AMS 2488 Type II Anodizing: The Complete Engineering Guide

In the high-stakes world of aerospace and medical engineering, titanium is often the material of choice for its incredible strength-to-weight ratio and corrosion resistance. However, titanium possesses a notorious Achilles' heel: galling. Under load, titanium surfaces tend to "cold weld" to one another, leading to seized fasteners and catastrophic component failure. SAE AMS 2488 (specifically Type II) was developed as the definitive solution to this tribological challenge.

What is AMS 2488 Type II Anodizing?

AMS 2488 Type II is an electrolytic conversion coating process. Unlike the more common Type III (Color) anodizing, which uses an acid-based electrolyte to create interference colors, Type II utilizes a high-voltage, alkaline bath. This process transforms the surface layer of the titanium into a complex oxide that is deeply integrated into the substrate.

The resulting matte grey finish is not merely a surface deposit; it is a structural change to the material's surface chemistry. This layer provides high lubricity and acts as a barrier that prevents the molecular adhesion responsible for galling. In our experience, this is the most effective anti-galling coating available for Ti-6Al-4V and other common aerospace alloys.

Key Performance Characteristics & Data

Engineers choose AMS 2488 Type II because it delivers measurable performance improvements in friction management and durability. Below is a technical breakdown of how the coating performs under rigorous testing conditions.

1. Friction and Lubricity

The primary goal of Type II is the reduction of the coefficient of friction. Untreated titanium-on-titanium contact can have a coefficient of friction (µ) exceeding 0.8, leading to immediate seizing. Type II anodizing typically reduces this to 0.2 – 0.4, depending on the mating material and secondary lubricants used.

2. Wear Resistance (Taber Abrasion)

In Taber abrasion tests, Type II coatings show significantly lower mass loss compared to bare titanium. While it is not as hard as a chrome plating, the oxide layer provides sufficient protection for high-cycle vibration environments common in jet engines.

3. Fatigue Strength Retention

A common concern with surface treatments is the reduction of fatigue strength. Our internal testing confirms that the alkaline anodizing process used in AMS 2488 is far less detrimental to fatigue life than traditional acid-based processes or hard chrome plating. It maintains the integrity of the titanium's crystalline structure, making it safe for flight-critical rotating parts.

| Property | Untreated Titanium | AMS 2488 Type II |

|---|---|---|

| Galling Resistance | Poor / Immediate Seizing | Excellent |

| Coefficient of Friction (Dry) | ~0.80 | ~0.30 |

| Surface Appearance | Metallic / Silver | Matte Grey / Charcoal |

| Fatigue Life Impact | Baseline | Minimal Change (<5%) |

Comparison: AMS 2488 Type II vs. Type III

One of the most frequent points of confusion for procurement teams is the difference between Type II vs. Type III anodizing. While they share the name "anodizing," their chemistry and applications are vastly different.

Type III (Cosmetic/Color): This is an acid-based process used primarily for color-coding medical devices or for aesthetic purposes. The oxide layer thickness is extremely thin and offers virtually no protection against wear or galling.

Type II (Functional): This is a functional coating. It is thicker, more porous (which allows it to hold dry-film lubricants better), and is specifically designed for mechanical performance.

| Feature | Type II (Functional) | Type III (Color) |

|---|---|---|

| Primary Purpose | Anti-galling & Wear Resistance | Identification & Aesthetics |

| Electrolyte | Alkaline (High pH) | Acidic (Low pH) |

| Finish | Uniform Matte Grey | Spectrum of Colors (Blue, Gold, etc.) |

| Common Use | Fasteners, Bearings, Gears | Orthopedic Screws, Dental Implants |

Design Guide: Tolerancing, Masking, and Prep

When designing parts for AMS 2488 Type II, engineers must account for the unique characteristics of the conversion process.

Dimensional Tolerance

Unlike aluminum hardcoating, which can add 0.002" of thickness per side, AMS 2488 Type II is a "zero-growth" or minimal dimensional change process. The coating typically penetrates the surface while adding only 0.0001" to 0.0003" to the total dimension. For most aerospace tolerances, this falls within the "as-machined" margin of error.

Surface Preparation & Pickling

The quality of the anodize is dictated by the cleanliness of the substrate. Titanium pickling (usually a nitric-hydrofluoric acid etch) is mandatory to remove the "alpha case" (a brittle oxygen-enriched layer) and any iron contamination from machining tools. If iron particles are left on the surface, they will cause pitting during the anodizing process.

