Mastering the Art of Welding Titanium to Steel: An Engineer's Guide

Joining titanium to steel isn't just a technical hurdle; it's a profound metallurgical challenge. For engineers and materials scientists, the prospect of combining titanium's exceptional strength-to-weight ratio and corrosion resistance with steel's structural integrity and cost-effectiveness is highly appealing. However, the inherent differences between these two metals make direct fusion welding a tough nut to crack, often leading to brittle joints and premature failure.

This guide cuts through the complexity, detailing why welding titanium to steel is so problematic and, more importantly, exploring the advanced solutions that make it possible. We'll lay out the principles, highlight the critical challenges, and walk through the cutting-edge techniques that engineers are employing to successfully bond these dissimilar materials for high-performance applications.

Understanding the Fundamentals: Why Welding Titanium to Steel is So Difficult

At first glance, it might seem straightforward to weld any two metals. But when it comes to titanium and steel, their fundamental differences clash. It's not just about melting points; it's about deep-seated metallurgical and physical incompatibilities that prevent a stable, strong joint from forming under conventional welding processes.

Understanding these core issues is the first step toward finding viable solutions. Without this foundational knowledge, attempts to weld titanium to steel are often dead on arrival.

The Problem of Intermetallic Compounds: Fe-Ti Phases

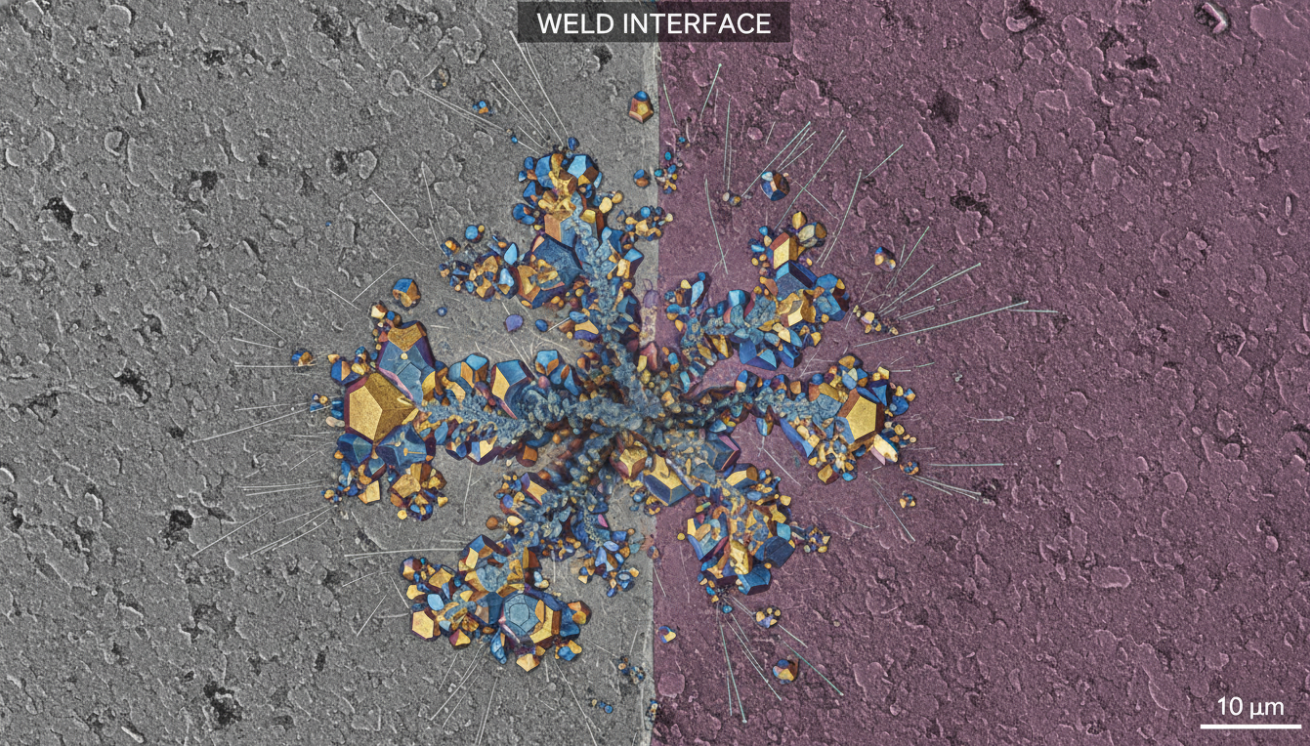

The most significant hurdle in welding titanium to steel lies in the formation of brittle intermetallic compounds. When iron (from steel) and titanium mix at high temperatures, they readily form compounds like FeTi and Fe2Ti. These phases are hard, but critically, they are also incredibly brittle, acting like microscopic stress concentrators within the weld metal.

Even tiny amounts of these intermetallics can severely compromise the joint's ductility and toughness, making it prone to cracking during cooling or under service loads. Think of it like a chain with a brittle link; the entire assembly is only as strong as its weakest point. For more on metallurgical reactions in dissimilar welds, consider resources like the American Welding Society (AWS).

