Introduction: Unpacking Anodizing's Influence on Titanium's Strength

Titanium. A marvel of modern metallurgy. Its exceptional strength-to-weight ratio, biocompatibility, and corrosion resistance make it indispensable across diverse sectors, from aerospace to medical devices. Engineers and designers constantly seek ways to push its performance envelope.

One common enhancement is anodizing. This electrochemical surface treatment is widely adopted for its ability to improve aesthetics, enhance corrosion resistance, and even modify surface hardness. But a critical question often arises: what's the effect of anodizing on titanium mechanical strength? Does it make titanium tougher, or does it compromise its inherent robustness?

This guide cuts straight to the chase. We'll explore the intricate relationship between titanium anodizing and its mechanical properties. Our goal is to provide a definitive answer, backed by scientific understanding, helping you make informed decisions for your applications. Understanding this interaction is key for anyone working with this versatile metal.

What is Titanium Anodizing? Process, Types, and Purpose

Before we dive into mechanical strength, let's get our ducks in a row about what titanium anodizing actually is. It's not merely a coating; it's a controlled electrochemical conversion of the titanium surface into an oxide layer.

Definition: Titanium Anodizing is an electrochemical passivation process that converts the surface of titanium into a stable, often colored, titanium oxide layer. This layer is integral to the substrate, enhancing corrosion resistance, wear resistance, and offering aesthetic appeal.

The primary anodizing purpose extends beyond mere aesthetics. It significantly boosts corrosion resistance, provides electrical insulation, and enhances surface hardness. These benefits are critical for high-performance applications.

