Unlocking Precision: The Power of Titanium Anodizing Equipment

Achieving superior surface finishes on titanium demands specialized equipment. Without precise control, critical applications suffer from inconsistent quality. This directly impacts product reliability and longevity.

Leading-edge titanium anodizing equipment provides the solution. It ensures consistent, high-quality metal treatment. These advanced systems deliver unparalleled precision for diverse industrial needs.

As a global leader, China Titanium Factory offers comprehensive solutions. Our technical expertise supports your most demanding projects. We emphasize reliability and efficiency in every system.

Understanding the Titanium Anodizing Process

Titanium anodizing transforms the metal's surface. This electrochemical process creates a protective oxide layer. It enhances performance across many applications.

Understanding this process is vital for quality control. It ensures optimal results for any titanium component. We adhere to stringent industry standards.

How Titanium Anodizing Works: A Step-by-Step Guide

Titanium anodizing involves an electrolyte bath. The titanium part acts as the anode. An electric current passes through the solution.

This forms a controlled oxide layer on the surface. The film thickness depends on voltage and time. This layer offers superior durability and aesthetics.

Titanium Anodizing: An electrochemical passivation process. It thickens the natural oxide layer on titanium. This enhances corrosion resistance, wear resistance, and allows for color effects.

Types of Titanium Anodizing: From Functional to Decorative

Several types of titanium anodizing exist. Each offers distinct properties for specific uses. Type II (medical) provides biocompatibility and a uniform oxide film.

Type III (hard coat) creates a thicker, harder layer. This enhances wear resistance significantly. Color titanium anodizing produces vibrant hues. It achieves this without dyes, through light interference.

Key Benefits of Titanium Anodizing for Industrial Applications

Anodized titanium offers numerous advantages. It significantly improves corrosion resistance. This is crucial for harsh industrial environments.

Enhanced wear properties extend component lifespan. Its biocompatibility is vital for medical applications. The process also provides unique aesthetic appeal.

Critical Anodizing Parameters and Industry Standards

Precise control of parameters is essential. Voltage, current density, and electrolyte composition affect the finish. Temperature also plays a critical role.

Adherence to standards like ASTM F86 ensures quality. This standard outlines surface preparation for surgical implants. Such compliance guarantees consistent, high-quality results.

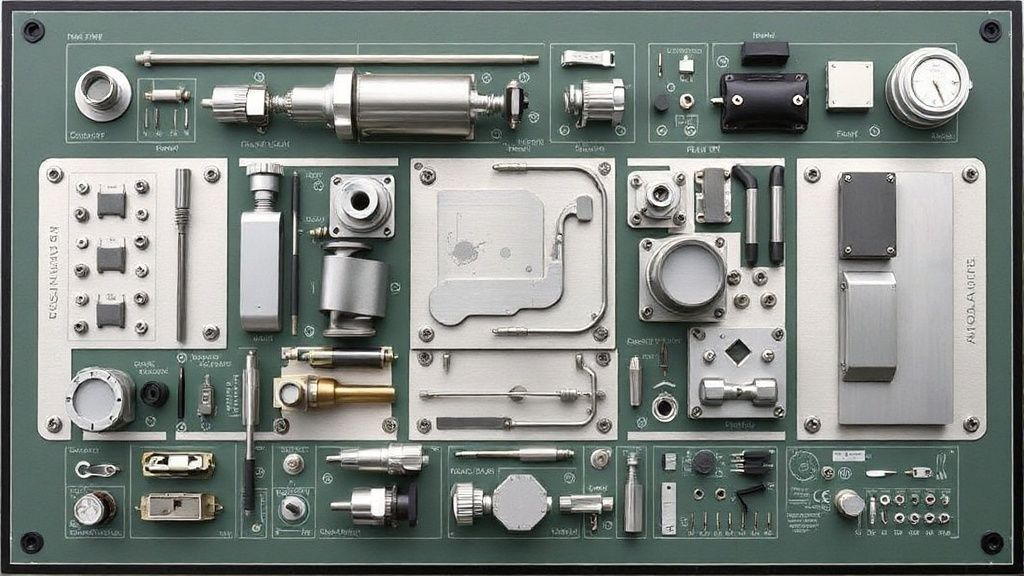

Building Your System: Essential Titanium Anodizing Equipment Components

A complete titanium anodizing line requires robust components. Each part contributes to overall system efficiency. Quality and reliability are paramount.