Definition: Intermetallic Compound

An intermetallic compound is a chemical compound formed between two or more metallic elements, typically characterized by a well-defined stoichiometry and crystal structure, often exhibiting properties distinct from its constituent metals. In the context of welding titanium to steel, these compounds (e.g., FeTi, Fe2Ti) are often brittle and detrimental to joint integrity.

Galvanic Corrosion: A Silent Threat in Dissimilar Welds

Beyond mechanical issues, an electrochemical problem looms large: galvanic corrosion. Titanium and steel have significantly different electrochemical potentials. When these two metals are in electrical contact and exposed to an electrolyte (like saltwater or even humid air), the less noble metal (typically steel) will corrode preferentially.

This isn't just a surface issue; it can lead to rapid degradation of the steel component near the weld interface, compromising the entire structure over time. It's a critical consideration, especially for marine or chemical processing applications where the joint will be exposed to corrosive environments. Understanding and mitigating this risk is paramount for long-term reliability.

Definition: Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals with different electrode potentials are in electrical contact and immersed in an electrolyte. The more active (anodic) metal corrodes at an accelerated rate, while the more noble (cathodic) metal is protected.

Thermal Expansion Mismatch and Residual Stress

Titanium and steel expand and contract at different rates when heated and cooled. This difference in the coefficient of thermal expansion (CTE) creates significant internal stresses as a welded joint cools from the molten state. As the weld solidifies and shrinks, these differing contraction rates can pull the materials apart, leading to residual stresses that are high enough to cause cracking.

This cracking often occurs in the heat-affected zone (HAZ) or at the interface, even without external loads. Managing these stresses is vital. It's like trying to perfectly fit two pieces of a puzzle that change size at different rates; it's a recipe for internal tension.

Key Challenges and Risks in Titanium-Steel Welding

Beyond the fundamental metallurgical obstacles, practical challenges abound when one attempts to weld titanium to steel. Manufacturers and engineers consistently run into a range of issues that can derail project timelines and compromise product quality. Tackling these head-on is crucial for any successful fabrication.

The primary risks include:

| Challenge Area | Specific Risk | Impact on Joint |

|---|---|---|

| Metallurgical Integrity | Brittle Intermetallic Formation | Severely reduced ductility and fracture toughness; immediate cracking. |

| Corrosion Resistance | Galvanic Corrosion | Accelerated degradation of the steel component in corrosive environments. |

| Mechanical Properties | Reduced Strength/Ductility | Joint fails under operational loads far below design expectations. |

| Physical Defects | Porosity, Cracking, Lack of Fusion | Compromised structural integrity; potential leak paths; catastrophic failure. |

| Process Control | High Heat Input, Inadequate Shielding | Exacerbates intermetallic formation and leads to contamination. |