The Anodizing Process Explained

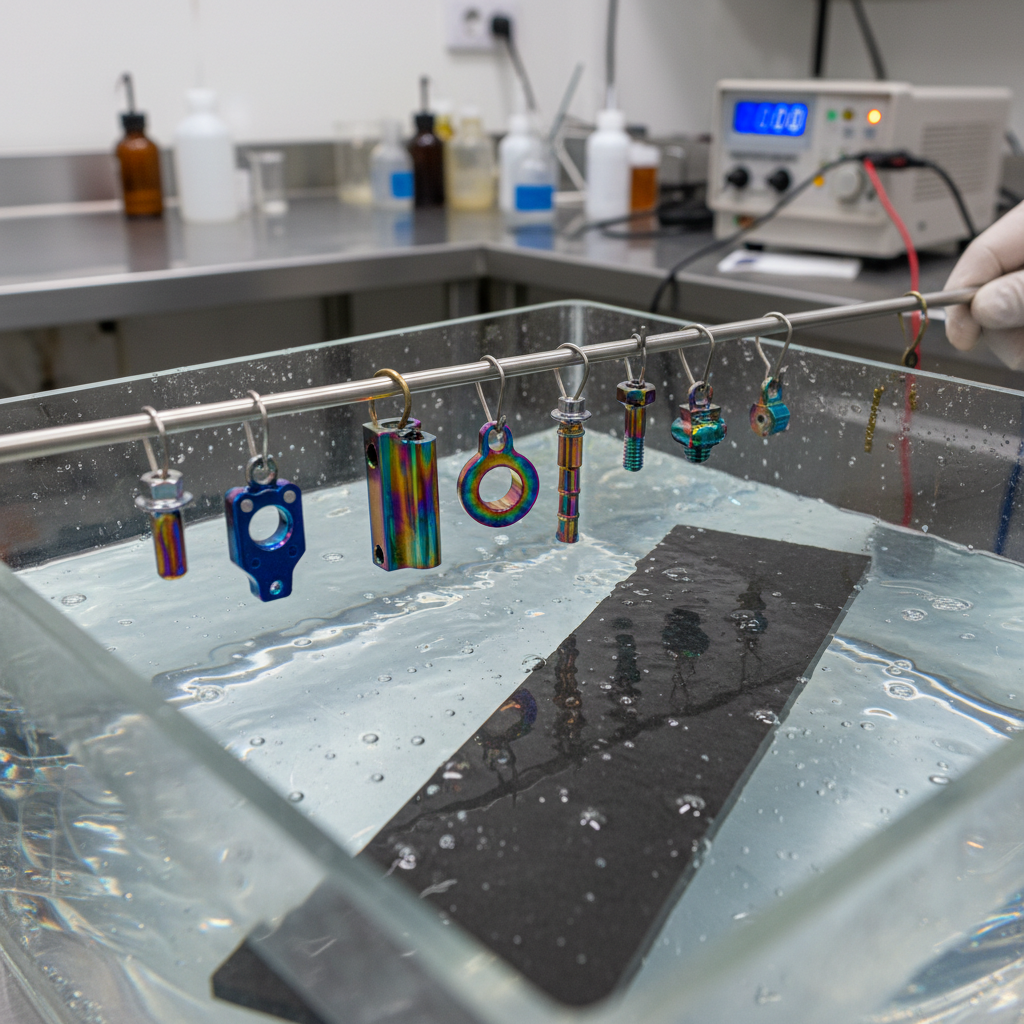

The titanium anodizing process is a multi-step operation:

Cleaning: The titanium part undergoes thorough cleaning to remove oils, greases, and surface contaminants. This is non-negotiable for consistent results.

Etching (Optional): Sometimes, a chemical etch might precede anodizing to ensure uniform surface reactivity or achieve a specific texture.

Anodizing Bath: The cleaned titanium acts as the anode in an electrolytic cell. It's immersed in an electrolyte solution, typically an acid (like sulfuric, chromic, or phosphoric acid) or a neutral salt solution.

Power Application: A DC current is applied, causing the titanium surface to oxidize. Oxygen ions from the electrolyte combine with titanium atoms, forming a dense, stable titanium oxide (TiO₂) layer. The thickness and characteristics of this layer depend heavily on the anodizing voltage and time.

Rinsing and Sealing: Post-anodizing, the part is rinsed thoroughly. Sealing (e.g., hot water or chemical sealing) can close pores in the oxide layer, further enhancing corrosion resistance.

Types of Titanium Anodizing and Their Characteristics

Different applications call for different approaches. Titanium anodizing comes in a few flavors:

Type II (Sulfuric Acid Anodizing): While more common for aluminum, a modified Type II can be used for titanium. It produces a relatively thin, clear, or light grey oxide layer.

Type III (Hard Anodizing): This process creates a thicker, denser, and harder oxide layer, primarily for improved wear and abrasion resistance. It’s less common for titanium than aluminum but exists for specific applications requiring extreme surface hardness.

Color Anodizing (Type II or III, often with varied voltage): This is unique to titanium. By precisely controlling the voltage during anodizing, different oxide layer thicknesses are achieved. These thicknesses interfere with light waves, producing a spectrum of vibrant colors without dyes. This is a big draw for many consumer and medical products.

Phosphoric Acid Anodizing: Often used as a pre-treatment for adhesive bonding due to its micro-porous surface structure.

Key Anodizing Parameters and Their Influence

The devil is in the details. Several anodizing parameters dictate the final properties of the oxide layer:

Voltage: Directly influences the oxide layer thickness and, for color anodizing, the resulting hue. Higher voltage generally means thicker layers.

Current Density: Affects the rate of oxide formation and the morphology of the layer.

Electrolyte Composition: The type and concentration of the acid or salt solution impact the oxide structure, porosity, and overall integrity. Some electrolytes produce more uniform, dense layers than others.

Temperature: Higher temperatures can increase reaction rates but might also lead to softer, more porous films.

Duration: The length of time the current is applied determines the extent of oxide growth, up to a certain point where dielectric breakdown might occur.

These variables are carefully controlled by manufacturers like China Titanium Factory to achieve precise surface characteristics for various titanium products.

Baseline: Understanding Titanium's Intrinsic Mechanical Properties

To grasp how anodizing changes things, we first need a solid understanding of titanium's mechanical properties in its untreated state. Titanium and its alloys are celebrated for their impressive mechanical profile.

Definition: Tensile Strength is the maximum stress a material can withstand while being stretched or pulled before breaking. It's a measure of its resistance to fracture under tension.

