The Alchemy of Electricity: Understanding Anodized Titanium Colors

Raw titanium is a dull, silver-grey metal. But apply a controlled electric current in an electrolyte bath, and it transforms. This isn't magic, and it certainly isn't paint. At ChinaTitaniumFactory.com, we see this transformation daily—a process where electricity dictates aesthetics.

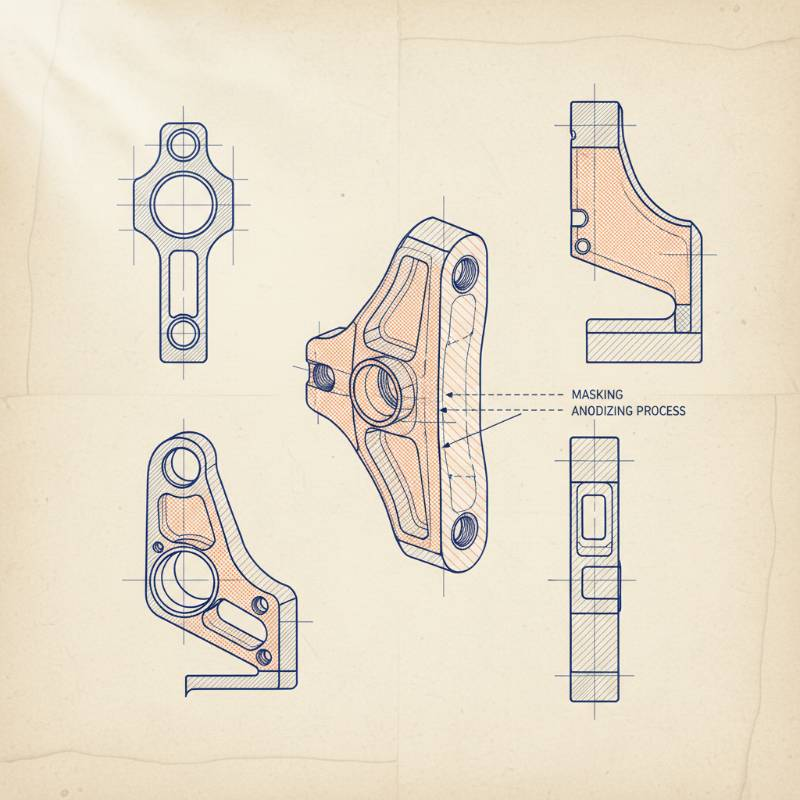

"Titanium anodizing is an electrolytic finishing process that increases the thickness of the natural oxide layer on the surface of titanium parts. Unlike aluminum anodizing, which uses dyes, titanium colors are generated by light refraction."

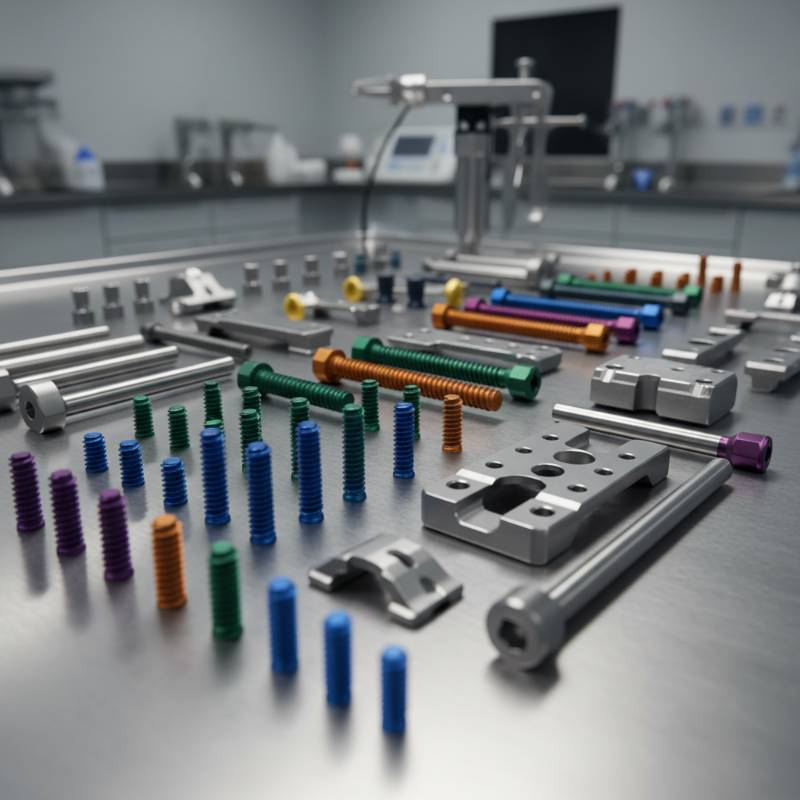

Engineers value it for component identification. Designers love it for the vibrant, iridescent pop. Whether you are working with medical grade titanium or custom jewelry, mastering anodized titanium colors by voltage is the difference between a professional finish and a splotchy mess.

The Physics of Brilliance: How Thin-Film Interference Creates Color

Why does 25 volts look blue while 65 volts looks gold? The answer lies in thin-film interference. When you anodize titanium, you aren't adding a pigment. You are growing a transparent layer of titanium dioxide (TiO2).

Light waves hit this transparent layer. Some reflect off the top surface. Others pass through the oxide, hit the metal underneath, and bounce back. These waves then interfere with each other. Depending on the thickness of the oxide layer—measured in nanometers—certain wavelengths of light are canceled out, while others are reinforced. This is the same phenomenon seen in oil slicks on puddles or soap bubbles.

