In demanding industrial environments, standard, off-the-shelf anodes often fall short. They might not deliver the precise performance, longevity, or efficiency your specific electrochemical process demands. This isn't just a minor inconvenience; it can mean higher operational costs, inconsistent product quality, or even system downtime. Getting it right from the jump can save you a bundle.

That's where custom titanium anode design comes into play. Precision-engineered solutions are the answer. They provide superior performance, enhanced efficiency, and extended service life, tailored exactly to your unique industrial requirements. We're talking about electrochemical solutions designed to hit the bullseye every single time.

Understanding Custom Titanium Anodes: A Technical Overview

A custom titanium anode isn't just another electrode. It's a precisely engineered component, purpose-built for specific electrochemical processes. At its core, it consists of a titanium substrate, which offers exceptional corrosion resistance and mechanical strength. But the real magic happens with the coating.

Mixed Metal Oxide (MMO) coatings are key. These proprietary formulations of noble metal oxides (like iridium and ruthenium) are applied to the titanium substrate. This coating is what gives the anode its catalytic activity, determining its efficiency and selectivity for particular electrochemical reactions. Think of it as the engine of the anode.

Mixed Metal Oxide (MMO) Coating: A thin, electrochemically active layer composed of various noble metal oxides (e.g., RuO₂, IrO₂) applied to a titanium substrate. This coating significantly enhances the anode's catalytic properties, conductivity, and corrosion resistance, tailoring its performance for specific electrochemical reactions.

Understanding these fundamental components is crucial. It’s the foundation for any successful anode customization project, ensuring the electrode performs exactly as needed for your application. Our expert team at China Titanium Factory specializes in developing and applying these advanced coatings.

Unlocking Efficiency: The Core Benefits of Tailored Anode Solutions

Why go custom when you can buy off the rack? Simple: tailored solutions pay dividends. They're not just about fitting a square peg into a square hole; they're about precision engineering for peak performance. Here’s how:

Enhanced Operational Efficiency: A custom anode is designed to optimize current distribution and reaction kinetics for your specific process. This means less energy waste and faster, more consistent results.

Extended Service Life: By matching materials and coatings precisely to the operating environment, custom anodes resist degradation longer. This translates to fewer replacements and lower maintenance costs over the long haul.

Precise Process Control: When an anode is designed for a particular reaction, you gain finer control over the electrochemical parameters. This is critical for achieving consistent product quality and yield.

Cost-Effectiveness: While the initial investment might seem higher, the long-term savings from increased efficiency, reduced downtime, and extended lifespan often make custom anodes the more economical choice. It's about looking at the whole picture.

Reduced Environmental Impact: Optimized processes can lead to less waste generation and more efficient use of resources, aligning with sustainability goals.

In essence, custom titanium anodes aren't merely components; they're strategic investments that drive your industrial success.

Precision Engineering: Principles of Custom Titanium Anode Design

Designing a custom titanium anode is a delicate dance between electrochemistry, materials science, and mechanical engineering. It's not a shot in the dark. Every aspect, from the base material to the coating thickness, is carefully considered to ensure optimal function and longevity.

Selecting the Right Foundation: Material and Substrate Considerations

The journey begins with the titanium substrate. Not all titanium is created equal. Different grades offer varying mechanical properties and corrosion resistance. For instance, commercially pure titanium (CP Titanium) Grades 1, 2, and 7 are common choices, each with specific advantages.

Grade 1 offers high ductility, while Grade 2 provides a good balance of strength and ductility. Grade 7, with its palladium addition, boasts superior resistance to crevice corrosion in reducing acids. The choice hinges entirely on the operating conditions – temperature, pH, presence of specific chemicals, and current density. Understanding these nuances is critical for the anode's long-term durability. For detailed specifications on titanium grades, you can refer to resources like ASTM International standards.

