Navigating Titanium Anodizing Turnaround Times

You've got a project on the clock. Every minute counts. When it comes to specialized processes like titanium anodizing, delays can throw a monkey wrench into your entire manufacturing schedule. Engineers, product designers, and manufacturers often grapple with unpredictable lead times, leading to missed deadlines and budget overruns.

Understanding what drives these timelines is half the battle. This guide will walk you through the ins and outs of titanium anodizing services, dissecting the factors that influence turnaround times and equipping you with the knowledge to plan smarter and execute faster. Let's cut to the chase.

What is Titanium Anodizing and Why is it Essential?

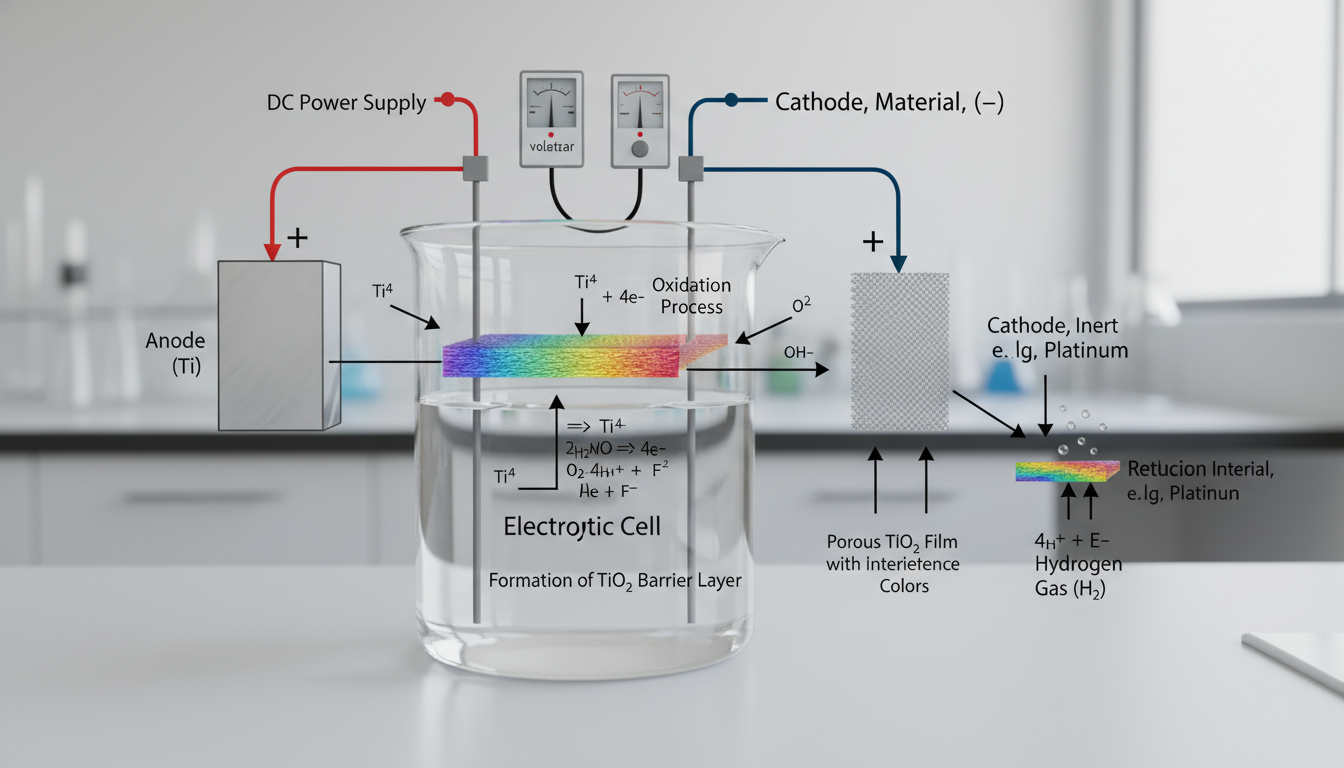

First things first: what are we talking about? Titanium anodizing isn't just a fancy coat of paint. It's a precise electrochemical process.

Titanium Anodizing: An electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of titanium parts. This process enhances corrosion resistance, wear resistance, and allows for aesthetic coloring without dyes.

