Exploring White Anodized Aluminum: Methods, Myths, and Modern Applications

In the realm of modern design and industrial applications, aluminum stands out for its lightweight properties, durability, and aesthetic versatility. The desire for a pristine white finish on aluminum components is prevalent across various sectors, from consumer electronics to architectural facades. However, the term "white anodized aluminum" often leads to a common misconception regarding the process and its outcomes. While anodizing is a highly effective method for enhancing aluminum's surface properties and enabling coloration, achieving a true, opaque white through traditional anodizing presents unique challenges. This article aims to demystify the technical realities of white anodized aluminum, explore the alternative finishing processes that yield a white appearance, and highlight their diverse applications.

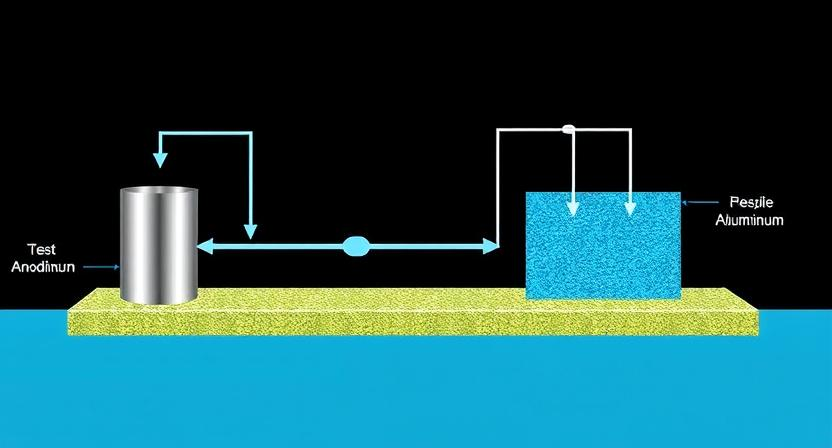

Anodizing is an electrochemical passivation process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. This process involves immersing aluminum in an electrolytic solution and passing an electric current through it. The aluminum acts as the anode, and oxygen ions are released from the electrolyte to combine with aluminum atoms on the surface, forming an aluminum oxide layer [1].

The anodic oxide layer is not merely a coating; it is an integral part of the aluminum substrate. During the anodizing process, the naturally occurring thin oxide layer on aluminum is significantly thickened and transformed into a highly ordered, porous structure. This porous nature is crucial for subsequent coloring processes. The thickness and porosity of this layer can be controlled by varying parameters such as electrolyte composition, temperature, and current density.

For most colored anodized aluminum, the porous oxide layer is immersed in an organic or inorganic dye solution. The dye penetrates the pores, and then the surface is sealed, trapping the color within the anodic layer. This sealing process enhances corrosion resistance and color fastness. The transparency of the anodic layer allows the underlying metallic luster to show through, giving anodized aluminum its characteristic depth of color.

Diagram illustrating the electrochemical anodizing process on aluminum.

Despite the wide spectrum of colors achievable through anodizing, true white remains an elusive goal for traditional methods. The primary reasons for this challenge stem from the fundamental nature of the anodizing process itself.

The anodic oxide layer, even when significantly thickened, is inherently transparent or translucent. When a dye is introduced, it colors this transparent matrix. To achieve an opaque white, a dye would need to completely obscure the underlying metallic substrate and reflect all wavelengths of light equally. Traditional white pigments, such as titanium dioxide, are opaque and particulate. These particles are generally too large to effectively penetrate the microscopic pores of the anodic layer and achieve a uniform, opaque white finish without compromising the integrity or transparency of the anodic film. Furthermore, the chemical composition and stability required for a true white dye compatible with the anodizing process are difficult to achieve.

Microscopic view of a porous anodized aluminum layer, highlighting the intricate structure that dyes penetrate.

Microscopic view of a porous anodized aluminum layer, highlighting the intricate structure that dyes penetrate.

Given the limitations of traditional anodizing for achieving a true white, several alternative and often more effective methods are employed to impart a white finish to aluminum. These processes offer varying degrees of durability, aesthetic quality, and cost.

E-coating, or electrophoretic painting, is a process where an organic paint film is applied to a conductive material using electrical current. When applied over an anodized aluminum substrate, E-coating can provide a durable, uniform, and truly opaque white finish. The anodized layer beneath offers enhanced corrosion resistance and adhesion for the E-coat. This combination leverages the benefits of both processes, resulting in a highly protective and aesthetically pleasing white surface.

Advantages: Offers a true, opaque white color; excellent corrosion resistance and durability due to the underlying anodized layer; uniform finish even on complex geometries.

Disadvantages: Involves multiple steps, which can increase cost and processing time compared to single-step finishes.

