Efficient and reliable disinfection is non-negotiable across municipal, industrial, and commercial sectors. Sodium hypochlorite generators provide a potent, on-site solution, eliminating the hazards and logistics of bulk chemical transport. The heart of these systems? The titanium anode for sodium hypochlorite generator. Its performance dictates the entire system's efficiency, longevity, and ultimately, your operational costs. At China Titanium Factory, we engineer these critical components for unrivaled performance, ensuring consistent and cost-effective disinfection.

The Core Technology: How Titanium Anodes Drive On-Site NaOCl Production

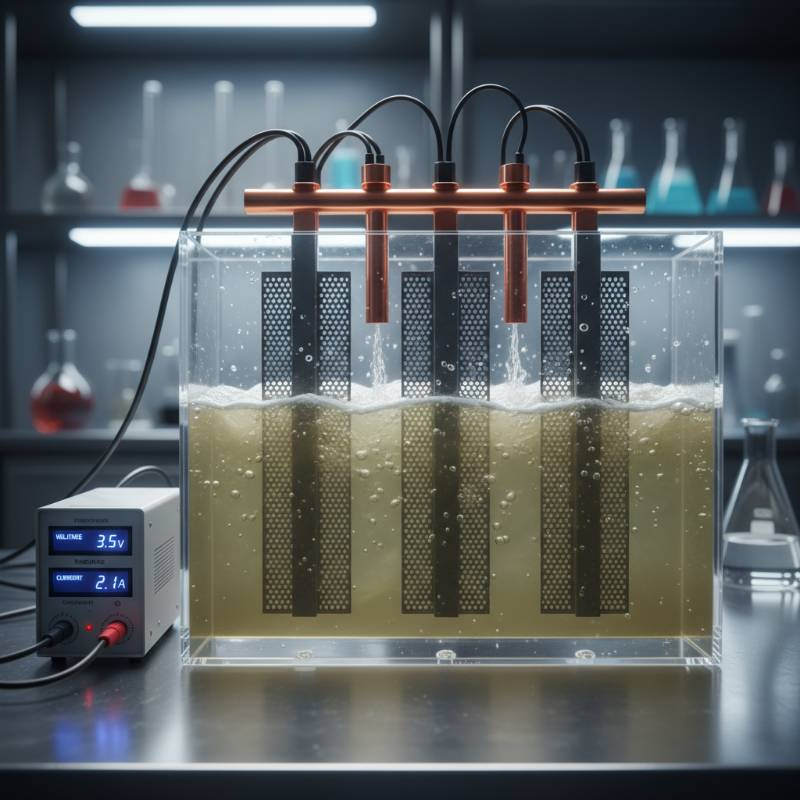

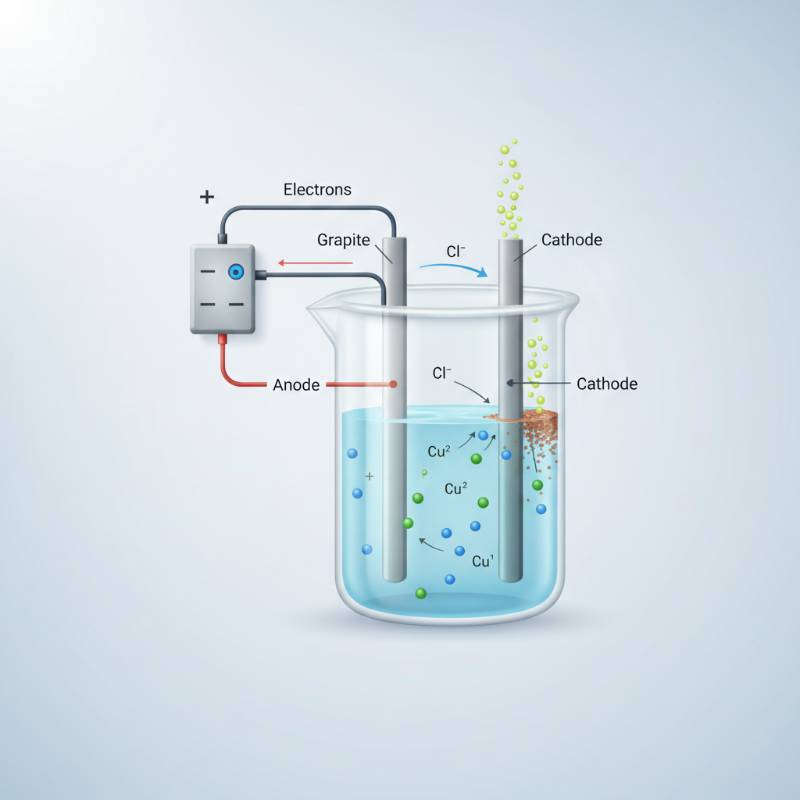

On-site sodium hypochlorite (NaOCl) generation is an electrochemical marvel. It transforms a simple brine solution into a powerful disinfectant. This process relies on an electrolytic cell, where direct current flows between an anode and a cathode immersed in saltwater.

