Understanding Titanium Anodes: An Essential Overview

In countless industrial settings, the integrity and efficiency of electrochemical processes hinge on one critical component: the anode. When conventional materials fall short, often failing due to corrosion or insufficient catalytic activity, titanium anodes step in. They offer a robust solution, marrying titanium's inertness with specialized coatings to facilitate a wide array of reactions.

This guide cuts right to the chase, laying out everything you need to know about titanium anodes. We'll cover their fundamental science, diverse applications, performance advantages, and practical considerations for engineers, chemists, and industry professionals. If you're looking for durable, high-performing electrodes, you're in the right place.

The Fundamentals of Titanium Anodes

At their core, titanium anodes are engineered workhorses. They leverage titanium's unique properties, enhanced by catalytic coatings, to drive electrochemical transformations with precision and longevity. Understanding their basics is key to unlocking their full potential.

What is a Titanium Anode?

Simply put, a titanium anode is an electrode fabricated from a titanium substrate, typically coated with a thin layer of electrocatalytically active material. This coating facilitates specific electrochemical reactions at its surface. Titanium itself is highly resistant to corrosion, making it an excellent base material.

An anode is an electrode through which the conventional electric current flows into a polarized electrical device. In an electrochemical cell, it's where oxidation reactions occur.

These anodes are central to processes requiring efficient electron transfer without significant degradation of the electrode itself. They're built to last, providing a stable platform for high-current operations.

Composition and Properties of Titanium Anodes

The magic of titanium anodes lies in their dual construction: an inert titanium substrate combined with a specialized, electrocatalytic coating. The substrate, typically commercially pure titanium (CP Titanium), provides mechanical strength and exceptional corrosion resistance.

The active coating is where the electrochemical heavy lifting happens. Common coatings include:

Mixed Metal Oxide (MMO) Coatings: These are blends of noble metal oxides (e.g., RuO₂, IrO₂) with valve metal oxides (e.g., TiO₂). MMO coatings are highly catalytic, offer excellent stability, and can be tailored for specific reactions like oxygen evolution or chlorine evolution.

Platinized Titanium: A thin layer of platinum is deposited onto the titanium. Platinum is a renowned catalyst, offering high conductivity and broad application versatility, though it comes at a higher cost.

These coatings provide high surface area, superior electrical conductivity, and incredible chemical stability, even in aggressive environments. This combination results in anodes that are both efficient and long-lasting.

