The Essential Role of Titanium Anodes in Modern PCB Manufacturing

Printed Circuit Boards (PCBs) are the bedrock of all modern electronics. From smartphones to complex industrial control systems, their functionality hinges on precise and reliable conductive pathways. Achieving these pathways demands sophisticated electroplating techniques. This is where the titanium anode for PCB industry steps in, not just as a component, but as a critical enabler of quality and efficiency.

For PCB manufacturers globally, the challenge is constant: how to ensure consistent, high-fidelity plating while managing operational costs and environmental impact? Inferior anodes lead to uneven deposition, bath contamination, and frequent downtime. This isn't just a nuisance; it's a direct hit to your bottom line and product reputation.

At China Titanium Factory, we recognize this industry pain point. The solution lies in purpose-engineered titanium anodes. These aren't generic electrodes; they are the heart of your plating bath, dictating everything from current distribution to coating uniformity. Our expertise focuses on delivering anodes that don't just work, but perform optimally under the rigorous demands of PCB fabrication.

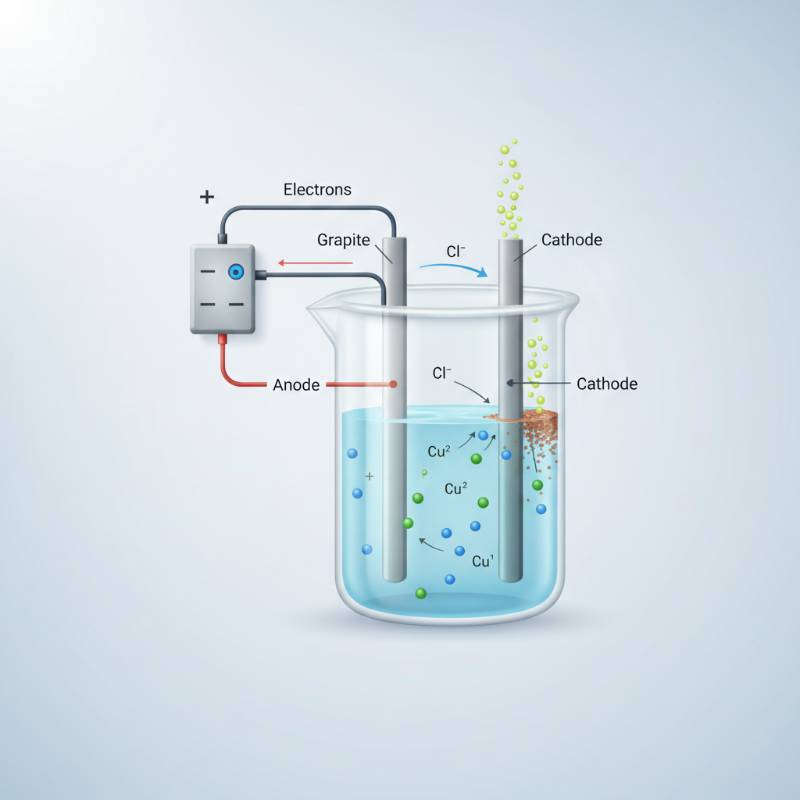

We define titanium anodes for the PCB industry as: highly durable, corrosion-resistant electrodes, typically made of titanium coated with electrochemically active materials (like Mixed Metal Oxides or platinum), specifically designed to facilitate uniform metal deposition in electroplating baths for Printed Circuit Board manufacturing.

Why Advanced Titanium Anodes are Indispensable for Your PCB Production

Traditional anodes often fall short. They corrode, leach impurities, and demand frequent replacement. This translates directly into higher operational costs, inconsistent product quality, and frustrating downtime. Advanced titanium anodes, however, flip the script. They are an investment that pays dividends.

Consider the benefits: enhanced electroplating efficiency means faster throughput and fewer rejects. Significant cost reductions stem from extended anode lifespan and reduced chemical consumption. Superior product quality is a given, with precise and uniform metal deposition across every board. This isn't just about making a better PCB; it's about making your entire production line run smoother, smarter, and more profitably. The truth is, cutting corners on your anodes is like trying to win a race with flat tires. It just doesn't compute.