Optimizing Anode Performance: Key Design Factors

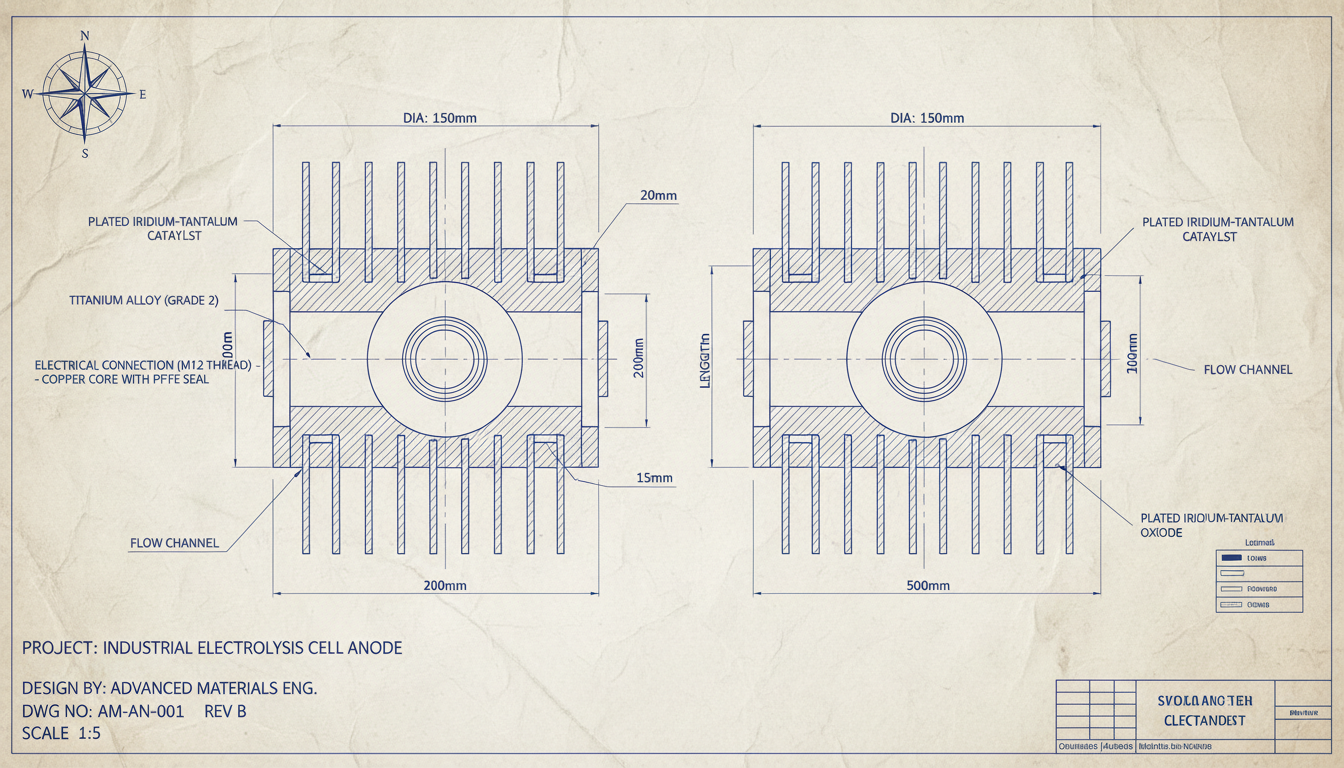

Once the material is chosen, geometric design takes center stage. Anode geometry directly impacts current distribution, which in turn affects plating uniformity, reaction rates, and overall efficiency. We consider various forms: plates, mesh, rods, tubes, or complex custom shapes.

The active surface area is another critical factor. Too little, and you compromise efficiency; too much, and you might increase costs unnecessarily. Our engineers fine-tune these elements to facilitate specific electrochemical reactions while maximizing operational output. It's all about precision.

Leveraging Advanced CAD and Simulation for Anode Design

Before any metal is cut, we bring designs to life virtually. Cutting-edge CAD (Computer-Aided Design) software allows us to create intricate 3D models. More importantly, simulation tools provide a window into real-world performance.

We use electrochemical modeling to predict current density distribution, potential fields, and even expected lifespan under various operating conditions. This virtual prototyping allows for rapid iteration and design validation, catching potential issues on the screen rather than on the factory floor. It saves both time and resources. This level of advanced design and engineering is a cornerstone of our service.

From Blueprint to Reality: The Custom Anode Manufacturing Process

Turning a meticulously crafted design into a high-performance anode requires a manufacturing process that’s just as precise. Every step is vital, from initial material preparation to the final quality checks. We leave no stone unturned.

Precision Fabrication and Shaping Techniques

Once the titanium substrate is selected, it undergoes a series of specialized fabrication processes. This often includes laser cutting, waterjet cutting, bending, and welding to form the exact geometric configuration specified in the design. Whether it’s a complex mesh, a perforated plate, or a tubular structure, our skilled technicians use advanced machinery to achieve tight tolerances.

Welding, for example, is performed under inert atmospheres to prevent contamination and maintain the titanium's inherent corrosion resistance. These techniques are crucial for creating anodes that fit perfectly into your existing systems and deliver uniform performance. Learn more about our manufacturing capabilities.