Here’s the breakdown:

Anode Reaction: Chloride ions (Cl⁻) from the brine are oxidized at the anode surface, producing elemental chlorine gas (Cl₂).

Cathode Reaction: Water (H₂O) is reduced, forming hydrogen gas (H₂) and hydroxyl ions (OH⁻).

Solution Reaction: The chlorine gas then reacts with the hydroxyl ions in the solution to form hypochlorous acid (HOCl) and hypochlorite ions (OCl⁻), the active disinfecting agents.

The titanium anode isn't just a conductor; it's the catalytic engine. It facilitates the critical oxidation reaction with minimal overpotential, ensuring high efficiency and low energy consumption. Without a robust, precisely engineered anode, the entire system falters. According to our analysis, anode quality is the single most important factor determining the reliability and cost-effectiveness of on-site NaOCl generation.

Electrolysis: The process by which an electric current is passed through a substance to effect a chemical change, specifically the decomposition of a chemical compound.

Why Our Titanium Anodes Stand Apart: Superior Materials and Coatings

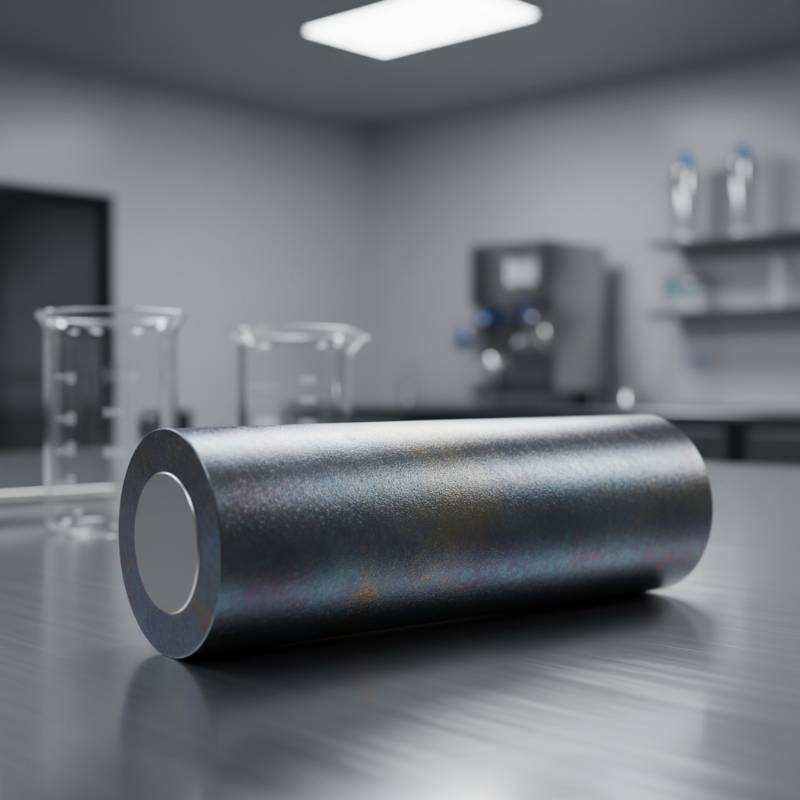

Not all titanium anodes are created equal. Their distinction lies in the substrate and, more critically, the Mixed Metal Oxide (MMO) coating. We define optimal anode performance as the perfect synergy of robust substrate, superior catalytic coating, and precise manufacturing.

The Titanium Advantage

Titanium, specifically Gr1 or Gr2, serves as the ideal substrate. It offers:

Exceptional Corrosion Resistance: Titanium naturally forms a passive oxide layer, protecting it from the aggressive, corrosive environment within the electrolytic cell.

High Strength-to-Weight Ratio: Durable yet manageable for various cell designs.

Excellent Electrical Conductivity: Ensures efficient current distribution across the anode surface.

MMO Coatings: The Catalytic Edge

The true magic happens with the Mixed Metal Oxide (MMO) coating. These proprietary formulations, typically containing Ruthenium (Ru), Iridium (Ir), Tantalum (Ta), and Titanium (Ti), are applied to the titanium substrate. They act as electrocatalysts, significantly lowering the overpotential required for chlorine evolution. This translates directly to:

Enhanced Efficiency: More NaOCl produced per unit of energy.

Extended Lifespan: The coating itself is highly stable and resistant to wear, greatly prolonging the anode's operational life.

Reduced Operating Costs: Lower energy consumption and fewer anode replacements mean significant savings.