Unpacking the Technology: MMO and Platinum-Plated Titanium Anodes for PCB

The core innovation behind high-performance titanium anode solutions lies in their coating. Two primary types dominate the PCB industry: Mixed Metal Oxide (MMO) and platinum-plated titanium anodes. Each brings unique electrochemical properties to the table.

MMO Titanium Anodes for PCB

MMO anodes feature a titanium substrate coated with a blend of noble metal oxides, typically iridium oxide and ruthenium oxide. This coating acts as a catalyst, promoting specific electrochemical reactions while remaining incredibly stable. They excel in highly acidic or alkaline plating baths, offering exceptional current efficiency and an impressively long service life. According to our analysis, MMO anodes are a workhorse for many copper plating processes, providing consistent performance without dissolving into the electrolyte. This prevents bath contamination, a common headache with soluble anodes.

Platinum-Plated Titanium Anodes for PCB

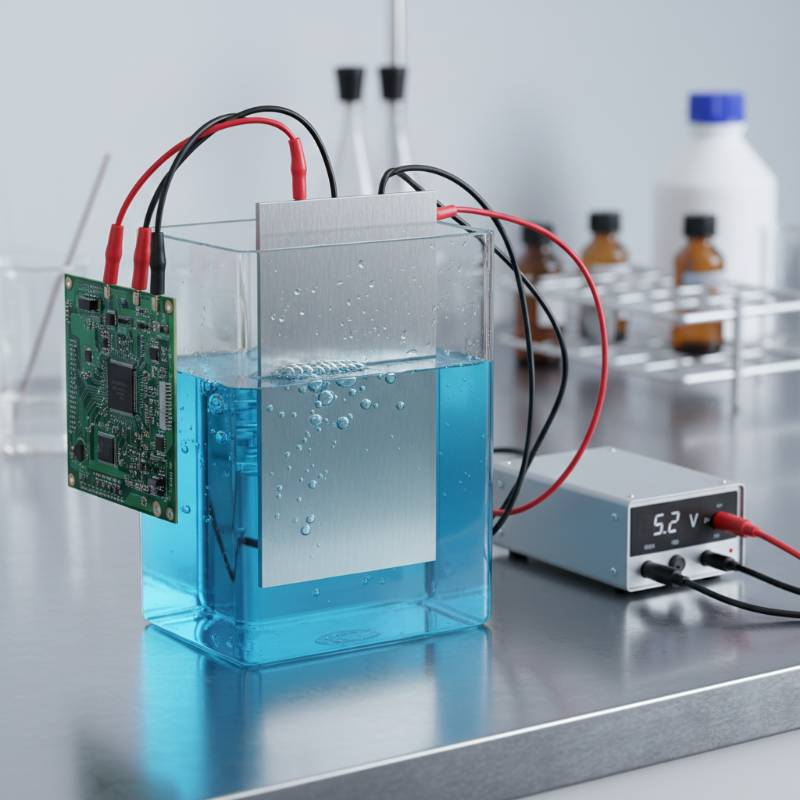

Platinum-plated titanium anodes, on the other hand, utilize a thin layer of pure platinum applied to a titanium base. Platinum is renowned for its superior conductivity and catalytic activity, making these anodes ideal for demanding applications like gold or rhodium plating, where purity and precise deposition are paramount. They offer robust performance and can withstand a wide range of bath chemistries. While potentially a higher initial investment, their performance and stability in critical plating processes often provide a rapid return.

Choosing between MMO and platinum-plated anodes isn't a shot in the dark. It depends on your specific plating bath chemistry, desired deposition metal, and operational budget. We've got the expertise to guide that decision. For a deeper dive into their construction, feel free to explore our dedicated pages on MMO titanium anodes and platinum-plated titanium anodes.

Precision Applications: Titanium Anodes Across Key PCB Electroplating Processes

The versatility of titanium anodes makes them indispensable across the entire PCB manufacturing spectrum. Their application isn't limited to a single process; rather, they are a fundamental tool in various critical stages.

Electroplating Copper on PCB with Titanium Anodes

Copper is the workhorse of PCB traces. Achieving uniform, ductile copper layers within through-holes and on surfaces is paramount. Titanium anodes, particularly MMO types, provide the stability and current distribution needed for consistent copper deposition. They prevent the build-up of sludge and maintain bath integrity, which is a major advantage for high-volume production. This precision ensures excellent conductivity and mechanical strength for the final board.

