Unlocking Titanium's Potential: An Introduction to Anodizing

Engineers and designers often grapple with optimizing material performance. Titanium, renowned for its strength-to-weight ratio and corrosion resistance, is a prime candidate for enhancement. But how do you push its boundaries further?

The answer often lies in surface treatments, specifically titanium anodizing. This electrochemical process transforms titanium's surface, imparting new properties like enhanced wear resistance, improved biocompatibility, or distinct aesthetic finishes. However, not all anodizing is created equal. Understanding the nuances between types is critical.

This guide cuts through the noise, offering a definitive comparison of Type 2 vs. Type 3 titanium anodizing. We'll lay out the processes, properties, and applications, giving you the clarity needed to make informed decisions for your next project. Let's dive in.

Titanium Anodizing Fundamentals: What You Need to Know

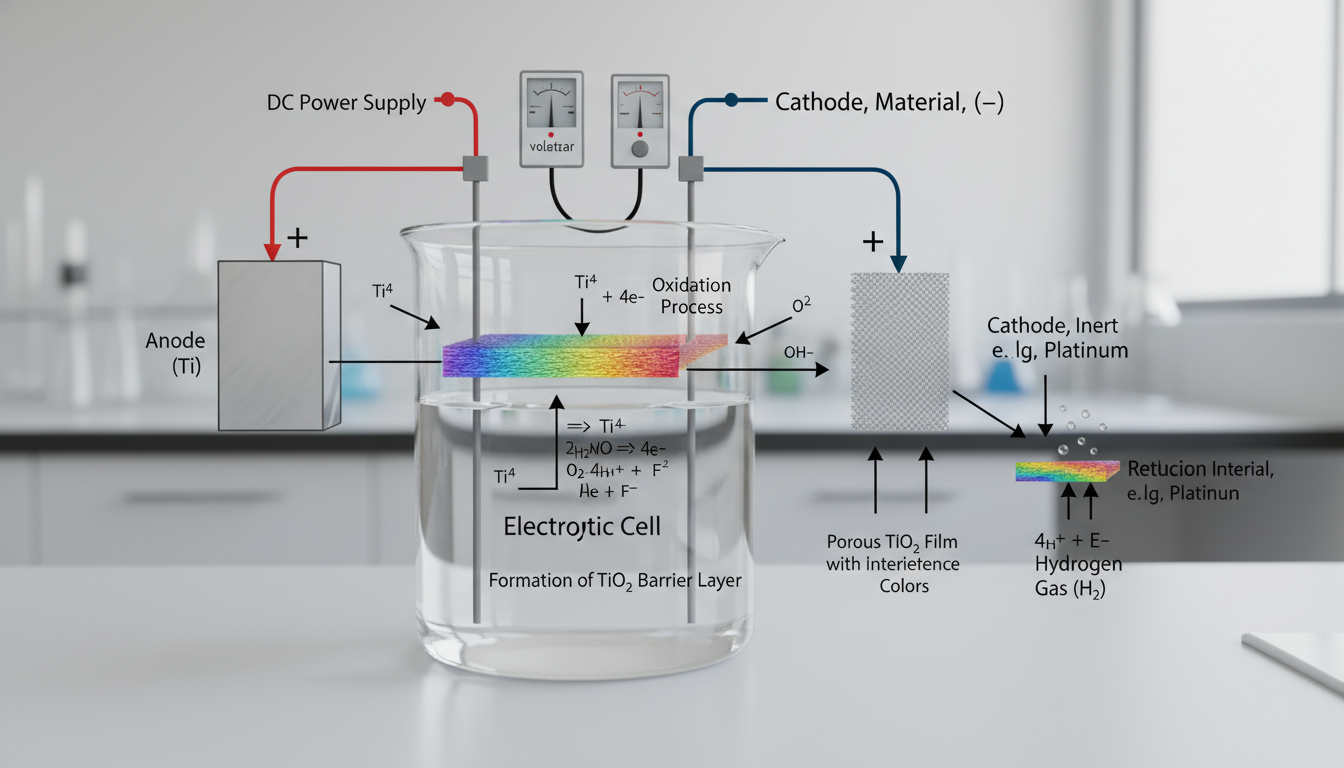

Titanium anodizing isn't some black magic; it's a controlled electrochemical process. We're talking about forming an oxide layer on the metal's surface. This isn't just a coating; it's an integral part of the material itself.

