Introduction: Unlocking the Potential of Titanium Anodizing

Engineers and manufacturers often face a common hurdle: achieving a specific surface finish on titanium that meets stringent performance or aesthetic demands. Suboptimal surface treatments can compromise a component's lifespan, functionality, and market appeal. It's a real head-scratcher when a material as robust as titanium falls short due to a misstep in finishing.

The solution often lies in titanium anodizing. This electrochemical process transforms titanium's surface, enhancing its properties and opening up a world of possibilities. But not all titanium is created equal when it comes to anodizing. Different grades react distinctly, producing varied results in color, uniformity, and protective qualities.

This comprehensive guide cuts to the chase, detailing the nuances of titanium anodizing, the specific grades best suited for the process, and what to expect from each. We'll provide the technical insights you need to make informed decisions, ensuring your projects consistently hit the mark. Consider this your go-to resource for navigating the intricate world of anodized titanium.

What Exactly is Titanium Anodizing?

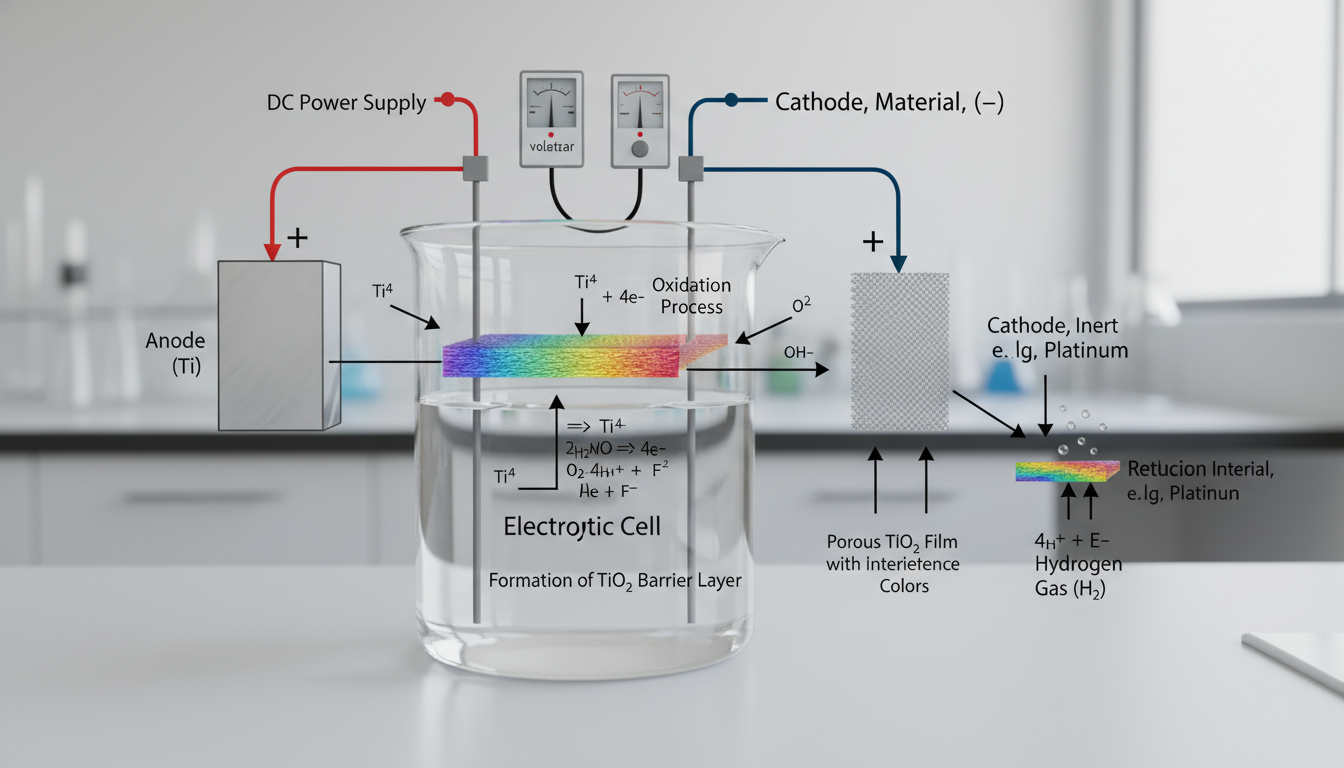

Titanium anodizing is an electrochemical passivation process. It’s not just a fancy paint job. This treatment intentionally thickens the naturally occurring oxide layer on the titanium surface, turning it into a robust, integrated protective coating.

Think of it as growing a superior skin on the metal. This enhanced oxide layer, typically titanium dioxide (TiO₂), is incredibly durable. It significantly improves corrosion resistance, wear resistance, and even biocompatibility. For applications where surface integrity is paramount, anodizing is a game-changer.

