What is Titanium Anodizing and Why Does it Matter?

Plain titanium, while incredibly strong and lightweight, often presents a rather muted, industrial gray. But what if your project demands a splash of color? Or perhaps enhanced surface properties without heavy coatings? That's where titanium anodizing steps in, a game-changer for countless applications.

Titanium anodizing is an electrochemical process. It intentionally grows an oxide layer on the surface of titanium parts. This isn't just a paint job; it's a fundamental alteration of the metal's outermost layer. The result? A stunning array of colors, improved durability, and even better biocompatibility.

This technique is a big deal in industries ranging from aerospace to medical devices. Jewelers and artists love it for its vibrant, non-fading colors. For anyone working with titanium, understanding anodizing is a serious advantage. When you source your materials, consider the finishing possibilities from suppliers like China Titanium Factory.

Titanium Anodizing: An electrochemical passivation process that forms a thin, protective oxide layer on the surface of titanium metal. This layer can produce a spectrum of interference colors and enhance surface properties like corrosion resistance and hardness.

The Science Behind the Shine: How Titanium Anodizing Works

This isn't magic. It's pure physics and electrochemistry. Titanium anodizing doesn't rely on dyes or pigments. Instead, it leverages the unique properties of light and a carefully controlled oxide layer.

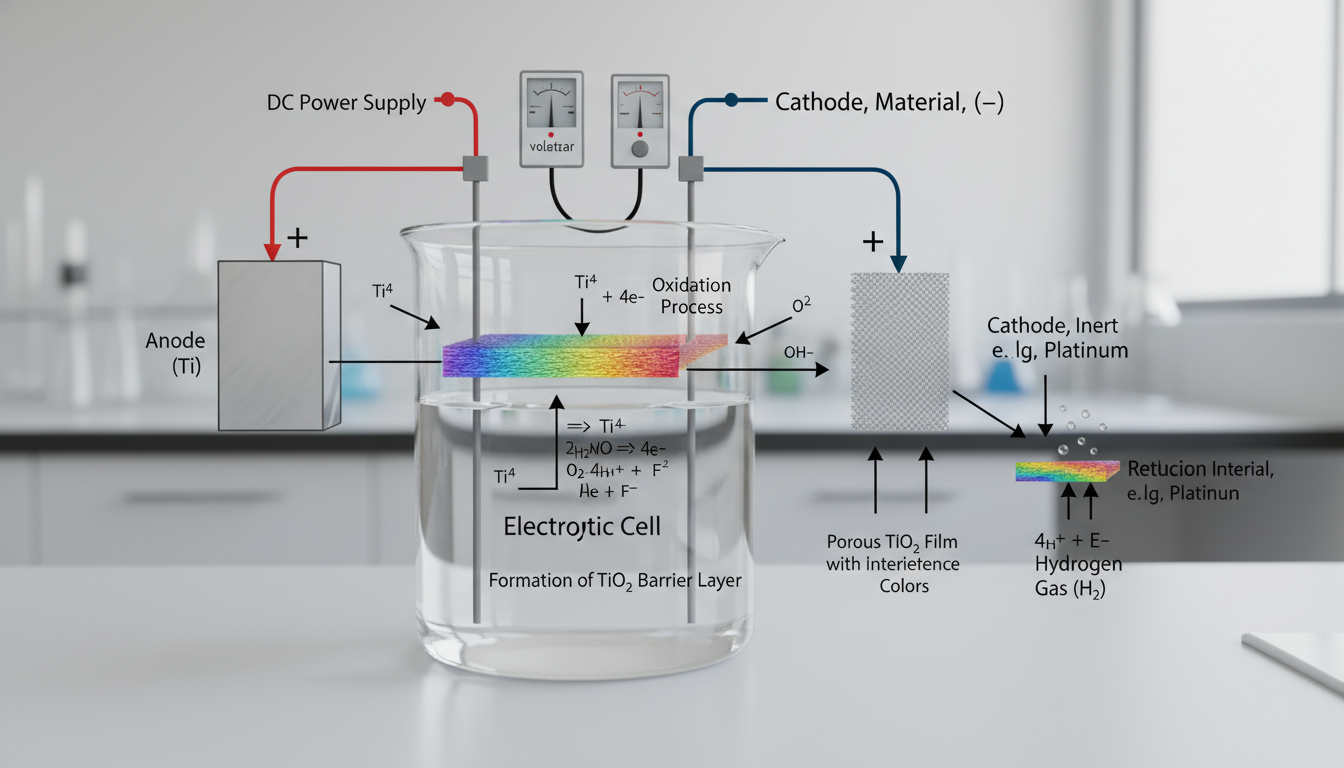

Here's the lowdown: When you immerse titanium in an electrolyte solution and apply an electric current, a controlled oxidation reaction occurs. This creates a transparent titanium dioxide (TiO₂) film on the metal's surface. The thickness of this film is directly proportional to the voltage applied during the process.

