct. Modern systems often feature automated safety shutdowns and remote monitoring capabilities, providing an extra layer of protection. Compliance with local health codes and CDC guidelines for pool water disinfection is straightforward with these systems.

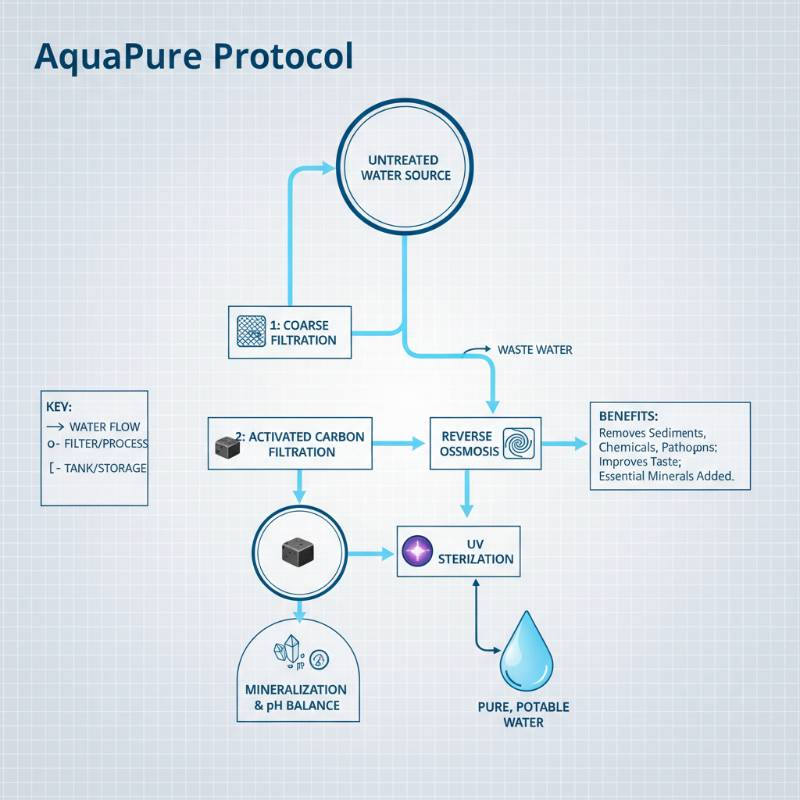

The 'AquaPure' Protocol: Our Proprietary Approach to Water Purity

Implementing a new water treatment system requires more than just hardware. It demands a strategic, tailored approach. We call ours the 'AquaPure' Protocol. This unique, multi-phase methodology ensures optimal integration and performance of industrial electrolysis solutions for any aquatic center. It’s our framework for guaranteeing an efficient, sustainable, and custom water treatment strategy.

The Golden Rule of Aquatic Electrodialysis: Proactive, precision-engineered on-site disinfection, underpinned by robust electrode technology, is the cornerstone of sustainable aquatic health and operational excellence.

Phase 1: Comprehensive Needs Assessment & Custom System Design

Every aquatic facility is unique. Our first step involves a meticulous evaluation of your specific requirements. We delve into your facility's size, bather load, existing water chemistry, and any operational challenges you face. This isn't a one-size-fits-all approach. We conduct detailed water analyses and site surveys. This data informs the custom engineering of an electrolysis system perfectly sized and configured for your distinct needs.

Phase 2: Seamless Integration & Expert Installation

Disruption is costly. Our expert team ensures a smooth transition and professional installation, minimizing downtime. We integrate the new electrolysis system flawlessly with your existing water treatment infrastructure. This often involves connecting to existing circulation pumps, filtration systems, and control panels. Our project managers oversee every detail, from delivery to commissioning, ensuring a hassle-free setup.

Phase 3: Ongoing Optimization, Training & Dedicated Support

Our commitment extends far beyond installation. We provide comprehensive operator training, empowering your team to manage and optimize the system effectively. Post-installation, we offer continuous system optimization services and responsive technical support. This ensures your system performs at its peak, always delivering superior water quality. Think of it as having an expert in your corner, ensuring long-term success. Need assistance? Our support team is just a call away.

Transformative Benefits for Modern Aquatic Centers

Adopting industrial electrolysis isn't just about switching technologies; it's about unlocking a cascade of benefits. From superior water quality to tangible cost savings and a greener operational footprint, the advantages are profound and far-reaching.

Superior Water Quality and Unmatched Disinfection

Achieve consistently pristine water. On-site generated disinfectants are fresher and typically more effective than stored chemicals. This translates to superior pathogen control, effective algae elimination, and a significant reduction in irritating chloramines. Swimmers notice the difference immediately: less "chlorine smell," fewer red eyes, and a more enjoyable experience. This aligns with EPA standards for water quality, ensuring public health.

Enhanced Safety and Streamlined Operational Efficiency

The elimination of bulk hazardous chemical storage is a huge win for safety. Staff no longer contend with caustic liquids or dangerous gases. This reduces workplace accidents and insurance liabilities. Automated electrolysis systems also reduce labor requirements significantly. Fewer manual chemical adjustments mean staff can focus on other critical tasks, streamlining operations and boosting overall efficiency.

Environmental Stewardship and Sustainable Practices

Electrolysis vs. Traditional Methods: A Strategic Comparison for Aquatic Facilities

Making the switch to industrial electrolysis is a strategic decision. It's not just about a different way to sanitize water; it's about a fundamental shift in operational philosophy. Let's stack it up against conventional chlorination.

Cost-Benefit Analysis: ROI and Long-Term Savings

While the initial investment for an industrial electrolysis system might be higher than a traditional chemical dosing setup, the long-term financial benefits are substantial. Significant savings come from:

Reduced Chemical Purchases: No more recurring costs for bulk chlorine. Only salt and electricity are needed.