Gold and Nickel Plating for PCB

When it comes to surface finishes, gold and nickel are often employed for their excellent corrosion resistance, solderability, and wire bondability. Platinum-plated titanium anodes are typically the go-to for gold plating PCB and nickel plating. Their inert nature guarantees the purity of the deposited metal, preventing contamination that could compromise the integrity of delicate surface features and contact pads. This is crucial for high-reliability applications.

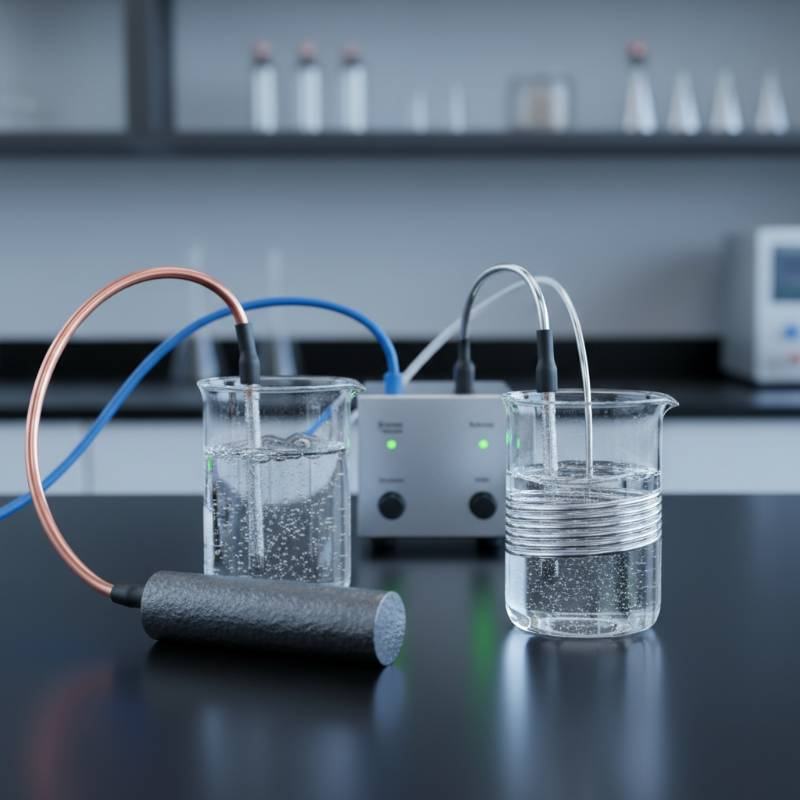

Titanium Anodes in PCB Wastewater Treatment

Beyond direct plating, the environmental responsibility of PCB manufacturing is non-negotiable. Electroplating processes generate wastewater containing heavy metals. Titanium anodes play a crucial role in PCB wastewater treatment. Through electrochemical oxidation and reduction, these anodes facilitate the removal or recovery of metals, ensuring compliance with stringent environmental regulations and promoting a cleaner footprint. It's a double win: efficient production and responsible waste management.

Introducing Our Company's 'Precision Plating Protocol™' for Optimized Anode Performance

You can have the best titanium anodes in the world, but without a systematic approach to their deployment and care, you're leaving performance on the table. That's why we've coined and developed the Precision Plating Protocol™. This isn't just a catchy name; it's a proprietary methodology refined over years of working with global PCB manufacturers.

The Precision Plating Protocol™ is a comprehensive framework designed to optimize every aspect of your anode's lifecycle, from initial selection to ongoing maintenance. It ensures maximum efficiency, minimizes downtime, and guarantees consistent plating quality, making it an industry benchmark for intelligent anode management.

According to our analysis, implementing a structured protocol like this can extend anode lifespan by up to 25%, significantly reducing replacement costs and improving overall process stability. It’s about getting the most bang for your buck, consistently.

The Precision Plating Protocol™: A Step-by-Step Framework

Application-Specific Anode Selection: We analyze your exact plating bath chemistry, current density requirements, and target metal. This ensures you get the right anode type (MMO, platinum, etc.) and geometry for your specific PCB process. No guesswork, just precision.

