For medical implants, failure is simply not an option. Patient safety hinges on the materials used, demanding the highest standards of biocompatibility. This isn't just about avoiding adverse reactions; it's about promoting seamless integration with the human body. Titanium, long revered for its strength and corrosion resistance, takes center stage. But its surface properties are what truly make or break an implant's success. That's where titanium anodizing comes in. This guide explores how this vital process elevates titanium, ensuring superior patient outcomes and devices built to last.

Understanding Titanium Anodizing for Advanced Medical Applications

Titanium's inherent qualities make it a standout for medical devices. However, raw titanium surfaces can be further optimized. Anodizing is a sophisticated surface modification technique. It transforms the material, making it even more suitable for the demanding environment of the human body. This process is key to unlocking titanium's full potential in healthcare.

What is Titanium Anodizing and How Does it Work?

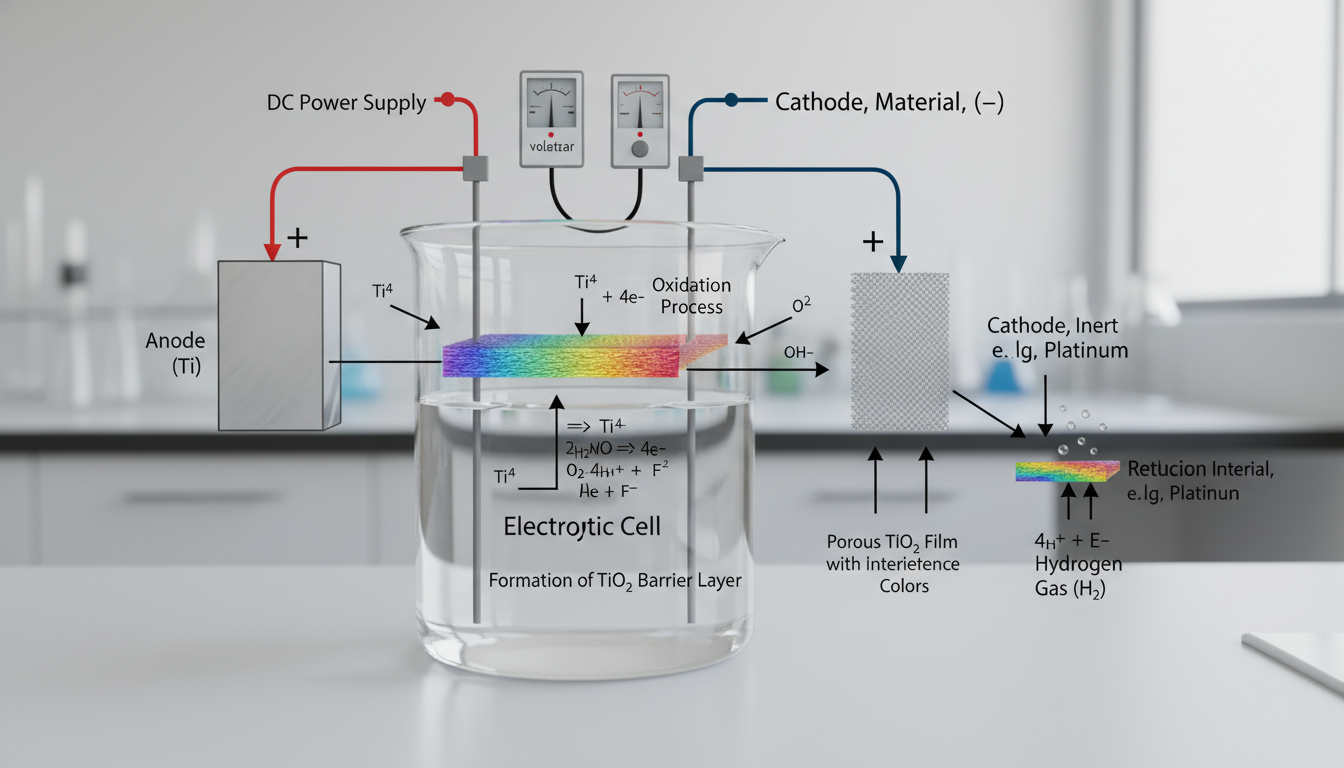

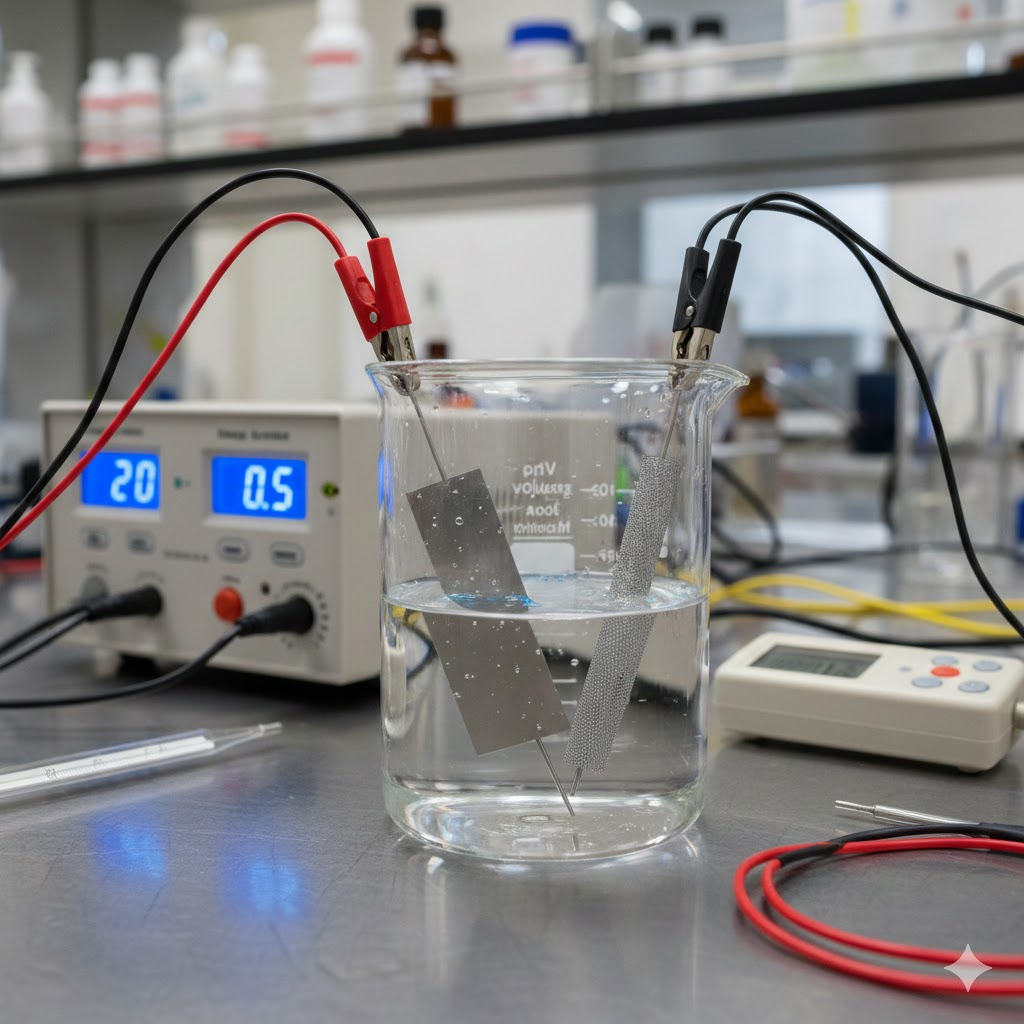

At its core, titanium anodizing is an electrochemical passivation process. You're essentially growing a controlled oxide layer on the titanium's surface. Think of it as controlled corrosion, but for the good of the implant.

Titanium Anodizing: An electrochemical process that forms a stable, protective titanium oxide layer on the surface of titanium or its alloys. This layer enhances corrosion resistance, wear resistance, and biocompatibility, particularly crucial for medical applications.

The mechanism is straightforward yet powerful. Titanium acts as the anode in an electrolytic cell. When current flows, oxygen ions from the electrolyte react with the titanium, forming a dense, uniform titanium oxide (TiO₂) layer. This layer is passive, highly stable, and incredibly resistant to chemical attack.

