Understanding Titanium Anodizing: The Foundation of Color

Titanium anodizing delivers a vibrant, durable, and biocompatible finish. It's a game-changer across industries, from medical implants to aerospace components and high-end consumer goods. But what happens when that brilliant hue starts to dim?

Professionals and hobbyists alike often face a vexing problem: their meticulously anodized titanium pieces lose their luster. This isn't just an aesthetic issue; it can signal underlying degradation of the protective oxide layer. Understanding why titanium anodizing fades is crucial for maintaining product integrity and customer satisfaction.

The Science of Hue: How Titanium Anodizing Works

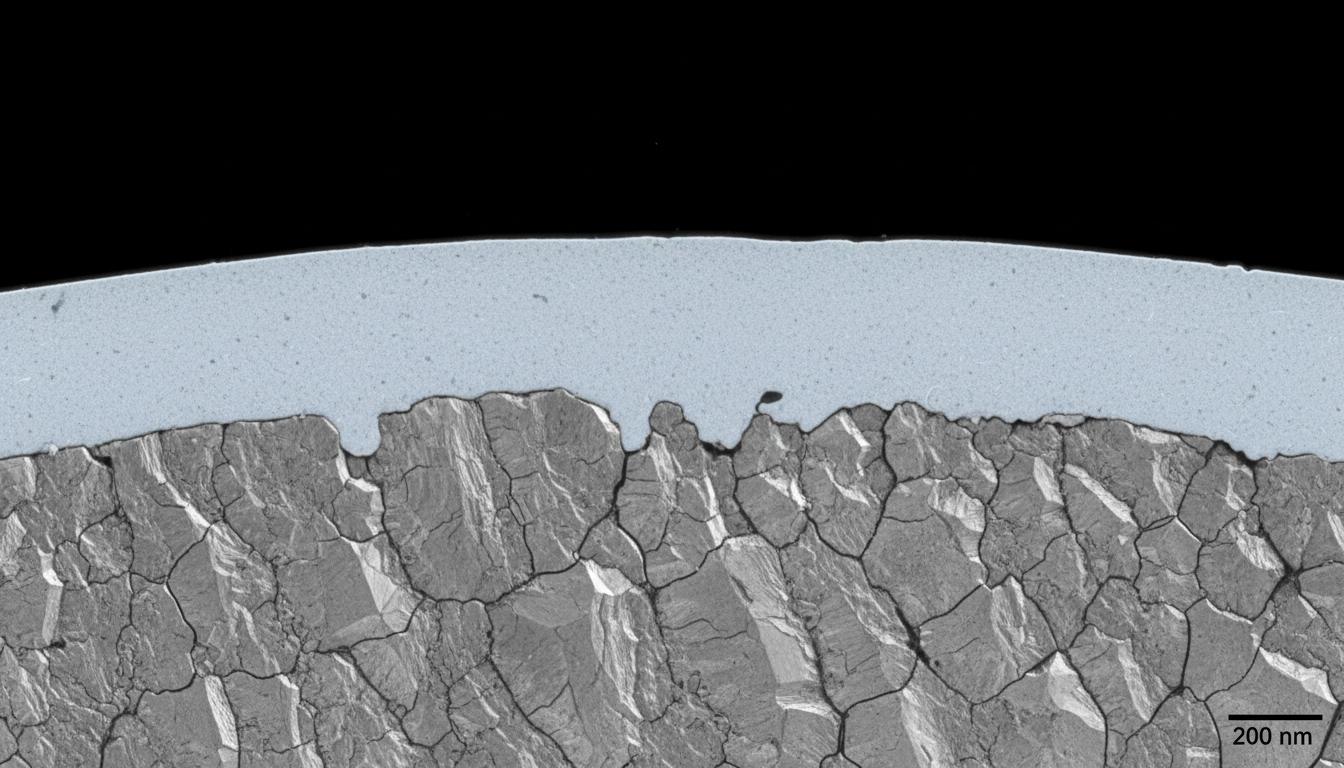

Unlike painted or dyed metals, anodized titanium doesn't get its color from pigments. It's all about light interference. A precisely controlled electrochemical process builds an oxide layer on the titanium surface. The thickness of this transparent layer dictates the color we perceive.

Here’s the skinny: When light hits the surface, some reflects off the top of the oxide layer, and some penetrates to the titanium underneath, reflecting back. These two light waves interfere with each other. Depending on the oxide layer's thickness, certain wavelengths are enhanced, while others are canceled out. What remains is the color our eyes see. Think of it like a prism, but on a microscopic scale.