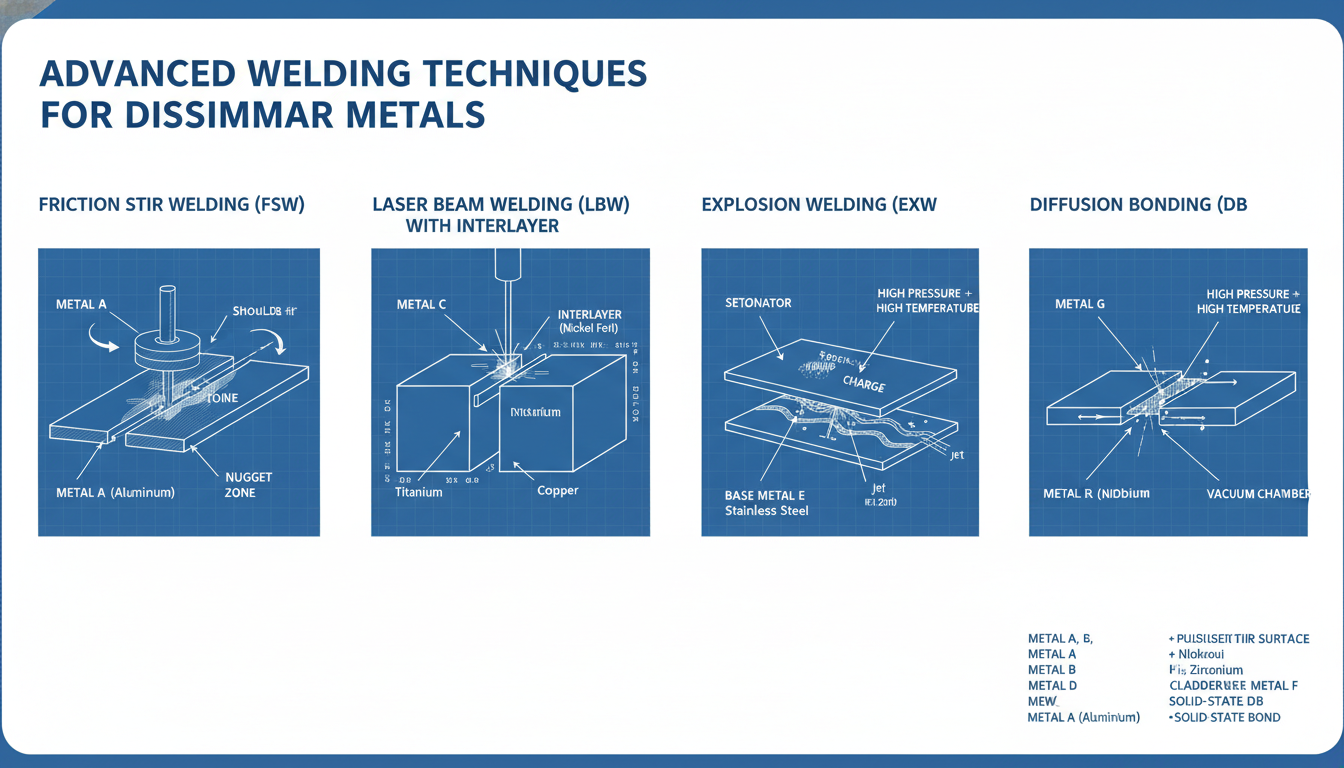

Advanced Methods for Successfully Joining Titanium and Steel

Given the inherent difficulties, direct fusion welding of titanium to steel is rarely successful. The good news? Engineers have developed sophisticated, indirect joining methods that circumvent these problems. These techniques focus on minimizing the formation of brittle phases, managing thermal stresses, and often employing intermediate materials to create a robust bond.

These advanced processes are the workhorses behind successful dissimilar metal joints in demanding industries. Finding the right approach often depends on the specific application, material thickness, and required joint properties.