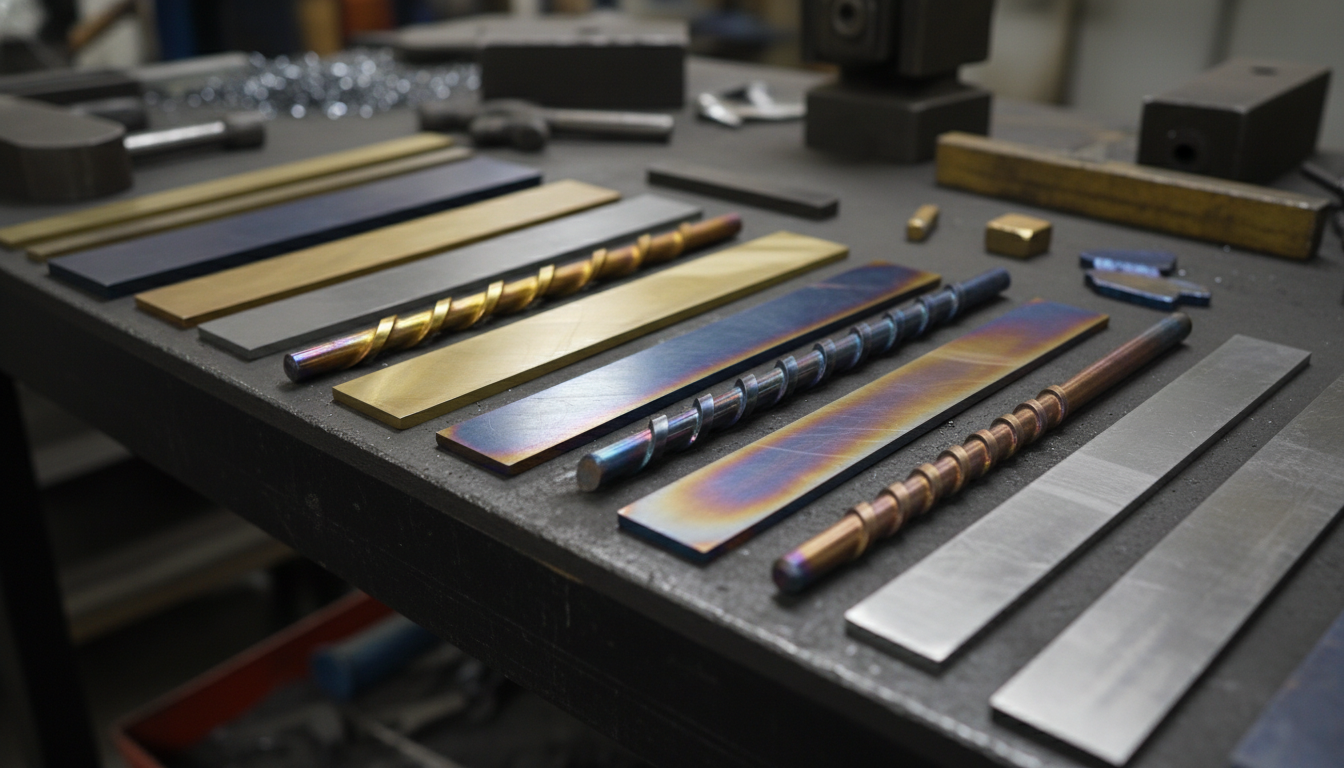

Exploring Different Types of Titanium Anodizing Techniques

Not all anodizing is created equal. The medical device industry often leverages specific types, each with unique characteristics. Type II (sulfuric acid anodizing) produces a thin, dense, and often colored oxide layer. It's a workhorse for many medical components.

Type III, or hard anodizing, yields thicker, harder layers. This is ideal when wear resistance is paramount. Then there's Plasma Electrolytic Oxidation (PEO), also known as micro-arc oxidation (MAO). PEO creates a rougher, porous ceramic-like coating. This microstructure can be a game-changer for promoting cell adhesion and osseointegration, which is crucial for things like dental and orthopedic implants.