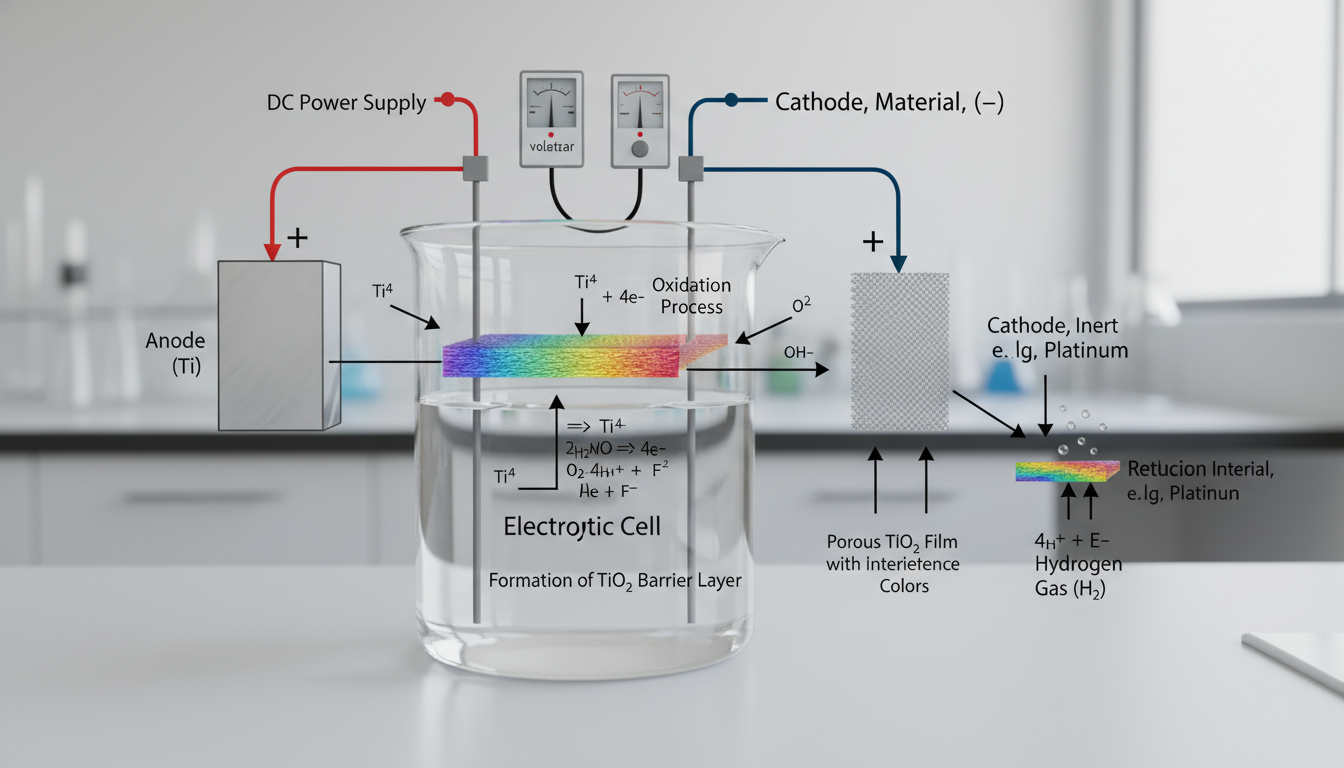

How Titanium Anodes Work: Electrochemical Principles

Titanium anodes operate on the fundamental principles of electrochemistry. When a direct current is applied across an electrolytic cell, the anode attracts anions (negatively charged ions) from the electrolyte. At the anode's surface, these anions undergo oxidation, releasing electrons and forming new chemical species.

The titanium substrate itself remains largely unreactive due to its passive oxide layer. The catalytic coating acts as the reaction site, lowering the overpotential required for the desired reaction. This means less energy is wasted, making the process more efficient. For instance, in water electrolysis, the coating facilitates the evolution of oxygen gas (2H₂O → O₂ + 4H⁺ + 4e⁻) without degrading the titanium base.

Types of Titanium Anodes and Their Characteristics

Not all titanium anodes are created equal. Their type is primarily defined by the catalytic coating, which dictates their suitability for specific applications.

Mixed Metal Oxide (MMO) Anodes: These are the workhorses. MMO anodes, often referred to as Dimensionally Stable Anodes (DSAs), boast exceptional lifespan and stability. Their coatings are tailored for specific reactions, such as oxygen evolution (IrO₂-based) or chlorine evolution (RuO₂-based). This customizability makes them incredibly versatile. You can find a wide range of custom titanium anodes designed for precise needs.

Platinized Titanium Anodes: Featuring a platinum layer, these anodes offer high conductivity and strong catalytic activity across various pH levels. They're often chosen for high-purity applications or where extreme resistance to aggressive media is required.

Lead Dioxide (PbO₂) Coated Titanium Anodes: Less common now due to environmental concerns, but historically used for strong oxidizing environments. They are gradually being replaced by more environmentally friendly MMO alternatives.

Choosing the right type depends on the electrolyte composition, current density, and the specific electrochemical reaction you need to drive. Each type brings its own set of performance characteristics to the table.

Titanium Anodes in Action: Key Industrial Applications

The versatility and robust nature of titanium anodes make them indispensable across a spectrum of industries. From adding a protective layer to metals to cleaning our water, their applications are both diverse and critical.

Electroplating and Metal Finishing

In electroplating, titanium anodes serve as insoluble anodes, providing the necessary current for depositing a thin layer of metal onto a substrate. Unlike soluble anodes that replenish the metal ions in the bath, titanium anodes maintain bath chemistry more consistently, leading to higher quality and uniform coatings. This is crucial for applications demanding precision, such as automotive parts, jewelry, and electronics. The consistent performance of titanium anodes in electroplating ensures superior surface finishes and functional properties.