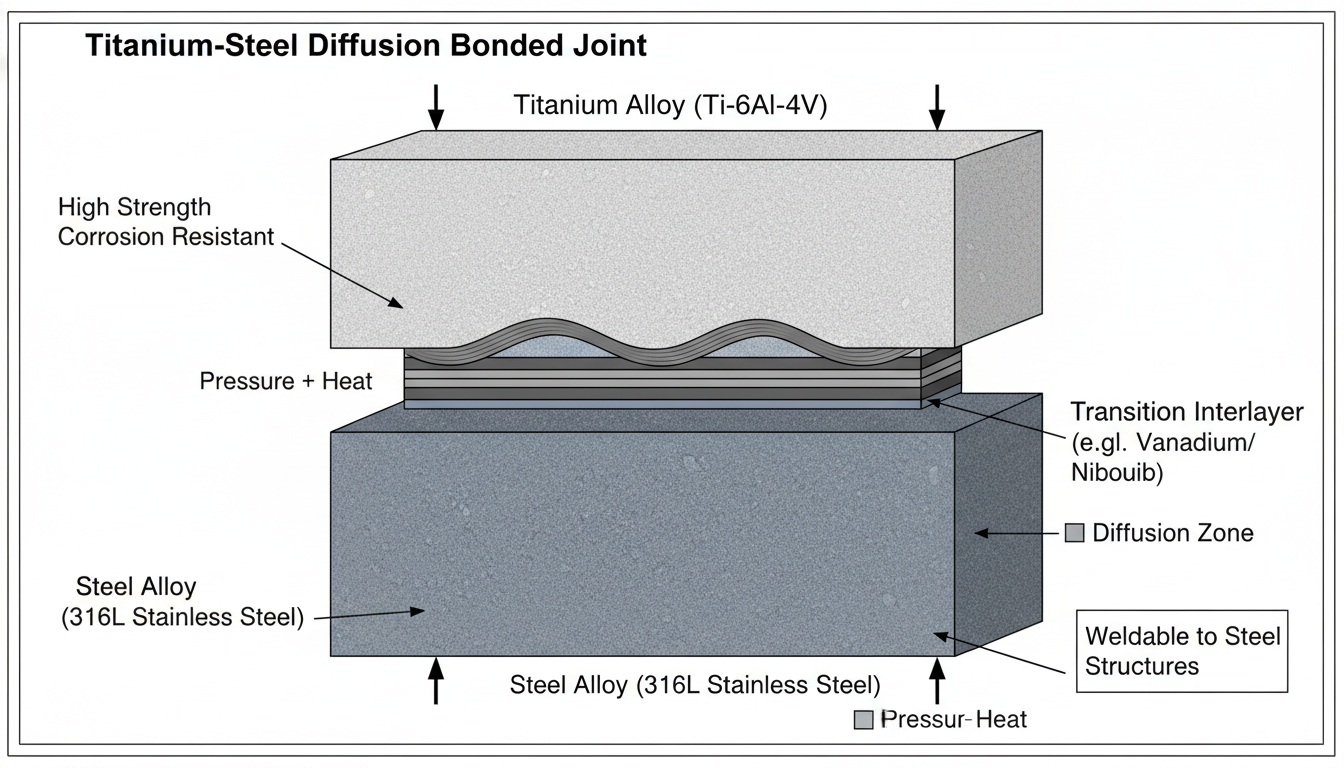

Diffusion Bonding: A Solid-State Solution

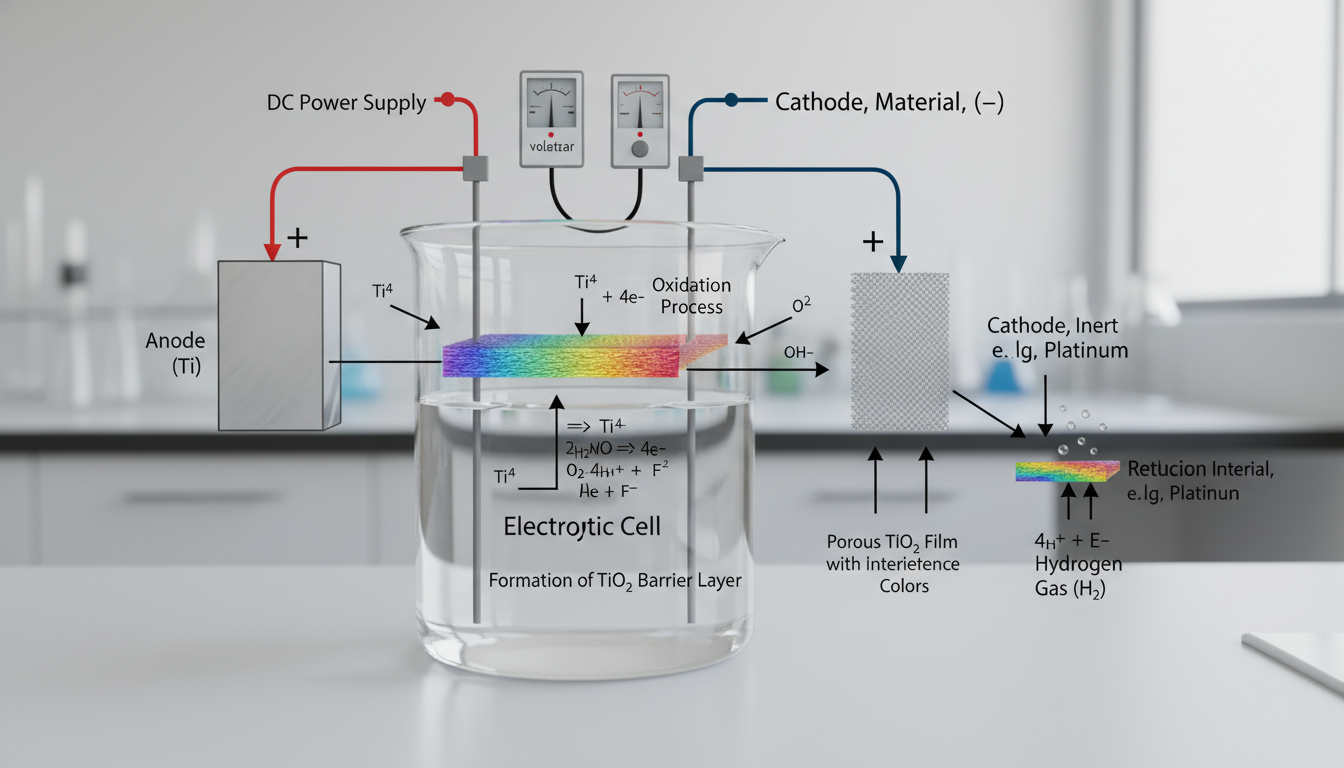

Diffusion bonding is a solid-state joining process. That means no melting occurs. Instead, components are brought into intimate contact under high pressure and elevated temperature for an extended period. Atoms diffuse across the interface, forming a metallurgical bond without the detrimental liquid-phase reactions that create brittle intermetallics.

This method is excellent for creating high-quality, defect-free bonds. It's often performed in a vacuum or inert atmosphere to prevent oxidation. While slow and requiring specialized equipment, diffusion bonding offers exceptional control over the interface microstructure, leading to strong and ductile joints. For complex custom titanium fabrication, this method can be indispensable.

Explosive Welding: High-Energy Impact Joining

Explosive welding, also known as explosion cladding, is a high-energy technique that uses controlled detonations to join materials. A controlled explosion forces one metal plate (the flyer plate, e.g., titanium) to collide at high velocity with another (the base plate, e.g., steel). The impact creates a jetting action at the interface, cleaning the surfaces and forming a strong, metallurgical bond.

This process is extremely fast, and the bond forms in solid-state conditions, preventing the formation of thick, brittle intermetallic layers. It's particularly effective for producing large clad plates, where a thin layer of titanium is bonded to a thicker steel substrate. These clad materials can then be further fabricated, benefiting from titanium's corrosion resistance and steel's strength.