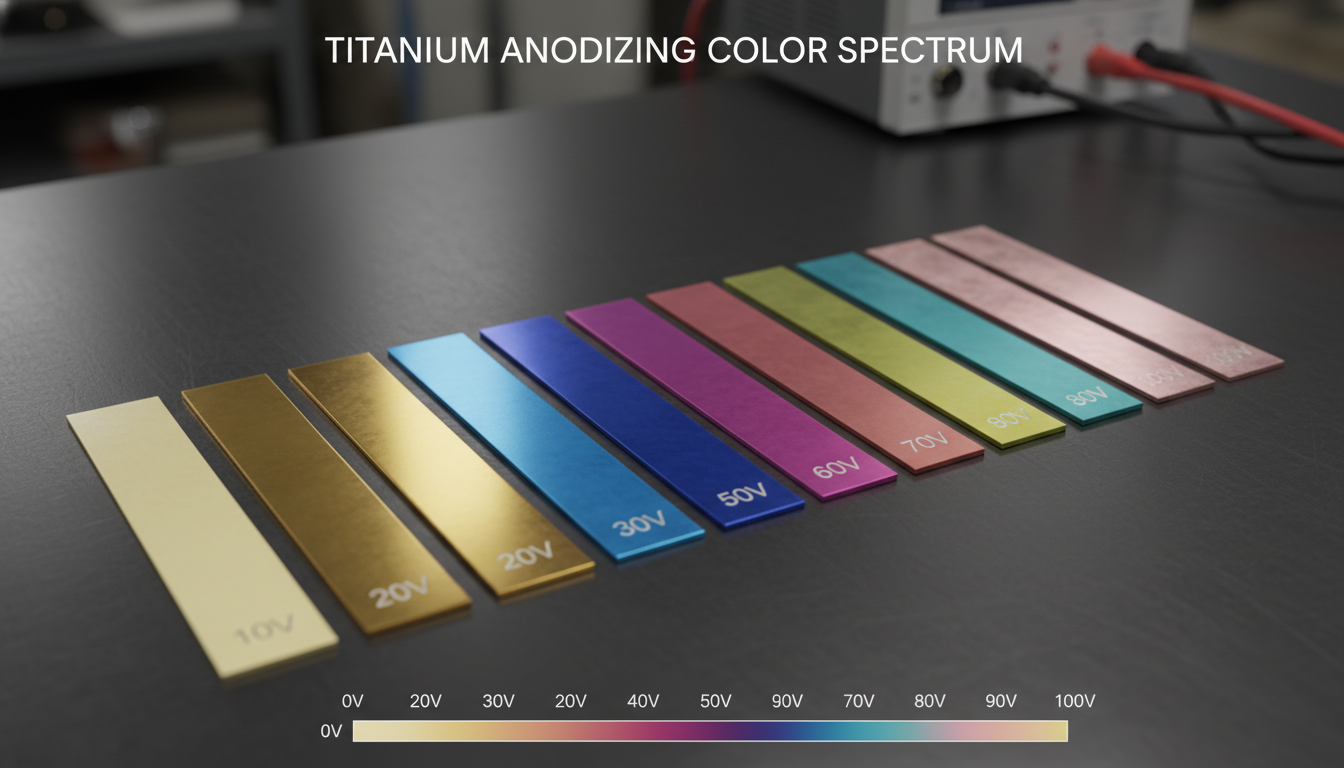

Key Anodizing Parameters and Their Impact on Surface Characteristics

Precision is everything in anodizing. Variables like voltage, current density, electrolyte composition, and treatment time aren't just knobs to turn; they dictate the final surface properties. A slight tweak can mean the difference between a successful implant and a non-starter.

Controlling these parameters allows manufacturers to fine-tune the oxide layer's thickness, porosity, crystallinity, and topography. These characteristics directly influence how the implant interacts with biological tissue. For a deeper dive into the technical capabilities and various anodizing solutions, China Titanium Factory offers comprehensive services tailored to specific medical requirements.

The Cornerstone of Success: Biocompatibility in Medical Implants

Biocompatibility isn't merely a buzzword; it's the bedrock of patient safety and implant efficacy. An implant must coexist peacefully with the body. Anything less can lead to inflammation, rejection, or even device failure. Anodized titanium addresses these stringent requirements head-on.

