Dealing with polluted water streams is a persistent headache for industries and municipalities worldwide. Traditional methods often fall short, struggling with complex contaminants or leaving a hefty environmental footprint. Enter wastewater electrolysis, a robust electrochemical treatment offering a powerful alternative.

At its heart lies the titanium anode. This isn't just another component; it's the workhorse that drives efficient pollutant degradation. For environmental engineers, chemical specialists, and plant operators, understanding this technology isn't just an option—it's a game-changer for achieving superior effluent quality and operational efficiency.

This article dives deep into why titanium anodes are integral to cutting-edge electrochemical treatment. We’ll explore how they tackle everything from industrial wastewater solutions to municipal wastewater treatment, setting a new benchmark in sustainable water management.

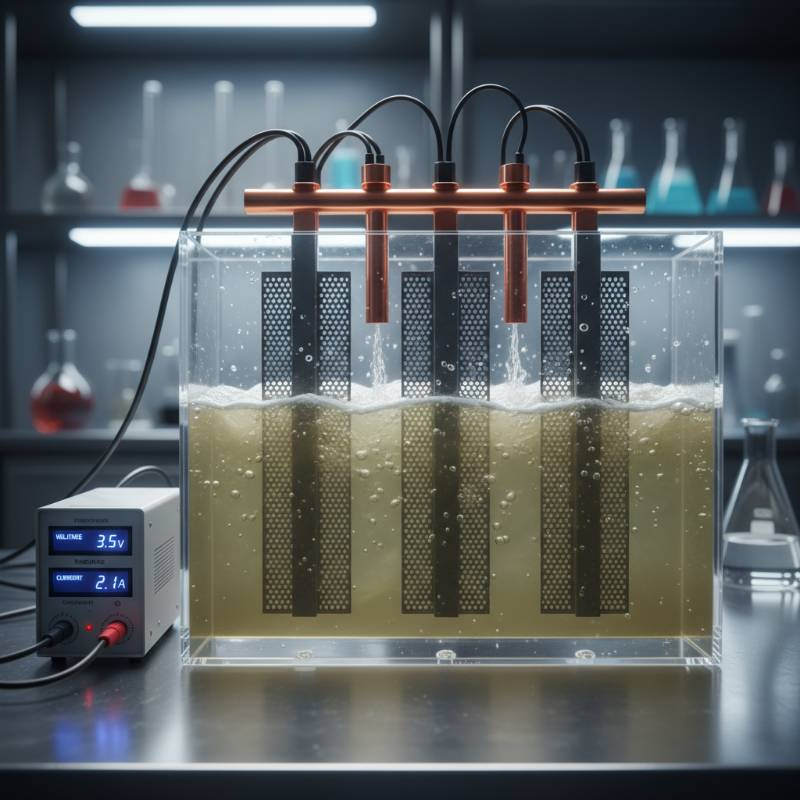

Electrochemical wastewater treatment isn't magic; it's smart chemistry. It leverages electrical energy to drive chemical reactions, directly oxidizing pollutants at the electrode surface or indirectly through generated powerful oxidants.

These electrochemical oxidation mechanisms are incredibly effective. Think direct electron transfer, where organic compounds lose electrons directly to the anode, breaking down. Or consider indirect oxidation, where the anode generates potent species like hydroxyl radicals (•OH), ozone (O3), or hypochlorite (ClO-), which then aggressively attack contaminants in the bulk solution. This is where advanced oxidation processes truly shine.

We define Electrochemical Oxidation as a process where electrical current induces redox reactions to degrade organic and inorganic pollutants in water, often utilizing highly reactive species generated at the anode surface.

Various electrochemical reactors exist, each with specific configurations. Plate-and-frame, packed-bed, or fluidized-bed reactors are common. Each design optimizes mass transport and contact between pollutants and the active electrode surface. Their operational nuances—flow rate, electrode spacing, cell voltage—are all fine-tuned for specific wastewater characteristics.

Compared to conventional methods like biological treatment or coagulation-flocculation, electrolysis offers distinct advantages of electrolysis. No sludge issues. No secondary pollution. It handles recalcitrant compounds that biological systems balk at. For industries facing tough discharge limits, it's often the strategic play.

The anode is the heart of an electrolytic cell. For wastewater, where conditions can be brutal—corrosive chemicals, high temperatures, fluctuating pH—you need something tough. This is precisely why titanium anode technology stands head and shoulders above the rest.

Titanium itself boasts incredible corrosion resistance and mechanical strength. But it’s the coating that makes it an electrochemical superstar. Uncoated titanium would quickly passivate. The coatings provide the catalytic activity necessary for efficient, long-term operation.

Two primary types dominate the market:

Mixed Metal Oxide (MMO) Coatings: These are blends of noble metal oxides like RuO2, IrO2, and TiO2. MMO coatings are engineered for specific reactions, offering low overpotential for oxygen evolution, high catalytic activity, and excellent durability. They are exceptionally stable in acidic and alkaline environments, making them versatile for diverse wastewater streams.