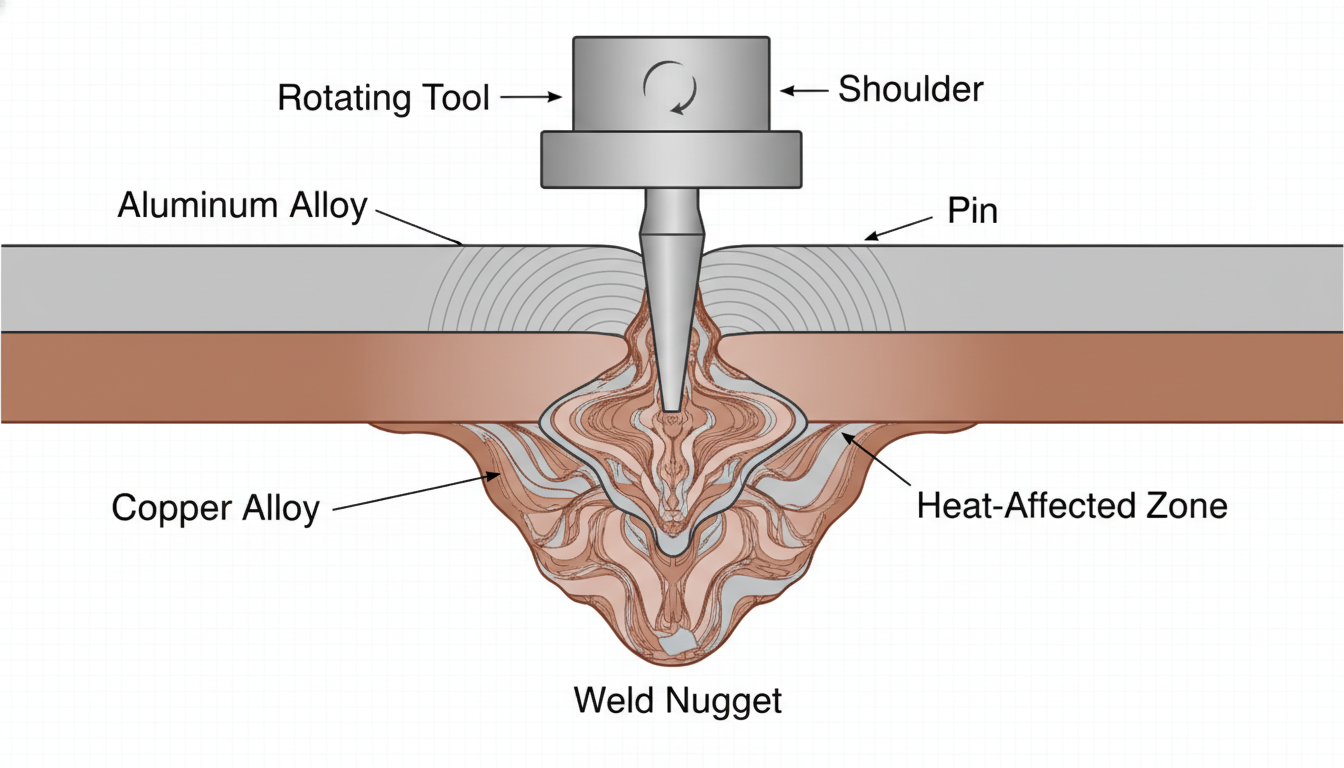

Friction Stir Welding (FSW): Mechanical Mixing for Dissimilar Metals

Friction Stir Welding (FSW) is another solid-state process that mechanically mixes the materials. A non-consumable, rotating tool plunges into the joint line and traverses along it. The friction generates heat, softening the material without melting it. The tool's unique geometry then stirs and forges the softened materials together, creating a fine-grained, consolidated joint.

FSW offers excellent control over heat input, minimizing intermetallic formation and residual stresses. It's particularly promising for joining dissimilar metals because it can precisely manage the mixing zone and microstructure. While typically used for aluminum, research into FSW for titanium to steel is showing considerable promise, often with the aid of interlayers.

Brazing Techniques: Using Filler Metals for Strong Bonds

Brazing involves joining two metals using a filler metal that has a lower melting point than the base metals. The filler metal melts and flows into the joint by capillary action, wetting the surfaces and forming a metallurgical bond upon solidification. When joining titanium to steel, the key is selecting an appropriate filler metal.

Active brazing alloys, often containing elements like titanium or zirconium, are crucial because they can wet the passive oxide layer on titanium. Vacuum brazing is commonly used to prevent oxidation during the process. The right filler metal can minimize the formation of brittle Fe-Ti intermetallics by creating a ductile, compatible interface. This is a common strategy for components requiring vacuum-tight joints.

Electron Beam and Laser Welding: Precision and Control

Electron beam (EBW) and laser welding (LBW) are high-energy density processes. They deliver highly concentrated heat to a very small area, resulting in narrow welds, deep penetration, and extremely fast cooling rates. This precision and speed are critical when attempting to weld titanium to steel, as they minimize the total heat input and the time available for detrimental intermetallic compounds to form and grow.

While still challenging, these processes can be more successful than conventional arc welding, especially when paired with thin interlayers or precise joint designs. Their ability to control the melt pool and heat-affected zone makes them valuable tools in the arsenal for dissimilar metal joining. High-quality titanium products often benefit from such precise joining technologies.