The primary purpose? To enhance specific surface properties. Think improved corrosion resistance, increased hardness, better wear characteristics, or even vibrant colors. It's about tailoring titanium for demanding environments.

Titanium Anodizing: An electrochemical passivation process that grows a protective oxide layer on the surface of titanium parts. This layer enhances corrosion resistance, wear resistance, and can provide aesthetic coloration.

This process begins with cleaning the titanium part, then submerging it in an electrolyte solution. An electrical current passes through, causing the titanium to oxidize, forming a uniform, highly adherent oxide film. The thickness and properties of this film depend heavily on the specific anodizing type and parameters used.

For those seeking comprehensive titanium finishing services, understanding these fundamentals is a solid first step.

Delving into Type 2 Titanium Anodizing (MIL-A-8625 Type II)

Type 2 titanium anodizing, often referenced by the aluminum standard MIL-A-8625 Type II, creates a relatively thin, controlled oxide layer. Don't let the "Type II" designation confuse you; while the MIL-spec is primarily for aluminum, the principles of a thinner, softer coating are applied to titanium in a similar context. It's a precise process, often involving phosphoric acid electrolytes.

Characteristics of Type 2 Anodized Titanium

Film Thickness: Typically thinner, ranging from 0.00005 to 0.00015 inches (1.27 to 3.81 microns).

Hardness: Softer than Type 3, providing good protection but less extreme wear resistance.

Corrosion Resistance: Excellent, inherently leveraging titanium's natural passivation.

Biocompatibility: Highly valued in medical applications due to its inert and non-toxic nature. It's often referred to as "medical grade" anodizing.