Defining Biocompatibility for Medical Devices: A Regulatory Perspective

In medical parlance, biocompatibility has a precise meaning. It's about how a material performs with an appropriate host response for a specific application. No adverse reactions. No cellular toxicity. The body needs to accept it, plain and simple.

Biocompatibility (Medical Device Context): The ability of a material to perform with an appropriate host response in a specific application. This implies the absence of unacceptable adverse effects on the body and the material's fitness for purpose within a living system.

International standards like ISO 10993 provide a comprehensive framework for evaluating the biological effects of medical devices. Adhering to these guidelines isn't optional; it’s the law of the land for device manufacturers.

Rigorous Biocompatibility Testing Methods for Anodized Titanium

Proving biocompatibility isn't a walk in the park. It involves a battery of tests, both in vitro (lab-based) and in vivo (live organism). Cytotoxicity tests assess cell harm. Sensitization and irritation tests check for allergic reactions or local tissue damage.

Systemic toxicity, genotoxicity, and implantation tests delve deeper into broader bodily effects and tissue integration. Hemocompatibility is crucial for devices contacting blood. Each test plays a vital role in building a bulletproof case for an anodized titanium implant's safety profile.

How Anodized Titanium Enhances Biocompatibility and Osseointegration

The anodized oxide layer isn't just a pretty face; it’s a biological powerhouse. It's incredibly inert, minimizing the release of metal ions that could trigger an immune response. This inertness is a big deal.

What's more, the controlled surface topography resulting from anodizing can actively promote cell adhesion and proliferation. For orthopedic and dental implants, this means superior osseointegration—the direct structural and functional connection between living bone and the surface of a load-bearing artificial implant. Bone grows right onto the surface, creating a strong, lasting bond.

Applications of Anodized Titanium Across Medical Fields

Anodized titanium isn't a one-trick pony. Its versatility and enhanced properties make it indispensable across a spectrum of medical disciplines. From fixing smiles to mending bones, its impact is profound.

Dental Implants: A Foundation for Oral Health and Stability

Walk into any modern dental office, and you'll find anodized titanium. It's the gold standard for dental implants. The optimized surface promotes faster and stronger osseointegration, meaning the implant fuses with the jawbone more effectively. This leads to exceptional long-term success rates and delighted patients in restorative dentistry.

The improved surface allows for better initial stability, reducing healing times and offering a solid foundation for crowns and bridges. It truly gives people their bite back.

Orthopedic Implants: Supporting Mobility and Recovery

Orthopedics relies heavily on anodized titanium. Think hip and knee replacements. Spinal fusion devices. Bone plates for fractures. The anodized layer reduces wear between articulating surfaces, a common failure point for many implants.

Crucially, it enhances bone-to-implant contact. This robust integration is vital for the longevity and functional success of orthopedic solutions, helping patients regain mobility and quality of life. It’s about getting people back on their feet.

Cardiovascular and Other Advanced Medical Devices

Beyond bone, anodized titanium finds its way into specialized applications. Cardiovascular stents, pacemakers, and neurosurgical devices often incorporate it. Here, the biocompatible and corrosion-resistant properties are not just important; they're life-saving.

Devices in direct contact with blood demand exceptional hemocompatibility to prevent clotting. In sensitive neural tissues, an inert and stable surface is non-negotiable. Anodizing provides that crucial layer of safety and performance.

Advantages and Considerations of Anodized Titanium Implants

Like any technology, anodized titanium comes with a clear set of advantages and some considerations. Understanding both sides of the coin is vital for manufacturers and medical practitioners alike. It’s about informed decisions.

Unlocking the Benefits: Enhanced Properties for Superior Performance

The benefits are compelling. Superior corrosion resistance protects the implant from the body's aggressive internal environment. Improved wear resistance means longer-lasting devices, especially for load-bearing applications. Enhanced osseointegration, as discussed, speeds up healing and creates stronger bonds.

Furthermore, an anodized surface can reduce bacterial adhesion, a critical factor in preventing implant-related infections. The ability to incorporate bioactive coatings onto the anodized layer also opens doors for even greater functionality. The right Titanium Anodizing Service can unlock these advantages, driving superior implant performance.