Tensile Strength: This is the big one. Untreated titanium, especially alloys like Ti-6Al-4V, boasts high tensile strength, often exceeding 1000 MPa (145 ksi). This means it can take a serious beating before it gives up the ghost.

Yield Strength: This indicates the stress at which a material begins to deform plastically (permanently). Titanium's high yield strength means it can withstand significant loads without permanent deformation.

Fatigue Strength: This is a critical property for components subject to cyclic loading. Titanium generally exhibits excellent fatigue resistance, allowing it to endure repeated stresses for a long service life.

Hardness: While not as hard as some steels, commercially pure titanium offers good hardness, contributing to its wear resistance. Alloys can be significantly harder.

Ductility: Titanium is reasonably ductile, meaning it can be stretched or drawn into wires without fracturing. This allows for complex fabrication and some degree of deformation before failure.

These properties are why titanium is a go-to for demanding applications. Any surface treatment, including anodizing, must respect this baseline.

The Core Question: How Anodizing Impacts Titanium's Mechanical Strength

Now, to the heart of the matter: the effect of anodizing on titanium mechanical strength. It's a nuanced picture, not a simple yes or no. The consensus is that anodizing primarily affects surface properties, with minimal impact on the bulk mechanical strength of the titanium substrate itself. However, "minimal" doesn't mean "zero."

Impact on Tensile and Yield Strength

Generally, anodizing titanium does not significantly alter its bulk tensile or yield strength. The oxide layer is typically very thin (nanometers to a few microns) compared to the overall thickness of the titanium component. Think of it like a coat of paint on a brick wall; the paint doesn't change the wall's structural integrity.

Studies show that while there might be minor variations, these are often within experimental error or negligible for practical applications. The titanium substrate carries the primary mechanical load. Therefore, if you're looking at the ultimate load-bearing capacity, anodized titanium largely holds its own against untreated titanium. A study published in ScienceDirect on titanium alloys often reiterates this point.

Effect on Fatigue Life and Performance

This is where things get a little more complex. The effect on fatigue life is highly dependent on the anodizing process and resulting oxide layer characteristics. Here’s the rundown:

Surface Stresses: The formation of the oxide layer can introduce residual compressive or tensile stresses on the surface. Tensile residual stresses, in particular, can act as crack initiation sites, potentially reducing fatigue life.

Brittleness of Oxide Layer: The hard titanium oxide layer itself is inherently more brittle than the ductile titanium substrate. Under cyclic loading, micro-cracks can form in this brittle layer, which might then propagate into the underlying titanium.

Process Optimization: However, this isn't a death knell for fatigue performance. Careful control of anodizing parameters, such as voltage, electrolyte, and post-treatments (like sealing), can minimize detrimental effects and even improve fatigue resistance in some cases by inducing beneficial compressive residual stresses.

The key is precision. For critical components requiring high fatigue resistance, a thorough understanding of the specific anodizing process and validation through testing is paramount. For detailed engineering support, specialists at China Titanium Factory can provide insights.

Changes in Hardness and Surface Wear Resistance

This is where anodizing really shines. The titanium oxide layer is significantly harder than the underlying titanium. This translates directly to improved surface hardness and wear resistance. The oxide acts as a protective barrier against abrasion and erosion.

For applications where parts experience friction or require enhanced durability against scratching, anodizing is a game-changer. Think medical instruments, sliding components, or architectural finishes. This increased surface robustness doesn't compromise the bulk strength, offering the best of both worlds.

Anodizing and Titanium's Ductility/Brittleness

As mentioned, the oxide layer is brittle. This doesn't mean the entire titanium component becomes brittle. The underlying titanium retains its ductility. However, for extremely thin components or those subjected to severe bending, the brittle surface layer might crack, potentially leading to delamination or initiating cracks in the substrate if not properly managed.

For most applications, where the oxide layer is thin and the underlying titanium is robust, the impact on overall ductility is negligible. It's a surface phenomenon. Engineers need to consider the load types and potential for severe deformation when specifying anodizing.

Quantitative Data and Research Findings on Mechanical Changes

Numerous studies have explored these effects. A review of literature from sources like ASTM International often indicates:

Tensile/Yield Strength: Typically, changes are within +/- 5%, often attributed to experimental variability rather than a significant material alteration.