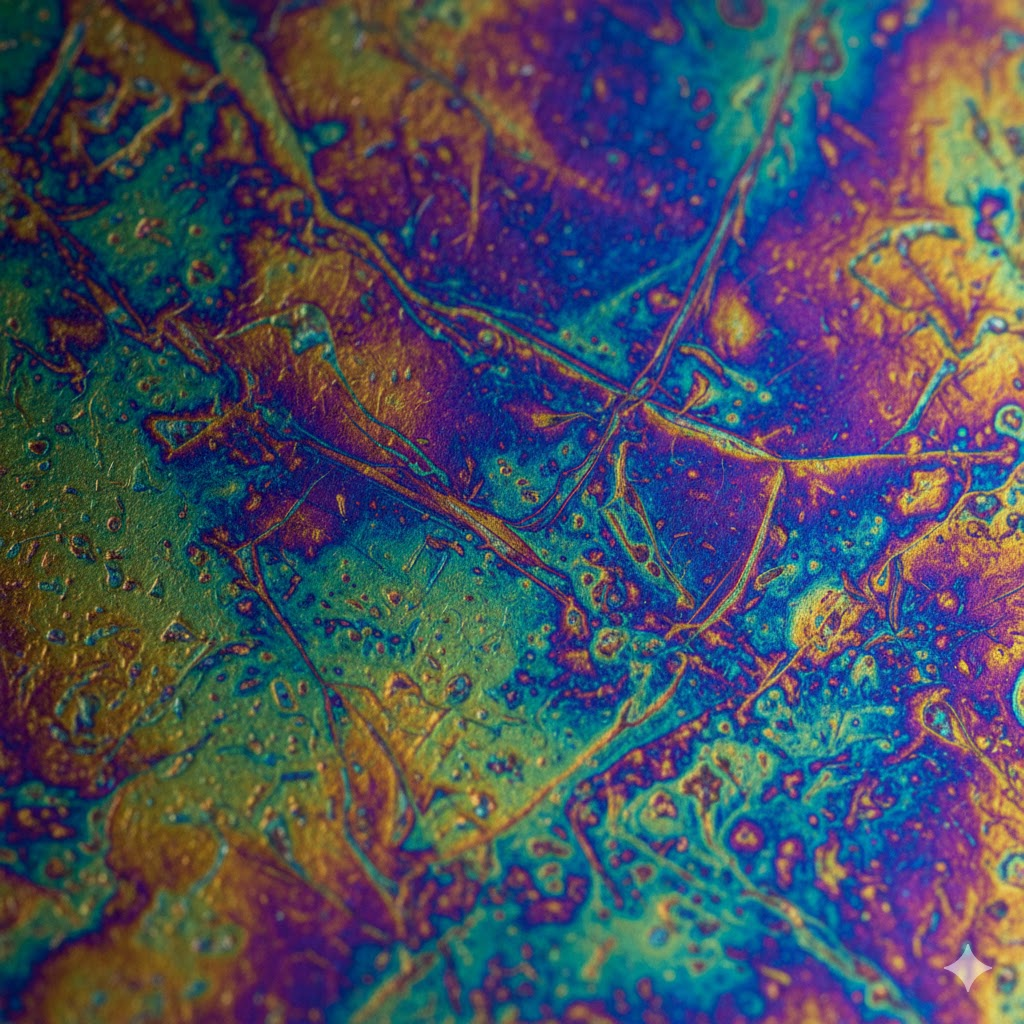

This thin film acts as an optical interference coating. Light waves hit the surface, with some reflecting off the top of the oxide layer and others passing through to reflect off the underlying titanium. These reflected waves interfere with each other. Depending on the film's thickness, certain wavelengths of light are amplified, while others are canceled out. The result is the perception of a specific color. Different voltages yield different thicknesses, hence different colors.

It's an elegant solution. No fading pigments. Just pure structural color. This process is distinct from anodizing other metals like aluminum, which typically require dyes for color. High-quality titanium materials from reputable suppliers are key to achieving consistent, vibrant results.

While the visual appeal is undeniable, anodizing titanium offers far more than just a pretty face. The process significantly enhances several critical material properties, making it invaluable across diverse sectors.

First, corrosion resistance gets a serious boost. The naturally formed oxide layer on titanium already offers excellent protection, but the anodized layer is thicker, more uniform, and less permeable. This makes anodized titanium exceptionally resistant to harsh chemicals and environmental degradation. It's why it's a staple in marine and chemical processing applications.

Next, consider biocompatibility. Titanium is already known for its compatibility with the human body. Anodizing further improves this. The inert, non-toxic oxide layer reduces the potential for ion release, making it even safer for medical implants, dental prosthetics, and surgical instruments. This is a crucial advantage. A study published inMaterials Science and Engineering Chighlights the enhanced biological response of anodized titanium surfaces.

Increased surface hardness is another perk. While the underlying titanium remains ductile, the surface oxide layer becomes harder. This provides improved wear resistance, extending the lifespan of components subject to friction or abrasion. Finally, the aesthetic versatility opens up a world of design possibilities. From vibrant jewelry to distinctive architectural elements, the ability to achieve a spectrum of colors without dyes offers unparalleled creative freedom. When looking for custom titanium solutions, remember these benefits and connect with experts at China Titanium Factory.