Addressing the Challenges: Potential Risks and Limitations

While beneficial, anodizing isn't without its considerations. The process itself adds to manufacturing costs. Precise process control is paramount; even slight deviations can compromise the desired surface properties. This demands specialized equipment and skilled operators.

In certain niche applications, other biomaterials might still be preferred due to specific mechanical or biological requirements. Navigating the regulatory complexities for a novel anodized device also requires significant resources and expertise. It's not a set-it-and-forget-it operation.

Navigating the Landscape: Practical Insights for Manufacturers

For medical device manufacturers, integrating anodized titanium into product lines requires more than just technical know-how. It demands strategic partnerships, stringent quality assurance, and a clear understanding of regulatory pathways. It's a high-stakes game.

Choosing the Right Anodizing Partner: Key Considerations

Selecting an anodizing service provider isn't a decision to take lightly. Look for partners with proven expertise in medical applications. Quality certifications like ISO 13485 are non-negotiable; they signal a commitment to medical device quality management systems.

Process validation capabilities are also critical. Can they consistently reproduce results? Do they adhere to strict quality control protocols? Reputable providers, like those at China Titanium Factory, understand the gravity of these requirements. They are a valuable asset in bringing safe, effective devices to market. Don't settle for less.

Regulatory Pathways for Anodized Medical Devices: FDA and CE Mark

Getting anodized titanium medical devices to market is a journey through regulatory landscapes. In the US, the FDA holds the keys. In Europe, it's all about the CE Mark. These bodies demand exhaustive documentation and rigorous testing results.

Understanding classification, premarket submissions (like 510(k) or PMA), and post-market surveillance is crucial. It’s a painstaking process, but essential for public trust and legal compliance.

The Future of Anodized Titanium in Medical Technology

The journey for anodized titanium is far from over. As medical technology advances, so too will surface engineering. Expect to see exciting innovations that push the boundaries of implant functionality and patient care. The horizon is bright.

Emerging Trends and Innovations in Anodized Surfaces

Nanotechnology is making waves. Imagine anodized surfaces enhanced at the nanoscale, precisely engineered to promote specific cellular responses. Drug-eluting coatings applied to anodized titanium could deliver medication directly at the implant site, reducing infection or promoting healing.

Smart implants, with integrated sensors, are another frontier. These devices could monitor their own performance or even biological conditions in real-time. Anodized surfaces provide an excellent foundation for these advanced functionalities. Companies like China Titanium Factory are at the forefront, exploring these cutting-edge developments to redefine medical device capabilities.

Frequently Asked Questions About Titanium Anodizing and Biocompatibility

Manufacturers, researchers, and healthcare professionals often have specific questions about titanium anodizing and its role in medical implants. Here are some common queries, answered directly.

Common Queries on Anodizing and Implant Safety

Is anodized titanium safe for long-term implantation?

Absolutely. The anodized oxide layer is highly stable and inert, significantly reducing ion release and making it exceptionally safe for long-term implantation. It's a proven performer.

Does anodizing affect the strength of titanium?

Generally, no. The anodized layer is extremely thin (microns thick) and does not significantly alter the bulk mechanical properties or strength of the underlying titanium. Its impact is purely superficial and beneficial.

What is the lifespan of anodized titanium implants?

With proper design, surgical placement, and patient care, anodized titanium implants are engineered for decades of service. Many can last a patient's lifetime. Their enhanced corrosion and wear resistance contribute significantly to this longevity.

Can all titanium alloys be anodized for medical use?

Most common medical-grade titanium alloys, such as Ti-6Al-4V ELI and pure titanium (Grade 1-4), can be effectively anodized. The specific alloy might influence the anodizing parameters and resulting surface characteristics, but the process is broadly applicable. For more details on specific material applications, consider browsing China Titanium Factory's product offerings.

Is the coloring from anodizing purely aesthetic, or does it serve a functional purpose?

While anodizing can produce a range of colors, which is useful for aesthetic purposes or for distinguishing implant sizes/types during surgery, the coloring itself is a byproduct of the oxide layer's thickness, which refracts light. The primary functional purpose is the enhanced biocompatibility, corrosion resistance, and surface properties, not the color. The color is just icing on the cake, or a helpful identifier.