Definition: Electrochemical Passivation

An electrochemical passivation process uses an applied electrical current within an electrolyte solution to intentionally create or thicken a protective oxide layer on a metal's surface, thereby increasing its corrosion resistance and often altering its aesthetic properties.

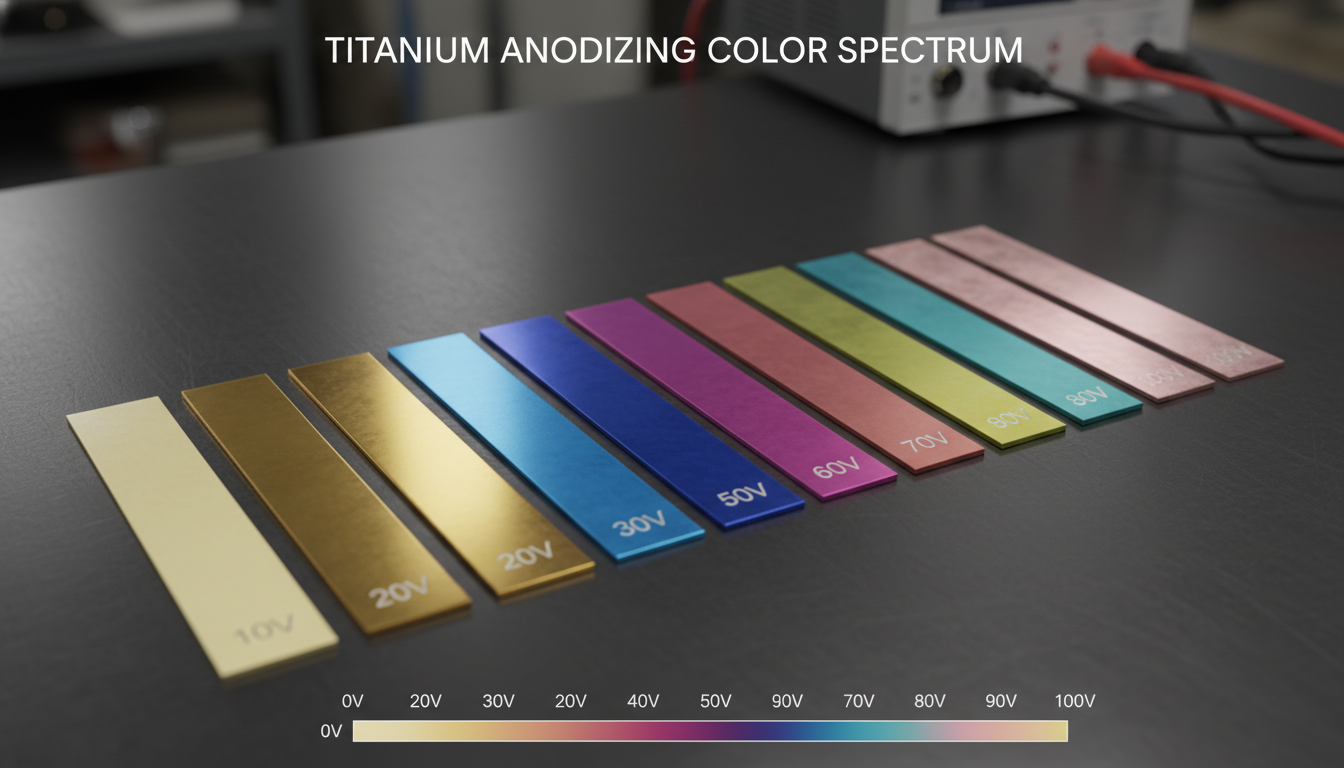

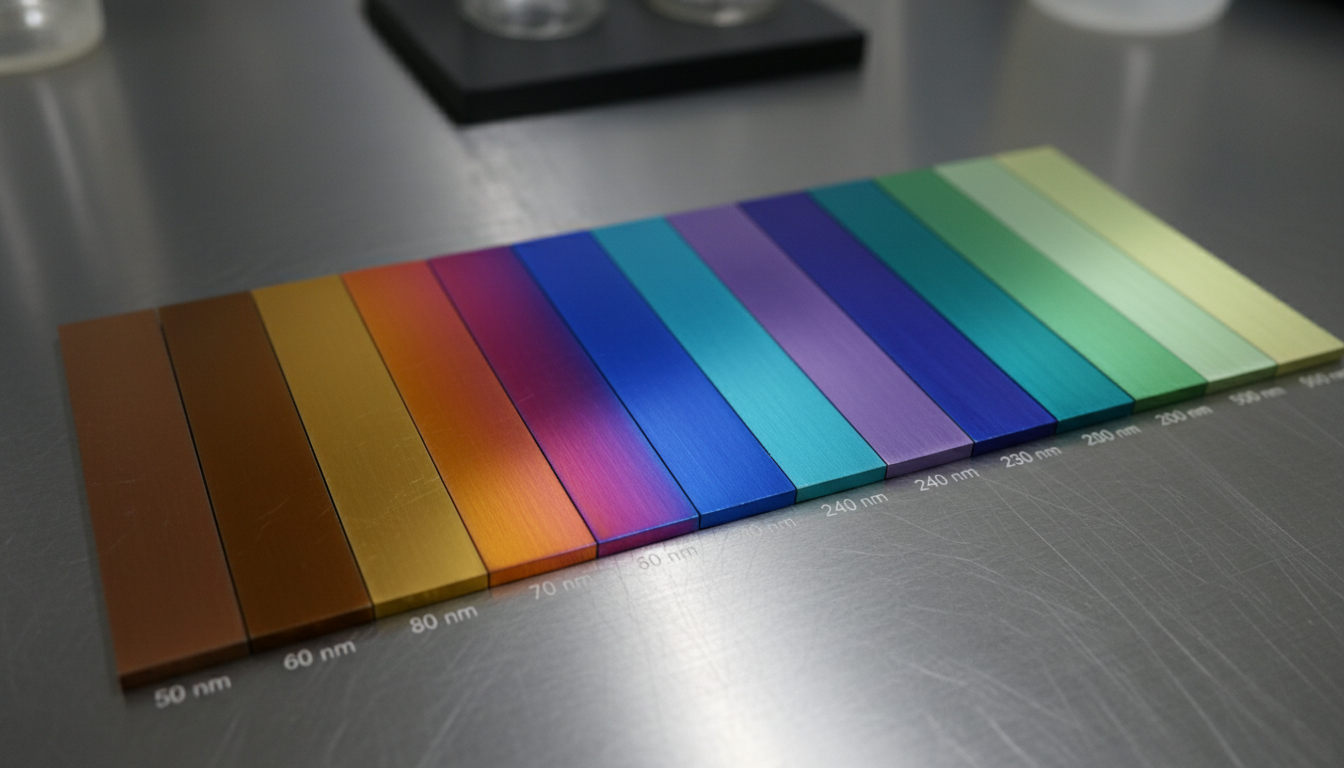

The Science Behind the Spectrum: How Voltage Creates Color

Here’s where it gets interesting: the vibrant colors you see on anodized titanium aren't dyes or pigments. They're a pure optical illusion, a trick of light interference. The thickness of the transparent titanium oxide layer dictates the perceived color.

During anodizing, titanium parts are submerged in an electrolyte bath – often a mild acid solution like phosphoric acid. A controlled electrical current is passed through the system. The titanium acts as the anode, and as electricity flows, oxygen ions from the electrolyte combine with the titanium surface to form a transparent oxide film. Varying the voltage directly controls the thickness of this film.

When light hits this film, some light reflects off the outer surface, while other light penetrates the film and reflects off the titanium metal underneath. These two reflected light waves interfere with each other. Depending on the film's thickness, certain wavelengths of light are amplified, while others are canceled out, resulting in a specific color perception. It's the same principle that creates colors in soap bubbles or oil slicks. This phenomenon is known as thin-film interference. For a deeper dive into the physics, you might consult resources like SPIE Digital Library on structural color.

