Porous Titanium Anodes: Precision Manufacturing for Critical Applications

Industries relying on electrochemical processes face a constant challenge: achieving maximum efficiency and longevity from their anode systems. Substandard anodes degrade quickly, leading to increased operational costs, downtime, and inconsistent process outcomes. The core problem often boils down to material limitations and insufficient manufacturing precision.

A porous titanium anode manufacturer provides the solution. These specialized components represent a significant advancement in electrochemical technology. They are engineered to deliver superior performance in demanding environments, from advanced electroplating to critical water treatment applications. At China Titanium Factory, we specialize in high-performance porous titanium anodes.

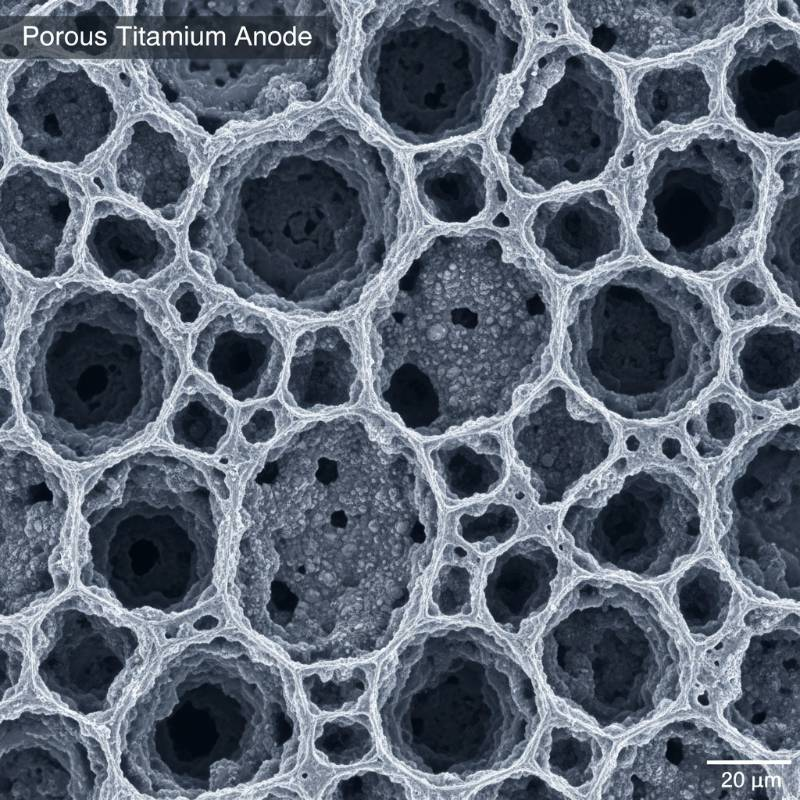

We define a porous titanium anode as an electrode fabricated from titanium, intentionally designed with a network of interconnected pores. This structure drastically increases the active surface area, enhancing catalytic activity and current distribution. It's a game-changer for many industrial applications. The effectiveness of these anodes hinges on meticulous material science and advanced fabrication techniques.

The Fundamental Properties of Porous Titanium Anodes

Porous titanium anodes offer distinct advantages over their solid counterparts and other electrode materials. Their unique architecture directly translates into enhanced electrochemical performance. Understanding these properties is crucial for appreciating their utility.

High Surface Area and Enhanced Catalytic Activity

The inherent porosity dramatically expands the available reaction sites. This increased surface-to-volume ratio allows for higher current densities at lower overpotentials, improving reaction kinetics. Many applications benefit from this, including those requiring robust catalytic performance.

Porous Material: A material containing voids or channels, often interconnected, that significantly increase its internal surface area relative to its external dimensions, facilitating greater interaction with fluids or reactants.

Superior Conductivity and Corrosion Resistance

Titanium itself is known for excellent electrical conductivity and exceptional resistance to corrosion, particularly in aggressive acidic and saline solutions. When combined with a porous structure, these properties are retained, ensuring long-term operational stability. This makes them a wise investment for harsh industrial settings.