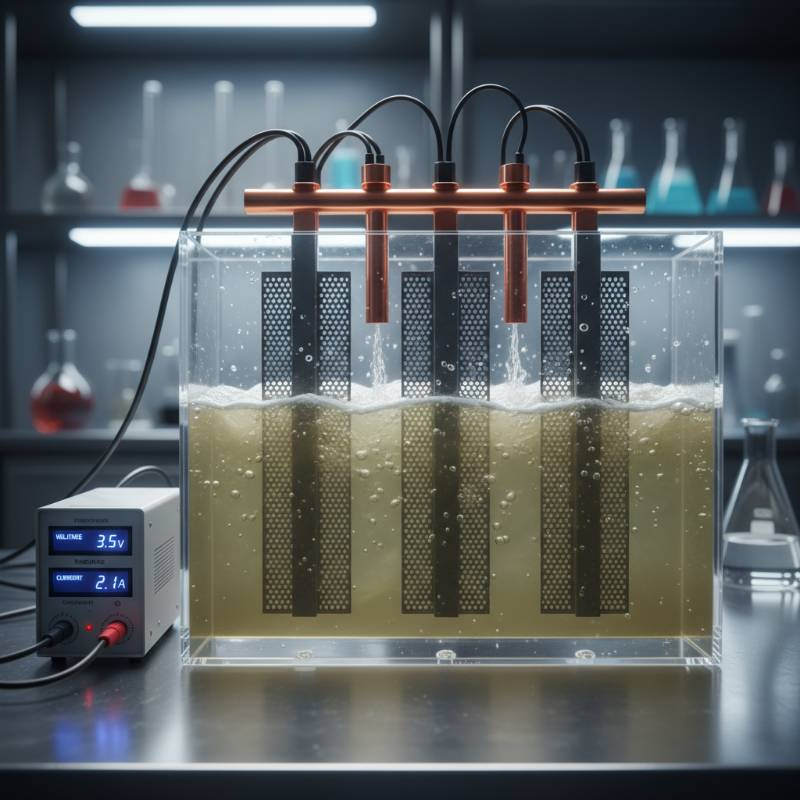

Optimized Anode Configuration: Proper placement and spacing within the plating tank are crucial. Our protocol includes guidelines for anode array design to ensure uniform current distribution, preventing hot spots and uneven deposition.

Proactive Maintenance Schedule: Regular inspection, cleaning, and timely re-coating or replacement are non-negotiable. We provide detailed schedules and best practices to prevent premature anode failure and maintain peak performance.

Performance Monitoring & Adjustment: Continuous monitoring of bath voltage, current, and plating quality allows for real-time adjustments. Our protocol emphasizes data-driven decisions to fine-tune your electroplating process.

This systematic approach, born from deep industry experience, ensures your anode manufacturing process and usage aligns with peak operational standards.

Tailored Solutions: Custom Titanium Anodes for Unique PCB Manufacturing Requirements

Every PCB manufacturing line has its quirks. Different tank sizes, unique bath chemistries, proprietary plating processes—one-size-fits-all rarely cuts it. That’s where our advanced capabilities in designing and manufacturing custom titanium anodes truly shine. We don't just sell anodes; we engineer solutions.

Our team thrives on solving complex challenges. Whether you need a specific anode shape for a non-standard tank geometry, a specialized coating tailored to an unusual electrolyte, or a high-current density design for rapid plating, we're geared up. We work closely with clients to understand their precise needs, providing application-specific solutions that scale for various operational demands. This bespoke approach ensures optimal results for even the most specialized PCB applications, preventing costly compromises down the line.

Maximizing ROI: Lifespan, Cost Analysis, and Strategic Procurement of PCB Anodes

When you're shelling out for critical components, you want to know you're getting your money's worth. Titanium anodes are no different. Their lifespan is a huge factor in your overall return on investment. Factors influencing durability include current density, electrolyte composition, operating temperature, and proper maintenance. A well-maintained MMO anode, for instance, can last for years, delivering consistent performance.

A comprehensive cost-benefit analysis is crucial. While the initial outlay for a high-quality titanium anode might be higher than a conventional lead anode, the long-term savings are compelling. Think reduced energy consumption, less bath contamination, fewer chemical additions, and significantly less downtime. It's not just about the sticker price; it's about total cost of ownership.