Our technical expertise ensures integrated solutions. We provide systems built for lasting performance. Explore the core elements of a superior anodizing setup.

Precision Power: Anodizing Rectifiers for Titanium

Anodizing rectifiers provide the necessary power. They control voltage and current precisely. This is critical for consistent film thickness and quality.

Advanced features include low ripple control. Programmable rectifiers allow for automated processes. They ensure repeatable, high-quality titanium anodizing results.

The Heart of the System: Anodizing Tanks and Their Design

Anodizing tanks hold the electrolyte solution. They must be chemically resistant. Materials like polypropylene or PVC are common.

Design considerations include temperature stability. Optimal part placement ensures uniform coating. Proper tank design is crucial for process success.

Maintaining Optimal Conditions: Cooling and Heating Systems

Temperature regulation is vital in anodizing baths. It impacts film formation and quality. Consistent temperatures prevent defects.

Chillers and heating coils maintain ideal conditions. They ensure superior and reproducible finishes. Effective process temperature management is key.

Intelligent Control: Automation and Anodizing Control Systems

Modern anodizing lines benefit from automation. PLC control systems enhance efficiency. They ensure repeatability and safety in operations.

Process monitoring and data logging are standard. These systems provide critical insights. They enable continuous improvement and quality assurance.

Secure and Efficient: Racks and Fixtures for Titanium Parts

Racks and fixtures hold titanium parts during anodizing. They ensure proper electrical contact. This is essential for uniform coating.

Their design minimizes contact marks. They also facilitate efficient handling. Correct rack materials prevent contamination and ensure process integrity.

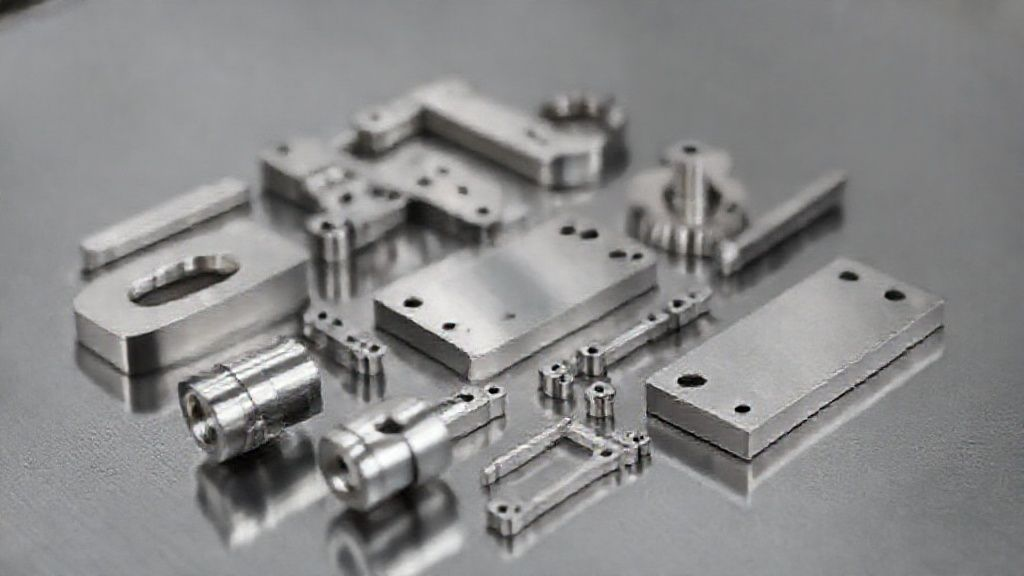

Where Precision Matters: Key Applications of Titanium Anodizing

Titanium anodizing serves diverse, high-stakes industries. Its versatility makes it indispensable. From aerospace to medical, its importance is clear.