Types of Titanium Anodizing: Distinguishing the Methods

While the basic principle remains consistent, titanium anodizing can be classified into different types, primarily based on the electrolyte used and the desired outcome. The most common distinction is between Type II (often referred to as medical or color anodizing) and hardcoat anodizing.

Type II Anodizing (Color Anodizing)

This is the workhorse for aesthetic and biocompatibility applications. It uses a mild acid electrolyte (like phosphoric acid or sulfuric acid at lower concentrations) and a relatively low voltage. The resulting oxide layer is thin, highly uniform, and offers a wide spectrum of colors through light interference. It's commonly used for medical implants, jewelry, and decorative components.

Hardcoat Anodizing (Type III Equivalent)

While less common for titanium than for aluminum, some processes aim for a thicker, harder oxide layer to enhance wear resistance. This typically involves higher voltages, lower electrolyte temperatures, and specific acid concentrations. The primary goal here is functional enhancement rather than aesthetic color, though some color may still result. This process is more complex and less standardized for titanium compared to aluminum.

It’s important to note that unlike aluminum, titanium doesn't have a universally recognized "Type I" chromic acid anodizing for thin, non-colored coatings or a distinct "Type III" hardcoat in the same way. The industry often refers to color anodizing (Type II) and specialized processes for wear resistance. For precision and adherence to specifications, it's crucial to work with a provider who understands these nuances, like the experts at China Titanium Factory.