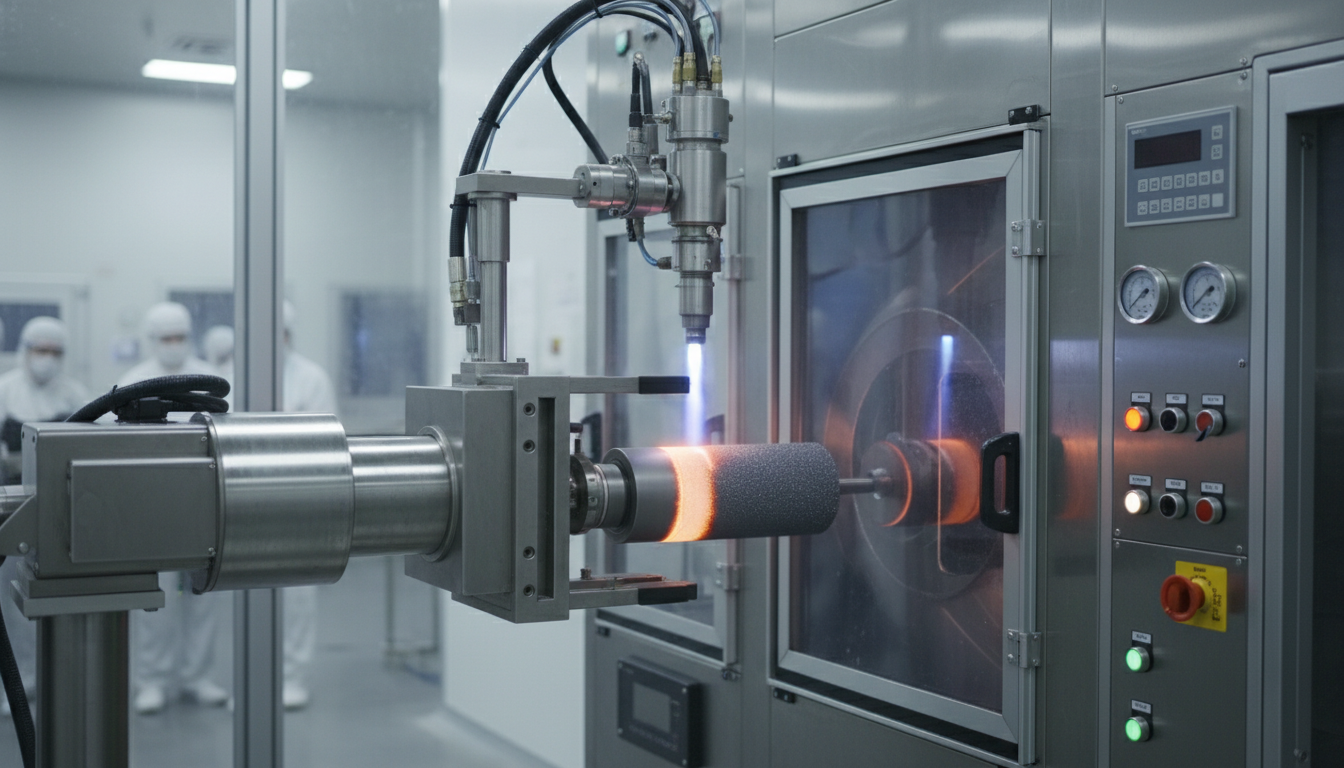

The Critical Role of MMO Coating in Anode Performance

The Mixed Metal Oxide (MMO) coating is, without exaggeration, the heart of a high-performance anode. It dictates catalytic activity, reaction selectivity, and ultimately, the anode's lifespan. The application process is intricate, involving multiple layers of noble metal oxides.

Our process typically involves thermal decomposition, where precise amounts of metal salt solutions are applied to the prepared titanium substrate and then heat-treated at specific temperatures. The composition of this coating is customized based on the intended application—different ratios of iridium, ruthenium, and other oxides are used for oxygen evolution, chlorine evolution, or other specific reactions. This bespoke approach ensures the anode performs optimally under your unique operational parameters. For more technical insights into MMO coatings, consider reviewing research from organizations like The Electrochemical Society.