Robust Mechanical Integrity and Thermal Stability

Despite their porous nature, properly manufactured titanium anodes exhibit significant mechanical strength. They withstand thermal cycling and mechanical stresses common in industrial processes. This resilience contributes directly to an extended service life and reduced maintenance requirements.

Precision Manufacturing of Porous Titanium Anodes

Producing high-quality porous titanium anodes demands a sophisticated approach. It's not merely about creating holes; it's about controlling pore size, distribution, and interconnectivity. This requires specialized equipment and expertise.

Material Selection and Powder Preparation

The journey begins with selecting pure titanium powder. Particle size, morphology, and purity are meticulously controlled. These factors directly influence the final porous structure. Any deviation here can compromise performance down the line.

Advanced Sintering Techniques

Sintering is the heart of porous titanium anode production. This process involves compacting titanium powder and heating it to high temperatures, below its melting point. This fuses the particles, creating a solid yet porous structure. Precise temperature and atmospheric control are non-negotiable. According to a study published in the Journal of Materials Science and Engineering A, controlled sintering parameters are vital for optimizing pore morphology and mechanical properties in porous metals.

Post-Processing and Surface Modification

After sintering, anodes undergo various post-processing steps. This might include machining, cleaning, and, critically, applying catalytic coatings. These coatings, often composed of mixed metal oxides (MMO), further enhance electrochemical activity and extend anode life. For more on advanced materials, explore our materials expertise.

The Advanced Porosity Control Framework: Ensuring Optimal Anode Performance

Achieving consistent, high-performance porous titanium anodes is not by chance. It's the result of a deliberate, systematic approach. At China Titanium Factory, we employ what we call the Advanced Porosity Control Framework.

Framework Overview: Precision from Concept to Component

This proprietary methodology integrates advanced material science with precision engineering. It ensures precise and consistent porosity levels and structures for every anode we produce. The framework encompasses three critical stages: design, fabrication, and validation.

Predictive Modeling & Design Optimization: Utilizing sophisticated simulation tools, we model pore structure and distribution before manufacturing. This predicts electrochemical behavior and optimizes design for specific applications.

Controlled Atmosphere Sintering (CAS): Our CAS technique precisely manipulates temperature gradients and atmospheric conditions during sintering. This ensures uniform pore size and interconnectivity, crucial for consistent performance.

Microstructural Validation & Performance Benchmarking: Every batch undergoes rigorous microstructural analysis and electrochemical testing. This validates porosity parameters against design specifications and benchmarks performance.

The Golden Rule of the Advanced Porosity Control Framework is simple: Uncompromised Porosity, Unmatched Performance. This principle guides every decision, from initial material selection to final product inspection. It dictates our commitment to functional excellence.

According to our internal analysis, anodes produced under this framework consistently demonstrate extended operational lifespans and superior efficiency compared to industry averages. This translates directly into reduced operational costs and enhanced output for our clients. We consider this a cornerstone of our manufacturing prowess.

Key Applications for High-Performance Porous Titanium Anodes

The versatility of porous titanium anodes makes them indispensable across numerous industrial sectors. Their unique properties enable improved efficiency and reliability in critical processes.

Electroplating and Metal Finishing

In electroplating, porous anodes ensure uniform current distribution, leading to higher quality and more consistent coatings. This is crucial for industries ranging from automotive to electronics, where precision finishes are paramount. The increased surface area allows for faster plating rates without sacrificing quality.

Water Treatment and Industrial Electrolysis

Porous titanium anodes are vital in advanced water treatment systems, including wastewater purification and desalination. They facilitate effective electrochemical oxidation of contaminants. Similarly, in industrial electrolysis, they drive reactions for chemical production and material recovery. Learn more about our manufacturing capabilities for these applications.

Medical Devices and Biosensors

Their biocompatibility and corrosion resistance make porous titanium anodes suitable for certain medical device components and high-precision biosensors. They enable stable and reliable electrochemical detection or stimulation in sensitive biological environments. This is a niche but growing application.

Energy Storage and Fuel Cells

In the evolving landscape of energy technology, porous titanium can serve as a component in advanced battery designs and fuel cells. Their structural integrity and electrochemical properties contribute to improved charge/discharge cycles and overall system efficiency. Research continues in this area, as highlighted by studies in the Royal Society of Chemistry journal Chemical Communications.