Strategic procurement also plays a big part. Partnering with reputable global titanium anode manufacturers like us offers several advantages: guaranteed quality, technical support, and the potential for long-term supply chain stability. Don't be penny wise and pound foolish when it comes to your anodes. For more insights on procurement, consider consulting industry resources like this guide on industrial purchasing strategies.

Best Practices for Anode Maintenance and Efficiency in PCB Manufacturing

Anode longevity and peak performance aren't accidental; they're the result of diligent maintenance. Ignoring anode care is like ignoring your car's oil changes—eventually, you're going to break down. Regular cleaning to remove scale or deposits, ensuring proper electrical contact, and monitoring bath parameters are non-negotiable. A clean anode is an efficient anode. It's a simple truth.

Optimizing anode efficiency also involves adhering to crucial industry standards. These standards dictate everything from material purity to coating thickness, ensuring reliable performance and safety. Furthermore, environmental regulations for titanium anodes in PCB manufacturing are constantly evolving. Staying compliant isn't just good practice; it's a legal necessity. For guidance on environmental compliance, organizations like the Environmental Protection Agency (EPA) offer valuable resources.

The Golden Rule for anode performance? Proactive monitoring trumps reactive repair every single time.

Commitment to Sustainability: Eco-Friendly Anode Solutions for the PCB Industry

Sustainability is no longer a buzzword; it's a core operational principle. The PCB industry, in particular, faces increasing scrutiny regarding its environmental footprint. Our titanium anode solutions align perfectly with this shift towards eco-friendly PCB manufacturing. Unlike consumable anodes that generate hazardous waste, titanium anodes are designed for longevity and, crucially, recyclability.

By preventing bath contamination and reducing the need for frequent chemical replenishment, our anodes contribute to a significantly reduced environmental impact. They help minimize sludge formation and facilitate more effective wastewater treatment. At China Titanium Factory, we are deeply committed to promoting greener manufacturing practices. We believe that high performance and environmental responsibility can—and must—go hand in hand. Look for detailed sustainability reports from leading manufacturers for comprehensive insights into anode recyclability and environmental impact assessments, for example, research from academic institutions studying sustainable materials.

Frequently Asked Questions About Titanium Anodes for PCB

Q1: What is the typical lifespan of a titanium anode in PCB electroplating?

A1: The lifespan varies significantly based on factors like current density, bath chemistry, temperature, and maintenance. However, high-quality MMO or platinum-plated titanium anodes, when properly maintained, can last from several months to several years, often outperforming traditional anodes by a factor of 5-10 times. Regular inspection and cleaning are key.

Q2: How do I choose between MMO and platinum-plated titanium anodes?

A2: The choice hinges on your specific application. MMO anodes are generally preferred for robust, high-volume processes like copper plating due to their cost-effectiveness and durability in aggressive chemistries. Platinum-plated anodes are often chosen for more sensitive, high-purity applications such as gold or rhodium plating, where the absolute prevention of bath contamination is critical. Our technical team can help you make an informed decision based on your exact requirements.

Q3: Can titanium anodes be re-coated or repaired?

A3: Yes, high-quality titanium anode substrates can often be stripped of their spent coating and re-coated, significantly extending their useful life and offering a cost-effective alternative to full replacement. This process requires specialized facilities and expertise to ensure the integrity of the substrate and the quality of the new coating. At China Titanium Factory, we offer re-coating services as part of our comprehensive anode support.

Q4: What are the main benefits of using titanium anodes over traditional lead anodes for PCB?

A4: Titanium anodes offer numerous advantages: they don't dissolve, preventing bath contamination and sludge formation; they maintain consistent current distribution for uniform plating; they have a significantly longer lifespan; they are more energy-efficient; and they are environmentally friendlier, avoiding the toxicity associated with lead. This translates to higher quality PCBs, reduced operational costs, and improved sustainability.

Q5: How do titanium anodes contribute to environmental compliance in PCB manufacturing?

A5: By being insoluble, titanium anodes eliminate the introduction of heavy metal ions (like lead) into the plating bath, which would otherwise complicate wastewater treatment. Their efficiency reduces chemical usage, and their role in electrochemical wastewater treatment directly aids in removing or recovering hazardous substances. This significantly lowers the overall environmental impact and helps manufacturers meet increasingly strict environmental regulations.