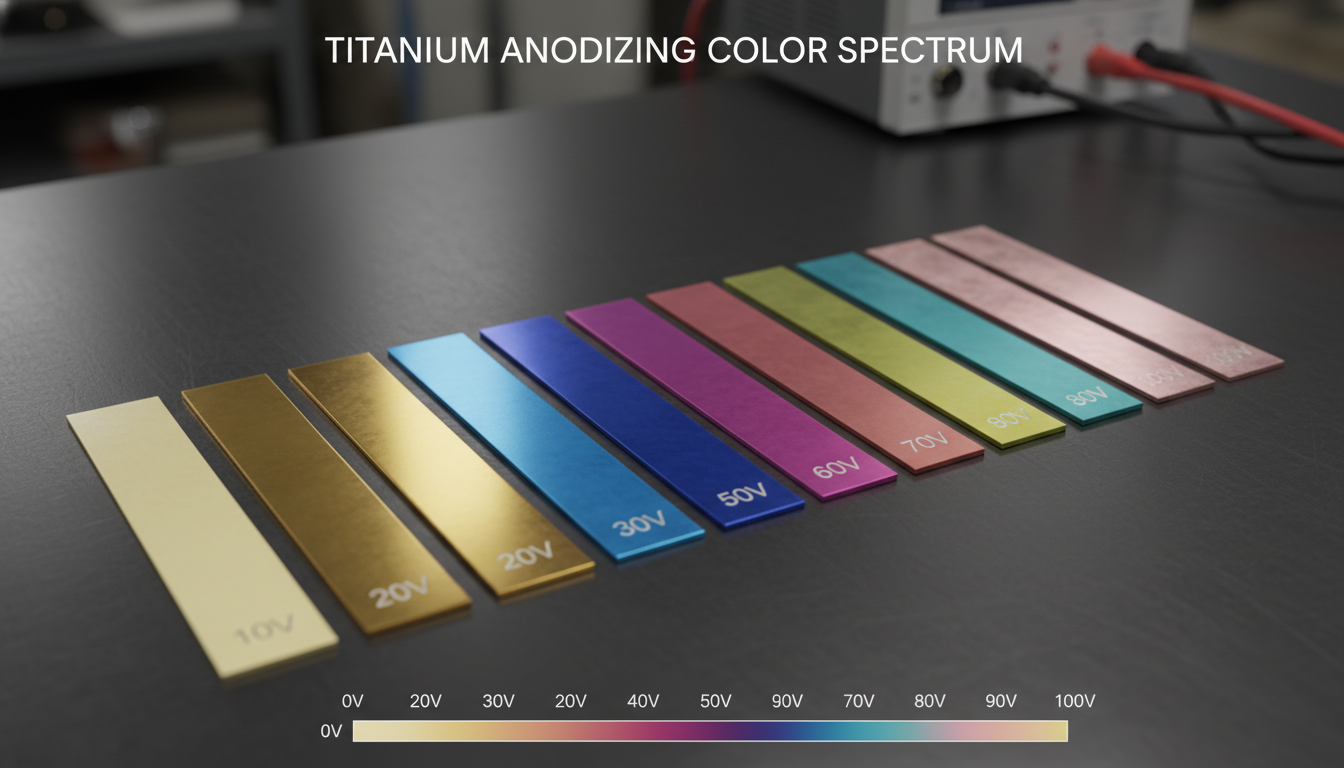

Your Color Palette: A Comprehensive Titanium Anodizing Color Chart

The beauty of titanium anodizing lies in its predictable voltage-to-color relationship. A little more voltage, a different hue appears. Mastering this relationship is key to achieving your desired aesthetic.

This chart serves as a general guide. Exact colors can vary slightly based on titanium alloy, electrolyte composition, surface finish, and specific equipment. Think of it as a starting point. Experimentation is part of the fun.

| Voltage (V) | Resulting Color | Notes |

|---|---|---|

| 10-20 V | Tan/Brown | Often subtle, can appear as a light bronze. |

| 20-30 V | Dark Blue/Purple | Rich, deep hues. |

| 30-40 V | Light Blue/Cyan | Bright, sky-like blues. |

| 40-50 V | Yellow/Gold | A popular choice for decorative items. |

| 50-60 V | Pink/Rose Gold | Delicate, often iridescent. |

| 60-70 V | Green | Can be tricky, often a yellow-green. |

| 70-80 V | Purple/Magenta | Vibrant, shifting purple. |

| 80-90 V | Light Green/Teal | Often shows hints of blue or yellow. |

| 90-100 V | Deep Gold/Bronze | Can revert to deeper golden tones at higher voltages. |

Remember, precision is king. A high-quality, stable power supply is crucial for consistent results. For industrial applications requiring specific hues and tolerances, partnering with experienced titanium finishing services is often the smartest move.

Anodizing Safely: Essential Precautions and Best Practices

Working with electricity and chemicals demands respect. Safety isn't optional; it's paramount. A small anodizing setup might seem benign, but overlooking precautions can lead to serious trouble. Don't cut corners here.

First, personal protective equipment (PPE) is non-negotiable. Always wear chemical-resistant gloves (nitrile or neoprene), splash goggles or a face shield, and a lab coat or old clothes. You don't want electrolyte splashing on your skin or in your eyes. Second, ventilation is key. The anodizing process can produce small amounts of hydrogen gas, and some electrolytes can emit fumes. Work in a well-ventilated area, preferably outdoors or under a fume hood. Good airflow keeps things safe.

Electrical safety demands attention. You're working with DC voltage, sometimes quite high. Ensure your power supply is properly grounded. Use insulated clips and wires. Never touch the titanium or electrodes while power is applied. Keep your work area dry. Spills and electricity don't mix. Finally, chemical handling. Electrolytes, typically containing phosphoric acid or TSP, require careful handling. Read the Safety Data Sheets (SDS) for all chemicals. Store them properly, away from children and pets. Dispose of waste solutions according to local regulations.OSHA guidelinesoffer comprehensive advice on chemical safety in the workplace, principles that apply to any chemical handling scenario.