Understanding Titanium Grades: Pure vs. Alloys

Before diving into anodizing specifics, it's vital to grasp the metallurgy of titanium. Titanium comes in two main categories: commercially pure (CP) and alloys. Their fundamental differences directly impact anodizing outcomes.

Commercially Pure (CP) Titanium

CP titanium, often designated as Grade 1, 2, 3, or 4, is essentially unalloyed titanium with varying levels of interstitial elements like oxygen, iron, hydrogen, and nitrogen. These elements influence the strength and ductility. The purer the grade (e.g., Grade 1), the softer and more ductile it is. As the grade number increases (e.g., Grade 4), so does the strength and hardness, with a slight decrease in ductility. CP grades are typically hexagonal close-packed (HCP) alpha phase at room temperature.

Their uniform chemical composition and microstructure make CP grades excellent candidates for anodizing. They tend to produce consistent, predictable colors across the surface, making them a favorite for aesthetic applications.

Titanium Alloys

Titanium alloys incorporate other metallic elements, such as aluminum, vanadium, molybdenum, and tin, to enhance specific properties like strength, creep resistance, or temperature performance. The most common is Ti-6Al-4V, known as Grade 5.

Alloys can have different microstructures: alpha, beta, or alpha-beta phases. These alloying elements and complex microstructures can influence the anodizing process. While alloys can be anodized, the presence of different elements might lead to variations in film thickness, color consistency, and overall appearance compared to CP grades. This is particularly true for complex alloys with multiple phases.

Key Titanium Grades for Anodizing: A Detailed Breakdown

Understanding which titanium grades perform best under anodizing conditions is paramount for achieving desired results. While all titanium can be anodized to some degree, certain grades are clear winners for specific applications, especially when consistent color and surface finish are priorities. Let's break down the key players.

| Titanium Grade | Composition/Key Properties | Anodizing Suitability | Typical Applications |

|---|---|---|---|

| Commercially Pure Grade 1 (CP1) | Softest, most ductile CP grade. Excellent formability. Lowest strength. | Excellent. Produces very consistent, vibrant colors. Ideal for aesthetic work. | Decorative items, architectural components, chemical processing equipment. |

| Commercially Pure Grade 2 (CP2) | "Workhorse" CP grade. Good strength, ductility, and corrosion resistance. | Excellent. Widely used for anodizing due to balanced properties and consistent color. | Aerospace, medical instruments, marine, general industrial. |

| Commercially Pure Grade 3 (CP3) | Higher strength than G2, with slightly less ductility. Good weldability. | Very Good. Reliable color consistency, slightly higher strength for structural needs. | Chemical processing, pressure vessels, marine components. |

| Commercially Pure Grade 4 (CP4) | Strongest CP grade. Moderate formability. Excellent corrosion resistance. | Good. Predictable color, but surface finish can impact vibrancy. Stronger applications. | Surgical implants, aerospace components, heat exchangers. |

| Titanium Grade 5 (Ti-6Al-4V) | Alpha-beta alloy. High strength-to-weight ratio, excellent fatigue resistance. | Moderate to Good. Can be anodized, but colors may be less vibrant and slightly less consistent than CP grades due to alloying elements. | Aerospace structures, medical implants, high-performance automotive. |

| Titanium Grade 23 (Ti-6Al-4V ELI) | Extra Low Interstitial (ELI) version of Grade 5. Improved ductility and fracture toughness. | Moderate to Good. Similar to Grade 5, often used for medical implants where anodizing adds biocompatibility and color coding. | Medical and dental implants, surgical components. |

For applications demanding both structural integrity and a striking visual finish, understanding these distinctions is paramount. For complex custom titanium fabrication and anodizing, consulting with specialists is always a smart move to ensure material compatibility and process optimization.

The Step-by-Step Titanium Anodizing Process

Achieving a flawless anodized finish isn't magic; it's a precise, multi-stage process. Each step is critical, with meticulous control required to ensure consistency and quality. Here’s a rundown of how it’s done:

1. Surface Preparation: Cleaning and Etching

This is where it all begins. Any oils, greases, or contaminants on the titanium surface will hinder proper oxide formation. Parts undergo thorough cleaning, often with alkaline degreasers, followed by rinsing. An optional etching step (using a mild acid or caustic solution) can remove minor surface imperfections and create a uniform matte finish, which can impact final color vibrancy.

2. Rinsing

After cleaning and etching, parts are meticulously rinsed with deionized water. This prevents cross-contamination of the anodizing bath and ensures no residues interfere with the electrochemical reaction.