We specialize in formulations like Ruthenium-Iridium and Iridium-Tantalum, each tailored for specific operational parameters. Ruthenium-Iridium is often preferred for seawater or higher chloride concentrations, while Iridium-Tantalum can offer superior performance in less saline or more demanding environments. Our MMO anode coatings are meticulously engineered for maximum catalytic activity and adhesion.

The "Electro-Longevity™ Protocol": Our Framework for Maximizing Anode Lifespan & ROI

Maximizing the lifespan and return on investment (ROI) for your sodium hypochlorite generation system isn't just about buying a good anode. It's about a holistic approach. At China Titanium Factory, we've coined the Electro-Longevity™ Protocol – our unique, multi-stage framework for optimizing anode performance from selection to retirement.

This protocol ensures you get the most bang for your buck, every single time. It's a game plan, not just a product.

The Three Pillars of Electro-Longevity™

Precision Design & Coating Selection: It starts with understanding your exact operational parameters. We don't just sell anodes; we engineer solutions. This involves detailed analysis of electrolyte composition, current density, temperature, and desired output. Our experts guide you through selecting the optimal MMO coating formulation and thickness for your specific environment.

Optimized Operational Guidance: Proper operation is key. We provide recommendations for maintaining ideal current density, preventing excessive scaling, and managing pH levels within the electrolytic cell. These factors directly impact coating wear and overall anode health.

Proactive Maintenance & Monitoring: Regular inspection, timely cleaning, and performance monitoring are crucial. Our protocol emphasizes predictive maintenance strategies to identify potential issues before they become costly failures, helping you avoid unexpected downtime.

The Golden Rule of Anode Performance: The quality of disinfection is directly proportional to the integrity and specificity of your anode technology. Adhering to the Electro-Longevity™ Protocol guarantees this integrity, translating into predictable performance and superior ROI. We even offer interactive tools to help estimate your potential cost savings.

Precision Selection: Matching the Right Anode to Your Application Needs

Choosing the correct titanium anode isn't a shot in the dark. It requires a clear understanding of your system's demands. Mismatched anodes lead to premature failure, inefficient generation, and wasted capital. We help you cut through the noise.

Consider these critical factors:

Current Density: Higher current densities accelerate coating wear. Your anode must be designed to withstand the operational current without compromising lifespan.

Electrolyte Concentration & Purity: The salinity of your brine solution matters. Anodes for seawater applications differ from those for softened water with added salt. Impurities can also foul the anode surface.

pH Levels: Extreme pH environments can impact coating stability. Our anodes are designed to perform optimally within the typical operating pH range of hypochlorite generators.

Temperature: Elevated temperatures can increase the rate of electrochemical reactions and coating degradation.

Desired Hypochlorite Output: Your required disinfection capacity directly influences anode size, shape, and coating specifications.

Our team at China Titanium Factory provides expert consultation to help you navigate these variables. We assist in selecting the optimal anode type, whether it’s a plate, mesh, rod, or tubular configuration, ensuring peak efficiency for your municipal, industrial, or commercial setup. A detailed comparison ensures you make an informed decision.

Real-World Impact: Diverse Applications of Our Anodes

Our titanium anodes are the silent workhorses behind countless successful disinfection operations worldwide. From large-scale municipal infrastructure to niche industrial processes, their reliability ensures consistent water quality and operational safety.

Key application areas include:

Municipal Water Treatment: Essential for potable water disinfection, ensuring safe drinking water for communities.

Wastewater Treatment: Effectively sterilizes effluent before discharge, protecting ecosystems.

Cooling Tower Biocide: Prevents biofouling, enhancing heat exchange efficiency and system longevity in industrial cooling systems.

Aquaculture Disinfection: Maintains pristine water quality in fish farms and hatcheries, preventing disease outbreaks.

Food & Beverage Sanitation: Crucial for facility and equipment sanitation, meeting stringent hygiene standards.

Swimming Pools & Spas: Provides a safer, more consistent alternative to stored chlorine products.

We've seen our anodes significantly reduce operating costs and improve safety profiles in these diverse environments. For instance, a major municipal water facility using our anodes reported a 15% reduction in energy consumption for NaOCl generation over two years. That's real impact. You can learn more about our water treatment solutions.

Our Commitment to Quality, Customization, and Global Supply

Quality isn't just a buzzword for us; it's foundational. Every titanium anode leaving our facility undergoes rigorous testing, adhering to the strictest international standards. Our manufacturing processes are ISO certified, ensuring consistency and reliability across every batch. We're not just a supplier; we're a partner.

Bespoke Anode Solutions

Many applications require more than off-the-shelf components. Our engineering team excels at custom anode manufacturing, working closely with clients to design bespoke solutions. Whether it's a unique geometry, a specific coating blend, or an unusual operational environment, we deliver anodes tailored to your exact specifications. This commitment to custom anode design sets us apart.