Platinum-Iridium (Pt-Ir) Anodes: Often used when extreme corrosion resistance and specific oxidation potentials are required. Pt-Ir anodes provide a very stable, highly catalytic surface, especially effective for generating strong oxidants or handling halogen-rich wastewaters.

The anode manufacturing processes are intricate. They involve precise surface preparation, application of multiple coating layers via thermal decomposition or electrodeposition, and careful annealing. These steps dictate the anode's microstructure, adhesion, and ultimately, its performance and anode lifespan.

According to our analysis, choosing the right coating for your specific wastewater matrix is paramount. A general-purpose anode might work, but an optimized one will deliver far greater efficiency and longevity. This is where expertise, like that found at China Titanium Factory, becomes invaluable.

When you weigh titanium anodes against other electrode material comparison options—like graphite, lead dioxide, or even bare platinum—the advantages become stark. Graphite degrades, lead dioxide poses toxicity risks, and bare platinum is prohibitively expensive for most large-scale applications. Titanium, with its specialized coatings, offers the sweet spot: high efficacy, long durability, and a compelling cost-benefit ratio.

The versatility of electrolytic wastewater treatment is genuinely impressive. It's not a niche solution; it's a broad-spectrum answer for complex challenges across industries.

Textile Industry: Dyes are notoriously hard to remove. Electrolysis, particularly with MMO anodes, effectively breaks down complex organic dyes, decolorizing effluent and reducing COD/BOD.

Chemical Manufacturing: From pharmaceuticals to specialty chemicals, process wastewaters often contain toxic or non-biodegradable organics. Electrolysis provides robust organic compound degradation, meeting stringent discharge limits.

Mining and Metallurgy: Heavy metal removal is critical. Electrochemical methods can plate out metals like copper, nickel, and chromium, recovering valuable resources while purifying water. This is a double win.

Food and Beverage: High organic loads and specific contaminants are no match for tailored electrolytic systems.

Beyond industry, electrolysis finds its place in polishing municipal effluents, particularly for removing emerging contaminants, disinfection byproducts, or recalcitrant micropollutants that traditional biological plants struggle with. It’s an effective tool for augmenting existing infrastructure.

A textile factory in Southeast Asia faced fines for high color discharge. Implementing an electrochemical system with MMO titanium anodes reduced color by over 95% and COD by 70%, resulting in significant operational cost savings and compliance. This isn't just theory; it's tangible proof.

Another example involved a metal finishing plant recovering nickel from rinse waters, turning a waste stream into a revenue source. The economic viability of such systems, coupled with their profound environmental impact, makes a compelling argument for their adoption. This is about true sustainability, not just lip service.

For more detailed insights into specific industry applications and success stories, explore the dedicated case studies available on China Titanium Factory's website.

Achieving peak performance in wastewater electrolysis isn't a shot in the dark. It demands a structured approach. That's why we at China Titanium Factory developed the Aqua-Pure Anode Protocol – our unique, proprietary methodology for optimal electrochemical system management.

This isn't just a guideline; it's a step-by-step anode optimization framework designed to ensure maximum efficiency, extended anode lifespan, and consistent performance across diverse wastewater treatment scenarios. We've poured years of research and field experience into this protocol.

The first principle of the Aqua-Pure Anode Protocol states: "An anode's true value isn't in its material, but its precise suitability for the specific electrochemical environment and target pollutant." Generic solutions yield generic results. Custom-engineered anodes, designed for your unique wastewater matrix, deliver unparalleled performance enhancement and operational efficiency.

The protocol covers everything from initial wastewater analysis and electrode material selection to system integration and predictive maintenance. This holistic approach sets a new benchmark for electrochemical system design and guarantees superior anode longevity.

Want to implement this framework for your facility? Explore our Aqua-Pure Anode Protocol Consultation services and let our experts guide you.

Getting the most out of your wastewater electrolysis system goes beyond just buying good anodes. It’s about smart design, meticulous optimization, and proactive maintenance.

Effective electrode design is paramount. Parameters like electrode geometry (plates, mesh, rods), spacing between anodes and cathodes, and flow dynamics within the reactor directly impact current distribution and mass transfer. Proper configuration ensures pollutants efficiently reach the active surface, boosting pollutant degradation rates. It's not rocket science, but it takes careful engineering.

Fine-tuning process parameters optimization is key. This includes:

Current Density: Too low, and reactions are slow. Too high, and you waste energy on side reactions like oxygen evolution. Finding the sweet spot for current density is crucial.

Voltage: Directly correlates with energy consumption. Lowering voltage while maintaining efficiency is the goal.

pH: The wastewater's pH can significantly influence reaction pathways and electrode stability. Some reactions favor acidic conditions, others alkaline.

Temperature: Generally, higher temperatures increase reaction rates, but also energy costs.

Optimizing these factors leads to significant energy consumption improvements, translating directly to lower operating expenses.

