The Engineering Behind High-Performance Titanium Anodes for Salt Chlorinators

A salt chlorinator is only as effective as the metal inside its cell. At the heart of this system is the titanium anode for salt chlorinator use, a component that facilitates the electrochemical conversion of salt into chlorine. Without a high-quality electrode, your water treatment system is just a hollow plastic pipe.

"We define a titanium anode as a dimensionally stable electrode (DSE) consisting of a high-purity titanium substrate coated with catalytic metal oxides to facilitate electrolysis without the base metal eroding."

The process, known as electrolysis, requires an anode that can withstand the harsh corrosive environment of evolved chlorine gas. Engineering compliance is non-negotiable here. Cheap alloys fail within months. High-grade titanium lasts for years. At China Titanium Factory, we focus on the electrochemical stability that industrial stakeholders demand.

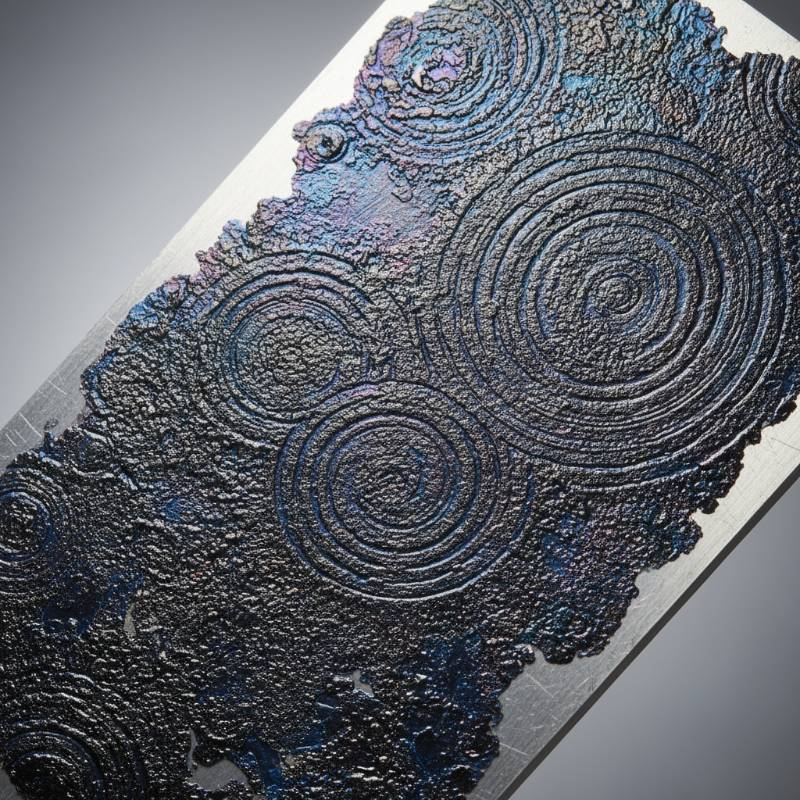

MMO Coating Technology: Ruthenium vs. Iridium Compositions

The secret isn't just the titanium—it's the coating. Mixed Metal Oxide (MMO) coatings are applied to Grade 1 titanium to act as a catalyst. Different formulations serve different salinity levels and duty cycles. Our technical analysis shows that the ratio of Ruthenium to Iridium dictates the oxygen evolution potential.

Ruthenium-Iridium: The Chlorine Powerhouse

For standard salt pools (3,000–4,000 ppm salinity), Ruthenium-based coatings are optimal. They offer the highest catalytic activity for chlorine evolution. They are cost-effective and highly efficient. However, they are sensitive to low-salinity environments which can accelerate coating wear.

Iridium-Tantalum: The Oxygen Suppressor

In applications where oxygen evolution is a risk or in seawater chlorination, Iridium-Tantalum is superior. It offers better stability and a longer lifespan in high-current density environments. We often recommend this for water treatment equipment used in industrial settings.

| Coating Type | Primary Use | Key Benefit |

|---|---|---|

| Ru-Ir (Ruthenium-Iridium) | Residential/Commercial Pools | High Chlorine Efficiency |

| Ir-Ta (Iridium-Tantalum) | Seawater/Industrial Chlorination | Extreme Corrosion Resistance |

The DuraElectrode™ 4-Point Reliability Protocol

Standard manufacturing often cuts corners on coating adhesion. To counter this, we developed The DuraElectrode™ 4-Point Reliability Protocol. This is our "Golden Rule" for electrode production. It ensures every replacement salt cell electrode meets industrial benchmarks.