Selecting Your Setup: Types of Titanium Anodizing Kits and Their Components

Choosing the right anodizing kit depends entirely on your ambitions. Are you a hobbyist looking to add flair to a few small pieces? Or an industrial designer needing precise, repeatable results on larger batches? There's a kit for every need.

Entry-level DIY kits are great for beginners. They typically include a basic DC power supply (often adjustable up to 120V), a small container for electrolyte, a titanium cathode, an anode wire, and some cleaning solution. These are perfect for jewelry makers, artists, or anyone testing the waters. They're usually compact and relatively inexpensive.

Professional-grade kits or industrial systems are a different beast. They feature highly stable, regulated power supplies capable of higher voltages and currents, often with digital readouts and programmable settings. They include larger tanks, specialized electrodes (often platinum-coated titanium for longevity), and a more comprehensive array of cleaning and post-treatment solutions. These setups are built for volume, precision, and durability. Regardless of scale, the fundamental components remain: a power supply (DC rectifier), an electrolyte bath (typically a mild acid or base solution), electrodes (titanium for the anode, stainless steel or titanium for the cathode), and connecting wires. Don't forget proper cleaning solutions for surface preparation. When planning larger projects, consider exploring specialized titanium products and expert consultation to ensure you have the right materials and setup.

From Prep to Polish: A Step-by-Step Guide to Titanium Anodizing

Getting it right means following the steps precisely. Skipping a stage or rushing the process often leads to uneven colors or poor adhesion. Take your time. Precision pays off.

Here’s a breakdown:

1. Surface Preparation is Paramount: This is arguably the most critical step. Any oils, dirt, or oxides on your titanium piece will prevent a uniform anodized layer.

Cleaning: Start with a thorough wash using soap and water. Ultrasonic cleaners work wonders for intricate pieces.

Degreasing: Use an appropriate degreaser, like acetone or isopropyl alcohol, to remove any remaining oils.

Etching (Optional but Recommended): For the best, most consistent colors, a quick etch in a mild acid (like a hydrofluoric acid solution – extreme caution advised) or even a simple TSP (Trisodium Phosphate) bath can remove surface impurities and create a uniform surface. Rinse thoroughly.

2. Set Up Your Anodizing Bath:

Container: Use a non-conductive container (plastic or glass).

Electrolyte: Fill with your chosen electrolyte. Common choices include TSP dissolved in distilled water, cola (phosphoric acid), or specialized anodizing solutions.

Cathode: Submerge your cathode (e.g., stainless steel sheet) into the electrolyte. Ensure it doesn't touch the titanium workpiece.

3. Wire Your Titanium Piece:

Attach a titanium wire to your workpiece. This wire will act as the anode. Ensure a good, tight connection. The connection point itself will not anodize.

Hang the workpiece in the electrolyte, ensuring it's fully submerged and not touching the cathode or the container walls.

4. Connect the Power Supply:

Connect the positive (+) lead from your DC power supply to the titanium wire (your workpiece).

Connect the negative (-) lead to the cathode.

Double-check all connections.

5. Apply Voltage and Observe:

Slowly increase the voltage to your desired level, referencing a color chart.

Watch the colors change! The process is usually quite fast, often taking mere seconds to a minute to reach the target color. Once the desired color is achieved and the current drops to near zero, the process is complete for that voltage.

6. Rinse and Dry:

Immediately remove the anodized piece from the electrolyte.

Rinse it thoroughly under running distilled water to remove all traces of electrolyte.

Gently pat dry or air dry. Avoid abrasive wiping that could scratch the fresh oxide layer.

7. Post-Anodizing Treatment (Optional):

Some prefer a quick dip in boiling distilled water to "seal" the oxide layer, enhancing its hardness and corrosion resistance slightly. This is more common in industrial aluminum anodizing but can be applied to titanium too.