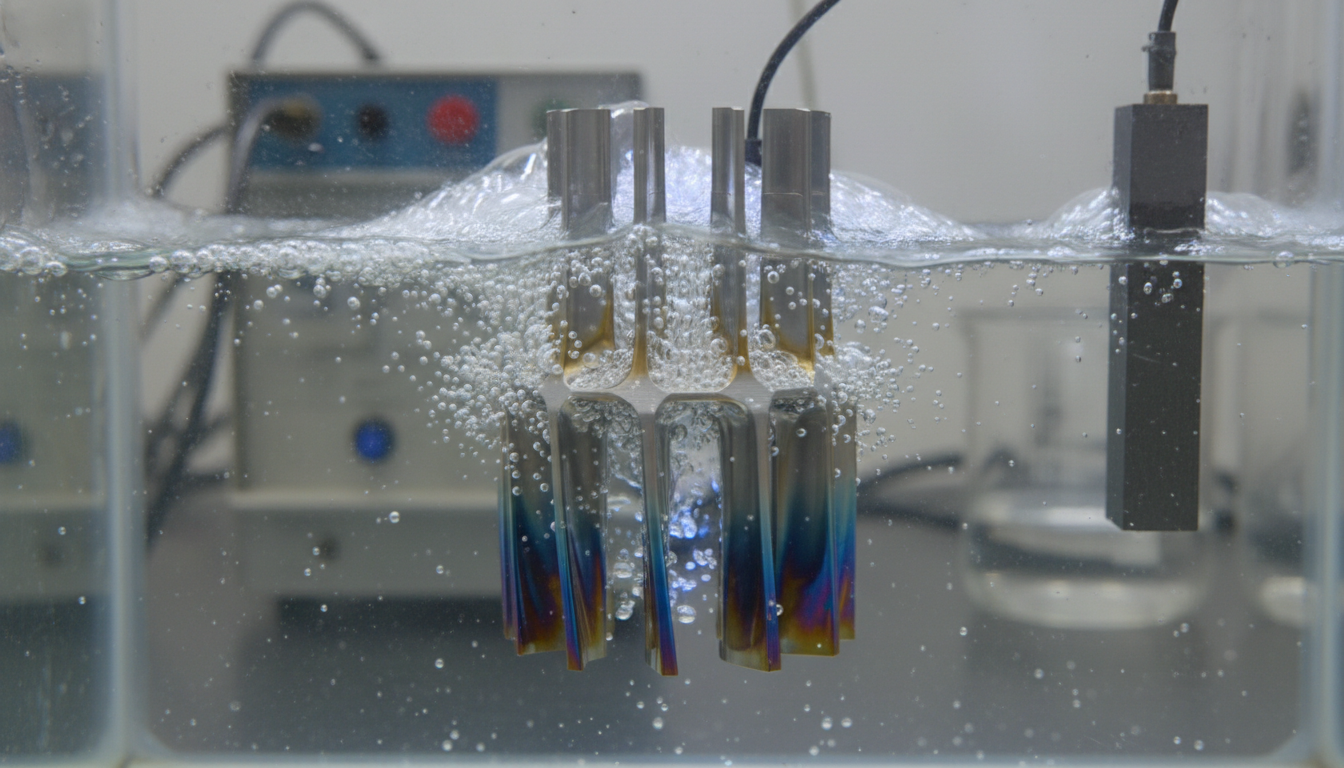

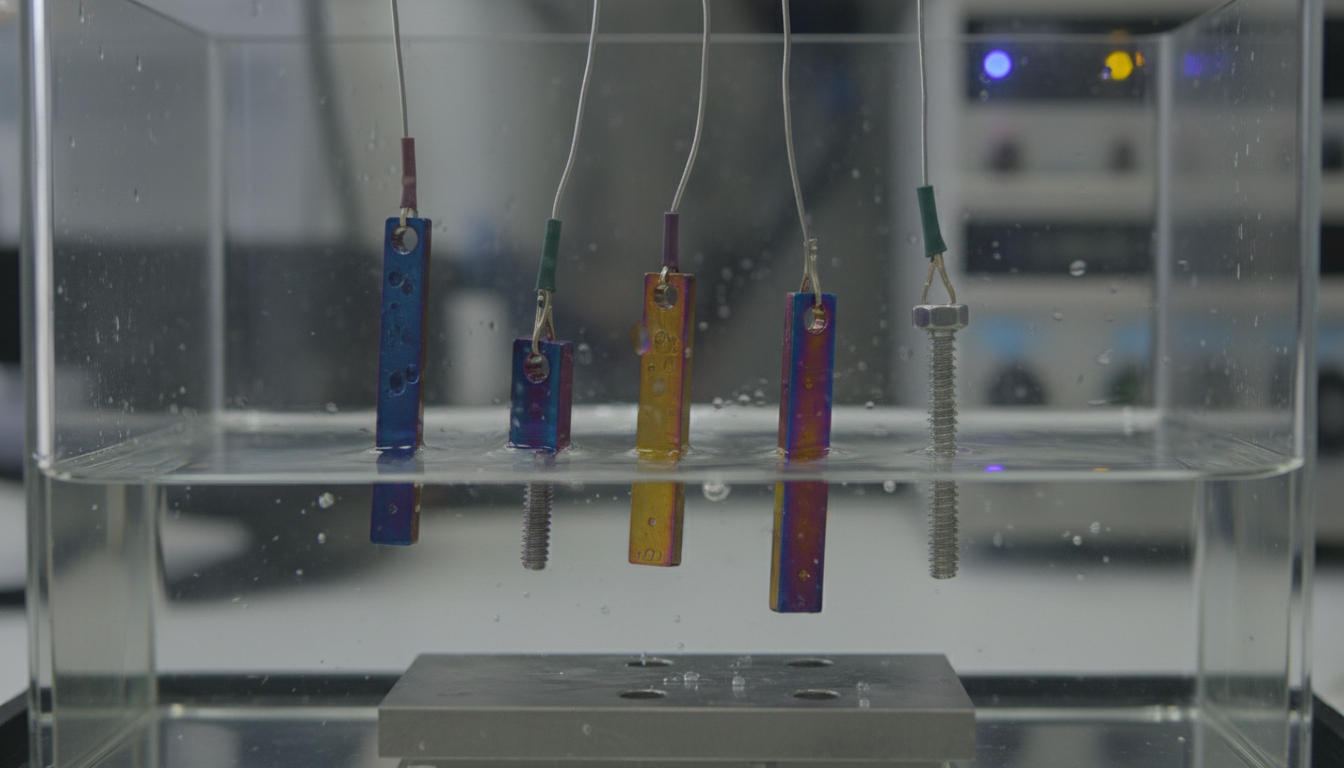

3. Anodizing Bath Immersion

The clean titanium components are then carefully immersed in the electrolyte bath. This bath typically contains a mild acid, like phosphoric acid, which acts as the medium for the electrochemical reaction but does not aggressively dissolve the titanium. Temperature control of the bath is crucial for consistent results.

4. Electrical Current Application

A DC power supply is connected, making the titanium component the anode (+) and an inert material (like stainless steel) the cathode (-). As voltage is applied, it's slowly ramped up to the desired level. The specific voltage determines the final oxide layer thickness, and thus the color. This step requires precise control to achieve the target hue.

5. Final Rinsing and Drying

Once the desired voltage is reached and held for a short period, the parts are removed from the bath and thoroughly rinsed again with deionized water to remove any residual electrolyte. Finally, they are dried, often with filtered air, to prevent water spots.

Each step needs a keen eye and strict adherence to protocol. Skipping corners here means you’re just asking for trouble down the line.

Benefits and Advantages of Anodized Titanium

Anodizing titanium is more than just a cosmetic upgrade. It’s a strategic engineering decision that yields a multitude of tangible benefits across diverse industries. The advantages extend far beyond mere visual appeal.

Enhanced Corrosion Resistance

Titanium is already known for its excellent corrosion resistance. Anodizing takes this a step further by thickening the passive oxide layer. This makes the surface even more impervious to harsh chemicals, saltwater, and biological environments, extending the lifespan of components in challenging conditions.