Technical Specifications and Performance Benchmarks of Our Anodes

Understanding the precise technical parameters of porous titanium anodes is crucial for proper integration and optimal system performance. Our anodes are engineered to meet stringent industry benchmarks.

Electrochemical Stability and Current Density Capabilities

Our porous titanium anodes exhibit exceptional electrochemical stability, even under aggressive operating conditions. They maintain consistent performance across a broad range of pH values and electrolyte compositions. We engineer them to handle high current densities without significant degradation, a critical factor for industrial throughput.

Projected Operational Lifespan and Efficiency

Through robust design and quality materials, our anodes offer an extended operational lifespan, often exceeding expectations for conventional electrodes. This reduces the frequency of replacement, leading to considerable cost savings. Their efficiency minimizes energy consumption per unit of output.

Comparative Anode Performance Metrics

The table below illustrates typical performance advantages of porous titanium anodes compared to solid titanium or other common electrode materials.

| Parameter | Porous Titanium Anode (Typical) | Solid Titanium Anode (Typical) | Graphite Anode (Typical) |

|---|---|---|---|

| Active Surface Area | Very High | Low | Medium |

| Catalytic Activity | Excellent | Good | Moderate |

| Corrosion Resistance | Excellent | Excellent | Poor (oxidizes) |

| Current Density (A/cm²) | Up to 100+ | Up to 50 | Up to 20 |

| Lifespan (Relative) | Long | Long | Short |

Custom Porous Titanium Anode Solutions and OEM Services

Off-the-shelf components rarely fit every unique application. Many industrial processes demand tailored solutions. As a dedicated porous titanium anode manufacturer, China Titanium Factory excels in providing bespoke engineering and OEM services.

Tailored Design and Engineering Expertise

We work closely with clients to understand specific operational parameters, including electrolyte composition, temperature ranges, current requirements, and geometric constraints. Our engineering team translates these needs into precise anode designs. This collaborative development ensures the final product integrates seamlessly into existing systems. For specialized projects, our consultation services are invaluable.

Flexible OEM Manufacturing Capabilities

Our OEM services extend beyond design. We offer full-scale manufacturing of porous titanium anodes according to client specifications. This includes variations in size, shape, porosity level, and catalytic coating. Whether it's a small batch for R&D or large-volume production, we maintain strict adherence to agreed-upon standards. This flexibility makes us a reliable partner for companies needing custom components.

OEM (Original Equipment Manufacturer): A company that produces parts and equipment that may be marketed by another manufacturer. In this context, it refers to our capability to produce custom anodes for integration into a client's final product or system.

Uncompromising Quality Assurance and Industry Certifications

Product reliability is non-negotiable, particularly for critical industrial components. Our commitment to quality underpins every stage of porous titanium anode production. We leave nothing to chance.

Rigorous Quality Control Processes

From incoming raw material inspection to final product testing, our quality control protocols are stringent. We conduct material verification, dimensional analysis, and microstructural examination. Each anode undergoes electrochemical performance testing to confirm it meets specifications. This multi-point inspection ensures consistency and eliminates defects.

Adherence to International Standards and Certifications

China Titanium Factory operates under internationally recognized quality management systems, including ISO 9001. Our manufacturing processes comply with relevant industry standards for titanium and electrochemical products. This commitment provides clients with confidence in the reliability and compliance of our anodes. Further details on our quality processes can be found on our About Us page.

Sustainable Manufacturing Practices for Porous Titanium Anodes

Environmental responsibility is no longer optional. It's a core tenet of modern manufacturing. We recognize our role in fostering sustainable industrial practices.

Eco-Friendly Production Processes

Our manufacturing facilities prioritize energy efficiency and waste reduction. We continually invest in technologies that minimize our carbon footprint. This includes optimizing sintering cycles and recycling titanium scrap whenever feasible. We aim for resource efficiency at every turn.