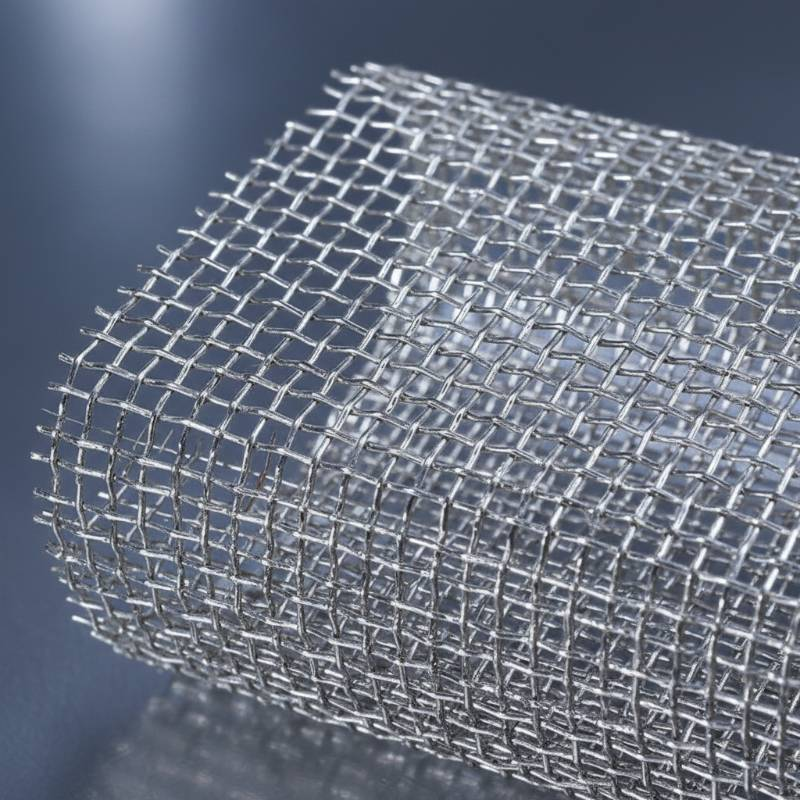

Substrate Micro-Abrasion: We use mechanical and chemical etching to increase surface area, ensuring the coating anchors deeply into the titanium.

Precision Layering: Coatings are applied in 18-25 micro-layers, with thermal decomposition occurring between each pass. This prevents "flaking."

Thermal Consolidation: Anodes are annealed in oxygen-controlled furnaces to stabilize the oxide crystal structure.

Electrochemical Stress Test: Every batch undergoes accelerated life testing to verify current density capacity before shipping.

Signs of Anode Failure: Troubleshooting Your Salt Cell

Don't wait for your water to turn green. Worn electrodes show clear physical and electrical symptoms. According to research on corrosion engineering, electrode erosion is often accelerated by improper pH balance.

Visual and Electrical Benchmarks

Low Chlorine Output: If your salt levels are correct but chlorine is low, the catalytic coating is likely depleted.

Voltage Drop/Spike: A failing anode increases resistance. Your control panel may show "Low Salt" even when salt levels are high.