Anodes aren't set-and-forget components. Anode maintenance strategies are vital for longevity. Scaling and fouling are the enemies here. Mineral deposits (scaling) or organic buildup (fouling) can reduce active surface area, increase cell voltage, and decrease efficiency. Regular cleaning protocols, often involving acid washes or mechanical brushing, are essential for scaling prevention and fouling control.

Furthermore, proper safety considerations must always be at the forefront, especially when dealing with electrical systems and potentially corrosive chemicals. Regular inspections ensure long-term reliability.

For expert guidance on system design or robust maintenance plans, refer to China Titanium Factory's services.

No single wastewater treatment method is a silver bullet. Understanding where electrolysis fits within the broader landscape is crucial for informed decision-making.

Let's look at a quick wastewater treatment technologies comparison:

Biological Treatment (Activated Sludge, MBR): Excellent for biodegradable organics. Cost-effective for large volumes. Limitations: Sensitive to toxic shock, ineffective for non-biodegradables, produces sludge.

Chemical Coagulation/Flocculation: Good for suspended solids, some colloids, and heavy metals. Limitations: High chemical consumption, generates chemical sludge, less effective for dissolved organics.

Filtration (Sand, Membrane): Removes suspended solids and some pathogens. Limitations: Fouling, requires frequent backwashing/cleaning, no removal of dissolved pollutants.

Electrolysis is often categorized under AOPs, but it's important to differentiate. Other AOPs include UV/H2O2, Fenton's reagent, or ozonation. While highly effective for recalcitrant organics, these methods can have higher operating costs, require careful chemical handling, or generate secondary wastes. Electrolysis, particularly with specific anode coatings, can generate similar powerful oxidants in situ without external chemical dosing, offering a cleaner, more controlled process.

The electrolysis advantages become clear: it’s robust, generates fewer byproducts, and can handle a wide range of pollutants, often achieving very low discharge limits. It excels where other methods fail—think highly saline industrial effluents or streams with complex organic matrices.

The Golden Rule of treatment method selection is to match the technology to the pollutant profile and desired effluent quality. For many challenging applications, electrolysis offers unparalleled performance and cost-effectiveness over the long haul, especially when considering the reduced need for chemical consumables and sludge disposal. For a deeper dive into comparative studies, check out this research on electrochemical methods. Source: ScienceDirect

Making an investment in advanced wastewater treatment requires solid data and robust planning. We believe in empowering our clients with the tools and information they need to make the best decisions.

We're developing an online ROI calculator to help you quantify your potential savings and investment returns. This tool will allow you to input your current treatment costs, wastewater characteristics, and project specific parameters to generate a clear cost-saving analysis for an electrolytic system. You can also leverage our anode configuration tool to explore optimal designs for your specific application, ensuring tailored system design.

Access a wealth of wastewater treatment resources, including downloadable whitepapers, on-demand webinars, and comprehensive expert guides. These materials delve deeper into specific applications, emerging trends in electrochemical treatment, and best practices for anode management.

According to research by the EPA, advanced treatment technologies are crucial for meeting future water quality standards. Source: EPA

Stay informed and make data-driven decisions. Visit the resources section on our website for continuous updates and valuable insights.

Titanium anodes offer superior corrosion resistance, high catalytic activity due to specialized coatings (like MMO or Pt-Ir), and exceptional durability. This translates to longer anode lifespan, consistent performance, lower energy consumption, and reduced operational costs compared to other electrode materials. They are robust in aggressive chemical environments.

The anode lifespan varies significantly based on operating conditions (current density, pH, temperature, presence of specific pollutants), the type and quality of the coating, and proper maintenance. High-quality MMO titanium anodes from China Titanium Factory can last anywhere from 3 to over 10 years in typical wastewater treatment applications, often exceeding the performance of alternative electrodes.

While the initial capital investment for an electrolysis system might be higher than some conventional methods, the long-term electrolysis system costs are often lower. This is due to reduced chemical consumption, minimal sludge generation (cutting disposal costs), lower labor requirements, and the ability to treat recalcitrant pollutants effectively, avoiding environmental fines. The titanium anode benefits quickly add up.

Maintenance tips typically focus on preventing scaling and fouling. Regular visual inspections are crucial. Depending on the wastewater composition, periodic acid washing or mechanical cleaning may be necessary to remove accumulated deposits and maintain optimal performance. Following manufacturer guidelines and our Aqua-Pure Anode Protocol ensures optimal operational questions and longevity.

Absolutely. Customization is a key strength. Anodes can be designed with specific geometries, sizes, and coating compositions tailored to the unique chemical profile of your wastewater, the desired treatment goals, and reactor design. This ensures the most efficient and effective pollutant removal. At China Titanium Factory, we specialize in providing custom-engineered titanium anode solutions.

Don't let complex wastewater challenges hold you back. Harness the power of advanced waste water electrolysis titanium anode technology and achieve unparalleled purity and efficiency.

Connect with the experts at China Titanium Factory today to discuss your project needs, explore our custom anode solutions, or learn more about our Aqua-Pure Anode Protocol.

Get a Custom Quote Now