An example of a product featuring an E-coated white aluminum finish, demonstrating its smooth and opaque appearance.

An example of a product featuring an E-coated white aluminum finish, demonstrating its smooth and opaque appearance.

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a grounded aluminum substrate. The charged powder particles adhere to the electrically grounded surfaces until heated and fused into a smooth coating in a curing oven. Powder coating offers a vast array of colors, including various shades of white, and provides a durable, chip-resistant finish.

Advantages: Wide range of white shades and textures; excellent durability and resistance to chipping, scratching, and fading; environmentally friendly (no VOCs); cost-effective for many applications.

Limitations: Can be thicker than anodizing, potentially obscuring fine details; typically does not offer the translucent, metallic luster sometimes desired from anodized finishes.

A white powder-coated aluminum component, showcasing the uniform and robust finish.

A white powder-coated aluminum component, showcasing the uniform and robust finish.

Traditional liquid painting involves applying a liquid paint (containing pigments, binders, solvents, and additives) to the aluminum surface, followed by drying or curing. Advances in paint technology have led to highly durable and aesthetically pleasing white liquid coatings for aluminum. Pre-treatment of the aluminum surface (e.g., cleaning, etching, or priming) is essential to ensure proper adhesion and long-term performance.

Considerations: Adhesion quality is highly dependent on surface preparation; durability varies significantly with paint type and application quality; offers flexibility in finish (gloss, matte, satin).

While true white anodizing remains challenging, some specialized processes can achieve white-like or very light finishes. These include certain types of hard anodizing or ceramic-based anodic coatings that produce a naturally lighter, often off-white or grayish-white, appearance due to their inherent structure and composition. These are typically chosen for their functional properties (e.g., extreme hardness, wear resistance) rather than purely aesthetic white color.

The demand for white-finished aluminum is driven by its aesthetic appeal and functional benefits across numerous industries. The choice of finishing method depends heavily on the specific application requirements.

Architectural Design: White aluminum is extensively used for building facades, curtain walls, window frames, and interior panels, offering a clean, modern aesthetic that reflects sunlight and contributes to energy efficiency. Its lightweight nature and corrosion resistance make it ideal for exterior applications.

Consumer Electronics: Many electronic devices, from laptops to smartphones, utilize white-finished aluminum for their casings and components, providing a sleek, premium look and feel.

Automotive Industry: White aluminum is found in decorative trims, interior components, and lightweight structural parts, contributing to both aesthetics and fuel efficiency.

Lighting: Reflectors, light housings, and fixtures often employ white-finished aluminum to maximize light reflection and create a bright, clean appearance.

Medical Devices: Due to its sterile appearance and ease of cleaning, white-finished aluminum is used for enclosures and components in medical equipment.

A modern building facade showcasing the extensive use of white aluminum elements, highlighting its architectural versatility.

A modern building facade showcasing the extensive use of white aluminum elements, highlighting its architectural versatility.

Selecting the optimal white finish for aluminum involves a careful consideration of various factors, including desired aesthetic, performance requirements, cost, and environmental impact. The table below provides a comparative overview of common white finishing methods.

| Finishing Method | Aesthetic (White) | Durability | Corrosion Resistance | Cost | Environmental Impact | Typical Applications |

|---|---|---|---|---|---|---|

| Traditional Anodizing (Clear) | Translucent, metallic sheen (not white) | High | High | Medium | Low | General industrial, decorative (colored) |

| E-coating over Anodizing | Opaque, true white | Very High | Very High | High | Medium | High-end electronics, architectural, automotive |

| Powder Coating | Opaque, various white shades | High | High | Medium | Low (VOC-free) | Architectural, automotive, consumer goods, furniture |

| Liquid Painting | Opaque, various white shades | Medium to High | Medium to High | Low to Medium | Medium (VOCs can be an issue) | General industrial, decorative |

| Specialized Anodizing | Off-white, grayish-white | Very High | Very High | Very High | Low | Functional parts, aerospace, military |

While the quest for a true "white anodized aluminum" through conventional methods faces inherent technical limitations, the industry has responded with innovative and effective alternative finishing processes. From the robust and aesthetically pleasing E-coating over anodizing to the versatile and durable powder coating, manufacturers and designers have a range of options to achieve a desirable white finish on aluminum. Understanding the nuances of each process is crucial for making informed decisions that balance aesthetic goals with performance requirements and cost considerations. As material science and finishing technologies continue to advance, we can anticipate even more sophisticated solutions for enhancing the appearance and functionality of aluminum in the future.

[1] Anodizing. Aalberts Surface Technologies. Available at: https://www.aalberts-st.com/processes/anodizing/