Frustrated by the limited palette of raw metals? Need a finish that’s both striking and incredibly durable?

Titanium anodizing offers a brilliant solution. This guide cuts through the complexity, laying out everything you need to know about creating a vibrant, lasting spectrum of colors on titanium.

What is Titanium Anodizing? A Colorful Introduction

Titanium isn't just strong and lightweight. It's also a chameleon. Unlike painting or plating, titanium anodizing doesn't apply a pigment. It transforms the metal itself, creating a spectrum of stunning, iridescent colors.

This process is an electrochemical marvel. It leverages titanium’s natural tendency to form a protective oxide layer. Instead of simply letting it happen, we control it precisely.

The result? A durable, biocompatible, and vibrant surface that retains all of titanium's inherent benefits.

Titanium Anodizing: An electrochemical passivation process that thickens the naturally occurring oxide layer on the surface of titanium, producing a range of colors determined by the oxide's thickness and light interference.

Why bother? Beyond aesthetics, the process enhances corrosion resistance and creates a harder surface. This makes anodized titanium ideal for everything from medical instruments to high-end jewelry and performance components.

The team at China Titanium Factory understands these nuances. They utilize advanced techniques to achieve consistent, high-quality finishes on various titanium products.

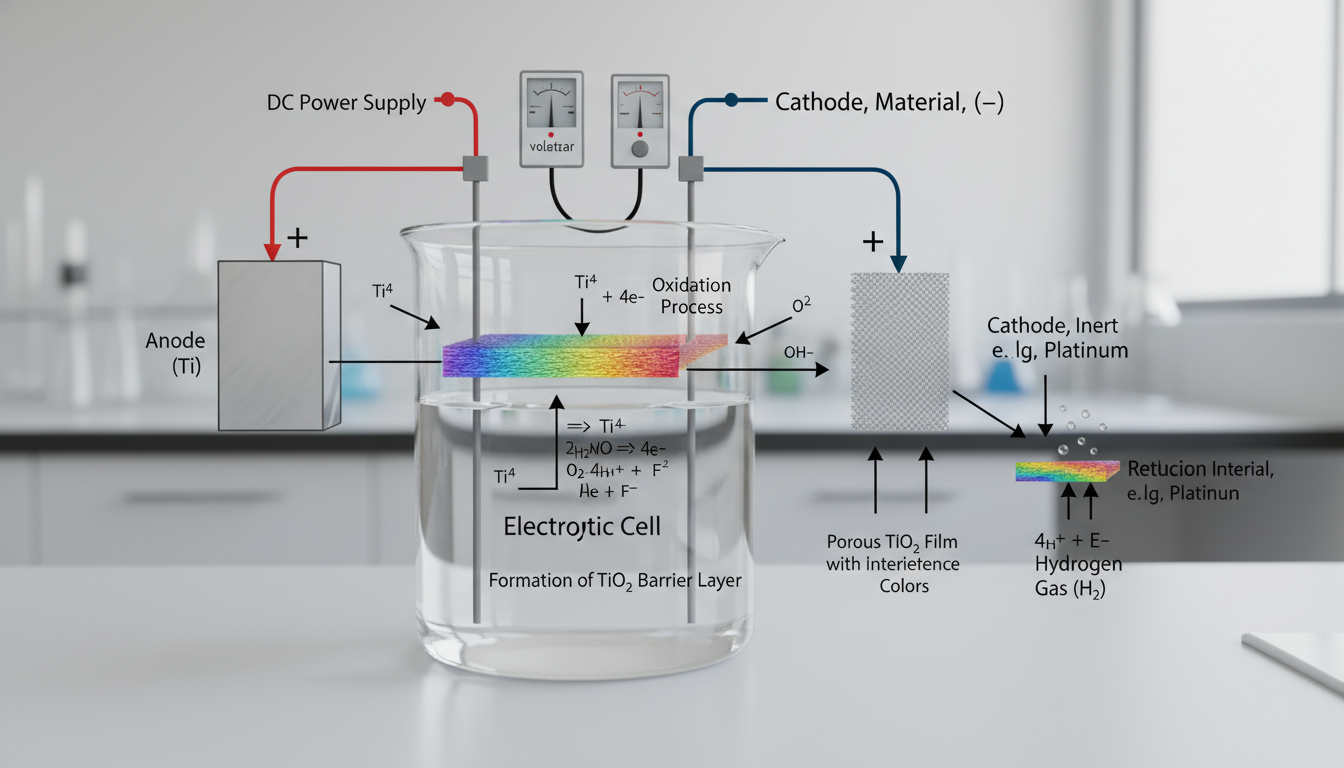

The Science Behind the Shine: How Titanium Anodizing Works

It's not magic; it's physics. Anodizing titanium is an electrochemical process. We immerse a titanium part (the anode) and a cathode (often stainless steel) into an electrolyte solution. Then, we apply a direct current.