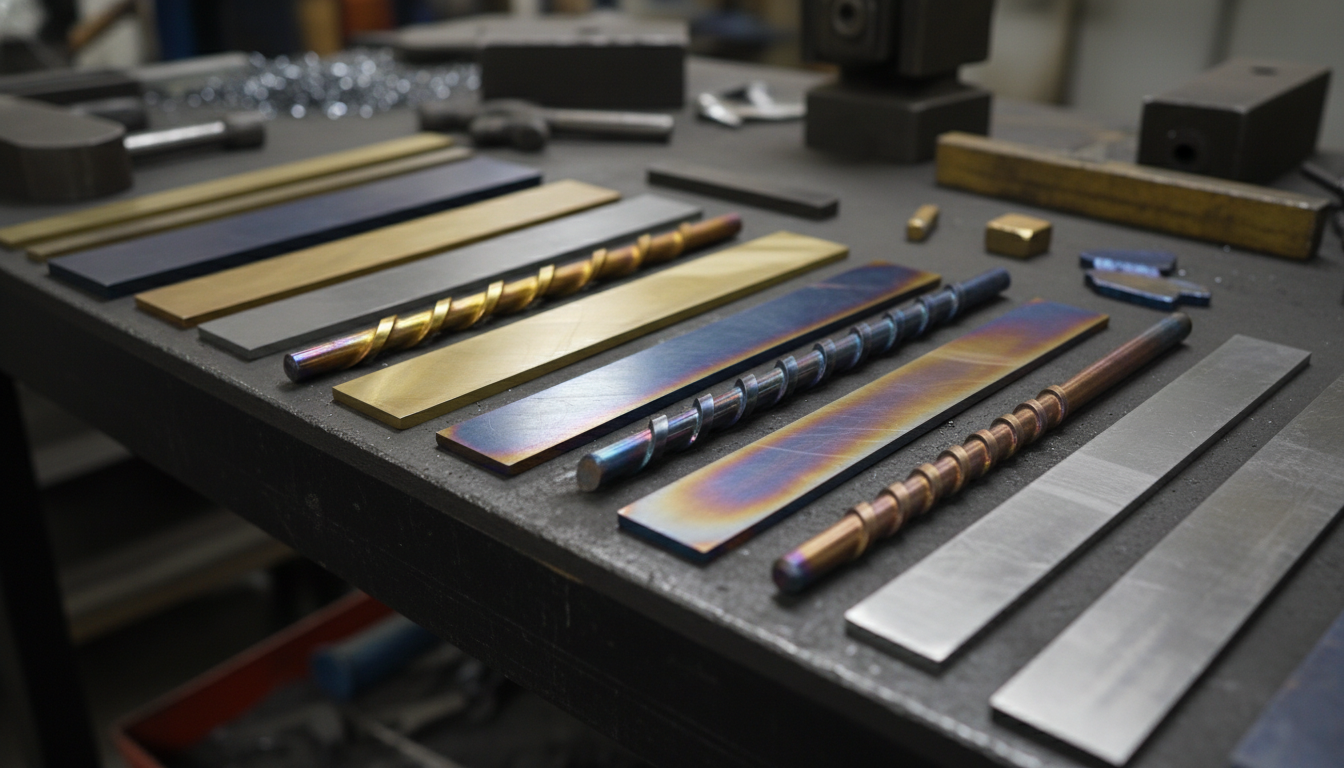

The Role of Transition Joints and Interlayers

One of the most effective strategies to successfully weld titanium to steel is to avoid direct contact between the two. This is achieved through the use of transition joints or interlayers. These are intermediate materials carefully selected to be compatible with both titanium and steel, creating a graded metallurgical transition.

Common interlayer materials include vanadium, nickel, copper, or various nickel-based alloys. The titanium is welded to the interlayer, and then the interlayer is welded to the steel. Each interface is designed to be metallurgically stable, preventing the formation of brittle phases and mitigating galvanic corrosion. This approach essentially breaks a very difficult problem into two more manageable ones, significantly improving joint integrity and performance.