Hardness: Vickers hardness values on the surface can increase by 2-5 times compared to untreated titanium, depending on the anodizing type and thickness.

Fatigue: Some studies report a slight reduction (e.g., 10-20%) in fatigue limit for certain anodizing conditions, while others show no significant change or even minor improvement with optimized processes. Surface roughness and residual stress are major players here.

The exact numbers are a moving target, varying with titanium alloy, surface preparation, electrolyte, voltage, and film thickness. This is why material characterization is crucial for high-stakes applications.

Factors Influencing the Mechanical Effects of Anodizing

The outcomes of anodizing aren't set in stone. Several variables play a role in how the process ultimately impacts titanium's mechanical behavior. It's all about fine-tuning.

Anodizing Parameters (Voltage, Electrolyte, Time)

We touched on these earlier, but it bears repeating: these parameters are powerful levers. Higher voltages typically lead to thicker oxide layers. While thicker might sound better for hardness, excessively thick, porous layers can sometimes be more prone to cracking and might negatively influence fatigue performance.

The choice of electrolyte (e.g., sulfuric acid, phosphoric acid, or alkaline solutions) fundamentally changes the growth mechanism and morphology of the oxide. Some electrolytes produce compact, dense films, while others might yield more porous structures. Each has its own fingerprint on the surface stress profile and, consequently, the mechanical response.

Treatment duration also plays a part. Too short, and you don't get the desired protective layer. Too long, and you risk over-processing, which can lead to film degradation or undesirable stress states.

Titanium Alloy Grade

Not all titanium is created equal. The specific titanium alloy grade matters. Commercially pure titanium (CP-Ti) grades (e.g., Grade 2, Grade 4) have different microstructures and compositions compared to alpha-beta alloys like Ti-6Al-4V (Grade 5).

These differences can influence how the oxide layer forms, its adhesion, and its inherent properties. For instance, the presence of alloying elements can affect the electrochemical reactions during anodizing, leading to variations in film thickness, density, and residual stress. Engineers must select the right alloy for the job, then tailor the anodizing process accordingly. For custom titanium solutions, reaching out to China Titanium Factory can connect you with experts.

Comparison with Alternative Surface Treatments for Titanium

Anodizing isn't the only horse in the race when it comes to titanium surface modification. It's helpful to see how it stacks up against other common methods.

Anodizing vs. PVD/CVD Coatings

Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) coatings apply a thin film of another material (e.g., TiN, TiC, DLC) onto the titanium surface. These coatings can offer exceptional hardness and wear resistance, often surpassing anodized layers.

However, PVD/CVD are additive processes. Adhesion can be a challenge if surface preparation isn't perfect, and there's always a risk of delamination under extreme conditions. Anodizing, by contrast, is a conversion process, meaning the oxide layer grows from the titanium substrate, creating an integral bond. This generally makes anodized layers less prone to chipping or peeling. From a mechanical standpoint, PVD/CVD can also introduce residual stresses, and their impact on fatigue life needs careful consideration, much like anodizing.

Anodizing vs. Nitriding/Carburizing

Nitriding and carburizing are thermochemical treatments that diffuse nitrogen or carbon into the titanium surface, forming hard nitride or carbide compounds. These processes create a hardened case that is significantly thicker than an anodized layer.

They provide excellent wear resistance and often improve fatigue performance by inducing compressive residual stresses. The trade-off? These are high-temperature processes that can alter the microstructure of the titanium bulk material, potentially affecting its core mechanical properties. Anodizing is a lower-temperature process, meaning it generally has less impact on the bulk microstructure. The choice depends on the desired depth of hardening and the acceptable thermal budget for the component.

Real-World Applications and Case Studies of Anodized Titanium

The rubber meets the road in practical applications. Anodized titanium isn't just a lab curiosity; it's a workhorse in many industries precisely because its mechanical integrity is maintained while surface benefits are gained.