Water and Wastewater Treatment

Titanium anodes are at the forefront of advanced water purification. They enable electrochlorination for disinfection, electrochemical oxidation of organic pollutants, and removal of heavy metals. By generating strong oxidants like hypochlorite or hydroxyl radicals directly in the water, they effectively break down contaminants, reduce pathogens, and improve water quality. This "green" technology minimizes the need for harsh chemicals, offering a more sustainable approach to water treatment. They're a game-changer for municipal water supplies, industrial effluent treatment, and even ballast water management on ships.

Cathodic Protection Systems

Corrosion is a constant threat to infrastructure, especially pipelines, marine structures, and storage tanks. Impressed Current Cathodic Protection (ICCP) systems use titanium anodes to safeguard these assets. The anode, buried or submerged near the structure, discharges current into the electrolyte (soil or water), forcing the protected structure to become the cathode. This prevents galvanic corrosion. Titanium anodes, particularly MMO-coated ones, are ideal for ICCP due to their low consumption rate and high current output, providing long-term, reliable protection. Learn more about corrosion prevention solutions.

The Chlor-Alkali Industry

The chlor-alkali process is a cornerstone of the chemical industry, producing chlorine, caustic soda (sodium hydroxide), and hydrogen from brine. Dimensionally Stable Anodes (DSAs), a type of MMO titanium anode, revolutionized this industry. They replaced graphite anodes, which degraded quickly and contaminated products. DSAs offer significantly longer lifespans, higher energy efficiency, and produce purer chemicals. This innovation slashed operational costs and improved environmental performance. It was a true paradigm shift for large-scale chemical manufacturing.

"Dimensionally stable anodes (DSAs) are highly engineered titanium electrodes coated with noble metal oxides, primarily used in the chlor-alkali industry for chlorine and caustic soda production due to their superior efficiency and durability compared to traditional graphite electrodes."

— ScienceDirect

Electrowinning and Electrorefining

In the recovery and refining of non-ferrous metals like copper, zinc, and nickel, titanium anodes are essential. Electrowinning uses these anodes to extract metals from leach solutions, while electrorefining purifies existing metals. The high current efficiency and resistance to the harsh acidic environments prevalent in these processes make titanium anodes ideal. They contribute to higher metal purity, lower energy consumption, and reduced environmental footprint compared to older methods. Many modern titanium manufacturing facilities rely on these anodes.

Weighing the Benefits and Challenges of Titanium Anodes

Like any advanced technology, titanium anodes come with a distinct set of advantages and a few considerations. Understanding both sides of the coin is vital for informed decision-making in material selection.

Key Advantages and Performance Benefits

Titanium anodes have earned their reputation for good reason. Their benefits are significant:

Exceptional Corrosion Resistance: Titanium's natural passivation layer makes it incredibly resistant to aggressive chemical environments, outperforming many other anode materials.

Long Lifespan: Thanks to the durable coatings and inert substrate, these anodes can operate for years, sometimes even decades, significantly reducing replacement frequency.

High Current Efficiency: Catalytic coatings ensure that more electrical energy is converted into the desired chemical reaction, minimizing side reactions and energy waste.

Dimensional Stability: Unlike consumable anodes, titanium anodes maintain their shape and size throughout their service life, ensuring consistent electrochemical performance and easier cell design.

Reduced Contamination: Being non-consumable, they don't introduce impurities into the electrolyte, which is crucial for high-purity applications.

Energy Savings: Lower overpotential leads to reduced power consumption, translating into substantial operational cost savings over time.

These advantages make titanium anodes a smart, long-term investment for many electrochemical processes.

Limitations and Operational Considerations

While powerful, titanium anodes aren't without their considerations:

Initial Cost: The upfront investment for titanium anodes can be higher than for conventional materials like graphite or lead. However, this is often offset by their longevity and efficiency.

Over-reduction: Titanium can be susceptible to hydrogen embrittlement or hydriding if exposed to excessively negative potentials, which can degrade the substrate.

Coating Degradation: While durable, coatings can eventually wear out or be damaged by harsh conditions, requiring re-coating or replacement.

Sensitivity to Fluoride Ions: Fluoride ions can attack the titanium substrate, so their presence in the electrolyte must be carefully managed.