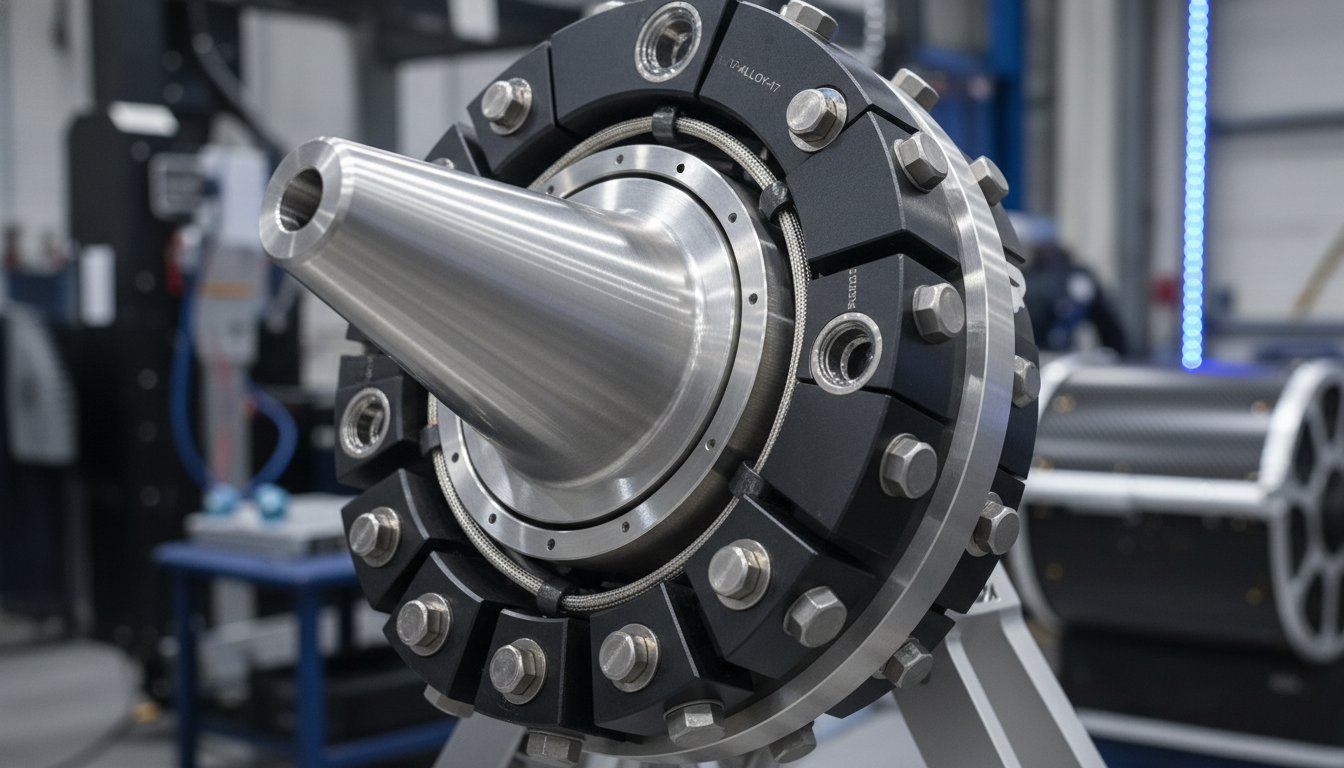

Real-World Applications of Titanium-Steel Joints

Despite the complexities, the ability to successfully join titanium and steel is a game-changer across numerous industries. These hybrid structures unlock possibilities that neither metal could achieve alone, leveraging titanium's superior corrosion resistance, biocompatibility, and high strength-to-weight ratio, combined with steel's robustness and lower cost.

Here's where these challenging joints really shine:

Aerospace Industry: Critical for lightweighting and high-performance components. Think structural elements where titanium is needed for specific properties, but a steel interface is required for attachment to other systems.

Marine and Shipbuilding: Essential for reducing weight and improving corrosion resistance in saltwater environments. Components like piping systems, heat exchangers, and structural parts on submarines or naval vessels often utilize titanium-steel transitions.

Chemical Processing Equipment: Used in vessels, pipes, and heat exchangers handling aggressive chemicals where titanium's inertness is vital, but the bulk structure needs to be steel for economic or structural reasons.

Medical Implants and Devices: Biocompatible titanium is often joined to stainless steel for certain surgical instruments or implantable devices, though this typically involves very small-scale, highly controlled joining.

Power Generation: In components exposed to high temperatures and corrosive steam, such as turbine blades or condensers, where hybrid structures can optimize performance and lifespan.

The successful implementation of these joints is a testament to advanced materials engineering and precise manufacturing capabilities. For those seeking expert guidance on materials and joining solutions, China Titanium Factory offers unparalleled expertise.

Limitations and Design Considerations for Titanium-Steel Welds

While advanced techniques have made welding titanium to steel feasible, it's not a silver bullet. Engineers must approach these joints with a keen eye for design limitations and specific service conditions. Ignoring these can lead to costly failures down the line. It's about working smarter, not harder.

Critical considerations include:

Cost Implications: Dissimilar metal welding is inherently more expensive than homogeneous welding due to specialized equipment, skilled labor, and often costly interlayer materials.

Service Environment: The joint's exposure to corrosive media, temperature cycling, or vibration will dictate the robustness required and the specific joining method chosen.

Stress Concentration: Design must minimize stress risers at the interface, especially with interlayers. Finite element analysis (FEA) can be invaluable here.

Inspection and Quality Control: Given the complexity, non-destructive testing (NDT) and rigorous quality assurance are more critical than ever.

Repairability: Repairing dissimilar metal welds can be incredibly challenging, sometimes requiring complete replacement. Design for service life is crucial.

Post-Weld Analysis and Quality Assurance

Once you weld titanium to steel, the job isn't done. Comprehensive post-weld analysis and robust quality assurance are absolutely non-negotiable. Without thorough inspection and testing, even the most advanced joining methods can hide critical flaws that lead to premature failure in service. Cutting corners here is simply asking for trouble.

Key methods include:

Visual Inspection: Initial check for gross defects like cracks, porosity, or misalignment.

Non-Destructive Testing (NDT):

Ultrasonic Testing (UT): Detects internal flaws, inclusions, and lack of fusion.

Radiographic Testing (RT): Identifies internal voids, cracks, and porosity.

Liquid Penetrant Testing (LPT) / Magnetic Particle Testing (MPT): Reveals surface-breaking defects.

Destructive Testing:

Tensile Testing: Measures ultimate tensile strength and yield strength.

Bend Testing: Evaluates ductility and freedom from cracking.

Impact Testing: Determines toughness, especially at low temperatures.

Hardness Testing: Maps hardness variations across the weld and HAZ, indicating intermetallic formation.

Metallographic Examination: Microstructural analysis of the weld interface, heat-affected zones, and base metals to confirm desired phase formation and absence of brittle intermetallics. This is often the ultimate proof of a sound joint.