Improved Wear Resistance

The anodized layer is harder than the base titanium metal. This increased surface hardness translates directly to improved resistance against abrasion and wear, crucial for parts subjected to friction or repeated contact. While not a "hardcoat" in the aluminum sense, it still offers significant functional improvement.

Biocompatibility and Medical Applications

For medical devices and implants, biocompatibility is non-negotiable. The titanium dioxide (TiO₂) layer formed during anodizing is highly inert and non-toxic, making anodized titanium an ideal material for surgical instruments, dental implants, and prosthetic components. Different colors can also serve as a functional identification system for various implant sizes or types.

Aesthetic Appeal and Color Coding

The ability to produce a wide spectrum of vibrant, stable colors without dyes is a major draw. This allows for striking visual designs in jewelry, consumer electronics, and decorative elements. In industrial and medical settings, color coding can simplify assembly, differentiate components, or indicate specific functionalities.

Electrical Insulation

The titanium oxide layer is an electrical insulator. This property can be beneficial in certain electronic applications where controlled electrical conductivity or insulation is required on specific surfaces.

From aerospace components needing robust protection to medical implants requiring inert surfaces, anodized titanium often provides a distinct edge. It’s a testament to versatile material science.

Limitations and Considerations for Titanium Anodizing

While titanium anodizing offers significant advantages, it’s not a panacea. Like any industrial process, it comes with its own set of limitations and critical considerations that designers and manufacturers must understand to avoid unwelcome surprises.