This process ensures critical components perform flawlessly. It adds value and extends product life. Explore its global impact.

Life-Saving Finishes: Titanium Anodizing for Medical Implants

Medical devices require the highest standards. Titanium anodizing provides critical biocompatibility. It is essential for implants and surgical instruments.

The process ensures sterilization compatibility. It also allows for unique identification markings. This enhances patient safety and traceability.

High-Performance Protection: Aerospace Titanium Anodizing

Aerospace components operate under extreme conditions. Anodized titanium offers enhanced corrosion resistance. It improves fatigue life for structural parts.

Its lightweight nature contributes to fuel efficiency. Rigorous industry specifications are consistently met. This ensures safety and performance in flight.

Aesthetic Appeal: Decorative Titanium Anodizing Solutions

Titanium anodizing creates stunning, vibrant colors. It does this without the use of dyes. The colors arise from light interference on the oxide layer.

This makes it ideal for jewelry and consumer electronics. Architectural elements also benefit from its unique visual effects. The finishes are both durable and beautiful.

Durability and Performance: Industrial Titanium Finishing

Industrial components often face harsh environments. Titanium anodizing improves their performance. It extends their longevity in chemical processing and marine engineering.

The durable finishes resist wear and corrosion. This ensures reliable operation. It reduces maintenance and replacement costs.

Lightweight and Robust: Automotive Titanium Anodizing

The automotive sector increasingly uses anodized titanium. It contributes to lightweighting efforts. This improves fuel efficiency and vehicle performance.

Performance parts and aesthetic components benefit. The finishes offer both durability and visual appeal. This enhances vehicle longevity and design.

Selecting Your Partner: Global Titanium Anodizing Equipment Manufacturers

Choosing the right equipment supplier is a critical decision. It impacts your operational success and product quality. You need a partner with proven expertise.

We stand as a reliable and trustworthy leader. Our solutions are backed by extensive technical knowledge. We offer unparalleled global support.

What to Look for: Key Considerations When Buying Titanium Anodizing Systems

Procurement managers must consider several factors. System scalability ensures future growth. Energy efficiency reduces operational costs.

Safety features protect personnel and equipment. Comprehensive technical support is essential. Robust after-sales service guarantees long-term value.

Consider the total cost of ownership, not just the initial price. A reputable supplier offers transparent pricing and support.

Leading the Way: Top Titanium Anodizing Equipment Brands

The market features several reputable equipment brands. They distinguish themselves through innovation and quality. Proven performance is a hallmark of top suppliers.

These leaders offer cutting-edge technology. They provide reliable solutions for complex anodizing needs. Researching their track record is advisable.

Global Reach: Finding Reputable Anodizing Equipment Suppliers

Identifying global suppliers requires careful evaluation. Look for companies with a strong international presence. They should offer high-quality equipment and reliable service.

Regardless of location, consistent quality is paramount. China Titanium Factory maintains a global network. We ensure access to advanced anodizing solutions worldwide.

Customization and Scalability: Tailoring Solutions to Your Needs

Flexible equipment solutions are crucial. They adapt to specific production volumes. They also accommodate varying part sizes and process requirements.

Customized systems ensure long-term value. They optimize efficiency for your unique operations. Scalability allows for future expansion.

Beyond the Basics: Innovation and Value in Titanium Anodizing

We are committed to continuous innovation. Our goal is to address industry gaps. We provide advanced features that set our solutions apart.

This includes tools for optimization and sustainability. We deliver exceptional value beyond standard offerings. Our leadership drives progress in anodizing technology.

