Comparative Metallurgy: Titanium vs. Conventional Marine Alloys

Seawater is a complex electrolyte. It facilitates rapid pitting and crevice corrosion in standard steels. While 316 Stainless Steel and Marine Bronze are traditional staples, they often fail under the thermal and pressure stresses of deep-sea exploration. Titanium offers an impervious oxide layer that reforms instantly if mechanically abraded.

| Material | Density (g/cm³) | Yield Strength (MPa) | PREN Value | Corrosion Rate |

|---|---|---|---|---|

| 316 Stainless Steel | 8.0 | 205 | 24-26 | Moderate |

| Marine Bronze | 8.8 | 180-400 | N/A | Surface Oxidation |

| Titanium Grade 5 | 4.43 | 880+ | >100 | Immune |

The Pitting Resistance Equivalent Number (PREN) for titanium exceeds that of even the most expensive super-duplex steels. According to research from AMPP (formerly NACE), titanium shows zero measurable corrosion in stagnant seawater at temperatures up to 250°C. This makes it the logical choice for high-reliability offshore hardware.

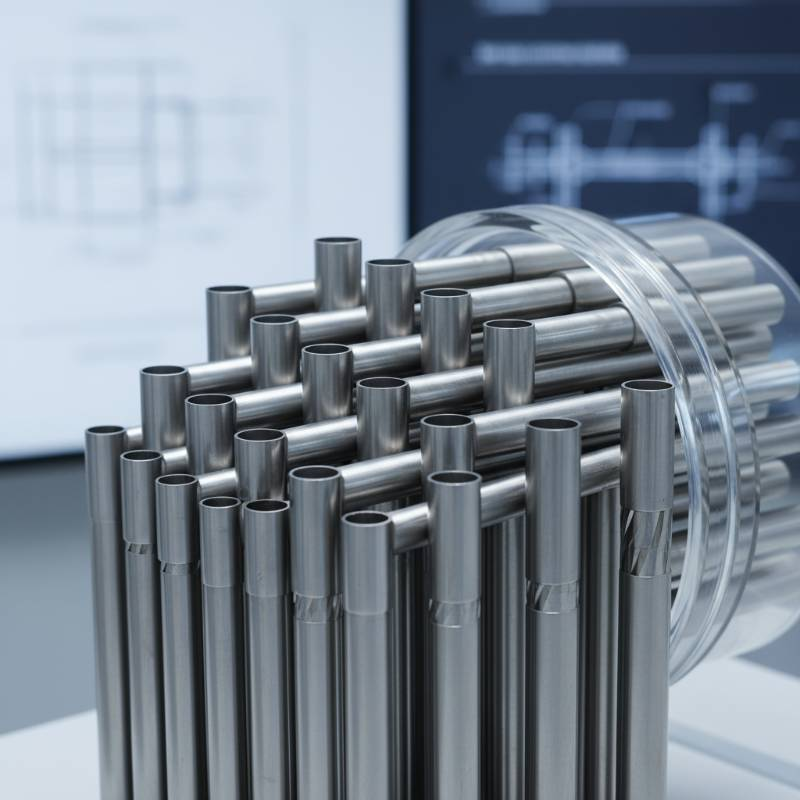

Essential Marine Titanium Grades: Grade 2 vs. Grade 5

Procurement must distinguish between ductility and tensile strength. Not all titanium is suitable for every marine application. At China Titanium Factory, we categorize supply based on the ASTM B265 standard to ensure mechanical compliance.

Titanium Grade 2 (Commercially Pure)

Grade 2 is the workhorse of the maritime industry. It offers exceptional weldability and moderate strength. It is the primary choice for heat exchangers and desalination piping systems. Its ability to withstand high-velocity seawater flow without erosion is unmatched by copper-nickel alloys.

Titanium Grade 5 (Ti-6Al-4V)

When structural integrity is paramount, Grade 5 is required. This alpha-beta alloy provides double the strength of Grade 2 at a similar density. We define its role as the "structural backbone" for subsea pressure housings and riser components. It is essential for components deep-sea ROVs (Remotely Operated Vehicles) where the strength-to-weight ratio dictates operational depth limits.

The Titanium Life-Cycle Integrity Protocol (TLIP)

Standard procurement often focuses on initial CAPEX. We challenge this through the Titanium Life-Cycle Integrity Protocol (TLIP). This framework evaluates the "Zero-Maintenance" threshold of a component.

"The Immortality Constant: Any marine component requiring replacement within a 20-year window represents a failure of material specification, not a failure of maintenance."

The TLIP methodology involves three stages:

1. Electrochemical Profiling: Assessing the specific salinity and temperature of the deployment site.

2. Stress-Corrosion Mapping: Identifying potential fatigue points in welded assemblies.

3. ROI Amortization: Calculating the savings from eliminated dry-docking and replacement labor costs.

Engineering Applications in Offshore and Subsea Environments

Marine grade titanium suppliers cater to diverse sectors. In offshore oil and gas, titanium is vital for downhole equipment and production risers. It meets NACE MR0175/ISO 15156 standards for use in H2S-containing (sour) environments.

Desalination and Power Generation

Modern desalination plants utilize titanium tubing to handle high-temperature brine. The material’s resistance to biofouling—when managed with appropriate chlorination—ensures thermal efficiency remains constant for decades. This reliability is a cornerstone of sustainable marine engineering.

Global Supply Chain Logistics and Certification Standards

Procuring titanium requires more than just a purchase order. It requires a certification audit. Leading marine grade titanium suppliers must provide full traceability from the melt to the final product. Key certifications include DNV (Det Norske Veritas) for offshore structures and ISO 9001 for quality management.

Lead times for industrial titanium vary based on ingot availability. We maintain a strategic inventory of marine-grade alloys to mitigate global supply chain volatility. For custom forgings, lead times typically range from 8 to 14 weeks depending on geometry and testing requirements.

Mitigating Galvanic Corrosion in Mixed-Metal Marine Assemblies

Titanium is the most noble metal in common engineering use. When coupled with steel or aluminum in seawater, it will accelerate the corrosion of the other metal. This is the "Noble Trap."

To avoid failure, engineers must use electrical isolation. Non-conductive gaskets, sleeves, and washers are mandatory. In some cases, cathodic protection systems must be recalibrated to account for the presence of titanium surfaces, which do not consume sacrificial anodes but do influence the local electrochemical potential.

Secure Your Marine Infrastructure Today

Stop replacing corroded components. Leverage the Titanium Life-Cycle Integrity Protocol to specify materials that outlast the project lifespan. Our technical team is ready to assist with ASTM B265 compliance and custom subsea fabrication.

Frequently Asked Questions Regarding Marine Titanium Procurement

Is titanium resistant to all types of seawater?

Yes. Titanium is virtually immune to all forms of seawater corrosion, including microbiologically influenced corrosion (MIC) and pitting, at temperatures below 250°C.

How does bulk pricing for marine alloys work?

Pricing is typically based on weight and the current market rate for titanium sponge. Large-scale maritime projects benefit from volume discounts when ordering standard plate or pipe dimensions.

Is welding titanium difficult for shipyards?

It requires strict atmospheric control. Titanium must be shielded by an inert gas (Argon) during welding to prevent embrittlement from oxygen or nitrogen. Most specialized marine fabricators are equipped for this.