Lower Labor Costs: Automated systems reduce manual handling and monitoring.

Minimized Maintenance: High-quality systems, especially those with durable titanium anodes, require less frequent component replacement.

Decreased Insurance Premiums: Reduced hazard exposure often leads to lower rates.

Our analysis shows many aquatic centers achieve a full return on investment within 2-5 years. That's a strong proposition.

Performance and Maintenance Differences Unveiled

Consider the stark differences:

| Feature | Industrial Electrolysis | Traditional Chlorine Dosing |

|---|---|---|

| Disinfectant Source | On-site generated from salt | Delivered bulk chemicals (liquid, gas, tablets) |

| Safety Profile | Significantly reduced chemical handling risks | High risks associated with storage & handling of hazardous chemicals |

| Water Quality | More stable, fewer chloramines, superior clarity | Fluctuations common, higher chloramine levels |

| Operational Costs | Lower long-term due to reduced chemical & labor costs | High recurring chemical purchase and labor costs |

| Maintenance | Periodic cell cleaning, general system checks | Regular calibration, pump maintenance, leak checks for chemical lines |

Electrolysis offers superior, more consistent performance with less hassle and greater reliability. It's a clear win for modern aquatic facility managers.

Tailored Solutions for Diverse Aquatic Venues

One size doesn't fit all in the aquatic world. A bustling municipal pool has different demands than a high-tech competitive venue. Our expertise lies in recognizing these nuances and providing specialized industrial electrolysis solutions that fit like a glove.

Municipal Pools & Public Facilities

These facilities often endure high bather loads and stringent public health standards. Our robust solutions are engineered for continuous operation, ensuring consistent disinfection and cost-effective management for large volumes of water and diverse user groups. Public safety remains our top priority.

Water Parks & Recreational Centers

Complex water features, varying demand, and extensive plumbing characterize water parks. We design advanced systems capable of handling these intricacies, maintaining optimal water quality across slides, wave pools, and interactive zones. Scalability is key here, and our solutions deliver.

Competitive & Therapy Pools

For competitive athletes, water quality directly impacts performance and health. Therapy pools require precise chemical balance for sensitive users. Our systems offer precision control, ensuring exact chemical parameters and maximizing swimmer comfort and well-being. No compromise on quality where it matters most.

Case Studies & Client Success Stories

The proof is in the pudding. Real-world applications demonstrate the power of industrial electrolysis. These examples highlight the quantifiable benefits and transformative impact on operations.

Leading Aquatic Center Achieves Peak Performance with Electrolysis

A major aquatic complex, grappling with escalating chemical costs and inconsistent water quality, transitioned to our industrial electrolysis system. The results were dramatic. Water quality improved markedly, with chloramine complaints dropping by 80%. Operational costs saw a 30% reduction within the first year, largely due to eliminating chemical procurement and storage. Staff reported a significant boost in safety and morale, no longer handling hazardous materials. This was a true operational overhaul.

Sustainable Operations for a Large-Scale Water Park

A prominent water park sought to enhance its environmental stewardship. By adopting our sustainable electrolysis solution, they drastically lowered their environmental footprint. Chemical waste was virtually eliminated, and the need for chemical transport trucks disappeared. This led to substantial chemical savings and positioned the park as an industry leader in green technology. It was a smart move for their bottom line and their public image.

Your Partner in Advanced Aquatic Water Treatment

Choosing the right partner is critical. At China Titanium Factory, we're more than just suppliers; we're innovators in the field of industrial electrolysis. Our expertise in durable, high-performance electrolytic cells and custom-engineered systems sets us apart. We understand the specific demands of aquatic environments.

Elevate your aquatic center's water quality, operational efficiency, and sustainability. Our team of experts is ready to collaborate, providing a tailored industrial electrolysis solution that meets your unique challenges and goals. Let's make your aquatic center a beacon of clean water and operational excellence.

Frequently Asked Questions (FAQ)

How does industrial electrolysis compare to traditional chlorine dosing?

Industrial electrolysis generates chlorine on-site from salt and water, eliminating the need for hazardous chemical storage and transport. This results in more stable water chemistry, significantly fewer chloramines (the cause of "chlorine smell" and irritation), and enhanced safety compared to traditional methods that rely on delivered, stored chemicals.

What is the typical ROI for an electrolysis system in an aquatic center?

While initial investment varies based on system size and complexity, many aquatic centers experience a return on investment within 2-5 years. This comes from substantial savings on chemical purchases, reduced labor for chemical handling, and lower maintenance costs due to the durability of industrial-grade components.

Are these systems safe for swimmers and staff?

Absolutely. Industrial electrolysis systems are inherently safer. They eliminate the storage and handling of bulk hazardous chemicals, drastically reducing risks for staff. For swimmers, the reduction of chloramines means less eye and skin irritation, and a more pleasant, healthier swimming environment.

What maintenance is required for an industrial electrolysis unit?

Routine maintenance typically involves periodic cleaning of the electrolytic cells to remove scale, checking salt levels in the brine tank, and general system monitoring. Our systems are engineered for ease of maintenance and long operational life, often requiring less intensive upkeep than traditional chemical systems.

Can an electrolysis system be integrated with my existing water treatment infrastructure?

Yes, most definitely. Our industrial electrolysis solutions are designed for seamless integration with existing water treatment infrastructure, including filtration, circulation, and control systems. Our expert team provides comprehensive support throughout the integration process, ensuring a smooth transition with minimal operational disruption.

Ready to Transform Your Aquatic Center's Water Quality?

Discover how industrial electrolysis can elevate your facility.

Contact us today for a tailored consultation and a quote on our advanced solutions.