Titanium Anode Price Per Kg: The 2026 Global Procurement & Market Report

Procuring industrial electrochemical components requires a nuanced understanding of raw material fluctuations. The titanium anode price per kg is not a static figure. It is a complex calculation involving the base titanium substrate and the catalytic coating. In 2026, we see a divergence in pricing. Standard industrial grades remain stable, but high-performance anodes for hydrogen evolution are seeing a premium due to Iridium scarcity.

At China Titanium Factory, we track these metrics daily. Our data shows that while the base metal cost is manageable, the "value per kg" increases exponentially with coating thickness and precious metal loading. This article breaks down the variables so procurement managers can move beyond simple line-item costs to strategic asset management.

Understanding the Fundamentals: What Defines Titanium Anode Value?

Before discussing dollars and cents, we must define the asset. A titanium anode is more than just a piece of metal. It is a precision-engineered catalyst carrier.

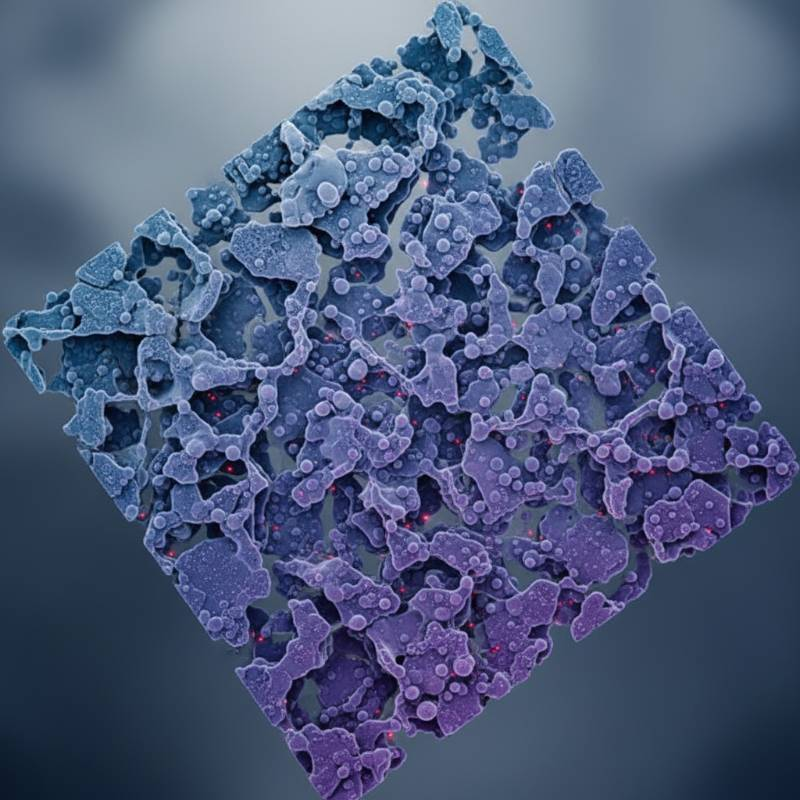

"A titanium anode consists of a high-purity titanium substrate, typically Grade 1 or 2, coated with a layer of mixed metal oxides (MMO) or precious metals like platinum. Its value is determined by its ability to facilitate electron transfer while resisting corrosion in aggressive electrolytes."

The substrate must meet ASTM B265 standards. If the substrate is compromised, the coating will fail. This is why "cheap" anodes often cost more in the long run. We define the Golden Rule of Electrochemical ROI as follows: The substrate is the skeleton; the coating is the lifeblood. Never sacrifice the marrow for a cheaper frame.

When you evaluate titanium anodes, you are paying for purity and electrical conductivity. Grade 1 titanium offers the best ductility and corrosion resistance for most electrolytic cells.

Current Market Pricing: MMO, Platinum, and Ruthenium-Iridium Coatings

The coating is where the price variance lives. While the titanium substrate might cost $25–$45 per kg depending on the form (mesh, plate, or rod), the coating can add hundreds or thousands of dollars to that base rate.

| Coating Type | Primary Application | Price Impact (Per Kg) |

|---|---|---|

| Ruthenium-Iridium (Ru-Ir) | Chlor-Alkali, Pool Salination | Moderate - High |

| Iridium-Tantalum (Ir-Ta) | Electrowinning, Oxygen Evolution | High (Ir Volatility) |

| Platinum Plated | Electroplating, Ionized Water | Very High |

Precious metal prices, tracked by the London Metal Exchange (LME), directly influence our daily quotes. For instance, a platinum plated titanium anode is priced primarily on the micron thickness of the platinum layer, not the weight of the titanium.

The TAEM Protocol: Our Proprietary Framework for Calculating Total Cost of Ownership

At China Titanium Factory, we developed the TAEM Protocol (Total Cost of Ownership - Anode Efficiency Matrix). This framework moves the conversation away from the "titanium anode price per kg" and toward "cost per operating hour."

The TAEM Protocol calculates value using three pillars:

Current Efficiency: How much power is wasted as heat versus used for the reaction?

Lifespan Multiplier: Does a 10% cheaper anode last 50% less time?