This controlled electrical current drives a chemical reaction. Oxygen ions from the electrolyte migrate to the titanium surface, bonding with the titanium atoms. This forms a transparent, non-conductive titanium oxide layer.

Oxide Layer and Light Interference: The Color Secret

Here's the kicker: the oxide layer's thickness is directly proportional to the applied voltage. The thicker the layer, the different the light interacts with it.

We're talking about light interference. White light, composed of all colors, hits the oxide surface. Some light reflects off the top of the oxide, and some penetrates, reflecting off the titanium metal underneath. These two reflected light waves interfere with each other. Depending on the oxide layer's thickness, certain wavelengths (colors) are amplified, while others are canceled out.

This phenomenon, known as thin-film interference, is what gives bubbles and oil slicks their rainbow sheen. With titanium, we precisely control it. The oxide itself is colorless; it's the interaction with light that creates the visual spectacle.

Light Interference: A phenomenon where two or more light waves superpose to form a resultant wave of greater, lower, or the same amplitude. In anodizing, it's the interaction between light reflected from the top and bottom surfaces of the transparent oxide layer that creates color.

This isn't a surface coating that can chip or peel. It's an integral part of the metal. For a deeper dive into the science, see sources like the ASM Handbook on Surface Engineering.

Setting Up for Success: Essential Equipment and the Anodizing Process

Ready to get your hands dirty? Or rather, clean?

Proper setup is paramount for consistent results. Think of it like cooking: the right ingredients and tools make all the difference.

Essential Equipment

Power Supply: A DC power supply capable of regulating voltage is crucial. Most applications use a range from 10V to 120V. Precision is key.

Electrolyte: Typically a mild acid. Trisodium phosphate (TSP) or even Coca-Cola can work for hobbyists, but specialized solutions offer better control.

Cathode: An inert conductor like stainless steel or graphite. It completes the circuit.

Anode: Your titanium workpiece.

Containers: Non-conductive plastic or glass beakers.

Cleaning Supplies: Acetone, isopropyl alcohol, detergent, and distilled water.

Safety Gear: Gloves, eye protection, and proper ventilation. Always.

The Anodizing Steps: A Walkthrough

The process is straightforward, but attention to detail is critical.

Cleaning: This is non-negotiable. Any oils, fingerprints, or oxides on the surface will prevent uniform anodization. Degrease with acetone, scrub with detergent, rinse thoroughly with distilled water. Some prefer an acid etch for a pristine surface.

Rinsing: Rinse the cleaned titanium with distilled water to remove any residues.

Setup: Place the electrolyte in your container. Suspend the titanium workpiece (anode) and the cathode, ensuring they don't touch. Connect the positive lead of the power supply to the titanium and the negative lead to the cathode.

Anodizing: Slowly increase the voltage to your desired level. You'll observe the color changing almost immediately. The current will drop significantly once the oxide layer reaches its target thickness for that voltage. Hold the voltage for 30-60 seconds after the current stabilizes.

Rinsing Again: Remove the part and rinse it thoroughly with distilled water to wash off any residual electrolyte.

Drying: Air dry or gently pat dry.

Safety First, Always

Working with electricity and chemicals demands respect. Always wear appropriate Personal Protective Equipment (PPE). Ensure your workspace is well-ventilated to avoid inhaling any fumes. If you're unsure, consult with experts or seek professional services. Professional titanium fabrication services often include advanced finishing options, including anodizing.