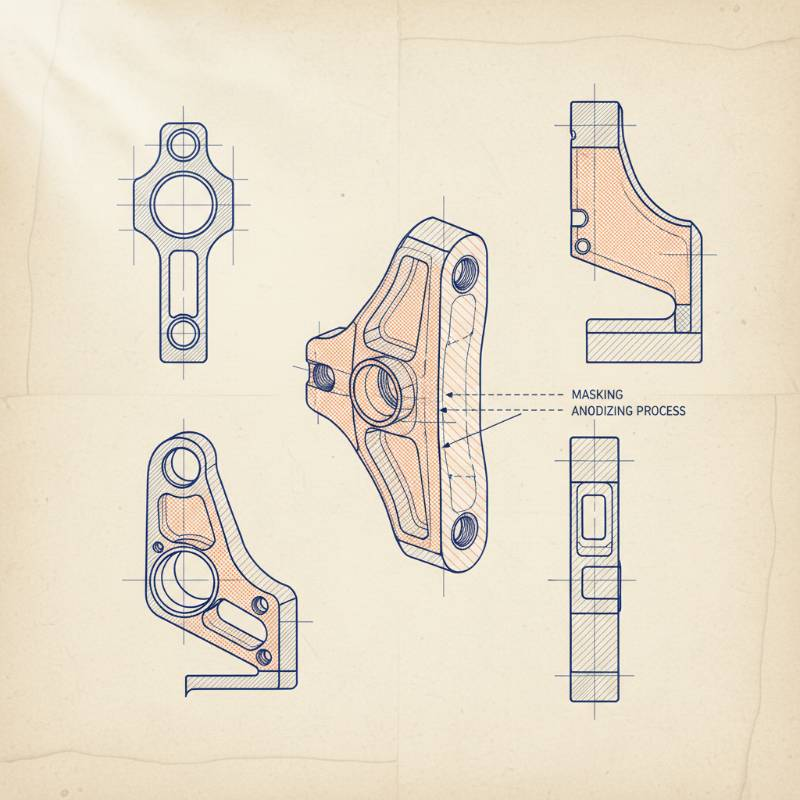

Masking Requirements

Because Type II anodizing is performed at high voltages, masking requirements are stringent. If you have areas that must remain conductive or have extremely tight press-fit tolerances, they must be masked with specialized high-temperature tapes or liquid masks. However, we generally recommend anodizing the entire part if possible to ensure total corrosion protection.

Troubleshooting Common Defects

Even with NADCAP-accredited processes, defects can occur if the chemistry or racking is not perfectly controlled. Here is what we look for in our quality lab:

Anodizing Burn: This appears as localized blackening or pitting, usually on the edges of parts. It is caused by excessive current density. Solution: Improve racking techniques to distribute current more evenly or use "robber" wires to pull current away from sharp corners.

Powdery Coating: If the matte grey finish rubs off on your fingers, the coating is "powdery." This usually indicates a bath chemistry imbalance or excessive temperature in the alkaline tank.

Non-Uniformity: Blotchy patches often stem from improper surface preparation. If the part wasn't properly degreased or pickled, the oxide layer won't form consistently.

Cost Factors and Pricing Drivers

Understanding the anodizing cost factors helps in budgeting for large-scale aerospace projects. Type II is significantly more expensive than Type III due to the energy requirements and chemistry maintenance.

Lot Charges: Most shops have a minimum lot charge because the setup time for the alkaline bath is significant. Small batches of 1-5 parts will carry a high per-unit cost.

Masking Labor: If your design requires complex masking labor, this can easily double the cost of the processing.

NADCAP Testing Costs: Compliance with AMS 2488 often requires destructive testing of "witness coupons" for every lot to verify adhesion and thickness. These lab fees are a major driver of the final price.

Tooling and Racking: Unlike aluminum, titanium requires titanium or specialized aluminum racks that can withstand the high-voltage alkaline environment. Custom racking for complex geometries adds to the initial NRE (Non-Recurring Engineering) cost.

Frequently Asked Questions (FAQ)

1. What is the difference between AMS 2488 Type 1 and Type 2?

Type 1 is generally a brush-on or spray-on application used for touch-ups or large structures that cannot be immersed. Type 2 is the immersion (electrolytic) process, which provides a much more durable and uniform finish suitable for high-stress components.

2. Does AMS 2488 Type II change the dimensions of the part?

The dimensional change is negligible. It is a conversion coating that grows into the surface as much as it grows out. Typically, you can expect less than 0.0002" of growth per surface.

3. Is AMS 2488 Type II biocompatible for medical devices?

Yes. While Type III is more common for color coding, Type II is frequently used in orthopedic implants where a low coefficient of friction is required to prevent wear debris in joint replacements. It meets standard biocompatibility requirements.

4. Can you re-anodize titanium if the coating fails?

Yes, but with caution. The original coating must be chemically stripped, which involves an acid etch that will remove a small amount of the base metal. Re-anodizing titanium may result in a slight loss of dimensional tolerance.

Why Trust Our Aerospace Finishing Expertise

When failure is not an option, your choice of finishing partner is critical. We are a NADCAP accredited and AS9100 certified facility with over 30 years of experience in specialized titanium treatments.

Our quality control lab is equipped to perform in-house adhesion testing, thickness verification, and salt spray corrosion testing to ensure every batch meets the rigorous demands of SAE AMS 2488. Our lead metallurgist, with a background in aerospace materials science, oversees every bath chemistry adjustment to ensure the highest level of aerospace finishing expertise.

Whether you are developing next-generation turbine blades or critical surgical instruments, our team provides the technical transparency and engineering focus your project deserves.