Anodized Titanium in Medical Implants

This is a prime example. Anodized titanium medical implants, such as orthopedic screws, dental implants, and prosthetic components, leverage the enhanced biocompatibility and corrosion resistance of the oxide layer. Crucially, the underlying titanium's strength (tensile, yield, and fatigue) remains robust enough to withstand physiological loads over years, if not decades.

The oxide layer also offers a micro-roughness that can promote osseointegration, further enhancing the implant's long-term success without compromising its structural role. The ability to color anodize implants also helps surgeons differentiate between implant sizes or types during surgery.

Aerospace Components and Structural Integrity

In aerospace, every ounce counts, and reliability is everything. Titanium alloys are widely used for aircraft components like landing gear, structural frames, and engine parts. Anodizing is employed here for corrosion protection and sometimes for wear resistance.

The key is that anodizing must not compromise the titanium structural integrity. Engineers in this sector rigorously test anodized components to ensure that fatigue life, fracture toughness, and overall strength meet stringent safety standards. The minimal impact on bulk mechanical properties, combined with enhanced surface protection, makes anodized titanium a viable choice for many non-critical and even some critical aerospace titanium anodizing applications, provided the process is tightly controlled.

When you put an anodized titanium part into service, you're counting on its performance for the long haul. The long-term anodized titanium mechanical stability is generally excellent, owing to the inherent stability of titanium oxide.

The oxide layer is chemically inert and tightly adhered to the substrate. This means it resists degradation from environmental exposure, including various chemicals, moisture, and temperature fluctuations. The primary concern, as always, revolves around fatigue. If the anodizing process introduced unfavorable residual stresses or a highly brittle surface, long-term cyclic loading could eventually lead to crack initiation.

However, properly processed and sealed anodized titanium maintains its enhanced surface properties and the underlying material's mechanical strength for extended periods. It’s not going to fall apart on you. This makes it a dependable choice for applications requiring both robust mechanical performance and superior surface characteristics.

Conclusion: Balancing Performance and Protection with Anodizing

So, does anodizing compromise the mechanical strength of titanium? In a nutshell, for most practical purposes, no. Anodizing titanium is a powerful surface treatment that predominantly enhances surface properties like hardness, wear resistance, and corrosion protection without significantly detracting from its bulk tensile or yield strength.

The nuance comes into play with fatigue life, where process control is paramount. A well-executed anodizing process can maintain, or even in some specific cases, slightly improve fatigue resistance by inducing beneficial compressive stresses. Poor processing, however, can introduce detrimental tensile stresses or brittle surface layers that may reduce fatigue performance.

Ultimately, anodizing is a tool in the engineer's arsenal, allowing for a strategic balance between maintaining titanium's renowned mechanical robustness and gaining superior surface functionality. For critical applications, partnering with experienced titanium specialists who understand these intricacies is always a smart move.

Frequently Asked Questions About Anodized Titanium Mechanical Properties

Does anodizing make titanium weaker?

No, anodizing generally does not make titanium weaker in terms of its bulk tensile or yield strength. The oxide layer is very thin and primarily affects surface properties. Any minor changes in overall strength are usually negligible for most applications.

How does anodizing affect titanium's fatigue life?

The effect on fatigue life is complex. Poorly controlled anodizing can potentially reduce fatigue life due to induced tensile residual stresses or the brittle nature of the oxide layer. However, optimized anodizing processes can minimize this impact, and some studies even suggest minor improvements by creating beneficial compressive stresses on the surface.

Does anodized titanium rust?

Titanium itself does not "rust" in the traditional sense like steel (forming iron oxides). Anodizing enhances titanium's natural corrosion resistance by thickening its passive oxide layer. This makes anodized titanium highly resistant to various forms of corrosion, performing exceptionally well in harsh environments.

Is anodized titanium more brittle?

The thin oxide layer formed during anodizing is indeed more brittle than the underlying ductile titanium substrate. However, this brittleness is localized to the surface. The bulk titanium material retains its ductility. For most applications, the overall component does not become brittle.

What are the main benefits of anodizing titanium?

The primary benefits include significantly enhanced corrosion resistance, increased surface hardness and wear resistance, improved biocompatibility (especially for medical devices), and the ability to achieve vibrant, durable colors without dyes (color anodizing).