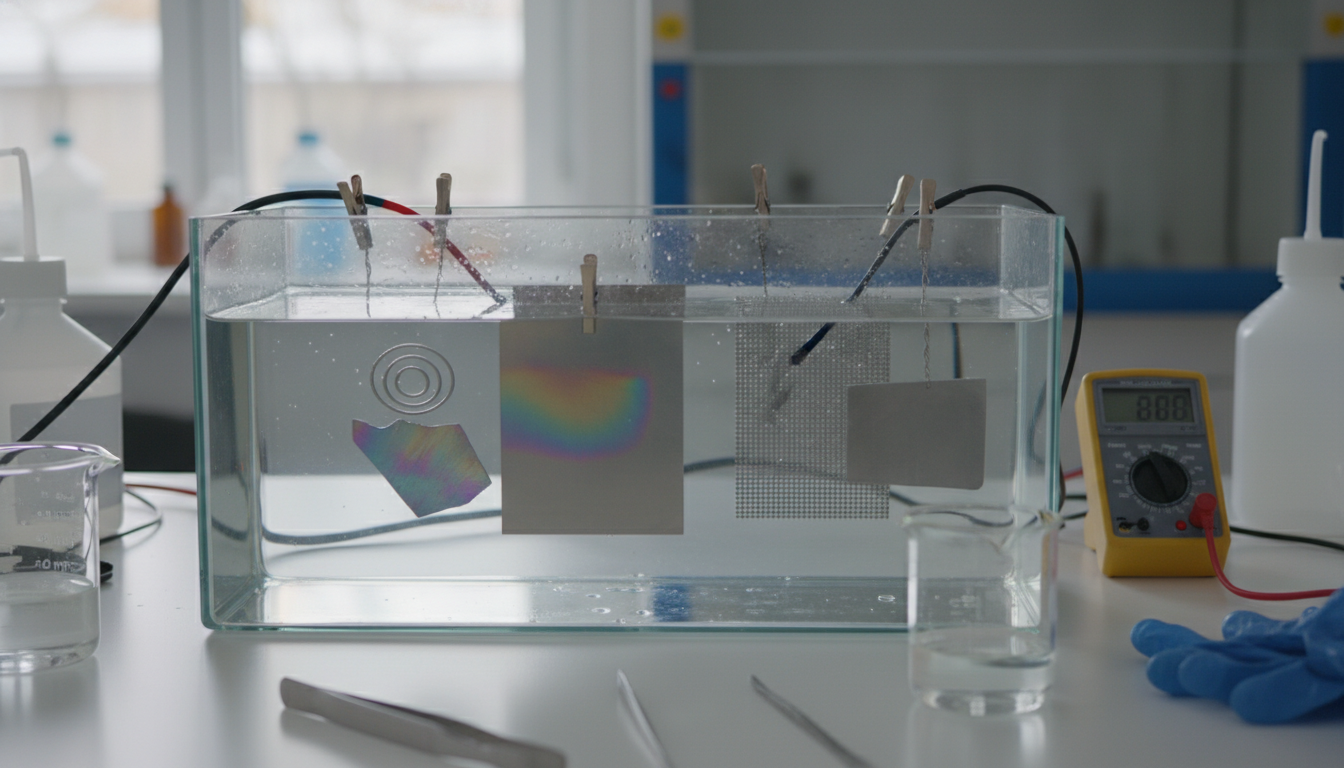

Ensuring Excellence: Rigorous Quality Control and Testing

Quality isn't an afterthought; it's baked into every stage of our manufacturing process. We implement stringent quality assurance protocols from raw material verification to final product validation. This means inspecting titanium substrates for purity and surface finish, meticulously controlling coating thickness, and performing adhesion tests to ensure the MMO layer won't flake off under stress.

Performance testing, often involving accelerated lifespan tests and electrochemical efficiency measurements, confirms that each custom anode meets the highest standards of reliability and longevity. We operate under the philosophy that if it doesn't pass our rigorous checks, it doesn't leave our facility. It’s how we maintain our reputation for excellence.

Application-Specific Solutions: Where Custom Anodes Excel

The true power of custom titanium anodes shines in their adaptability across a vast array of industrial sectors. They aren't one-size-fits-all components. Instead, they are engineered to solve specific challenges, delivering unparalleled efficiency and reliability where generic options simply can't compete.

Enhancing Electroplating and Surface Finishing Processes

In electroplating, anode design directly impacts plating uniformity, current efficiency, and bath life. Custom anodes, with their optimized geometry and coating composition, ensure an even deposit, reduce unwanted side reactions, and minimize sludge formation. This leads to superior product quality, reduced rework, and significant savings in operational costs for applications like chrome plating, nickel plating, and precious metal deposition.

Custom Anodes for Advanced Water Treatment and Disinfection

Water treatment is a critical area where custom anodes make a substantial difference. They are vital in wastewater purification, producing strong oxidants for disinfection without relying on harsh chemicals. In ballast water management systems, custom anodes facilitate on-site chlorine generation, effectively neutralizing invasive species. These tailored solutions ensure efficient, eco-friendly water purification, from municipal facilities to marine vessels. Our anodes are engineered for various demanding applications.