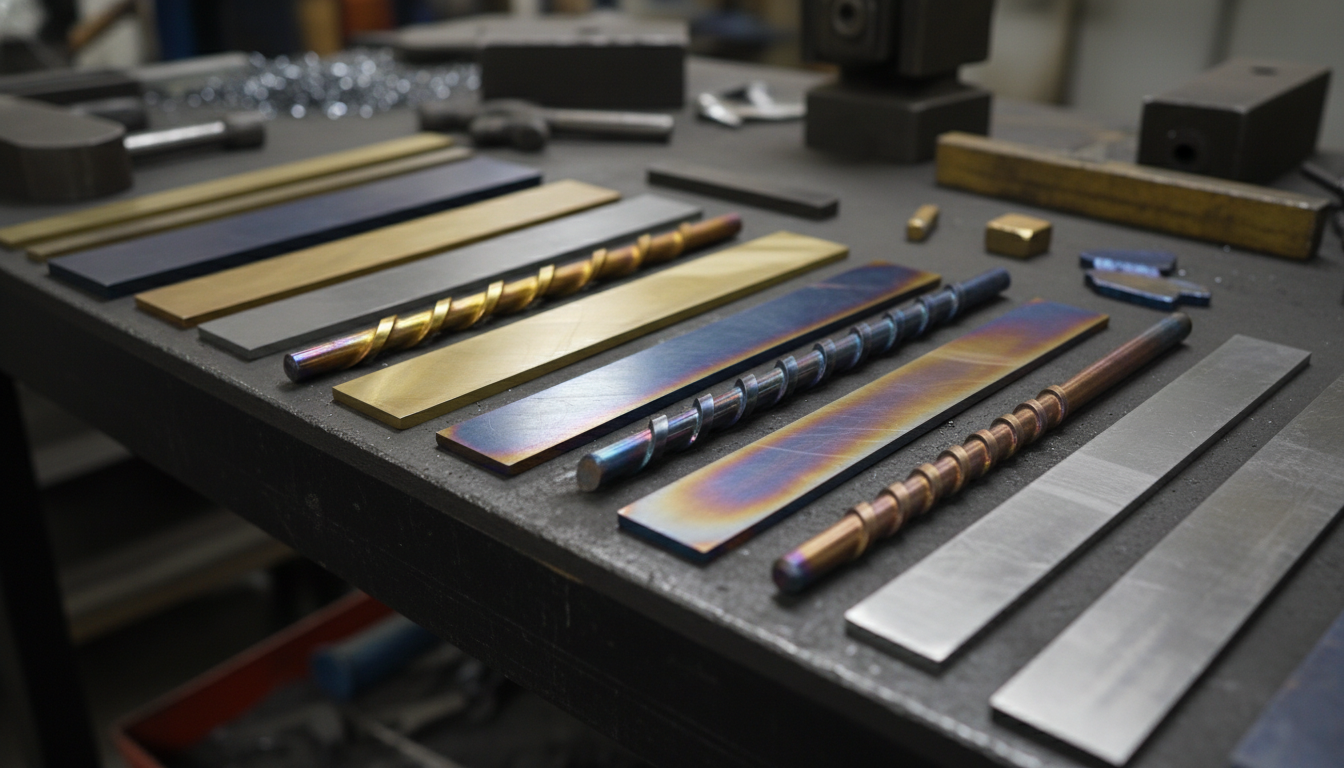

Why bother? Titanium already boasts impressive properties. But anodizing takes it up a notch. It forms a hard, durable, and highly adherent oxide layer. This translates to superior corrosion resistance, crucial for medical implants or aerospace components. It also offers unique aesthetic possibilities, creating vibrant, stable colors without fading. And for many applications, like medical devices, biocompatibility is paramount. Anodizing ensures that.

Types of Titanium Anodizing: From Functional to Aesthetic

Not all anodizing is created equal. There are different types, each serving specific purposes:

Type II (Medical & Functional): This type, often conforming to ASTM F86, produces a thin, clear oxide layer. It's essential for medical implants, improving biocompatibility and fatigue resistance. Think bone screws and dental implants.

Type III (Hardcoat): While less common for titanium than aluminum, some specialized hardcoat processes exist for enhanced wear resistance. It creates a thicker, denser layer for extreme durability.