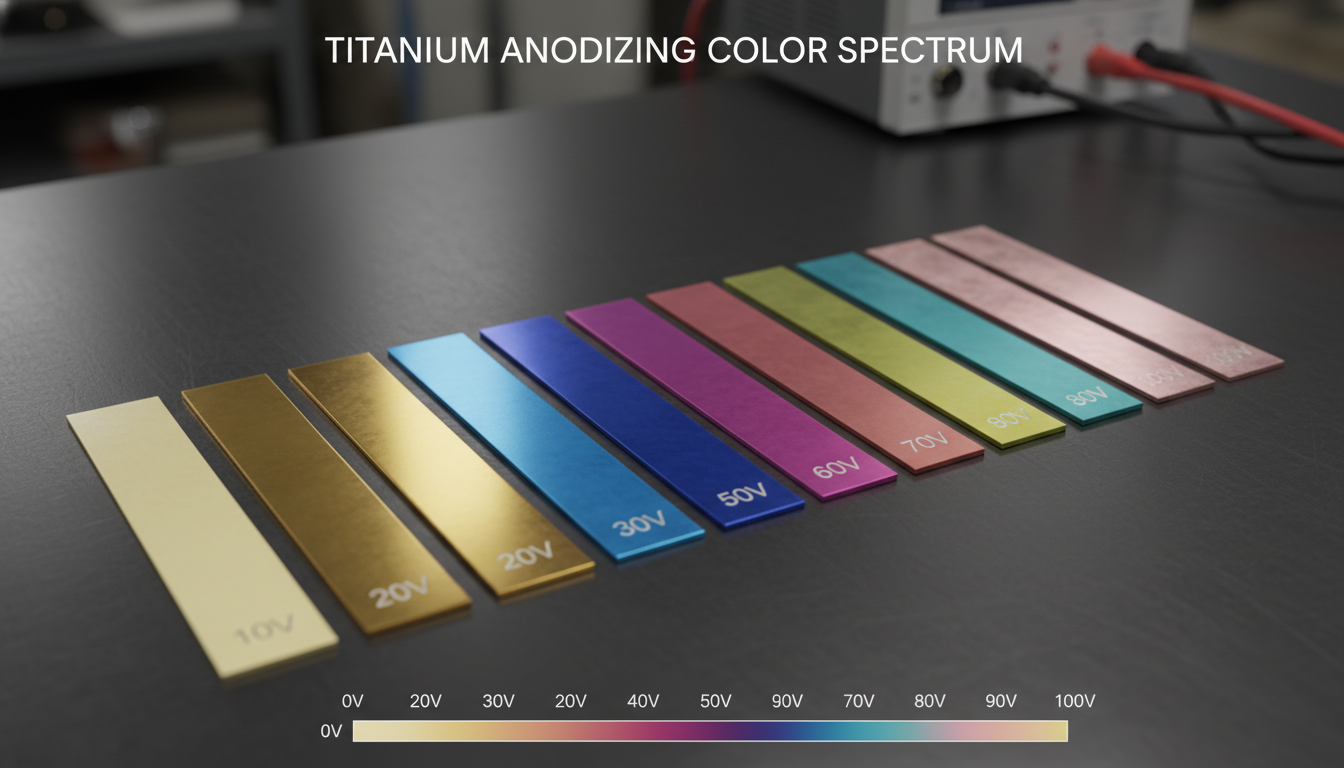

Aesthetics: Capable of producing a wide range of interference colors without dyes, depending on the oxide layer thickness and light refraction.

Applications and Advantages of Type 2 Anodizing

Type 2 finds its niche where aesthetics, biocompatibility, and moderate corrosion protection are key. Medical device manufacturers use it for surgical instruments, implants, and prosthetics. It’s also popular in consumer electronics and sporting goods for its appealing, dye-free color finishes and enhanced surface durability.

The main advantages include its superior biocompatibility, excellent corrosion resistance, and the ability to achieve attractive, stable colors. It's a workhorse for many industries.

Disadvantages of Type 2 Anodizing

While robust, Type 2 isn't a silver bullet. Its thinner film means it offers less abrasion and wear resistance compared to its Type 3 counterpart. If your application involves significant friction or harsh mechanical stress, Type 2 might not be tough enough to go the distance.

Exploring Type 3 Titanium Anodizing (Hardcoat Anodizing)

When you need titanium to take a beating and come back for more, Type 3 anodizing—often called hardcoat anodizing—is your go-to. This process is engineered for maximum durability. It involves specific electrolyte compositions, often sulfuric acid, and lower temperatures to grow a much thicker, denser oxide layer.

Characteristics of Type 3 Anodized Titanium

Film Thickness: Significantly thicker, ranging from 0.0005 to 0.004 inches (12.7 to 101.6 microns). This added bulk is critical for performance.

Hardness: Exceptionally hard, rivaling tool steel. This is where Type 3 truly shines.

Wear Resistance: Outstanding. It's built to withstand severe abrasion and sliding wear.

Corrosion Resistance: Superior due to the increased film thickness and density.