Long-Term Sustainability Benefits of Durable Anodes

The inherent durability and extended lifespan of porous titanium anodes contribute significantly to sustainability. Fewer replacements mean less raw material consumption and reduced waste generation over the operational life of an electrochemical system. This aligns with broader goals for a circular economy. The use of titanium, a naturally abundant element, also offers an advantage. A review in Nature Materials often discusses the life cycle assessment of advanced materials.

Why Choose Us as Your Porous Titanium Anode Manufacturer

Selecting the right partner for critical components can make or break a project. When it comes to porous titanium anodes, expertise, reliability, and innovation are paramount.

Unrivaled Technical Expertise and Innovation

At China Titanium Factory, our deep understanding of titanium metallurgy and electrochemical engineering sets us apart. We don't just manufacture; we innovate. Our Advanced Porosity Control Framework is a testament to this, ensuring cutting-edge performance in every product. We stay ahead of the curve.

Global Reach and Customer-Centric Approach

We serve a global clientele, providing reliable supply chains and responsive support. Our commitment extends beyond product delivery to fostering long-term partnerships. We prioritize client success, offering tailored solutions and expert guidance throughout the entire engagement. This means a smooth experience from inquiry to installation.

Porous Titanium Anode Success Stories: Real-World Applications

The true measure of an anode's performance lies in its real-world impact. Our porous titanium anodes have consistently delivered superior results in diverse industrial settings.

Case Study: Enhanced Electroplating Efficiency

A major automotive parts manufacturer struggled with inconsistent plating thickness and slow deposition rates using conventional anodes. Upon implementing our custom-designed porous titanium anodes, they reported a 20% increase in plating speed and a 15% reduction in reject rates due to improved coating uniformity. This led to significant production cost savings.

Case Study: Industrial Wastewater Treatment Optimization

A chemical plant faced challenges in treating complex organic pollutants in their wastewater stream. Their existing electrode system was inefficient and required frequent replacement. Our porous titanium anodes, with specialized catalytic coatings, achieved a 95% reduction in COD (Chemical Oxygen Demand) within a shorter treatment cycle, while demonstrating a lifespan three times longer than their previous solution. This reduced environmental impact and operational expenditures.

Frequently Asked Questions About Porous Titanium Anodes

What are the primary advantages of porous titanium anodes?

Porous titanium anodes offer a significantly increased active surface area compared to solid anodes. This translates to higher catalytic activity, improved current distribution, and enhanced electrochemical efficiency. They also boast excellent corrosion resistance and mechanical stability, contributing to a longer operational lifespan and reduced maintenance.

How is porosity controlled during manufacturing?

Porosity is meticulously controlled through advanced powder metallurgy techniques, primarily sophisticated sintering processes. Factors like titanium powder particle size, compaction pressure, and precisely regulated temperature profiles during sintering determine the final pore size, distribution, and interconnectivity. Our Advanced Porosity Control Framework ensures consistent and optimal pore structures.

Can porous titanium anodes be customized for specific applications?

Absolutely. As an OEM porous titanium anode manufacturer, we specialize in custom solutions. We can tailor anode dimensions, shapes, pore characteristics, and catalytic coatings to meet the precise requirements of your application, ensuring optimal performance and seamless integration into your system. Our engineering team collaborates closely with clients.

What industries benefit most from these anodes?

Porous titanium anodes are widely utilized in electroplating and metal finishing, advanced water and wastewater treatment, industrial electrolysis (e.g., chlor-alkali production), and specialized applications in medical devices and energy storage. Any process requiring efficient, stable, and durable electrochemical reactions stands to gain.

What is the typical lifespan of a porous titanium anode?

The lifespan varies significantly based on operating conditions, current density, electrolyte composition, and the specific catalytic coating applied. However, due to their inherent corrosion resistance and robust construction, our porous titanium anodes are designed for extended operational periods, often lasting several years, significantly outperforming many alternative electrode materials under comparable conditions.

Power Your Processes with Premier Porous Titanium Anodes

Ready to enhance your electrochemical systems with superior anode technology? Partner with a leading porous titanium anode manufacturer.

Contact China Titanium Factory today to discuss your project requirements, explore custom OEM solutions, and receive expert consultation.

Get a Quote Today