Precision Titanium Nitride (TiN) Coating Services for High-Performance Engineering

Surface failure is the silent killer of industrial productivity. In high-speed machining and aerospace applications, friction and abrasive wear lead to premature tool degradation and catastrophic component failure. Standard heat treatments often fall short. Modern engineering demands more. This is where professional titanium nitride coating services bridge the gap between material limitations and operational excellence.

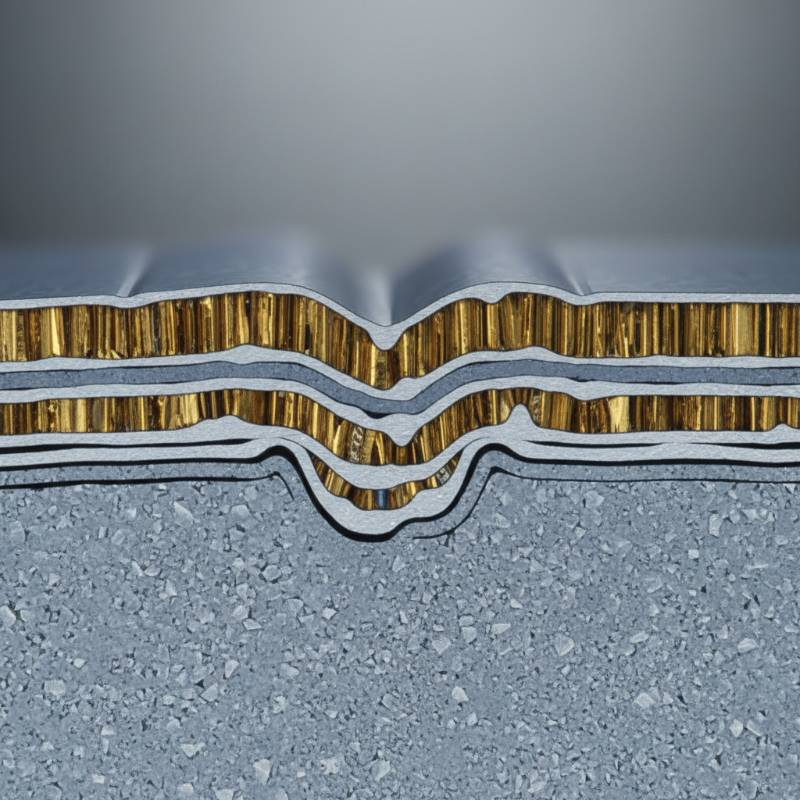

By utilizing Physical Vapor Deposition (PVD), we transform soft substrates into ultra-hard, low-friction surfaces. This isn't just a cosmetic finish. It is a molecular-level reinforcement. Our facility specializes in high-volume, high-precision titanium alloy components and specialized steel treatments that withstand the most punishing environments on the planet.

What is Titanium Nitride (TiN) Coating?

Titanium Nitride is a stoichiometric ceramic material. It is formed by combining titanium and nitrogen in a high-vacuum environment. While its striking gold color is iconic, its utility lies in its lattice structure. It is incredibly dense. It is chemically inert.

"Titanium Nitride (TiN) is a hard ceramic thin-film coating applied via PVD, characterized by a Vickers hardness exceeding 2,300 HV and a distinctive metallic gold appearance."

According to research published by ScienceDirect, the effectiveness of TiN depends entirely on the nitrogen-to-titanium ratio. At precision manufacturing levels, maintaining this ratio is the difference between a coating that flakes and one that survives 1,000 thermal cycles.