Recoating Potential: Can the substrate be stripped and reused?

According to our analysis, a higher upfront price for a ruthenium iridium anode often results in a 20% reduction in operational expenditure (OPEX) over three years compared to "budget" alternatives.

Technical Specifications Influencing Per-Kilogram Rates

Several technical factors can inflate the price per kg. Complexity adds labor and specialized processing time. If your application requires a high current density (above 2000 A/m²), the coating must be applied in multiple thermal decomposition cycles. Each cycle adds cost.

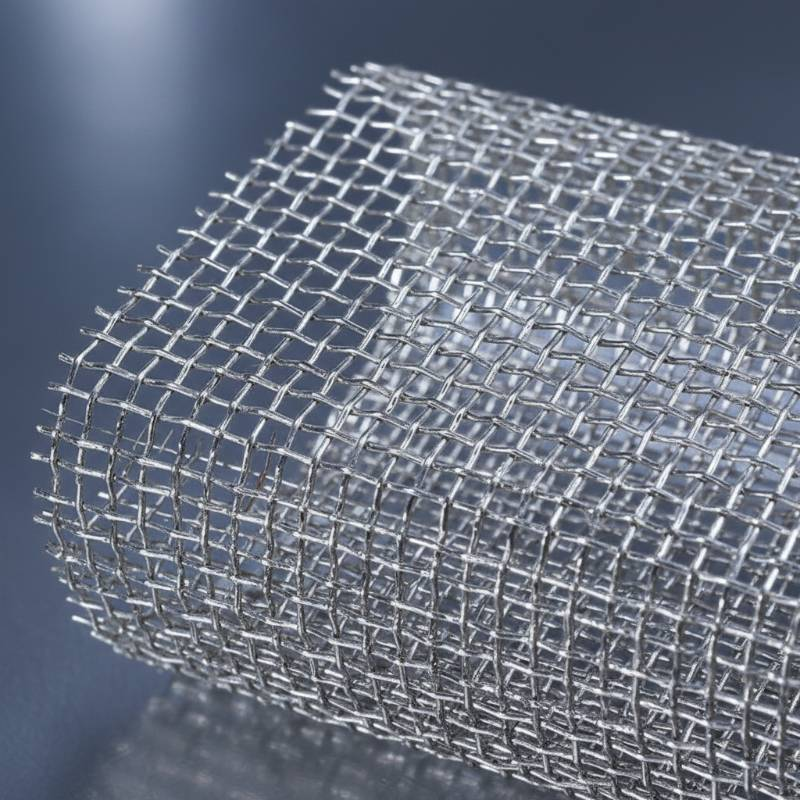

Geometric Surface Area vs. Weight

A solid plate is cheaper per kg than a complex expanded mesh. Why? Mesh fabrication involves higher scrap rates and more surface area to coat per unit of weight. When you buy an MMO titanium anode, the geometry determines how much catalyst is actually required to achieve the target current distribution.

We also consider coating adhesion. Poorly bonded coatings flake off, leading to "passivation" where the titanium forms an insulating oxide layer. This kills the cell. Our TAEM Protocol prioritizes bonding strength to ensure the price you pay translates to years of service.

Global Logistics, Tariffs, and Supply Chain Volatility

The "landed cost" of titanium anodes includes more than just the factory gate price. Import duties and shipping logistics play a massive role. In the US market, Section 301 tariffs or specific trade anti-dumping duties can impact the final titanium anode price per kg.

Procurement teams should consult U.S. Customs and Border Protection for current HTS code classifications. We mitigate these risks by optimizing our shipping volumes and providing transparent documentation to streamline the customs process. Supply chain risk management is now a core part of our consultative selling process.

Visual Wear-and-Tear Comparison: Price vs. Durability

A visual inspection can often reveal why one anode is priced lower than another. High-quality anodes show a uniform, dark, and matte finish (for MMO). Shiny spots or "rainbowing" often indicate uneven coating thickness, which leads to premature failure.

We utilize Accelerated Life Testing (ALT) to prove durability. By running the anode at extreme current densities in a lab setting, we can predict its lifespan in your specific environment. This data is the foundation of our TAEM Protocol, providing empirical proof that the price per kg correlates with performance longevity.

Frequently Asked Questions Regarding Titanium Anode Pricing

Does bulk purchasing significantly lower the titanium anode price per kg?

Yes. Bulk orders allow for more efficient precious metal procurement and longer production runs, which reduces the per-unit setup cost. Typically, orders over 50kg see a 10-15% reduction in labor-related costs.

How much does customization add to the fabrication cost?

Custom shapes, specialized welding, or non-standard mounting brackets can increase the price by 20-30%. Standardized plates or meshes are always the most cost-effective option.

Is recoating an old anode cheaper than buying a new one?

Usually, yes. Recoating can save 30-50% of the cost of a new anode because you are reusing the titanium substrate. However, the substrate must be inspected for structural integrity before we accept it for recoating.

Optimize Your Electrochemical OPEX Today

Don't just buy by the kilogram. Invest in performance. Our engineers are ready to apply the TAEM Protocol to your specific industrial application.