Optimizing Chemical Synthesis and Industrial Production

From chlor-alkali production to electrowinning and organic electrosynthesis, custom anodes are indispensable. They are engineered to selectively drive specific reactions, leading to higher yields and purer end products. Whether it's producing chlorine, caustic soda, or recovering metals from solutions, the right anode design can dramatically improve process economics and product quality. It's about getting the chemistry just right.

Reliable Cathodic Protection with Custom Anodes

Corrosion is a silent killer for critical infrastructure. Custom titanium anodes are at the forefront of impressed current cathodic protection (ICCP) systems. Designed for specific soil conditions, water salinity, or structural geometries, they provide robust, long-lasting corrosion prevention for pipelines, marine structures, storage tanks, and reinforced concrete. A tailored anode means your assets are protected, extending their lifespan and safeguarding your investment.

Proven Performance: Case Studies and Success Stories

We've helped countless clients overcome their toughest electrochemical challenges. For instance, a major chemical producer faced inconsistent yields in their chlor-alkali process. After implementing our custom-designed MMO anodes, they saw a 15% increase in production efficiency and a 20% reduction in energy consumption over two years. That's real money in the bank.

Another client, struggling with frequent anode replacements in a harsh wastewater treatment plant, experienced a dramatic extension of anode life from 18 months to over 4 years with our tailored solution. These aren't just numbers; they're testaments to the tangible impact of precision engineering and a deep understanding of electrochemical processes. Our track record speaks for itself.

Your Partner in Innovation: Our Custom Anode Expertise

Choosing a partner for your custom anode needs isn't just about finding a supplier; it's about finding a collaborator. At China Titanium Factory, we bring more than just manufacturing capabilities to the table. We bring a commitment to innovation, a wealth of technical expertise, and a dedication to understanding your unique operational demands.

Unmatched Design and Engineering Capabilities

Our team comprises seasoned electrochemists, materials scientists, and mechanical engineers. They live and breathe anodes. We don't just take orders; we engage in a collaborative design process, working hand-in-glove with your technical teams. This ensures every custom anode solution is precisely engineered to address your most demanding specifications and challenges, from concept to deployment. Our design and engineering services are comprehensive.

A Commitment to Uncompromising Quality and Performance

We stand by the quality and performance of every custom titanium anode that leaves our facility. Our manufacturing processes adhere to stringent international standards, and our quality control measures are second to none. We're not just selling anodes; we're selling reliability, longevity, and optimal functionality. That's our promise.

Frequently Asked Questions About Custom Titanium Anodes

What makes a titanium anode "custom"?

A custom titanium anode is specifically designed and manufactured to meet the unique requirements of a particular electrochemical application. This involves tailoring the titanium substrate's grade and form, the geometry of the anode, and crucially, the composition and thickness of the Mixed Metal Oxide (MMO) coating to optimize performance for specific operating conditions and reactions.

How long do custom titanium anodes typically last?

The lifespan of a custom titanium anode varies widely based on its design, coating type, and operating conditions (e.g., current density, electrolyte composition, temperature). However, custom anodes are engineered for extended durability, often lasting several years, sometimes even decades, outperforming generic alternatives significantly due to precise material and coating selection.

What information is needed to design a custom anode?

To design an effective custom anode, we typically need details on the electrochemical process, including the electrolyte composition, pH, temperature, target current density, desired reaction products, and any specific dimensional constraints or existing system integrations. The more information you provide, the better we can tailor the solution.

Are custom anodes more expensive than standard ones?

The initial upfront cost for a custom titanium anode can be higher than a standard, off-the-shelf option due to the specialized design and manufacturing. However, this initial investment is often offset by significant long-term savings. These savings come from increased efficiency, reduced energy consumption, extended service life, less downtime, and improved process reliability, leading to a much lower total cost of ownership.

What industries benefit most from custom titanium anodes?

Many industries benefit, including electroplating and surface finishing, water and wastewater treatment, chlor-alkali production, electrowinning, cathodic protection for infrastructure, and various other chemical synthesis and manufacturing sectors. Anywhere precise electrochemical control, high efficiency, and long-term reliability are critical, custom anodes shine.

Ready to Design Your Custom Anode Solution?

Don't settle for "good enough." Your industrial process deserves an anode solution built to perform optimally, day in and day out. Take the next step towards superior efficiency and reliability.

Contact our expert team at China Titanium Factory today

for a personalized consultation. Let's discuss your specific requirements and craft a tailored quote for your custom titanium anode project. We're here to help you hit your goals.