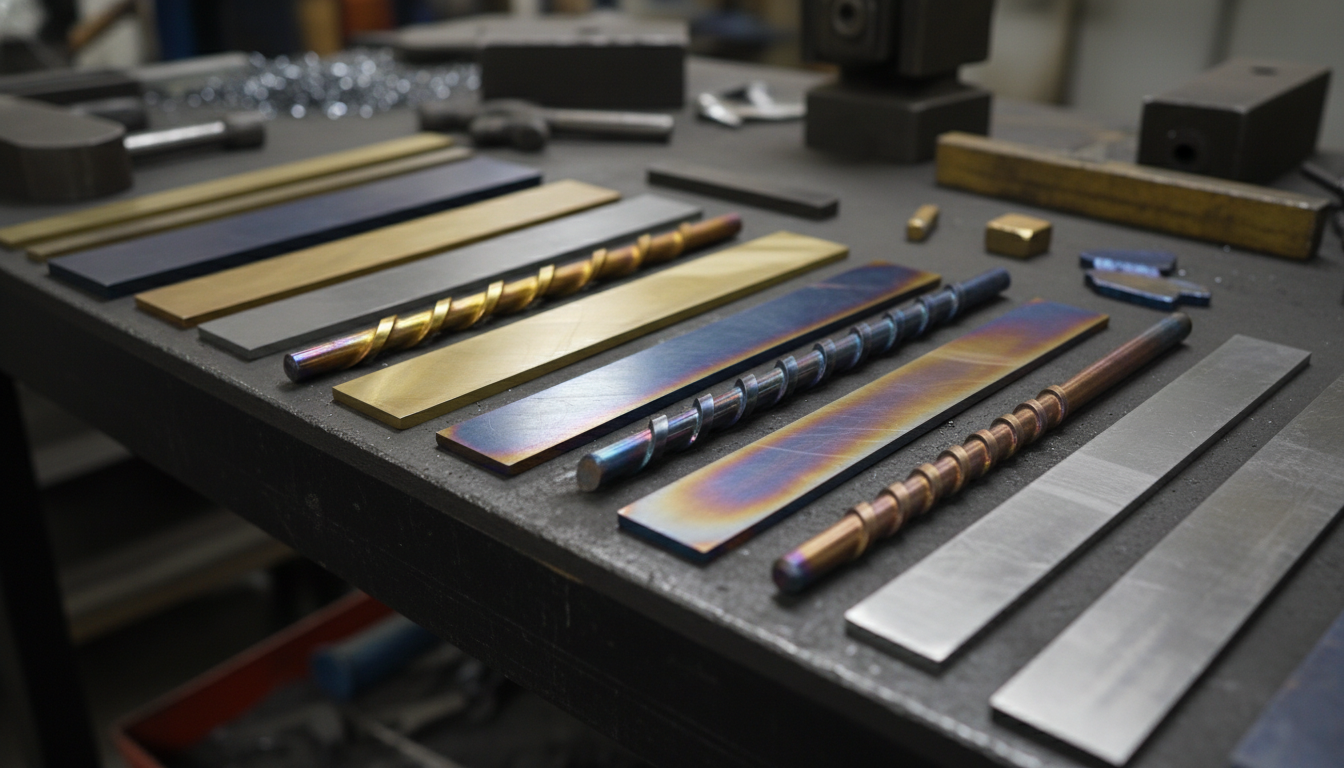

Beyond Basic Hues: Advanced Anodizing Techniques and Creative Projects

Once you've got the basics down, a world of creative possibilities opens up. Titanium anodizing isn't just about single, solid colors. You can achieve intricate patterns and gradients, pushing the boundaries of what titanium can be.

Multi-color anodizing is a popular technique. It involves selectively anodizing different areas of a piece at varying voltages. You can use masking agents, like nail polish or wax, to protect areas that have already reached a desired color. Anodize for one color, mask, then increase the voltage to anodize exposed areas to a higher color. Remove the mask, and voilà: multiple colors on one piece. Another approach is gradient anodizing, achieved by slowly dipping or raising a piece from the electrolyte while the voltage is applied, creating a smooth transition of colors. It takes a steady hand, but the results are captivating.