A Reliable Global Supply Chain

We understand the importance of timely delivery. Our robust global supply chain ensures that your titanium anodes reach you efficiently, wherever you are. We manage logistics, customs, and delivery, providing a seamless experience from order to installation. Our extensive network guarantees supply chain reliability.

Sustainable Disinfection: The Environmental Advantages of On-Site NaOCl

The shift to on-site sodium hypochlorite generation isn't just about efficiency and cost; it's a significant stride towards sustainable water treatment. Utilizing durable titanium anodes, these systems offer compelling environmental and safety benefits.

Reduced Hazardous Chemical Transport: On-site generation eliminates the need to transport and store bulk quantities of hazardous chemicals like chlorine gas or concentrated hypochlorite. This minimizes road risks, potential spills, and associated carbon emissions from logistics.

Lower Carbon Footprint: By reducing reliance on external chemical production and transport, the overall carbon footprint of your disinfection process shrinks considerably.

Enhanced Operational Safety: Generating NaOCl on-demand and at a lower concentration significantly reduces the risks to personnel and the surrounding environment, aligning with stricter safety regulations.

Eco-Friendly Disposal: Spent brine is less problematic than the disposal of residual bulk chemicals.

By investing in high-quality titanium anodes for your NaOCl generator, you're not just ensuring effective disinfection; you're actively contributing to a greener, safer operational footprint. This is the future of responsible water treatment. The EPA consistently advocates for safer water treatment practices, and on-site generation perfectly aligns with this goal.

Frequently Asked Questions About Titanium Anodes

We get a lot of questions. Here are some of the most common inquiries about titanium anodes for sodium hypochlorite generators, answered directly.

What is the expected lifespan of a typical MMO titanium anode?

The lifespan of an MMO titanium anode varies significantly based on operational current density, electrolyte purity, temperature, and maintenance. Under optimal conditions, our anodes typically last between 3 to 7 years. Higher current densities, presence of contaminants (like iron or manganese), and frequent power fluctuations can reduce this. Adhering to our Electro-Longevity™ Protocol can push these boundaries.

A study by the Journal of Applied Electrochemistry highlights how specific operating conditions directly influence anode degradation rates.

How do I determine the correct anode coating for my specific application?

This is crucial. Ruthenium-Iridium coatings are generally excellent for applications involving higher chloride concentrations, like seawater electrolysis. Iridium-Tantalum coatings often excel in environments with lower chloride levels or where greater resistance to oxygen evolution is needed. The best way is to consult with our technical team. Provide us with your brine source, desired NaOCl concentration, current density, and system design, and we'll recommend the optimal coating.

Can your company provide custom-designed titanium anodes?

Absolutely. Customization is a cornerstone of our service. We understand that every system has unique requirements. Our engineering team works collaboratively with clients, from initial concept to final production, to design and manufacture bespoke titanium anodes. We tailor dimensions, shapes, coating compositions, and connection points to integrate seamlessly with your existing or new generator setup. Just reach out to our sales team with your specifications.

What are the key maintenance considerations for titanium anodes?

Regular maintenance extends anode life and maintains efficiency. Key considerations include:

Cleaning: Periodically remove scale and deposits (e.g., calcium carbonate) from the anode surface using a mild acid solution or mechanical brushing.

Inspection: Regularly check for signs of coating wear, damage, or corrosion.

Operational Parameters: Ensure your generator operates within recommended current density and pH ranges. Avoid prolonged exposure to very low chloride concentrations, which can accelerate oxygen evolution and coating degradation.

Proper maintenance is a non-negotiable part of our Electro-Longevity™ Protocol.

What are the benefits of on-site sodium hypochlorite generation compared to bulk chemicals?

The advantages are substantial:

Safety: Eliminates handling and storage of hazardous bulk chlorine or concentrated bleach.

Cost Savings: Reduces purchase, transport, and storage costs for chemicals.

Freshness & Efficacy: Generates fresh, potent hypochlorite on demand, avoiding degradation issues of stored chemicals.

Reduced Logistics: Simplifies supply chain management; only salt and water are needed.

Environmental Impact: Lower carbon footprint and reduced risk of chemical spills.

It's a smarter, safer, and more economical approach to disinfection.

Partner with Us for Advanced Anode Solutions

Ready to optimize your sodium hypochlorite generation with superior titanium anodes?

Our expertise ensures you receive the highest quality, most efficient, and longest-lasting anode solutions tailored to your specific needs. Experience the difference of the Electro-Longevity™ Protocol.

Request a Custom Quote TodayOur team is standing by to provide expert consultation and transparent pricing.