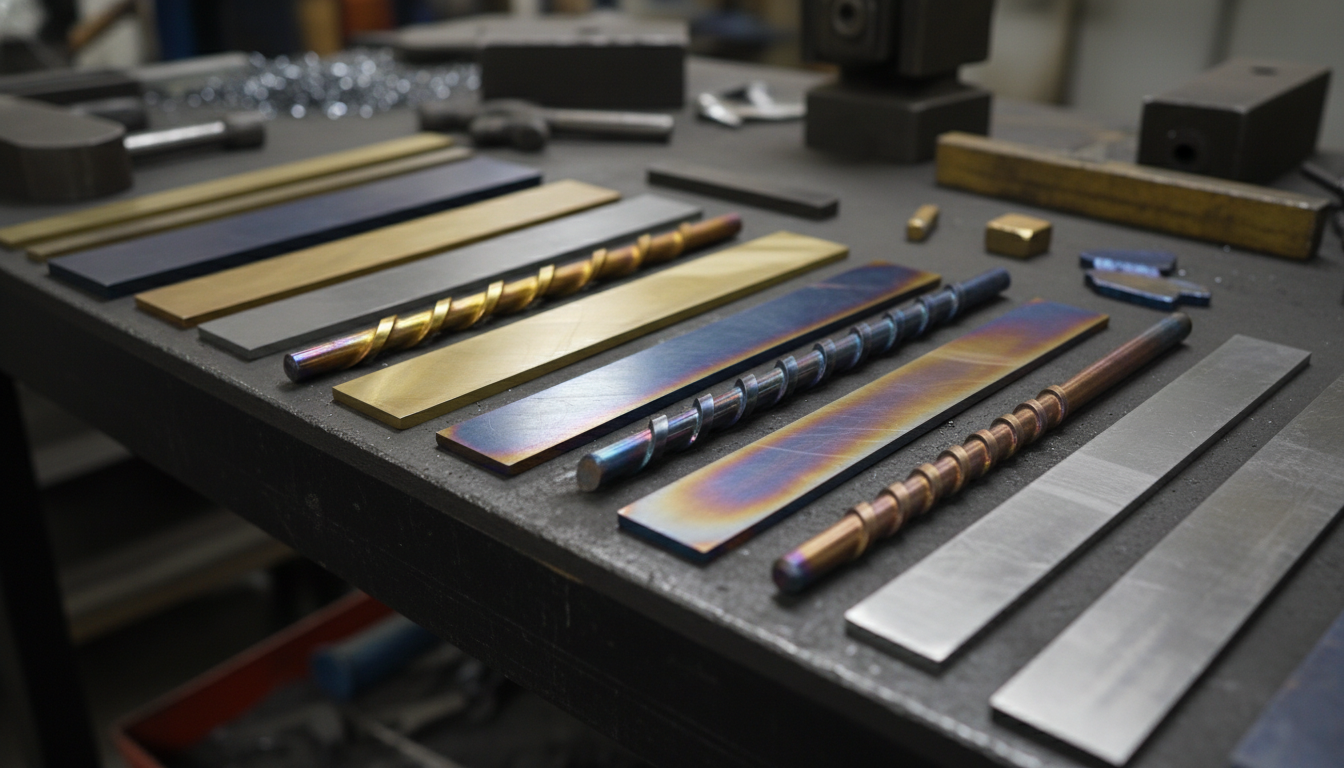

Aesthetics: Typically a darker, more muted gray or bronze finish. Colors are generally not a primary consideration or benefit.

Applications and Advantages of Type 3 Anodizing

Type 3 hardcoat anodizing thrives in harsh environments. Aerospace components, military hardware, high-performance automotive parts, and industrial machinery often rely on its robust properties. Wherever extreme wear, abrasion, or heavy loads are anticipated, Type 3 steps up.

Its unparalleled hardness and wear resistance are its biggest draws. It significantly extends the service life of components, providing a major return on investment.

Disadvantages of Type 3 Anodizing

The strength of Type 3 also presents its limitations. The thicker film can affect dimensional tolerances, requiring careful masking or post-machining. While highly corrosion resistant, the process itself is more complex and often more costly. Plus, the aesthetic range is limited compared to Type 2.

Finding a partner capable of custom titanium fabrication and precise anodizing is key for demanding projects.

Type 2 vs. Type 3 Titanium Anodizing: A Head-to-Head Comparison

Picking the right anodizing type is like choosing the right tool for the job. You wouldn't use a sledgehammer to tap in a small nail, right? Let's get down to brass tacks and compare Type 2 and Type 3 side-by-side.

| Feature | Type 2 Anodizing | Type 3 Anodizing (Hardcoat) |

|---|---|---|

| Process | Electrochemical (e.g., Phosphoric acid, room temp) | Electrochemical (e.g., Sulfuric acid, low temp) |

| Film Thickness | Thin (1.27 - 3.81 microns) | Thick (12.7 - 101.6 microns) |

| Hardness | Good (Moderate) | Excellent (Extremely High) |

| Wear Resistance | Moderate | Superior |

| Corrosion Resistance | Excellent | Superior |

| Biocompatibility | Outstanding (Medical Grade) | Good (Less common for direct implant due to thickness) |

| Aesthetics | Wide range of interference colors possible | Typically dull gray to bronze |

| Dimensional Impact | Minimal | Significant (must account for build-up) |

| Cost | Moderate | Higher |

The core difference boils down to film thickness and hardness. Type 2 offers controlled growth and aesthetic versatility. Type 3 is all about robust, industrial-strength surface protection. Your application's demands will steer your choice.

Strategic Selection: When to Choose Type 2 or Type 3 Anodizing

Making the right call on anodizing isn't just about understanding the differences; it's about applying that knowledge. It's about looking at your project through a practical lens. What problem are you trying to solve? What performance absolutely cannot be compromised?

When Type 2 is Your Best Bet

Medical Devices: Implants, surgical tools, and dental components demand superior biocompatibility and a sterile, inert surface. Type 2 is the industry standard here.

Aesthetic Finishes: If color coding, brand identity, or simply an attractive finish is important, Type 2's ability to produce vibrant, stable interference colors without dyes makes it ideal.

Corrosion Protection in Mild Environments: For applications needing solid corrosion resistance without extreme wear, Type 2 offers an excellent balance.