Etching before anodizing can also create stunning effects. Chemical or laser etching can produce patterns or textures that will be highlighted by the anodized layer. Imagine a deeply etched pattern, then anodized to a brilliant blue. Jewelers often use these methods for unique pendants, earrings, and rings. Artists create vibrant sculptures. Hobbyists personalize knife handles or bike components. The limit is your imagination. For specialized industrial components requiring specific patterns, consider reaching out to custom titanium fabrication services who can integrate advanced finishing options.

Solving the Snags: Troubleshooting Common Titanium Anodizing Problems

Even seasoned pros hit snags sometimes. Don't throw in the towel if your first few tries aren't perfect. Most issues stem from common culprits and have straightforward fixes. Let's tackle them head-on.

Problem: Inconsistent or Patchy Color. This is the most frequent complaint.

Solution: Almost always a surface preparation issue. Go back to basics: meticulously clean, degrease, and rinse. Even a fingerprint can cause a patchy spot. Ensure uniform etching if you're doing it.

Solution: Poor contact. Make sure your anode wire is tightly secured to the titanium piece, making solid electrical contact. The area under the clip won't anodize, so choose a discreet spot.

Solution: Contaminated electrolyte. Over time, electrolytes can get dirty. Replace it with fresh solution if you suspect contamination.

Problem: No Color Change, or Only a Faint Hue.

Solution: Check your power supply. Is it on? Is it set to DC? Is the voltage high enough for the color you want?

Solution: Verify your wiring. Is the positive lead connected to the titanium (anode) and the negative to the cathode? Reverse polarity won't work.

Solution: Weak electrolyte. Your solution might be too dilute or depleted. Try a stronger mix or fresh electrolyte.

Problem: Streaks or Lines on the Anodized Surface.

Solution: Air bubbles. Bubbles can cling to the surface during anodizing, preventing the oxide layer from forming evenly. Gently agitate the piece or electrolyte.

Solution: Uneven current distribution. Ensure the cathode is adequately sized and positioned to provide a uniform electrical field around your workpiece.

Don't be afraid to strip a piece (a quick dip in a mild acid can often remove the oxide layer) and start over. Persistence pays dividends. For critical applications, consistency in raw material quality is a big factor, something China Titanium Factory prioritizes.

Preserving the Brilliance: Care and Maintenance for Anodized Titanium

You've achieved that perfect vibrant hue. Now, how do you keep it looking fresh? Anodized titanium is tough, but a little care goes a long way in preserving its beauty and integrity.

The key is gentle cleaning. Avoid abrasive cleaners, scrub brushes, or harsh chemicals. These can scratch or degrade the thin oxide layer, dulling or removing the color. Instead, use a soft cloth, warm water, and a mild soap (like dish soap). Gently wipe the surface. Rinse thoroughly with clean water and pat dry with a soft, lint-free cloth. For intricate pieces, a soft-bristle brush (like a toothbrush) can help reach crevices.

Protect your anodized pieces from excessive wear and strong impacts. While the anodized layer adds hardness, it's still a surface coating. Repeated rubbing or sharp blows can wear it down or chip it, especially at edges. Store jewelry in soft pouches. For industrial components, design considerations should account for the surface finish. With proper care, your anodized titanium creations will maintain their captivating colors for years to come.

Your Definitive Buying Guide: Choosing the Best Titanium Anodizing Kit

Ready to jump in? Selecting the right titanium anodizing kit means weighing your needs against available options. Don't just grab the first one you see. Consider these factors carefully.

First, your budget and intended application. For small-scale jewelry or artistic projects, a basic DIY anodizing kit with a simple rectifier and small tanks might suffice. These are cost-effective and easy to set up. If you're planning larger pieces, batches, or require ultra-precise color matching for industrial components, you'll need to invest in a more robust, professional-grade system with a highly regulated power supply and larger capacity. These kits offer greater control and consistency but come with a higher price tag.