Technical Specifications and Material Properties

TiN is not a one-size-fits-all solution. The deposition parameters must be tuned to the substrate. We adhere to the Golden Rule of Stoichiometric Integrity: The coating is only as strong as the interface bond. If the substrate isn't prepared, the coating is useless.

| Property | Typical Value | Industrial Benefit |

|---|---|---|

| Hardness (Vickers) | 2,300 - 2,500 HV | Superior scratch/wear resistance. |

| Coeff. of Friction | 0.4 (Dry vs. Steel) | Reduced heat and galling. |

| Max Temp. | 600°C (1,100°F) | Thermal stability in cutting. |

| Thickness | 1 - 5 Microns | Maintains tight tolerances. |

The TiN-Sync™ Proprietary Deposition Protocol

Standard PVD can be inconsistent. We developed the TiN-Sync™ Protocol to solve the adhesion gap. This methodology focuses on synchronized plasma activation and multi-stage ion bombardment. It isn't just "spraying" a surface. It is an atomic-level integration.

The protocol follows three distinct phases:

Hyper-Purification: Substrates undergo ultrasonic cleaning followed by in-situ plasma etching to remove every trace of oxide.

Molecular Seeding: A pure titanium transition layer is deposited to act as a "glue" between the steel and the ceramic TiN.

Synchronized Growth: Nitrogen flow is throttled in real-time to match the evaporation rate of the titanium, ensuring a perfectly uniform ceramic lattice.

Industry-Specific Applications

Our titanium nitride coating services cater to sectors where failure is not an option. In the medical field, TiN is prized for its non-toxic, biocompatible nature. It prevents the release of metallic ions into the body from implants.

Medical and Orthopedic Implants

TiN provides a barrier for nickel-sensitive patients. Hip and knee replacements coated with TiN show significantly reduced polyethylene wear. It is the definitive choice for surgical instrumentation that requires repeated sterilization without losing its edge.

Aerospace and Defense

Fasteners, bearings, and engine components rely on TiN to prevent "cold welding." In the vacuum of space or the high-pressure environment of a jet turbine, lubrication often fails. TiN provides a permanent dry-lubricant surface that keeps parts moving.

Our Advanced PVD Coating Technologies

We don't rely on outdated equipment. Our facility utilizes both Cathodic Arc Evaporation and Magnetron Sputtering. Cathodic Arc is our workhorse for industrial tools. It offers the highest ionization rate, leading to superior adhesion. Magnetron Sputtering is reserved for decorative and high-precision electronic components where a "droplet-free" finish is mandatory.

According to ASM International, the development of filtered arc technology has virtually eliminated surface macro-particles. We implement these filtered systems to provide the smoothest TiN finishes available in the global market.

Quality Assurance, Certifications, and Global Logistics

Consistency is everything. Every batch processed at China Titanium Factory undergoes rigorous testing. We use Calotester thickness measurement and Rockwell C adhesion tests (HF1-HF6 scale) to verify every run.

We understand that logistics can be a bottleneck. Our Global Rapid-Transit Framework minimizes downtime. We offer end-to-end logistics support, handling customs and international shipping for clients in North America, Europe, and Southeast Asia. Our ISO 9001:2015 certified processes ensure that the part you receive in Munich is identical to the one tested in our lab.

Frequently Asked Questions: Technical Troubleshooting

Can TiN coating be removed if needed?

Yes. We offer specialized chemical stripping services. Our stripping agents selectively dissolve the TiN layer without attacking the underlying steel or titanium substrate. This allows for re-coating and refurbishment of expensive tooling.

What is the temperature limit for TiN?

TiN begins to oxidize at approximately 600°C (1,100°F). For applications exceeding this, such as high-speed dry machining, we recommend custom coating solutions like TiAlN (Titanium Aluminum Nitride), which handles higher thermal loads.

Does TiN coating change the dimensions of my part?

Minimally. The typical thickness is 2-4 microns. For most industrial tolerances, this is negligible. However, for ultra-precision gauge blocks, we can calibrate the TiN-Sync™ cycle for sub-micron deposition.

Ready to Elevate Your Component Performance?

Stop settling for rapid wear and frequent replacements. Leverage our advanced PVD technology to double your tool life today.

Get a Technical Consultation