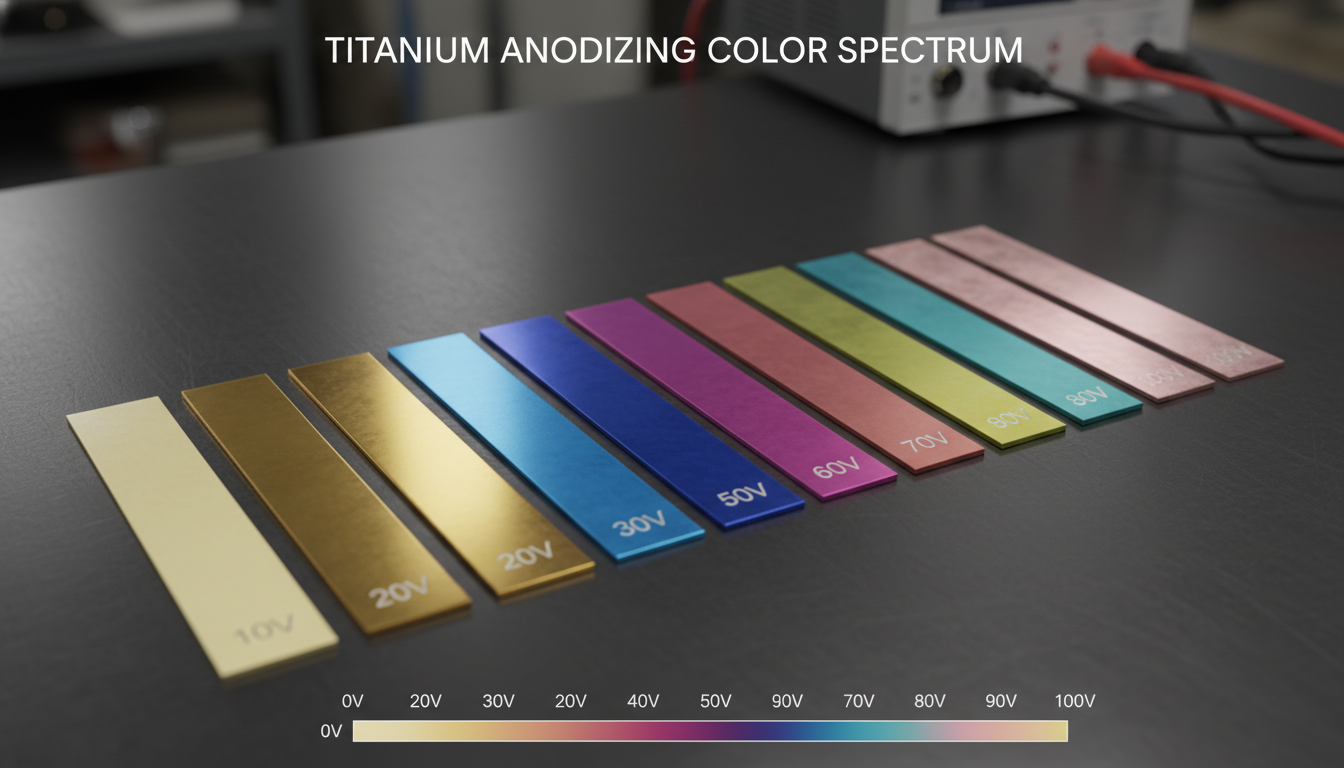

Color Anodizing: This is where the magic happens for aesthetics. By precisely controlling voltage, a spectrum of interference colors appears. No dyes are used; it's all about light refraction off the oxide layer.

The choice of type directly impacts the process parameters and, you guessed it, the turnaround time. Different specifications require different setups and checks.

The Step-by-Step Anodizing Process

To truly grasp turnaround times, you need to understand the journey a part takes. It's not a quick dip. Each stage is critical:

Cleaning & Degreasing: Parts must be surgically clean. Any oil, grease, or debris will lead to defects. This often involves ultrasonic baths and chemical degreasers.

Rinsing: Thorough rinsing after cleaning prevents cross-contamination.

Etching (Optional but Common): A mild acid etch can prepare the surface for better adhesion and a more uniform finish.

More Rinsing: Again, absolutely vital.

Anodizing Bath: The parts are immersed in an electrolyte solution (often phosphoric or sulfuric acid) and connected to a positive electrical current. The voltage and time determine the oxide layer's thickness and, for color anodizing, the final hue.

Final Rinsing & Drying: Post-anodizing, parts are meticulously rinsed to remove any residual electrolyte and then dried carefully.

Each step needs precise timing and control. Rushing leads to rejects. That's a waste of time and money.

The Impact of Anodizing Lead Times on Manufacturing Schedules

Efficient lead times aren't just a nicety; they're a necessity. In today's lean manufacturing environments, every delay ripples through the entire supply chain. A hiccup in anodizing can push back assembly, delay product launches, and ultimately cost a pretty penny.