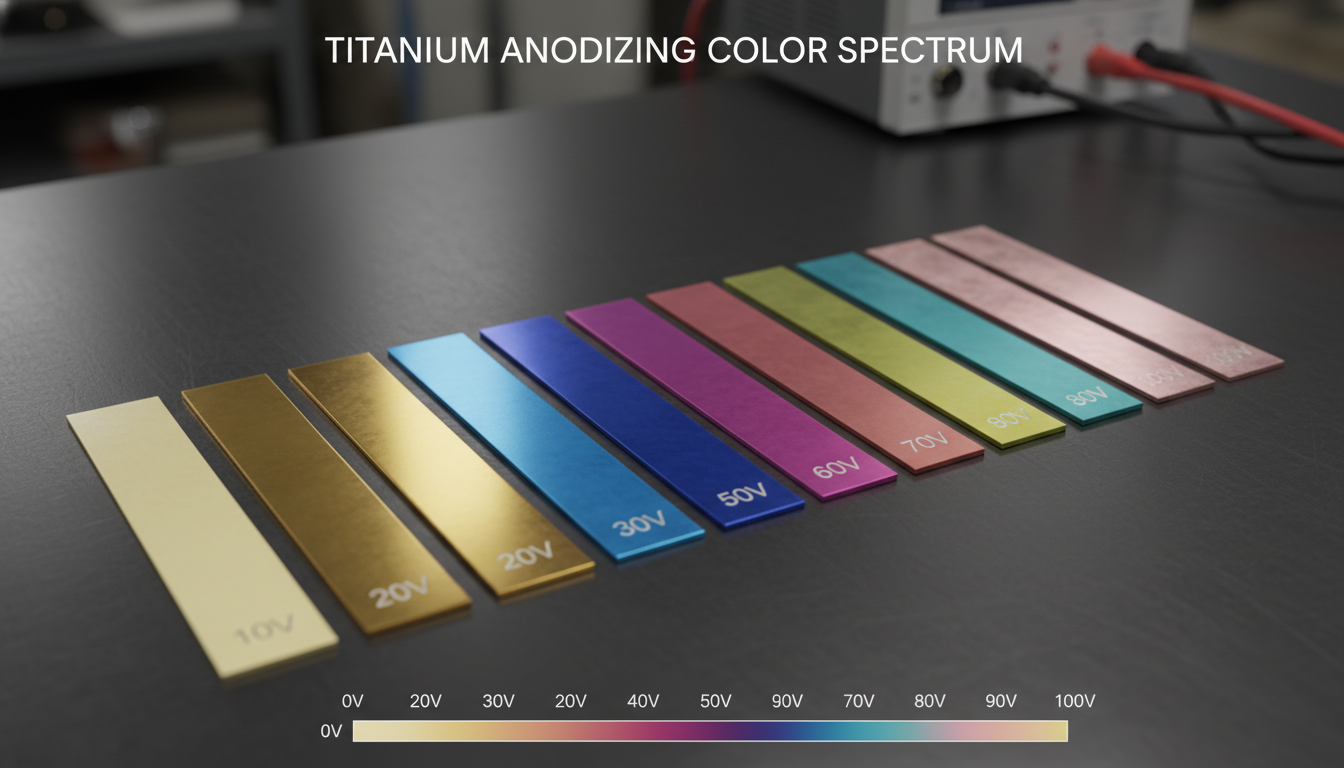

Unlocking the Rainbow: Your Comprehensive Titanium Anodizing Color Chart by Voltage

This is where the magic happens. The direct correlation between voltage and color is the cornerstone of titanium anodizing. A slight bump in voltage can dramatically shift the hue.

Below is a general guide. Exact colors can vary based on titanium alloy, surface finish, and electrolyte composition. Consider this a starting point, not a strict bible.

| Voltage (V) | Approximate Color | Notes |

|---|---|---|

| Less than 10V | Tan/Brown | Very thin oxide, often hard to achieve uniformly. |

| 10-15V | Bronze/Brown | Warm, subtle tones. |

| 20-25V | Dark Blue/Purple | Often the first noticeable vibrant color. |

| 30-35V | Blue | A common and popular shade. |

| 40-45V | Light Blue/Sky Blue | Brighter, ethereal blues. |

| 50-55V | Yellow/Gold | Striking and often sought-after. |

| 60-65V | Pink/Rose | Can be delicate and translucent. |

| 70-75V | Purple/Magenta | Rich and deep. |

| 80-85V | Teal/Green | Can be challenging to achieve a pure green. |

| 90-95V | Green/Yellow-Green | Often appears as a lime green. |

| 100-110V | Fuchsia/Bright Pink | Vibrant and intense. |

| 110-120V+ | Light Green/Silver (High Order) | Colors repeat in higher orders, but become fainter. |

Remember, these are approximate. Experimentation is part of the fun. Start low and gradually increase voltage to see the color progression. You'll gain a feel for it.

Need custom anodized titanium components? Understanding this chart helps in communicating your desired finish to a manufacturer.