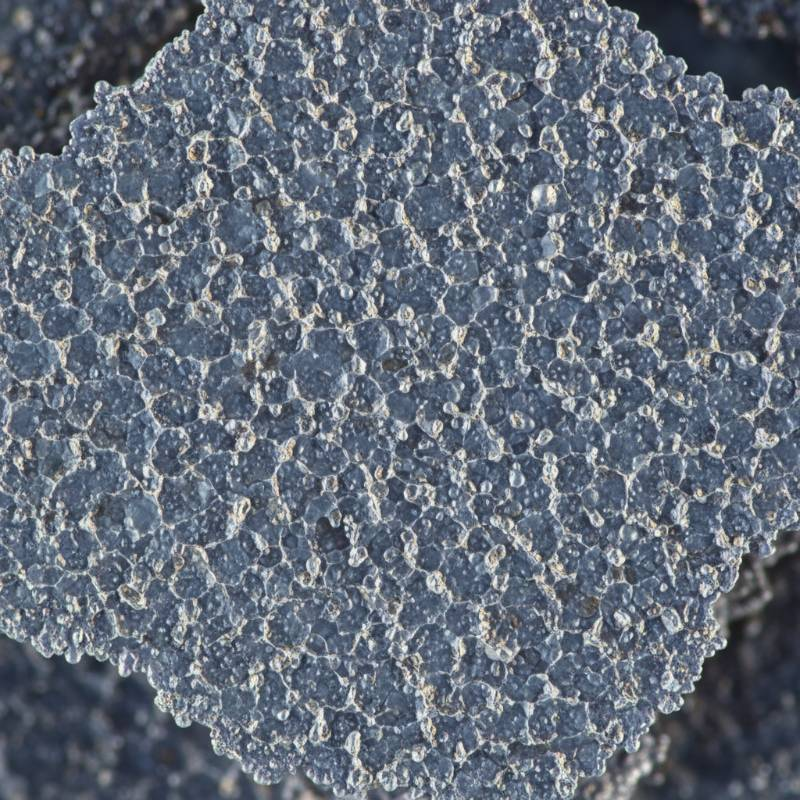

Calcium Buildup: Excessive scaling on the plates that doesn't resolve with mild acid washing indicates a loss of the protective MMO layer.

Thinning Plates: If the titanium substrate itself looks "eaten away," the coating has failed completely, exposing the base metal.

OEM vs. Aftermarket Titanium Anodes: A Comparative ROI Analysis

The "OEM-only" myth is expensive. Many pool professionals believe only original manufacturer cells work. However, engineering-grade aftermarket anodes provide a higher ROI. The cost-per-hour of operation is the only metric that matters.

High-grade aftermarket anodes from reputable sources like China Titanium Factory use the same Grade 1 titanium and Ru-Ir coatings as OEM brands but without the 300% brand markup. For industrial stakeholders, this translates to thousands of dollars in annual savings across multiple systems.

Optimizing Lifespan: Polarity Reversal and Water Chemistry

To maximize your investment in a titanium anode for salt chlorinator, you must manage the environment. Chemistry is king. Poor balance destroys electrodes faster than heavy usage.

The Role of Polarity Reversal

Most modern chlorinators use polarity reversal (self-cleaning). By switching which plate is the anode and which is the cathode, the system sheds calcium scale. While this extends cleaning intervals, it puts mechanical stress on the coating. Our DuraElectrode™ technology is specifically designed to handle these frequent shifts without delamination.

The Salinity Sweet Spot

Never run your cell in low-salt conditions. When salt is low, the system struggles to find ions to oxidize. It ends up attacking the water molecules (oxygen evolution), which is significantly more corrosive to the MMO coating. Keep your salinity within the manufacturer's recommended range—usually 3,200 ppm.

Frequently Asked Questions About Salt Chlorinator Anodes

How long do titanium anodes last?

In residential settings, a high-quality MMO titanium anode lasts 3 to 7 years. Industrial applications with 24/7 operation typically see 10,000 to 15,000 hours of runtime before the coating depletes.

How should I clean my salt cell?

Avoid heavy scraping. Use a weak solution of muriatic acid (1 part acid to 10 parts water). Only soak the plates until the fizzing stops. Over-cleaning or using strong acid concentrations will strip the MMO coating.

What titanium grade is best?

Grade 1 Titanium is mandatory. It offers the best ductility and corrosion resistance. Grade 2 is acceptable but less resistant to the hydrogen embrittlement that occurs during the electrolysis process.

Ready to Upgrade Your Chlorination System?

Stop overpaying for OEM replacements. Get industrial-grade titanium anodes engineered for longevity and performance.

Request a Technical Quote Today