Industrial Anodes Explained: Titanium vs. Lead Fundamentals

Choosing between a titanium anode and a lead anode is no longer just a matter of initial budget. It is a strategic decision that affects power consumption, product purity, and regulatory standing. Lead anodes have been the workhorse of the electrowinning and electroplating industries for decades. They are cheap. They are heavy. But they are also inefficient.

"We define industrial anodes as the primary electrochemical drivers in a cell, where the choice of substrate material determines the theoretical minimum energy required for the reaction."

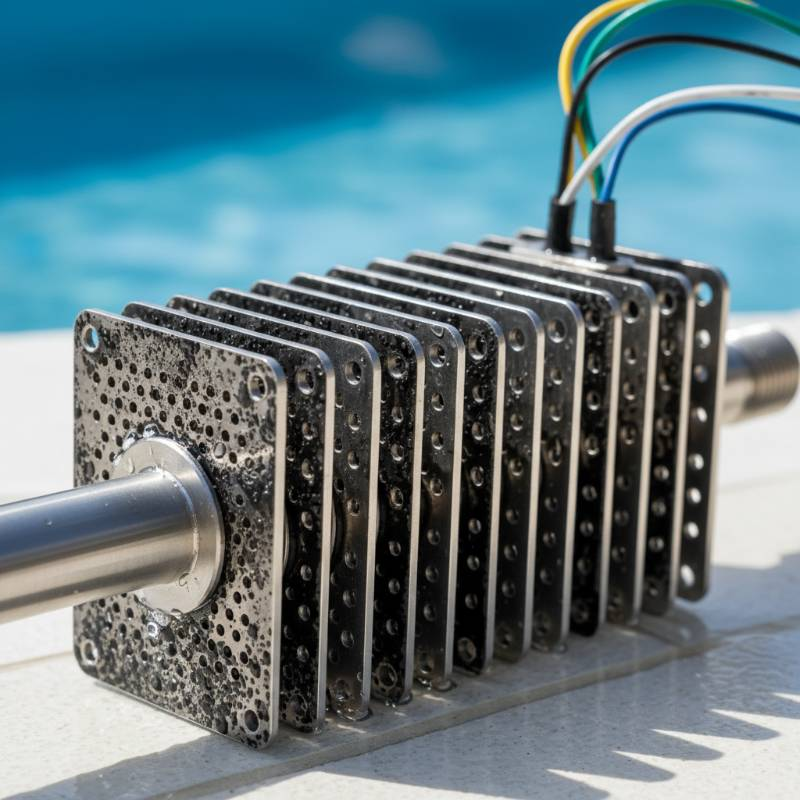

Titanium anodes, specifically MMO titanium anodes, represent the modern standard. Unlike lead, which acts as both the conductor and a sacrificial participant in many reactions, titanium serves as a permanent, inert substrate for electrocatalytic coatings. This fundamental difference dictates everything from cell maintenance to the final cost per ton of produced metal.

Performance Benchmarks: Efficiency and Dimensional Stability

In the world of industrial electrochemistry, The Principle of Dimensional Constancy is our Golden Rule. At China Titanium Factory, we argue that an anode that changes shape is an anode that loses money.

Lead anodes are notorious for "creeping" or warping under high current densities. As the lead deforms, the inter-electrode distance (IED) becomes inconsistent. This leads to uneven current distribution and potential short circuits. Titanium anodes are Dimensionally Stable Anodes (DSA). They do not move. They do not dissolve. They keep the IED constant, ensuring a stable cell voltage throughout their service life.

Consider the oxygen evolution potential. Lead anodes typically operate at a much higher overpotential than titanium electrodes coated with Mixed Metal Oxides (MMO). This translates directly to energy consumption. Lower overpotential means lower voltage. Lower voltage means lower electricity bills. For large-scale operations, a 100mV reduction in cell voltage can save hundreds of thousands of dollars annually.