Mastering the Hue: Factors Affecting Color Consistency and Achieving Specific Shades

Achieving a specific, consistent color isn't always a cakewalk. Several variables can throw a wrench in your plans. Knowing them is half the battle.

Surface Finish: The Foundation of Color

The texture of your titanium matters. A highly polished surface will yield a brighter, more reflective color. A matte or sandblasted finish will produce a softer, more diffused hue. Uneven finishes lead to uneven colors. Period.

Think about how light behaves. Smooth surfaces reflect light more coherently, enhancing the interference effect. Rough surfaces scatter light, softening the perceived color.

Electrolyte Purity and Temperature: Unsung Heroes

Contaminants in your electrolyte are color killers. Even small impurities can cause streaks, spots, or dull colors. Use distilled water for your solution. Keep your electrolyte clean, replacing it if it looks cloudy or discolored.

Temperature also plays a role. A cooler electrolyte generally results in a slower, more controlled growth of the oxide layer, potentially leading to more uniform colors. Warmer solutions can speed up the process but might sacrifice precision.

Current Density and Immersion Time: Fine-Tuning

While voltage dictates the final thickness (and thus color), the current density influences the rate of oxide formation. A lower current density means a slower process, which can lead to better uniformity, especially on complex shapes.

Immersion time isn't as critical once the voltage is stable and the current drops. The oxide layer stops growing significantly when it reaches the thickness dictated by the voltage. However, keeping the part immersed for a short period (30-60 seconds) after the current stabilizes ensures complete formation.

Troubleshooting Tips for Perfect Hues

Streaky Colors: Usually a sign of improper cleaning or uneven electrical contact. Re-clean thoroughly, ensuring good contact with the anode lead.

Dull Colors: Could be due to a rough surface finish, contaminated electrolyte, or insufficient voltage. Polish your titanium better, change electrolyte, or increase voltage slightly.

No Color Change: Check your circuit. Is the power supply on? Are the leads connected correctly? Is the titanium making good contact?

Inconsistent Color Across Part: Often a result of poor contact or the part not being fully immersed. Ensure full immersion and multiple contact points for larger pieces.

Expert titanium manufacturing facilities implement rigorous quality control to mitigate these issues, ensuring a uniform and vibrant finish.

Beyond the Basics: Exploring Different Types of Titanium Anodizing

While the voltage-controlled coloring is the most visually striking, titanium anodizing isn't a one-trick pony. Different methods exist, each serving distinct purposes.

Type II (Decorative) Anodizing: The Colorful Standard

This is what we've primarily discussed. Type II, or "decorative" anodizing, focuses on aesthetics. It creates the vibrant, iridescent colors through thin-film interference. The oxide layer is typically very thin (nanometers thick), primarily offering visual appeal and a minor boost in corrosion resistance.

It's widely used in jewelry, art, and consumer products where visual impact is key.

Type III (Hardcoat) Anodizing: Built for Toughness

While less common for titanium than aluminum, hardcoat anodizing aims for maximum wear and abrasion resistance. It typically involves higher voltages, lower temperatures, and specialized electrolytes. The resulting oxide layer is significantly thicker and harder.

This process is more about functional enhancement than color. Colors produced, if any, are usually duller (grays, browns) and less vibrant, due to the thicker, more opaque layer. It's often used for industrial components requiring extreme durability.

Other Specialized Methods: Beyond the Spectrum

Plasma Electrolytic Oxidation (PEO): Also known as micro-arc oxidation, PEO creates very hard, ceramic-like coatings on titanium. It uses higher voltages and specialized electrolytes, resulting in coatings with superior wear, corrosion, and thermal resistance. Colors are typically limited to shades of gray or off-white.

Black Anodizing: Achieving a true, deep black on titanium through anodizing is difficult. It usually involves a multi-step process, often combining a specific anodizing voltage with a subsequent dying process or specialized electrolyte.

Each type serves a specific engineering or aesthetic need. Understanding these distinctions helps in selecting the right finishing process for your titanium alloy.