Higher voltage creates a thicker oxide layer. According to ScienceDirect's research on surface engineering, the refractive index of this layer determines exactly which color reaches your eye. It is a precise, repeatable science.

Setting Up Your Laboratory: From Electrolytes to the 'Sacrificial Lamb'

Success starts with the right gear. You need a DC power supply (rectifier) capable of reaching at least 120 volts if you want the full spectrum. You also need an electrolyte bath. While industrial setups use specialized chemicals, a simple solution of distilled water and Trisodium Phosphate (TSP) or even Borax works for most applications.

The Essential Toolkit

DC Power Supply: Must provide stable voltage control.

Cathode: Stainless steel or scrap titanium.

Anode: The piece you are coloring.

The "Sacrificial Lamb": Never dip your final part first. Always use a scrap piece of the same alloy to test your current density and electrolyte strength.

Surface prep is non-negotiable. Fingerprints are the enemy. At our facility, we define the "Gold Standard" of prep as a three-stage de-greasing and ultrasonic cleaning process before the part ever touches the electrolyte.

The Definitive Voltage-to-Color Chart: Grade 2 vs. Grade 5 Titanium

Not all titanium is created equal. Grade 2 (commercially pure) and Grade 5 titanium (6Al-4V) react differently. The alloying elements in Grade 5, like aluminum and vanadium, slightly shift the voltage requirements for specific hues.

| Voltage (Approx.) | Color Result (Grade 2) | Color Result (Grade 5) |

|---|---|---|

| 10 - 15V | Bronze / Brown | Deep Bronze |

| 20 - 25V | Dark Blue | Purple-Blue |

| 30 - 35V | Light Blue / Sky Blue | Bright Blue |

| 50 - 55V | Yellow / Gold | Pale Gold |

| 65 - 75V | Purple / Magenta | Vibrant Purple |

| 85 - 95V | Green / Teal | Seafoam Green |

| 100V+ | Pink / High-Voltage Green | Fuchsia |

Note: These values are approximations. Your specific electrolyte concentration and surface finish (polished vs. matte) will shift these numbers. Polished surfaces yield much brighter, more metallic colors.

The 'Triple-Point Precision Protocol' for Flawless Color Transitions

At ChinaTitaniumFactory, we utilize what we call the Triple-Point Precision Protocol. This framework ensures that every batch of custom titanium parts meets exact spectral requirements.

1. Mechanical Homogenization

The surface must be uniform. Any scratches or uneven textures will cause the oxide layer to grow at different rates, leading to "ghosting" or muddy colors. We recommend a fine abrasive blast or high-mirror polish depending on the desired reflectivity.

2. Incremental Voltage Ramping

Don't slam the metal with 90 volts instantly. Start low and ramp up. This allows the oxide layer to build structural integrity. Rapid "shock" anodizing can lead to porous layers that look dull and rub off easily.

3. Post-Anodic Stabilization

Once the color is achieved, the part must be rinsed in distilled water and dried immediately. Residual electrolytes can continue to react with the surface, causing "blooming" or spots over time.

Debunking the Myths: Why You Can't Anodize Titanium Red or Black

There is a lot of misinformation online. Let’s set the record straight: True red and jet black do not exist in the titanium anodizing spectrum.

Because the colors are based on light interference, the physical thickness required to produce "red" simply doesn't occur naturally in this process. You can get close with a deep magenta or pink, but it will never be "fire engine red."

Similarly, black isn't a color of the spectrum; it’s the absence of light. To get a black finish on titanium, you need PVD coating (Physical Vapor Deposition) or a specialized heat-treating process that creates a thick, dark oxide. If someone promises you "anodized black titanium," they are likely using the wrong terminology or a different process entirely.

Industrial Applications: From Medical Implants to Aerospace Components

While hobbyists love the aesthetics, industry uses anodized titanium colors by voltage for functionality. In a surgical suite, a surgeon doesn't have time to measure a screw. They know the green screw is 3.5mm and the blue one is 4.0mm. This color-coding saves lives.

In aerospace, anodizing serves as a secondary inspection tool. If a part shows color shifting after use, it may indicate excessive heat exposure or stress, acting as a visual "canary in a coal mine." According to NASA technical standards, surface treatments like these are critical for component longevity in harsh environments.

Troubleshooting Common Anodizing Errors

Is your color splotchy? It’s likely oil from your skin. Even a tiny smudge will block the electrolytic reaction. Always wear powder-free nitrile gloves.

Is the metal "burning" or turning grey/white? This is usually caused by too much current or a short circuit. If your piece is small and your power supply is set too high, you can literally "cook" the oxide layer until it becomes a thick, non-reflective crust.

The Golden Rule of Troubleshooting: If the color is wrong, check your ground. A weak connection to the cathode is the primary cause of "voltage drop," where your rectifier says 30V but the metal is only seeing 15V.

Frequently Asked Questions

Is anodized titanium color permanent?

It is durable but not indestructible. Since the color is just a surface oxide layer, it can be worn away by heavy abrasion. However, it will never fade, chip, or peel like paint would.

What is the best electrolyte for titanium anodizing?

For industrial precision, we use proprietary acid blends. For most users, a 5-10% solution of Trisodium Phosphate (TSP) in distilled water provides the most consistent conductivity and color clarity.

Can I anodize titanium at home?

Yes, but safety is paramount. You are dealing with electricity and chemicals. Always work in a ventilated area, use GFCI protection, and never leave the power supply unattended.

Ready to Engineer Your Spectrum?

Whether you need precision-coded medical components or vibrant aerospace parts, our team at ChinaTitaniumFactory delivers world-class results.

Get a Precision Quote Today