Tight Tolerances: The thin film has minimal impact on critical dimensions, simplifying design and manufacturing.

When Type 3 Commands the Job

High-Wear Applications: Components subjected to constant friction, abrasion, or sliding wear—like gears, bearings, or piston parts—will benefit immensely from Type 3's extreme hardness.

Harsh Industrial Environments: Equipment exposed to severe conditions, chemical agents, or high mechanical stress requires the robust protection only hardcoat anodizing can provide.

Aerospace and Defense: Critical parts where durability and extended service life are non-negotiable often utilize Type 3 for its enhanced resilience.

Impact Resistance: The thicker, harder layer offers better resistance against impact and surface damage.

Cost Implications: Don't Leave Money on the Table

Generally, Type 3 anodizing is more expensive than Type 2. The process is more involved, requires tighter controls, and specialized equipment. You're paying for that superior performance. However, consider the total cost of ownership. A more durable part might cost more upfront but save a fortune in replacements, maintenance, and downtime.

Always weigh initial cost against long-term performance and reliability. A trusted reliable titanium supplier can help you navigate these cost-benefit analyses.

Navigating Industry Standards and Specifications for Titanium Anodizing

In the world of precision engineering, standards aren't just suggestions; they're the rulebook. For titanium anodizing, understanding the relevant specifications ensures your components meet performance and safety requirements, especially in critical applications.

MIL-A-8625 and Titanium: A Common Reference

While MIL-A-8625, "Anodic Coatings for Aluminum and Aluminum Alloys," is fundamentally for aluminum, its Type II (sulfuric acid anodize) and Type III (hardcoat anodize) classifications are frequently referenced by analogy for titanium. Engineers often use these as a shorthand to describe desired film thickness and hardness characteristics, even if the exact chemical processes differ for titanium.

It’s important to remember this is a reference point, not a direct specification for titanium. Always clarify specific titanium requirements with your finishing partner.

ASTM F86: The Gold Standard for Medical Titanium

For medical device applications, ASTM F86, "Standard Practice for Surface Preparation and Marking of Metallic Surgical Implants," is the authoritative standard. This specification outlines best practices for cleaning, surface preparation, and the application of an anodic oxide coating on titanium and titanium alloys used in surgical implants.

The standard ensures the oxide layer promotes biocompatibility and helps prevent adverse tissue reactions. Compliance with ASTM F86 is non-negotiable for medical-grade titanium components. You can find more details directly from ASTM International.

Other Relevant Standards and Best Practices

Depending on the industry, other standards or internal specifications may apply. For instance, aerospace companies often have their own stringent requirements. Working with a finishing house that understands and can meet these diverse standards is crucial. Don't be shy about asking for certifications and process controls.

A good resource for general material science and processing standards can be found at ASM International.

Frequently Asked Questions About Titanium Anodizing Types

What is the primary difference between Type 2 and Type 3 titanium anodizing?

The primary difference lies in the thickness and hardness of the resulting oxide layer. Type 2 produces a thinner, softer film ideal for biocompatibility and aesthetics. Type 3, or hardcoat, creates a much thicker, significantly harder, and more wear-resistant layer for demanding industrial applications.

Which type offers better corrosion resistance for titanium?

Both types offer excellent corrosion resistance due to titanium's inherent passivation. However, Type 3 (hardcoat) provides superior corrosion protection due to its greater film thickness and density, offering a more robust barrier against aggressive environments.

Is Type 3 anodizing more expensive than Type 2?

Yes, Type 3 (hardcoat) anodizing is generally more expensive than Type 2. The process is more complex, requires specialized equipment, and uses more energy, leading to higher operational costs. This increased cost is offset by its superior durability and performance.

Can Type 2 anodizing be colored?

Absolutely. Type 2 titanium anodizing is well-known for its ability to produce a wide spectrum of vibrant, iridescent colors without using dyes. These colors result from light interference patterns caused by the thin, transparent oxide layer, allowing for precise aesthetic control and component identification.

What are the most common applications for each type?

Type 2 is predominantly used for medical implants, surgical instruments, decorative components, and consumer electronics where biocompatibility, aesthetics, and moderate wear resistance are critical. Type 3 is favored for aerospace components, military hardware, industrial machinery, and high-performance automotive parts where extreme wear resistance, hardness, and durability are paramount. For specific titanium products, the choice is clear based on application.