Interactive Tools: Anodizing Calculators and Configurators

Interactive tools simplify complex decisions. Anodizing calculators help estimate costs. Equipment configurators optimize system designs.

These tools provide immediate value to users. They streamline process parameter optimization. This empowers informed decision-making.

Making Informed Decisions: Equipment Comparison Tables

Detailed comparison tables are invaluable. They allow side-by-side evaluation of equipment. Features and specifications become clear.

This ensures a transparent purchasing process. It helps identify the best fit for your needs. Make confident, informed buying decisions.

| Feature | Standard Model | Advanced Model | Premium Model |

|---|---|---|---|

| Voltage Control | Manual Dial | Digital, Basic Programmable | Advanced PLC, Multi-step Programming |

| Current Ripple | <5% | <3% | <1% (Ultra-low) |

| Efficiency | >85% | >90% | >95% (Energy Star Rated) |

| Data Logging | No | Basic via USB | Comprehensive, Networked, Cloud Integration |

| Remote Access | No | Optional | Standard via HMI/SCADA |

Seeing is Believing: Video Demonstrations and Walkthroughs

Visual content offers invaluable insights. Video demonstrations showcase equipment in action. Virtual tours highlight operational efficiency.

They provide practical understanding of complex systems. Seeing the process helps in making informed choices. Explore our product videos for detailed views.

Real-World Success: Titanium Anodizing Case Studies

Case studies illustrate tangible results. They show how our equipment solves specific challenges. Clients across industries achieve success.

These stories demonstrate proven performance. They provide confidence in our solutions. Learn from real-world applications and outcomes.

Investment Insights: Understanding Titanium Anodizing Equipment Pricing

Equipment costs vary based on features and scale. Factors like automation level influence pricing. We offer transparent insights into investment ranges.

Focus on the long-term return on investment (ROI). Quality anodizing systems deliver lasting value. They reduce operational costs over time.

Sustainable Solutions: Environmental Impact of Modern Anodizing

Sustainability is a growing priority. Modern anodizing practices minimize environmental footprint. This includes waste reduction and energy-efficient designs.

We champion eco-friendly finishing solutions. Our equipment helps reduce chemical consumption. This supports a more responsible manufacturing future. For more on sustainable practices, refer to EPA Safer Choice initiatives.

Frequently Asked Questions About Titanium Anodizing Equipment

What is the typical lifespan of titanium anodizing equipment?

The lifespan varies significantly. It depends on maintenance, usage, and component quality. High-quality systems from reputable suppliers can last 15-20 years or more with proper care.

Can existing anodizing lines be upgraded for titanium?

Yes, often they can. Upgrading may involve new rectifiers, tank linings, and control systems. A detailed assessment by an expert is recommended to determine feasibility and cost-effectiveness. Our services page offers more information on system upgrades.

What are the primary safety considerations for titanium anodizing?

Safety is paramount. It includes handling corrosive electrolytes and high voltages. Proper ventilation, personal protective equipment (PPE), and emergency protocols are essential. OSHA guidelines provide comprehensive safety standards for chemical processes; refer to OSHA Chemical Safety for more details.

How does titanium anodizing compare to other titanium surface treatments?

Titanium anodizing offers unique benefits. It creates a highly adherent, biocompatible, and corrosion-resistant oxide layer. Other treatments, like PVD coatings, offer different property enhancements. The choice depends on specific application requirements.

What maintenance is required for titanium anodizing equipment?

Regular maintenance is crucial. This includes electrolyte analysis, tank cleaning, and rectifier calibration. Inspecting racks, fixtures, and cooling systems prevents downtime. Following manufacturer guidelines ensures optimal performance.

Elevate Your Titanium Finishing with Global Expertise

Ready to achieve unparalleled precision and reliability in your titanium anodizing operations? Partner with the industry leader.

Our advanced equipment and comprehensive support ensure superior results. Contact us today for a tailored solution that meets your exact needs.

Request a Quote Today