The voltage applied during anodizing directly controls this oxide layer's thickness. Higher voltage means a thicker layer, resulting in a different color. A precise voltage-color relationship exists, which expert anodizing services meticulously control.

Titanium Oxide Layer: A passive, transparent film of titanium dioxide (TiO₂) formed on the surface of titanium through an electrochemical process (anodizing). Its thickness, precisely controlled by voltage, dictates the interference colors observed.

This interference phenomenon means the color isn't "in" the material; it's a structural effect. That's why any alteration to this delicate oxide layer can change or erase the color.

For a deeper dive into the science, the National Institute of Standards and Technology (NIST) provides extensive resources on thin film optics and material properties (Source).

Fading vs. Illusion: Differentiating True Color Loss from Apparent Changes

Before jumping to conclusions about fading, it's vital to distinguish between actual degradation and mere optical tricks. Sometimes, what looks like fading is anything but.

True color loss means the oxide layer itself has been damaged, thinned, or removed. This is irreversible without re-anodizing. On the other hand, apparent fading often stems from external factors that temporarily obscure or alter how light interacts with the surface.

Think of a dusty car. It looks dull, but a wash brings back the shine. The paint hasn't faded; it was just dirty. Anodized titanium can experience similar effects. Surface contamination, oils, or even specific lighting conditions can make a vibrant piece appear dull or faded.

For instance, a piece may look less vibrant under warm incandescent light compared to cool LED light. This isn't fading; it's just how different light spectra reflect off the interference layer. Always assess fading under consistent, neutral lighting conditions.

Unmasking the Culprits: Primary Causes of Titanium Anodizing Fading

When the fade is real, specific mechanisms are at play. The oxide layer, while robust, isn't invincible. Its integrity can be compromised in several ways, leading to irreversible color loss.

Chemical Attack: How Acids and Alkalis Damage Anodized Finishes

The titanium oxide layer, TiO₂, is generally stable. However, strong acids and alkalis are its kryptonite. These chemicals can dissolve or etch the oxide layer, thinning it or removing it entirely. The result? Color loss or a return to the natural silver-gray of raw titanium.

Common household cleaners, industrial solvents, or even some hand soaps can contain ingredients that are harsh enough to cause damage. Ammonia, bleach, strong acids like hydrochloric acid, or powerful alkaline solutions are particularly problematic. Even prolonged contact with sweat (which is slightly acidic) can, over time, have an effect, especially on jewelry.

Always check the chemical resistance of your anodized parts. For applications requiring high chemical stability, proper surface treatment and material selection are paramount. Trust a reputable titanium manufacturer to guide you.

Wear and Tear: The Impact of Friction and Abrasion

The anodized layer, though hard, is still a thin surface coating. Physical abrasion, rubbing, or scratching can mechanically remove or thin this layer. Think about keys jingling against an anodized keychain or frequent handling of a tool.

Every scrape, every rub, chips away at that delicate oxide. The areas experiencing the most friction will show wear first, often manifesting as dull spots or streaks of raw titanium peeking through. This is a common issue for items in daily use, such as jewelry, knife handles, or pen bodies.

Sun's Out, Colors Fade? UV Radiation and Environmental Stress

Prolonged exposure to ultraviolet (UV) radiation is a known enemy of many materials, and anodized titanium is no exception. While titanium oxide is generally UV stable, the long-term effects of intense sunlight, especially combined with heat and humidity, can contribute to subtle color shifts or gradual fading.

This isn't an overnight change; it's a slow burn. Outdoor architectural elements or components used in sunny climates are more susceptible. The exact mechanism isn't always straightforward, sometimes involving photodegradation or subtle changes in the oxide's microstructure over extended periods.

Process Pitfalls: When Anodizing Techniques Go Wrong

The quality of the anodized finish starts with the quality of the anodizing process itself. Shortcomings here can lead to colors that fade prematurely or are inconsistent from the get-go.

Common issues include:

Insufficient Layer Thickness: A too-thin oxide layer is inherently less durable and more prone to wear and chemical attack.

Electrolyte Contamination: Impurities in the anodizing bath can lead to uneven or faulty oxide formation, compromising color stability.

Incorrect Voltage Application: Inconsistent voltage during the process results in patchy, uneven colors or a finish that won't hold up.

Poor Surface Preparation: Residual oils, dirt, or previous oxide layers can prevent uniform anodization, creating weak spots.

This is where partnering with a specialist in quality titanium fabrication really pays off. Their expertise ensures a robust, consistent finish.