Think about it: if your components are stuck in anodizing, your assembly line sits idle. Your inventory piles up. Customer satisfaction takes a hit. It's a domino effect. Reliable turnaround is crucial for maintaining project momentum and hitting those all-important deadlines. It's a real headache for project managers.

Unpacking the Variables: What Affects Your Anodizing Schedule?

Why do some jobs fly through while others crawl? Several factors play a role. Understanding these variables helps you get a clearer picture of your project's timeline and how to potentially speed things up.

Batch Size and Order Volume: Small Runs vs. Large Orders

It's simple math, really. A handful of parts requires less setup and processing time than a truckload. Small, specialized batches might get squeezed in faster if a facility has open capacity. However, large volumes often benefit from economies of scale in terms of scheduling, once they are on the docket.

Batch processing efficiency is key. A reputable titanium factory like China Titanium Factory, with extensive experience, can optimize its production capacity to handle diverse order volumes efficiently.

Part Complexity and Geometry: The Shape of Your Project

Intricate designs are a different ballgame. Parts with tight tolerances, internal channels, or areas requiring selective anodizing (masking) demand more labor and precision. Masking, for instance, is a manual process that adds significant time. The more complex the part, the longer it will take to prepare, process, and inspect.

Material Grade and Surface Finish: Starting Conditions Matter

Different titanium grades react slightly differently to anodizing solutions. While generally consistent, minor adjustments may be needed. More critically, the initial surface finish plays a huge role. Parts that are heavily contaminated, rough, or poorly machined will require more extensive pre-treatment, which naturally extends the overall lead time. Garbage in, garbage out, as they say.

Facility Capacity and Scheduling: The Provider's Perspective

This is often the biggest bottleneck. A facility's current workload, available equipment, and staffing levels directly impact how quickly they can slot your project in. If they're swamped, your job might wait. Good providers, however, manage their queues meticulously, offering realistic estimates based on their capacity.

Quality Control and Inspection Procedures

After anodizing, parts undergo rigorous quality checks. This isn't optional. Thickness measurements, visual inspections, adhesion tests, and potentially biocompatibility tests (for medical applications) all add time. While necessary, these procedures are a planned part of the turnaround. Skipping them is a recipe for disaster.

Adherence to standards like those from ASTM International ensures consistency. This commitment to quality, though it takes time, prevents costly reworks down the line. It's about getting it right the first time.

Shipping and Logistics Considerations

Don't forget the journey! The time parts spend in transit to and from the anodizing facility is part of your total project timeline. Packaging, shipping methods (ground, air freight), and potential customs delays for international orders all contribute. Factor this in, especially if your provider is geographically distant.

Selecting the Best Partner for Your Titanium Anodizing Needs

Choosing the right anodizing partner is paramount. It’s not just about price; it’s about reliability, quality, and hitting your deadlines. A good partner is an extension of your team.

Key Criteria for Evaluating Anodizing Companies

When you're vetting providers, keep these points in mind:

Experience & Expertise: How long have they been in the game? Do they specialize in titanium?

Technological Capabilities: Do they have modern equipment and processes? Can they handle your specific requirements (e.g., masking, custom colors)?

Reputation: What do their other clients say? Look for testimonials or case studies.

Customer Support & Responsiveness: Can you get a hold of them? Do they answer your questions thoroughly and promptly?

Communication: Are they proactive with updates? Do they clarify ambiguous specs?

Certifications and Industry Standards (ISO, ASTM)

Don't overlook this. Certifications like ISO 9001 indicate a robust quality management system. Adherence to industry standards such as ISO for manufacturing or ASTM F86 for medical titanium anodizing isn't just a badge; it's a promise of consistency and quality. It ensures they speak the same language as you do regarding specifications and performance.

Understanding Cost Estimation and Transparent Pricing

Get clear quotes. Understand what's included and what's extra. Are there setup fees? Charges for masking? Expedited service costs? Transparent pricing builds trust. Don't be shy about asking for a detailed breakdown. Nobody likes surprises on the invoice.

Communication and Project Management Expectations

A good partner keeps you in the loop. They provide regular updates. They flag potential issues early, not when it's too late. Effective project management from your anodizing partner can make or break your timeline. It’s better to have a heads-up about a minor delay than a last-minute shock.

Guaranteed Lead Times and Expedited Options

For urgent projects, ask about guaranteed lead times or expedited services. Many reputable providers offer these, often at a premium. Understand the conditions and costs involved. It’s like paying for a faster shipping option – sometimes, it’s worth every penny to keep your project on track.