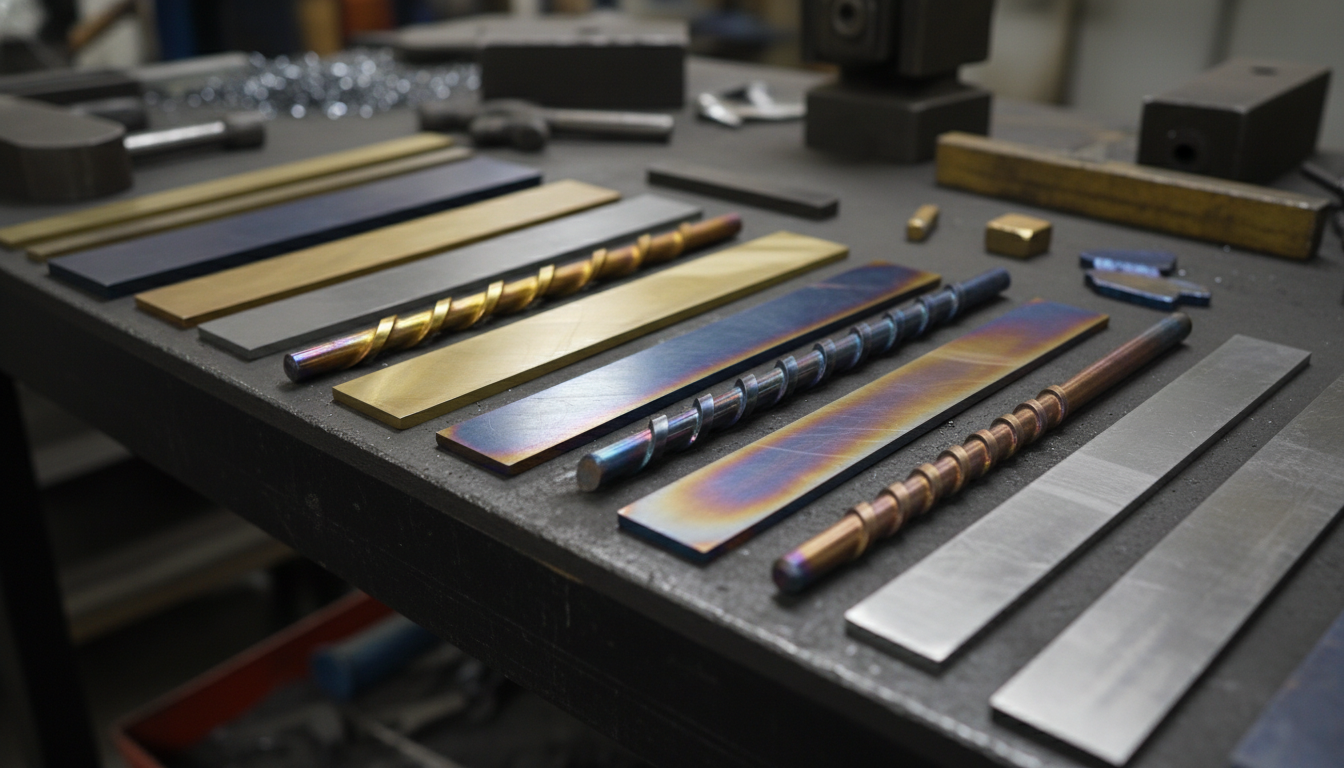

Surface Finish Impact on Appearance

The initial surface finish of the titanium component plays a huge role in the final anodized appearance. A highly polished surface will yield brighter, more reflective colors, while a bead-blasted or matte finish will result in a muted, satin look. Imperfections like scratches or uneven polishing will be amplified, not hidden, by the anodizing process. What you put in is what you get out.

Color Consistency on Alloys

As discussed, alloying elements in grades like Ti-6Al-4V (Grade 5) can lead to less uniform color compared to commercially pure titanium. The different phases within the alloy might react at slightly different rates, causing subtle variations in the oxide layer thickness and thus in color. Achieving perfectly uniform color on complex alloys can be a different ball game, requiring advanced process control.

Limitations of Oxide Layer Thickness

Unlike aluminum anodizing, where very thick, porous oxide layers can be grown, titanium anodizing produces relatively thin, dense oxide films. This means while wear resistance is improved, it won't achieve the extreme hardness or thickness of a true hardcoat aluminum anodize. The maximum practical thickness for color anodizing is usually around 200-300 nanometers, corresponding to higher voltages and specific colors.

Process Control Demands

Maintaining precise control over voltage, current density, electrolyte composition, and temperature is absolutely essential. Even minor fluctuations can lead to off-color results or inconsistent film quality. This isn't a process you can just wing. For instance, the purity of the water used for rinsing can impact the final finish, as detailed in studies on titanium surface treatments.

Navigating these considerations requires experience and specialized equipment. It's a prime example of why professional expertise is invaluable.