The Hidden Enemy: Surface Contaminants and Their Effect

As mentioned, not all "fading" is true fading. Often, the culprit is simply dirt, oils, fingerprints, or other residues accumulating on the surface. These contaminants scatter light differently, making the anodized finish appear dull, hazy, or less vibrant.

This isn't damage to the oxide layer itself, but an obscuring film on top of it. A good cleaning can often bring the color right back. It's a common issue for frequently handled items, where skin oils and environmental dust build up over time.

Preserving the Brilliance: Best Practices for Longevity

Preventing fade is always better than trying to fix it. A few sensible steps, from initial processing to daily care, can significantly extend the life and vibrancy of your anodized titanium.

Mastering the Process: Ensuring Durable Anodized Finishes

The foundation of a long-lasting finish is a well-executed anodizing process. Precision matters.

Impeccable Surface Preparation: Thorough cleaning, degreasing, and etching ensure a pristine surface for uniform oxide growth.

Optimal Electrolyte Selection: Using the right electrolyte (e.g., phosphoric, sulfuric, or hydrofluoric acid solutions, depending on desired finish) and maintaining its purity is non-negotiable.

Precise Voltage Control: Consistent, stable voltage application is key to achieving the desired color and a uniform, robust oxide layer.

Effective Sealing: While not always done for titanium anodizing due to its already dense oxide layer, some processes may benefit from post-anodizing treatments to further seal pores (if any) and enhance corrosion resistance.

These steps are standard operating procedure for professional titanium parts manufacturers.

Gentle Care: Cleaning and Maintaining Anodized Titanium

Daily maintenance is straightforward but critical.

Mild Detergents Only: Use lukewarm water with a small amount of mild, pH-neutral soap (like dish soap). Avoid harsh chemicals, abrasives, or anything containing bleach or ammonia.

Soft Cloth: Gently wipe the surface with a soft microfiber cloth or sponge. Steer clear of abrasive pads, brushes, or scouring agents.

Rinse and Dry: Rinse thoroughly with clean water to remove all soap residue, then dry immediately with a clean, soft cloth to prevent water spots.

Avoid Ultrasonic Cleaners: For delicate or highly decorative anodized pieces, ultrasonic cleaners can sometimes cause issues due to cavitation, so use with caution or avoid.

Simple, right? Just treat it like you would a fine piece of optical equipment.

Adding a Shield: Protective Coatings for Enhanced Durability

For items exposed to particularly harsh conditions, an extra layer of protection can work wonders.

Clear Coats: High-quality clear lacquers or ceramic coatings can provide a physical barrier against abrasion, chemicals, and UV radiation. Ensure the coating is compatible with anodized titanium and applied correctly to avoid hazing or peeling.

Waxes/Polishes: Specialized waxes designed for metal finishes can offer a temporary protective layer and enhance luster. These typically need reapplication.

Nanocoatings: Advanced nanocoatings can impart hydrophobic and oleophobic properties, making the surface easier to clean and resistant to fingerprints and minor stains.

Always test any coating on an inconspicuous area first.

Mindful Handling: Preventing Damage Through Proper Use and Storage

Common sense goes a long way.

Avoid Abrasion: Keep anodized items separate from other metal objects that could scratch them. Don't toss them into a bag with keys or coins.

Proper Storage: Store items in a dry, temperate environment, away from direct sunlight or extreme temperature fluctuations. A soft pouch or lined box is ideal for jewelry or delicate parts.

Limit Chemical Exposure: Be aware of environments where the item might encounter harsh chemicals – cleaning products, swimming pools (chlorine), or even some cosmetics.

Treat your anodized titanium with a little TLC, and it'll serve you well.

Reviving the Hue: When Fading Occurs, What Are Your Options?

Sometimes, despite your best efforts, fading happens. The good news is, depending on the severity and cause, you might have options for bringing that color back.

Diagnosing the Problem: Can Your Anodizing Be Saved?

First things first: diagnose the issue.

Superficial Dullness: If the item just looks dull or slightly hazy, a thorough but gentle cleaning might be all it needs. This is often the case with surface contaminants.

Patchy Color Loss/Streaks: This usually indicates abrasion or localized chemical exposure. If the underlying titanium is visible, the oxide layer is gone.

Overall Fading/Color Shift: This could be UV degradation, poor initial anodizing quality, or widespread chemical exposure.

A simple clean with mild soap and water is the first line of defense. If that doesn't restore the color, you're likely dealing with true oxide layer damage.