Next, examine the power supply specifications. Look for adjustable voltage output, ideally up to at least 120V for a full color spectrum. A stable, regulated output is crucial for consistent color. Digital readouts are a big plus. Consider the electrolyte type included or recommended. Some kits come with pre-mixed solutions; others expect you to source common household items like TSP. Think about the completeness of the kit. Does it include everything you need to get started, from electrodes and wires to cleaning solutions? Or will you need to buy additional components?

Finally, research brand reputation and customer reviews. Look for brands known for reliability and good customer support. A comparison table can help you visualize the differences:

| Feature | DIY/Hobbyist Kit | Professional/Industrial System |

|---|---|---|

| Price Range | $100 - $500 | $500 - $5000+ |

| Power Supply | Basic rectifier, often analog, 0-120V | High-precision, regulated, digital, programmable, higher voltage/current |

| Tank Size | Small (for jewelry, small parts) | Medium to large (for batches, larger components) |

| Electrolyte | TSP, household acids, or basic solution | Specialized industrial-grade solutions |

| Precision | Good for general colors, some variability | Excellent, highly repeatable color control |

| Best For | Hobbyists, artists, small-scale custom work | Production, research, high-volume/precision applications |

Hear From Users: Reviews, Testimonials, and a Gallery of Anodized Creations

Seeing is believing. The true impact of titanium anodizing comes alive in the hands of users. From intricate jewelry to custom bike parts, the possibilities are vast. Real-world examples solidify the technique's value.

"I never thought I could get such vibrant colors on my custom knife scales," says Alex, a hobbyist from Texas. "The anodizing kit made it straightforward. The blue is just stunning." Sarah, a jewelry designer, notes, "It's transformed my collection. Clients love the unique, non-fading hues. It really sets my pieces apart." These testimonials highlight the practical, aesthetic, and commercial advantages.

Imagine a gallery of anodized components: surgical-grade instruments with subtle color coding, aerospace fasteners in a striking gold, or custom art pieces shimmering with a full spectrum. The proof is in the pudding, or rather, in the brilliantly colored titanium. We're proud to see what our clients achieve with high-quality titanium raw materials and the anodizing process. The sheer diversity of projects underscores titanium's versatility and the power of this finishing technique.

Frequently Asked Questions About Titanium Anodizing Kits

Got questions? You're not alone. Here are answers to some of the most common queries about titanium anodizing kits and the process.

Is Titanium Anodizing Safe for Home Use?

Yes, with proper precautions. Many hobbyists successfully anodize titanium at home. The key is strict adherence to safety guidelines: wear PPE (gloves, goggles), ensure good ventilation, handle chemicals responsibly, and maintain electrical safety. Never leave an active setup unattended. Treat it like any other process involving electricity and mild chemicals. Be smart, be safe.

How Long Does Anodized Titanium Color Last?

Anodized titanium colors are exceptionally durable. Since the color is created by an optical effect within the oxide layer, not a dye, it won't fade from UV exposure. However, the physical integrity of the layer can be compromised by abrasion, harsh chemicals, or scratching. With reasonable care, anodized colors can last for many years, even decades. Think of it like a gemstone; its inherent color is stable, but the surface can still be damaged physically.

Can I Anodize Other Metals with a Titanium Kit?

Generally, no. Titanium anodizing kits are specifically designed for titanium. The electrolyte solutions and voltage ranges are optimized for forming a colored oxide layer on titanium. While some kits might technically work for niobium (which also forms interference colors), they are typically unsuitable for metals like aluminum. Aluminum anodizing uses different chemical processes and often requires dyes for color. Trying to anodize other metals with a titanium kit will likely yield poor results or no results at all.

Ready to Transform Your Titanium?

Unlock the full potential of titanium with vibrant, durable, and biocompatible finishes. Whether you're a designer, engineer, or hobbyist, the right titanium and the proper anodizing technique can bring your vision to life.

For premium titanium materials and expert processing advice that ensures exceptional results, trust the specialists.

Get a Quote for Your Titanium Project Today!