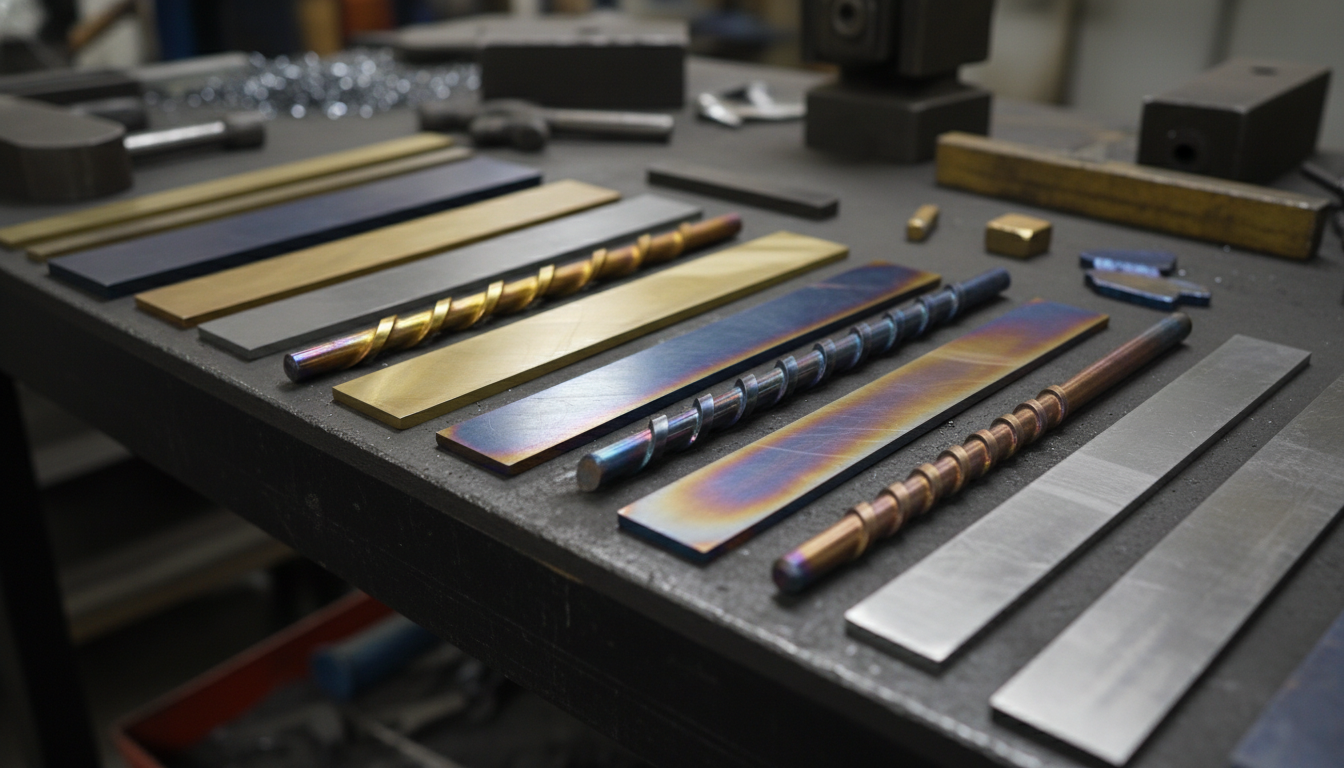

Where Color Meets Function: Diverse Applications of Anodized Titanium

Anodized titanium isn't just a pretty face. Its unique properties make it indispensable across numerous industries.

Medical and Biomedical: The Ultimate Biocompatibility

Titanium is renowned for its biocompatibility. Anodizing enhances this. The oxide layer is inert, non-toxic, and resistant to bodily fluids. This makes anodized titanium perfect for medical implants like pacemakers, dental implants, and orthopedic prosthetics.

The colors also serve a practical purpose: identification. Surgeons can quickly distinguish between different sizes or types of instruments and implants, improving efficiency and reducing errors.

Aerospace and Automotive: Performance with a Pop

Lightweight, strong, and corrosion-resistant titanium is a staple in aerospace. Anodizing can further improve its surface properties, offering enhanced wear resistance for certain components. While decorative colors are less common for critical structural parts, functional anodizing provides protective layers.

In high-performance automotive parts, especially aftermarket components, anodized titanium adds a distinctive, high-tech aesthetic, standing out in engine bays or on custom builds.

Jewelry and Artistic Creations: Wearable Art

This is where decorative anodizing truly shines. Artists and jewelers leverage the full spectrum of colors to create stunning, unique pieces. From earrings to pendants, the lightweight nature of titanium combined with its vibrant, hypoallergenic finish makes it a favorite material.

The ability to selectively anodize different areas or create gradients opens up endless creative possibilities. It’s a medium that truly allows the metal to sing.