At-Home Remedies: Limited Solutions for Minor Fading

For apparent fading due to surface issues, gentle at-home cleaning is your best bet.

Rubbing Alcohol: For stubborn oils or residues, a quick wipe with isopropyl alcohol (rubbing alcohol) on a soft cloth can help. Test in an inconspicuous area first.

Jewelry Polishing Cloths: Some non-abrasive jewelry cloths designed for titanium might help restore a bit of sheen, but be cautious. If they contain abrasives, they can damage the oxide layer.

Remember, these are for superficial issues. If the oxide layer is truly compromised, no amount of rubbing will bring the color back. You might just make it worse.

The Professional Touch: Re-anodizing for a Fresh Start

When the oxide layer is significantly damaged, the only real solution is professional re-anodizing. This process involves:

Stripping: The old, faded, or damaged anodized layer is carefully removed using a specific chemical solution. This essentially brings the titanium back to its raw, unanodized state.

Repreparation: The surface is cleaned and prepped again, just as it would be for a new piece.

Re-anodizing: The electrochemical process is performed anew, applying voltage to grow a fresh, vibrant oxide layer.

This is a job for specialists. Attempting to strip and re-anodize at home without the right equipment and expertise is a recipe for disaster. For critical components or high-value items, always consult with experienced titanium fabrication companies.

Anodized Titanium in Action: Key Applications and Quality Standards

Anodized titanium isn't just pretty; it's a workhorse. Its unique combination of aesthetics, biocompatibility, and corrosion resistance makes it indispensable across diverse sectors.

Consider medical implants, where titanium's inertness is critical. Anodizing provides a sterile, color-coded finish for surgical tools or prosthetic components. In aerospace, where every gram counts, lightweight titanium parts benefit from anodizing for identification and enhanced surface hardness. Jewelry, of course, thrives on the vibrant, hypoallergenic colors. Even luxury watches and consumer electronics leverage its sleek, durable appeal.

Ensuring these applications meet stringent requirements means adhering to rigorous quality standards. ASTM F86 for surface preparation of titanium medical implants, for example, is non-negotiable. For general anodizing, standards like MIL-A-8625 for aluminum anodizing provide a framework, though titanium has its own unique considerations. Manufacturers, particularly those in global hubs like China, often align with ISO 9001 and other international benchmarks to guarantee consistent quality and process control.

When you seek professional titanium anodizing and finishing, ensure your provider understands these critical industry specifications. Quality control isn't just a buzzword; it’s the bedrock of a reliable, fade-resistant finish.

For more insights into metal finishing standards, the Metal Finishing Association of North America (MFANC) offers valuable resources (Source).

Your Top Questions Answered: Titanium Anodizing Fading FAQs

Still have questions swirling around your head? Let's clear the air with some frequently asked questions.

Can all anodized titanium be re-anodized?

Generally, yes. Most anodized titanium can be stripped and re-anodized. The key factors are the integrity of the underlying titanium and whether previous treatments have caused any deep surface damage. If the metal itself is severely pitted or compromised, re-anodizing might not yield a perfect finish, but it will typically still take color.

What's the best way to clean anodized titanium jewelry?

Simple is best. Use lukewarm water with a small drop of mild, pH-neutral soap (like unscented dish soap). Gently rub with a soft microfiber cloth or your fingers. Rinse thoroughly under clean water, then pat dry immediately with another clean, soft cloth. Avoid abrasive cleaners, stiff brushes, or ultrasonic cleaners for best results.

Does clear coating prevent fading?

Clear coatings can certainly help. They provide an additional physical barrier against abrasion, chemical splashes, and UV exposure, all of which contribute to fading. However, a clear coat won't entirely eliminate the risk, especially if the underlying anodized layer was poorly applied. The coating itself can also degrade over time, requiring reapplication.

How long does titanium anodizing typically last?

The lifespan varies wildly depending on use. For items subject to heavy wear, like jewelry or EDC (Everyday Carry) gear, noticeable fading might occur within months or a few years. For static or protected applications, like medical implants or decorative architectural elements, the anodizing can last for decades. Quality of initial anodizing and adherence to maintenance protocols are huge factors.

Is titanium anodizing safe for skin contact?

Absolutely. Titanium, even when anodized, is renowned for its biocompatibility and is considered hypoallergenic. This is why it's a go-to material for medical implants, body jewelry, and sensitive skin applications. The oxide layer is inert and stable, posing no risk upon skin contact. This is one of its major advantages over other colored metals.