Environmental Impact and Global Regulatory Compliance

The regulatory walls are closing in on lead. Between REACH standards in Europe and strict EPA guidelines in the US, the "hidden" costs of lead are rising. Lead anodes produce lead sludge—a hazardous byproduct that requires expensive filtration, handling, and disposal. According to research published in ScienceDirect, lead contamination in electrolytic cells can reduce the quality of the cathode deposit, leading to further industrial waste.

Titanium is the clean alternative. It is lead-free, non-toxic, and produces zero sludge. By transitioning to titanium, facilities eliminate the risk of lead-related health issues for workers and ensure long-term RoHS compliance. Sustainable electrochemistry isn't just a buzzword; it's a requirement for modern global supply chains.

The 4-Pillar Anode Lifecycle Framework (ALF)™

According to our analysis at China Titanium Factory, evaluating an anode requires more than a simple price check. We developed the Anode Lifecycle Framework (ALF)™ to help engineers make data-driven decisions.

| Pillar | Lead Anode Performance | Titanium Anode Performance |

|---|---|---|

| Stability | Poor (Warps/Corrodes) | Excellent (Rigid/Inert) |

| Conductivity | Moderate | Superior (Optimized Coatings) |

| Longevity | 6-12 Months (Sacrificial) | 5-10 Years (Recoatable) |

| Footprint | High Toxicity/Sludge | Zero Sludge/Recyclable |

Economic Analysis: CAPEX, OPEX, and Long-Term ROI

Let's talk numbers. The CAPEX (Capital Expenditure) for titanium anodes is undeniably higher—often 3 to 5 times the price of lead. However, focusing on the sticker price is a rookie mistake. The OPEX (Operating Expenditure) is where titanium wins. Lead anodes require frequent replacement, labor-intensive cleaning, and high power usage. Titanium anodes are "fit and forget" components that offer massive energy savings.

A typical ROI calculation for a copper electrowinning plant shows that switching to titanium pays for itself through energy reduction alone within 14 months. When you add the scrap value of titanium and the lack of hazardous waste disposal fees, the financial case becomes ironclad. Use our internal energy savings calculator logic: a 15% reduction in voltage across 1,000 cells isn't just a technical win; it's a bottom-line transformation.

Industry-Specific Applications: From Electroplating to Water Treatment

Where does the battle between titanium and lead play out most fiercely? In high-speed electroplating and hydrometallurgy. In chromium plating, lead-tin anodes have been the standard, but they contaminate the bath. Titanium anodes with special coatings ensure the bath remains pure, resulting in a higher quality finish and fewer rejected parts.

In wastewater treatment, particularly in electrochemical oxidation, lead is non-viable due to environmental leaching. Titanium anodes excel here, providing the high electrocatalytic activity needed to break down complex organic pollutants without poisoning the water they are meant to clean.

Coating Selection: MMO, Lead Dioxide, and Platinum

The "secret sauce" of the titanium anode is the coating. While lead is just lead, a titanium substrate can be customized:

MMO (Iridium/Ruthenium): Best for chlorine and oxygen evolution in brine or acid.

Lead Dioxide (PbO2) on Titanium: A unique hybrid that offers the electrochemical benefits of lead with the structural integrity of titanium.

Platinum Plated: The gold standard for platinum titanium anodes used in high-precision plating and cathodic protection.

Frequently Asked Questions About Industrial Anodes

Can I use titanium anodes in my existing lead anode busbars?

Yes. Titanium anodes can be engineered with copper-cored hangers or specific contact points to ensure busbar compatibility. We often customize the "hook" design to match existing cell layouts perfectly.

What is the scrap value of a titanium anode?

Unlike lead, which is often heavily oxidized and contaminated by the end of its life, the titanium substrate remains intact. It can be stripped, recoated, or sold as high-grade scrap titanium, retaining significant residual value.

How long does the MMO coating last?

Depending on the current density and chemical environment, an MMO coating typically lasts between 3 and 10 years. Once the voltage begins to rise, the anode can be returned to China Titanium Factory for recoating at a fraction of the cost of a new unit.

Ready to Modernize Your Electrochemical Process?

Stop paying for lead sludge and high energy bills. Switch to the Anode Lifecycle Framework (ALF)™ approved solutions from China Titanium Factory.

Get a Technical Consultation Today