Strategies to Streamline Your Anodizing Project

You're not just a passenger in this process. You can actively influence the speed and efficiency of your anodizing project. A little proactive planning goes a long way.

Effective Communication with Your Provider

Clear, concise, and complete information upfront is gold. Provide detailed drawings, material specifications, required finish, and any critical areas for masking. Don't leave anything to guesswork. Engaging with your anodizing partner early in the design phase can flag potential issues before they become expensive problems. It's about getting on the same page from day one.

Preparing Parts for Anodizing: Best Practices

The cleaner your parts arrive, the faster they get processed. Pre-treatment at your end can save significant time and cost. Ensure parts are free of heavy oils, machining coolants, or excessive burrs. A smooth, clean starting surface means less prep work for the anodizer and a higher chance of a first-pass success. This is where you can truly move the needle on turnaround.

Addressing Delays: Common Challenges and Solutions

Even with the best planning, sometimes things go sideways. What causes delays, and how can you fix them?

| Challenge | Impact on Turnaround | Solution |

|---|---|---|

| Unclear Specifications | Rework, clarification delays, incorrect finish. | Provide precise drawings and detailed requirements upfront. |

| Poor Part Preparation | Additional cleaning/etching steps, potential rejections. | Pre-clean parts thoroughly before shipment to the anodizer. |

| Unexpected Quality Issues | Reruns, re-processing, extended inspection. | Choose a certified vendor with robust QC, maintain open communication. |

| Logistical Hiccups | Shipping delays, customs hold-ups. | Plan shipping early, use reliable carriers, prepare customs documentation. |

The key is proactive communication and a solid partnership. Don't wait for problems to snowball. Tackle them head-on.

Success Stories: Real-World Anodizing Project Timelines

Let's consider a hypothetical scenario. A medical device company needed 5,000 intricately machined titanium bone plates anodized to ASTM F86 standards. Their previous supplier consistently missed deadlines, causing production bottlenecks.

By partnering with a facility like China Titanium Factory, they provided precise CAD files and an initial sample for pre-approval. The factory, leveraging its extensive capabilities, optimized its racking and batching for efficiency. Result? The entire order was completed and shipped within the agreed-upon 10-day lead time, including stringent QC. No drama, just delivery. This kind of reliability keeps projects on the straight and narrow.

Your Top Questions About Titanium Anodizing Turnaround Time Answered

What is the average titanium anodizing turnaround time?

There's no one-size-fits-all answer. For standard projects with moderate volume, expect anywhere from 5 to 15 business days. Highly complex parts, large orders, or specialized finishes might push that to 3-4 weeks. Always get a specific quote based on your project details.

Can I get expedited titanium anodizing services?

Absolutely. Most high-capacity facilities offer expedited options for a premium. This could reduce lead times by 30-50%, depending on their current workload and your part's complexity. Be prepared for an increased cost, as it often involves re-prioritizing production schedules.

How does part volume affect anodizing lead time?

Larger volumes generally mean longer overall processing times. However, the per-part time might decrease due to efficient batching. Small volumes can sometimes be processed faster if they fit existing runs, but dedicated small runs might have similar setup times to larger ones, making the per-part lead time seem higher.

What information do I need to provide for an accurate turnaround estimate?

To get a precise estimate, you'll need to provide:

Part drawings (CAD files preferred).

Titanium alloy grade.

Desired anodizing type (e.g., Type II, specific color).

Quantity of parts.

Any specific quality standards or certifications required (e.g., ASTM F86).

Masking requirements, if any.

Are there different turnaround times for color anodizing vs. Type II?

Not significantly in terms of the core process. Both involve similar cleaning, anodizing, and rinsing steps. However, color anodizing might require more precise voltage control and potentially more stringent visual inspection for color consistency, which could add marginal time. Generally, the difference isn't a deal-breaker for overall lead time.

Mastering Your Titanium Anodizing Project from Start to Finish

Navigating titanium anodizing turnaround times doesn't have to be a guessing game. By understanding the process, the variables at play, and how to select a reliable partner, you can take control of your project schedule. Proactive communication and meticulous preparation are your ace in the hole for efficient, on-time delivery.

Don't let unpredictable lead times leave you in a lurch. Equip yourself with knowledge, choose your partners wisely, and keep your projects humming. When you need a partner who understands the rhythm of manufacturing and delivers on time, every time, you know who to call.

Ready to Optimize Your Project Timelines?

Don't leave your titanium anodizing turnaround to chance. Partner with experts who deliver quality and punctuality. We're here to help you hit your deadlines, every time.

Get a Fast, Accurate Quote Today!