Consumer Electronics and Everyday Carry: Durable Style

Smartphones, laptops, and premium accessories increasingly feature titanium for its strength-to-weight ratio. Anodizing allows manufacturers to add custom colors and branding, differentiating products while retaining the metal's inherent durability.

For everyday carry (EDC) items like knives, flashlights, and pens, anodized titanium offers a personalized touch that stands up to daily abuse. It’s tough as nails and looks good doing it.

Preserving the Brilliance: Maintenance and Durability of Anodized Titanium

You've got a beautifully anodized titanium piece. Now, how do you keep it looking fresh?

Good news: anodized titanium is remarkably durable. But it's not invincible.

How to Clean Anodized Titanium

It's simple. For most anodized titanium, a mild soap (like dish soap) and warm water are all you need. Use a soft cloth or sponge. Avoid abrasive cleaners, harsh chemicals, or scouring pads, as these can scratch or dull the finish.

Rinse thoroughly with clean water and dry with a soft cloth to prevent water spots.

Durability and Scratch Resistance

The anodized layer is an oxide, which is harder than raw titanium. This provides a decent level of scratch resistance. However, it's still a thin layer. Deep scratches or abrasion from harder materials (like steel or ceramics) can penetrate the oxide, revealing the underlying gray titanium.

Think of it as a hard, clear coat. It protects, but it's not diamond-hard. Proper handling and storage, especially for artistic pieces or jewelry, will prolong its pristine look.

Fading and Longevity of Anodized Colors

Anodized titanium colors do not fade from UV exposure like organic dyes. The color comes from light interference, not pigment. So, sunlight won't bleach it out.

However, the perceived color can change or dull if the surface becomes scratched, dirty, or if certain chemicals (especially strong acids or bases) etch the oxide layer. With proper care, anodized titanium colors can last indefinitely.

Can it be Re-Anodized?Yes! If you're tired of a color or it gets damaged, the anodized layer can be carefully stripped using specialized chemicals (like Whink Rust Remover for a quick dip, use with extreme caution). This removes the oxide, returning the titanium to its original gray state, ready for a fresh start. Then, you can re-anodize to a new color.

This re-anodizing capability adds to the versatility and long-term value of titanium products. It's a testament to the forgiving nature of the material and process.

Frequently Asked Questions About Titanium Anodizing Colors

Is titanium anodizing safe?

Yes, when done correctly and with proper safety precautions. The process uses mild electrolytes and low voltages compared to some industrial processes. The resulting oxide layer is biocompatible and non-toxic. The main risks involve handling chemicals and electricity, so PPE and good ventilation are essential.

Can all grades of titanium be anodized?

Generally, yes. Commercially Pure (CP) titanium grades (like Grade 1, 2, 3, 4) and common alloys like Ti-6Al-4V (Grade 5) all anodize beautifully. The purity of the titanium can slightly influence the clarity and vibrancy of the colors. Higher purity often yields cleaner colors.

Are the colors permanent? Will they chip or peel?

The colors are very durable and will not chip, flake, or peel because they are not a coating applied to the surface. Instead, they are an integral part of the titanium's surface oxide layer. They can be scratched off if the underlying metal is damaged, or chemically removed, but they won't spontaneously degrade.

Can I create multiple colors on one piece of titanium?

Absolutely! This is a popular technique for artists. You can mask off areas or use a "brush anodizing" technique (where a smaller applicator is used with the electrolyte to target specific areas) to apply different voltages to different sections, creating multi-color designs. It requires a steady hand and patience, but the results are stunning.

How does anodizing affect the dimensions of the part?

The oxide layer formed during Type II (decorative) anodizing is extremely thin, typically a few tens of nanometers (billionths of a meter). This is negligible and will not significantly alter the dimensions of precision-machined titanium parts. Functional hardcoat anodizing might add a few microns, which could be relevant for very tight tolerances.

Conclusion: The Enduring Appeal of Anodized Titanium Colors

Titanium anodizing is more than just a finishing technique; it's an art and a science rolled into one. It transforms a formidable metal into a canvas of vibrant hues, all while maintaining or even enhancing its inherent strength, lightweight nature, and corrosion resistance.

Whether you're an engineer seeking a functional finish, an artist crafting unique jewelry, or a hobbyist exploring new frontiers, the ability to control color with precision voltage opens up a world of possibilities. It's a testament to titanium's versatility and its enduring appeal.

The beauty of anodized titanium lies in its unique blend of aesthetics and performance. It’s a material that truly offers the best of both worlds.