Careful process design and monitoring are essential to mitigate these limitations and ensure optimal performance. A thorough cost-benefit analysis is always recommended.

Comparison with Other Anode Materials

To truly appreciate titanium anodes, it helps to see how they stack up against alternatives:

| Feature | Titanium Anodes (MMO/Pt) | Graphite Anodes | Lead Anodes | Stainless Steel Anodes |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (passive layer) | Moderate (oxidizes over time) | Good (forms protective layer) | Poor to Moderate (pitting corrosion) |

| Lifespan | Very Long (years to decades) | Short to Moderate (months to few years) | Moderate (few years) | Short (weeks to months) |

| Efficiency | High | Moderate | Moderate | Low |

| Cost (Initial) | High | Low | Moderate | Low |

| Product Purity | High (non-consumable) | Moderate (carbon particulate) | Low (lead contamination) | Low (iron contamination) |

This comparison clearly illustrates why, despite a higher initial cost, titanium anodes often offer the best return on investment due to their superior performance and longevity.

From Production to Performance: Manufacturing and Care for Titanium Anodes

The journey of a titanium anode, from raw material to a high-performing electrode, involves precise engineering. Proper care ensures it delivers on its promise of durability and efficiency.

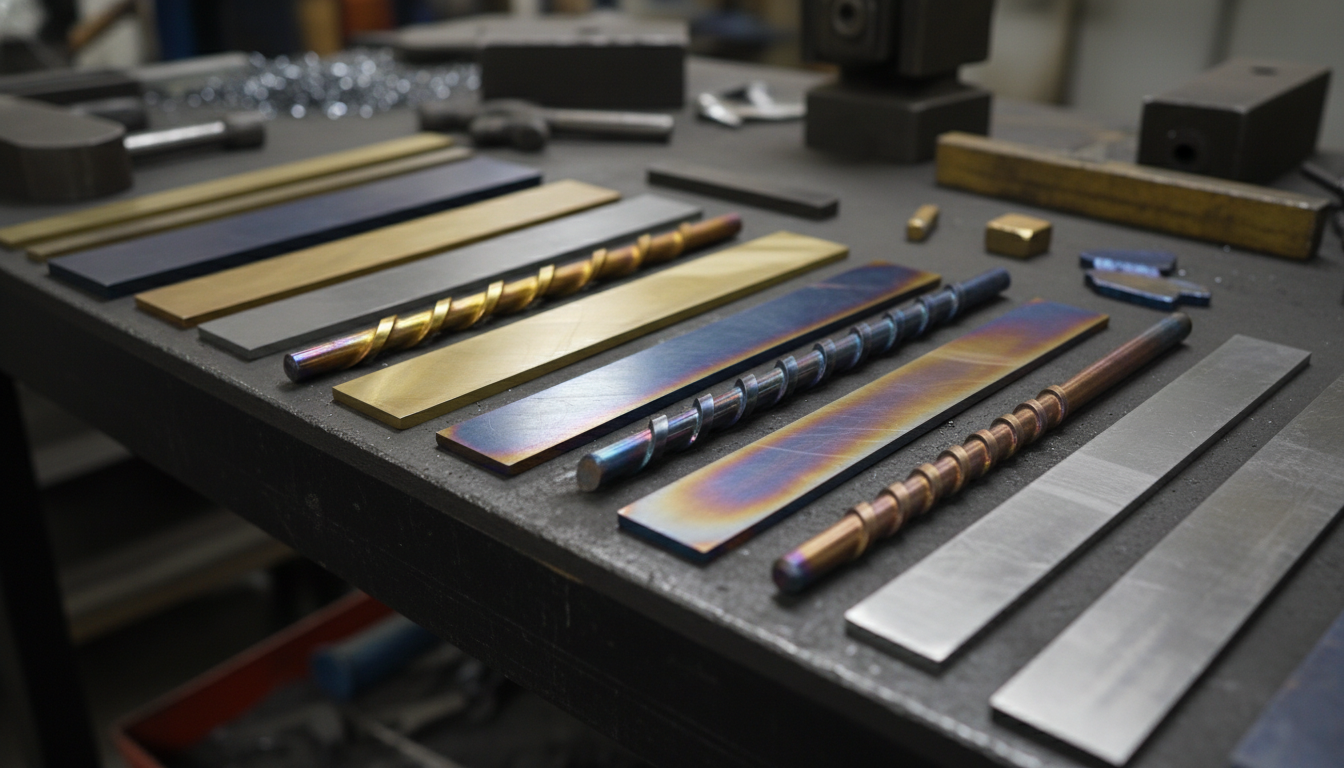

The Production Process of Titanium Anodes

Manufacturing titanium anodes is a multi-step, meticulous process:

Substrate Preparation: High-purity titanium sheets, mesh, rods, or tubes are selected. The surface is thoroughly cleaned and prepared through sandblasting, degreasing, and acid etching. This creates a rough, active surface for optimal coating adhesion.

Coating Application: The electrocatalytic solution (e.g., noble metal salts for MMO coatings) is applied. This can involve brushing, spraying, or dipping.

Thermal Decomposition: The coated substrate is then heated in a high-temperature furnace. This process thermally decomposes the metal salts, converting them into stable, crystalline oxide coatings that are chemically bonded to the titanium surface.

Repeat Cycles: Multiple coating layers and thermal decomposition steps are often repeated to achieve the desired coating thickness and uniformity, building up the active material.

Quality Control: Each anode undergoes rigorous testing for coating adhesion, thickness, electrochemical performance, and corrosion resistance to meet stringent industry standards. At China Titanium Factory, quality is non-negotiable.

This controlled production ensures a robust, high-performance product ready for demanding industrial use.

Lifespan, Durability, and Factors Affecting Performance

The lifespan of a titanium anode is not set in stone; it's a moving target influenced by several factors:

Current Density: Higher current densities accelerate coating wear. Running an anode too hard is like driving a car at redline constantly.

Electrolyte Composition: Aggressive chemicals, pH extremes, or the presence of certain impurities (e.g., fluorides, chlorides at high concentrations) can shorten lifespan.

Temperature: Elevated operating temperatures generally increase reaction rates and can accelerate coating degradation.

Presence of Fouling Agents: Biofilm or scale buildup can block active sites, requiring higher potentials and increasing wear.

Reverse Polarity: Accidental or intentional reverse polarity can rapidly destroy the catalytic coating.

Mechanical Damage: Physical impact can chip or delaminate the coating, exposing the titanium substrate.

Understanding these variables allows operators to optimize conditions, thereby extending the anode's service life and maximizing return on investment.

Handling, Storage, and Installation Recommendations

Proper care starts long before an anode goes into service:

Handling: Treat anodes with care. Avoid dropping or impacting them, which can chip the coating. Use gloves to prevent grease or dirt contamination of the active surface.

Storage: Store anodes in a dry, clean, and cool environment, away from corrosive fumes or direct sunlight. Keep them in their original packaging until ready for installation.

Installation: Follow manufacturer guidelines meticulously. Ensure proper electrical connections, avoiding hot spots. Verify that the anode is correctly positioned and fully immersed, preventing "hot spots" at the waterline. Ensure adequate electrolyte flow around the anode to prevent localized depletion and overheating.

A little attention to detail during these stages can prevent costly early failures.

Troubleshooting Common Issues and Maintenance Guides

Even with the best practices, issues can arise. Knowing how to troubleshoot keeps operations running smoothly:

Low Current Output/High Voltage: This often points to fouling (scale, biofilm) on the anode surface or depletion of electrolyte. Clean the anode carefully using mild acid or mechanical brushing (avoiding harsh abrasion). Check electrolyte concentration.

Localized Coating Wear: Indicates uneven current distribution, excessive current density in one area, or presence of aggressive local impurities. Adjust anode placement or current.

Bubbling/Gas Evolution Issues: If gas evolution is insufficient or occurs unevenly, check for short circuits, power supply issues, or anode fouling.

Anode Passivation: In some electrolytes, a non-conductive layer might form. This usually requires specific chemical cleaning or adjusting electrolyte composition.