Corrosion Testing: For critical applications, immersion tests or electrochemical tests verify the galvanic corrosion resistance of the joint in the target environment.

The rigor of these tests directly correlates with the reliability of the final product. For specialized titanium components requiring stringent quality control, consider partnering with a manufacturer like China Titanium Factory, known for its adherence to high standards.

Troubleshooting Common Issues in Titanium-Steel Welding

Even with meticulous planning, problems can crop up. When you're trying to weld titanium to steel, issues like cracking, excessive porosity, or poor mechanical properties are common. Knowing how to diagnose and address these problems is crucial for maintaining production quality and avoiding costly rework.

Here’s a quick rundown of typical issues and their fixes:

Cracking:

Diagnosis: Often due to brittle intermetallics or high residual stresses.

Solution: Optimize heat input, use preheating/post-heating carefully (if applicable with interlayers), select more suitable interlayers, or transition to solid-state methods like FSW or diffusion bonding. Slow cooling rates can also help.

Excessive Porosity:

Diagnosis: Usually from atmospheric contamination (oxygen, nitrogen, hydrogen) or inadequate shielding gas.

Solution: Ensure impeccable joint cleanliness, use high-purity shielding gas (argon) at correct flow rates, improve gas coverage (trailing shields), or perform welding in a vacuum chamber (EBW) or inert atmosphere.

Poor Mechanical Properties (Low Strength/Ductility):

Diagnosis: Signifies extensive brittle intermetallic formation, incorrect interlayer selection, or poor fusion.

Solution: Re-evaluate interlayer material and thickness, fine-tune welding parameters (speed, power) to minimize melt pool interaction time, or consider a different joining method entirely.

Effective troubleshooting requires a deep understanding of the materials and processes involved. Sometimes, it means going back to the drawing board on material selection or process parameters.

Cost Analysis and Economic Benefits of Dissimilar Titanium-Steel Welds

At first glance, the complexity and specialized nature of welding titanium to steel might suggest exorbitant costs. And yes, the initial investment in equipment, materials, and skilled labor can be higher than conventional welding. However, a comprehensive cost analysis reveals significant long-term economic benefits that often tip the scales in favor of these advanced solutions.

Consider the following:

Material Costs: While titanium is pricier than steel, using a titanium-steel joint allows for selective application of titanium where its unique properties are truly needed. This means a smaller volume of expensive titanium is used, reducing overall material costs for large structures.

Manufacturing Efficiency: Advanced methods like explosive welding can produce large clad plates efficiently, which can then be fabricated using more conventional techniques, streamlining subsequent manufacturing steps.

Enhanced Performance: The primary driver for these joints is superior performance. Combining titanium's corrosion resistance or high strength-to-weight ratio with steel's structural integrity leads to products that outperform homogeneous alternatives.

Extended Service Life: Improved corrosion resistance and mechanical reliability translate directly into longer operational lifespans for components and systems. This reduces maintenance, repair, and replacement costs over time.

Reduced Downtime: In critical industrial applications (e.g., chemical plants, offshore platforms), extended service life means less downtime for repairs or replacements, leading to significant operational savings.

Weight Savings: In aerospace or marine applications, weight reduction achieved by using titanium can lead to substantial fuel savings over the lifetime of a vehicle.

Ultimately, the economic justification for welding titanium to steel comes down to a lifecycle cost analysis. The upfront investment often pays dividends through enhanced performance, extended service life, and reduced operational expenses, making it a smart choice for demanding applications. For inquiries regarding specific titanium components or joining solutions, don't hesitate to contact China Titanium Factory.

Frequently Asked Questions (FAQ) about Welding Titanium to Steel

Is it possible to weld titanium to steel?

Yes, it is possible, but it's highly challenging and rarely achieved with conventional fusion welding. Successful joining almost always requires advanced techniques like diffusion bonding, explosive welding, friction stir welding (FSW), or specialized brazing, often incorporating interlayers to mitigate metallurgical incompatibilities.

Why is welding titanium to steel so difficult?

The primary difficulties stem from three factors: the rapid formation of brittle iron-titanium intermetallic compounds at the weld interface, a significant mismatch in coefficients of thermal expansion leading to high residual stresses, and the risk of galvanic corrosion due to their differing electrochemical potentials.

What are interlayers and how do they help?

Interlayers (or transition joints) are intermediate metallic materials (e.g., vanadium, nickel, copper) inserted between the titanium and steel. They create a graded metallurgical transition, allowing for two separate, more compatible welds (titanium-to-interlayer and interlayer-to-steel), thereby preventing the direct formation of brittle Fe-Ti intermetallics and managing stress.

What are the best methods for joining titanium to steel?

The "best" method depends on the application, but leading techniques include diffusion bonding, explosive welding (for clad plates), friction stir welding (often with interlayers), and specialized brazing. Electron beam and laser welding can also be used with great precision, especially with interlayers.

What industries benefit from titanium-steel joints?

Industries that benefit immensely include aerospace (lightweight, high-strength structures), marine (corrosion resistance in saltwater), chemical processing (handling aggressive chemicals), and power generation (high-temperature, corrosive environments).