Choosing the Right Titanium Grade for Your Anodizing Project

Selecting the optimal titanium grade for anodizing is a critical decision that hinges on balancing desired properties with aesthetic goals. There's no one-size-fits-all answer; it's about aligning the material to the mission.

1. Prioritize Application Requirements

First and foremost, what does the component need to do? If it's a structural part in aerospace, strength and fatigue resistance (like Grade 5) will outweigh color consistency. If it's a medical implant, biocompatibility and fracture toughness (like Grade 23) are non-negotiable. The functional demands of the end-use application should always be your North Star.

2. Consider Aesthetic Goals

If consistent, vibrant color is a primary driver (e.g., jewelry, decorative accents, color coding), then commercially pure grades (Grade 1, 2, 3, 4) are generally your best bet. Grade 2 is often the sweet spot, offering a good balance of formability, strength, and excellent anodizing response. For more muted, functional colors, or if the structural requirements dictate an alloy, then Grade 5 or 23 can still be anodized effectively, albeit with potentially different aesthetic outcomes.

3. Evaluate Fabrication Needs

How will the component be manufactured? Grades with higher ductility (like CP1 or CP2) are easier to form and machine, which can streamline the overall production process. Consider how the material handles machining, welding, or bending before anodizing. The easier it is to work with, the smoother the journey from raw material to finished product.

4. Consult with Experts

When in doubt, lean on experience. Material specialists and anodizing service providers have a deep understanding of how different grades behave. They can offer invaluable guidance, helping you iron out the kinks before you commit to a production run. For reliable insights on titanium material selection and processing, look to established partners.

Professional Titanium Anodizing Services: What to Look For

While DIY anodizing exists, for complex projects, high-volume production, or applications with strict specifications, engaging professional Titanium Anodizing Services is not just a convenience—it's often a necessity. The precision required means leaving it to the pros can save time, money, and headaches.

Expertise and Experience

A reputable service provider brings a wealth of knowledge to the table. They understand the intricacies of different titanium grades, the subtle effects of surface preparation, and the precise voltage curves needed for specific colors. This expertise ensures consistent, high-quality results every time.

Advanced Equipment and Process Control

Professional facilities invest in specialized power supplies, precisely controlled electrolyte baths, and rigorous quality assurance protocols. This level of equipment and process monitoring is hard to replicate in-house, especially for demanding applications where tolerances are tight and failures are costly.

Quality Assurance and Certification

For industries like aerospace and medical, certifications (e.g., ISO standards) are non-negotiable. Professional anodizers operate under strict quality management systems, providing documentation and traceability for every batch. This provides peace of mind and ensures compliance.

Custom Solutions and Scalability

Whether you need a one-off prototype or thousands of components anodized, a professional service can scale to meet your needs. They can also offer custom solutions for unique geometries or specific aesthetic requirements, leveraging their deep understanding of the process. China Titanium Factory, for instance, offers comprehensive services from material sourcing to complex titanium manufacturing and finishing, including anodizing, ensuring a seamless production chain.

Frequently Asked Questions About Titanium Anodizing Grades

Does anodized titanium color fade over time?

The color of anodized titanium is quite stable. Since it's not a dye but an optical effect of the oxide layer, it won't fade like organic pigments. However, harsh abrasion or chemical exposure that damages the oxide layer can alter or remove the color. Under normal conditions, the color is very durable.

Can Grade 5 titanium (Ti-6Al-4V) be anodized effectively?

Yes, Grade 5 titanium can be anodized. However, due to its alloy composition, the colors may appear slightly less vibrant or consistent compared to commercially pure titanium grades (like Grade 2). It's still a viable option, especially when the mechanical properties of Grade 5 are essential for the application.

Is anodizing more expensive for certain titanium grades?

The cost difference for anodizing itself between grades is usually minimal. The primary cost drivers are the complexity of the part, surface finish requirements, and the volume of production. The initial cost of the titanium raw material itself will vary significantly by grade, with alloys generally being more expensive than CP grades.

How thick is the anodized layer on titanium?

The anodized layer on titanium is extremely thin, typically ranging from tens to a few hundreds of nanometers (nm). For comparison, a human hair is about 80,000 to 100,000 nm thick. This thinness is precisely what allows for the light interference that creates color.

What kind of surface preparation is best before anodizing?

Optimal surface preparation usually involves thorough cleaning and degreasing to remove contaminants. Depending on the desired final aesthetic, mechanical finishes like polishing, brushing, or bead blasting can be applied beforehand. A smoother, more reflective surface generally yields brighter, more vivid colors, while a matte finish gives a subdued, satin appearance.

Ready to Transform Your Titanium Projects?

Don't let guesswork hold you back. Partner with experts who understand the nuances of titanium grades and anodizing processes. From custom fabrication to precision anodizing, we're here to help you achieve unparalleled results.

Explore Our Titanium Services Today