Regular visual inspections and performance monitoring are your best friends. Keep an eye out for changes in color, pitting, or unusual deposits. Proactive maintenance, including periodic cleaning, extends life. For complex issues, consulting an expert in titanium anode solutions is always a smart move.

Beyond the Basics: Advanced Insights and Future Outlook for Titanium Anodes

The story of titanium anodes is still being written. Innovations continue to push the boundaries of what's possible, driven by sustainability goals and the demand for even greater efficiency.

Sustainability and Environmental Impact

Titanium anodes are inherently a "greener" choice compared to many traditional electrode materials. Their energy efficiency translates to lower carbon footprints. Their long lifespan reduces waste generation from frequent replacements. Furthermore, their ability to facilitate advanced oxidation processes in water treatment minimizes the need for hazardous chemical disinfectants, protecting ecosystems.

The industry is also exploring ways to improve the recyclability of titanium anode components, further enhancing their environmental profile. This commitment to sustainability makes them a fitting choice for modern, eco-conscious industrial practices.

Emerging Technologies and Research Directions

Research and development in titanium anode technology are vibrant. Scientists are constantly exploring:

Novel Coating Materials: Developing new mixed metal oxide formulations with even higher catalytic activity, selectivity, and durability for specific reactions.

Nanostructured Coatings: Utilizing nanotechnology to create coatings with increased surface area and enhanced electrochemical performance.

Advanced Manufacturing Techniques: Exploring additive manufacturing (3D printing) to create complex anode geometries optimized for specific flow patterns and reaction efficiencies.

Sensor Integration: Incorporating smart sensors into anodes for real-time monitoring of performance and predictive maintenance.

These innovations promise to unlock new applications and push efficiency levels even higher.

"The development of advanced electrode materials, particularly those based on noble metal oxides, continues to be a frontier in electrochemistry, with a focus on enhancing catalytic activity, stability, and cost-effectiveness for energy and environmental applications."

— Advanced Materials

Market Overview and Key Supplier Landscape

The global market for titanium anodes is robust and growing, driven by increasing demand in water treatment, chemical manufacturing, and corrosion protection. Key players are constantly innovating, offering specialized anode solutions tailored to specific industrial needs. Suppliers like China Titanium Factory are at the forefront, providing high-quality, reliable titanium anode products and manufacturing services to a global clientele.

The competitive landscape emphasizes not just product quality, but also technical expertise, customization capabilities, and post-sales support. As industries continue to seek more efficient and sustainable electrochemical solutions, the demand for advanced titanium anodes will only intensify.

Frequently Asked Questions About Titanium Anodes

Have more questions? Here are answers to some common inquiries about titanium anodes.

What is the primary function of a titanium anode?

A titanium anode's primary function is to serve as an electron acceptor in an electrochemical cell, facilitating oxidation reactions at its surface. Its titanium substrate provides structural integrity and corrosion resistance, while the catalytic coating drives specific chemical transformations efficiently and without significant electrode degradation.

How long do titanium anodes typically last?

The lifespan of titanium anodes varies significantly, often ranging from 3 to 15 years, and in some cases, even longer. Factors like current density, electrolyte composition, temperature, and the specific type of catalytic coating all play a critical role. Proper maintenance and operational conditions are key to maximizing their longevity.

Are titanium anodes cost-effective in the long run?

Absolutely. While the initial investment for titanium anodes might be higher than for conventional materials, their long-term cost-effectiveness is superior. Their extended lifespan reduces replacement costs, and their high energy efficiency leads to significant operational savings. Lower maintenance and reduced downtime further enhance their return on investment.

Can titanium anodes be customized for specific applications?

Yes, titanium anodes are highly customizable. Manufacturers can tailor their shape, size, substrate geometry (e.g., mesh, plate, rod), and most importantly, the specific catalytic coating formulation. This allows for optimization to meet the precise electrochemical requirements, current density, and environmental conditions of diverse industrial processes.

What safety precautions should be taken when handling titanium anodes?

When handling titanium anodes, always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and chemical-resistant clothing. Avoid mechanical shock to prevent coating damage. Ensure proper electrical isolation during installation and maintenance. Store them in a dry, clean area away from corrosive chemicals. Always follow the manufacturer's specific safety data sheets and installation guidelines.