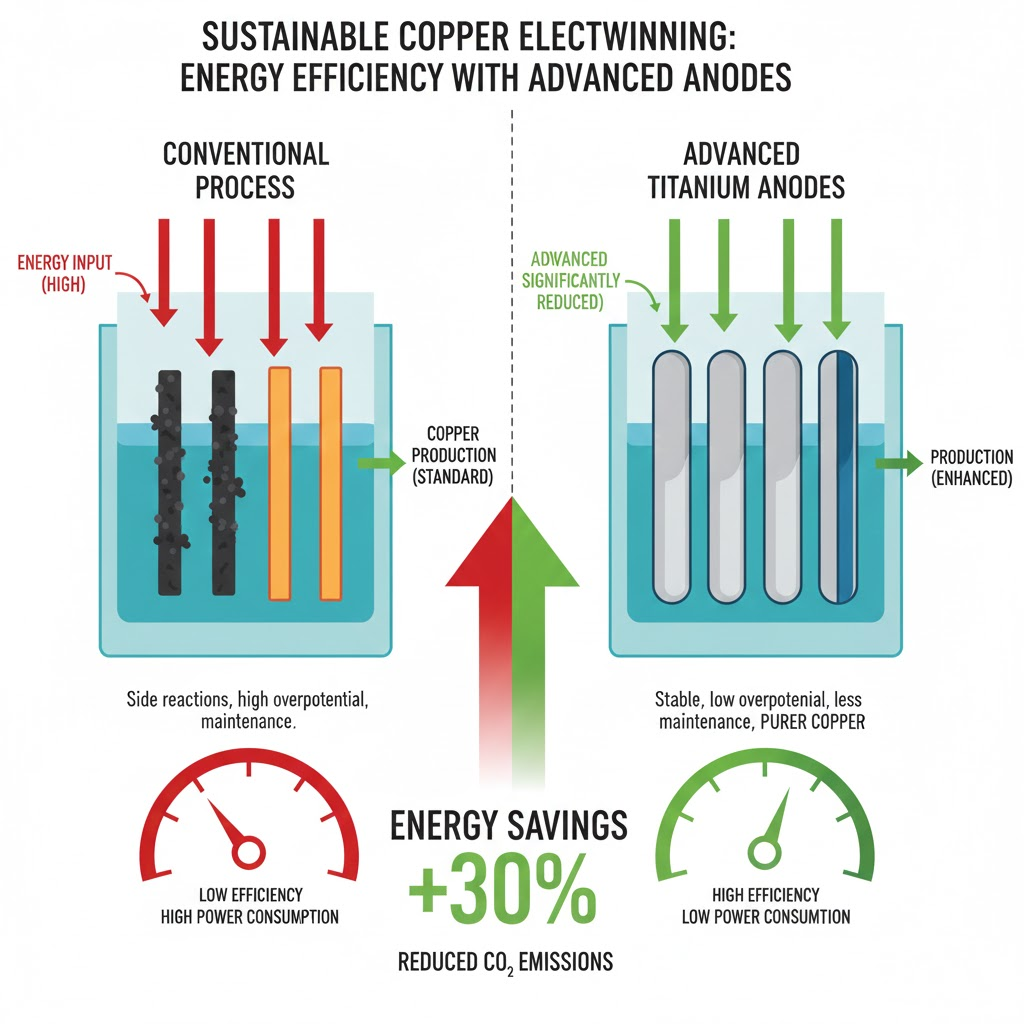

Enhanced Efficiency: Titanium anodes significantly boost current efficiency and reduce energy consumption in copper electrowinning.

Extended Lifespan: Advanced MMO and DSA coatings provide exceptional durability and corrosion resistance, minimizing replacement frequency.

Superior Purity: Contribute to the production of higher purity copper cathodes, meeting stringent industry standards.

Customized Solutions: Anodes are precisely engineered and tailored to specific operational requirements and plant configurations.

Sustainable Operations: Support greener metallurgy through reduced environmental impact and optimized resource utilization.

Copper electrowinning represents a critical electrochemical process for recovering high-purity copper from leach solutions. This metallurgical technique relies fundamentally on the efficiency and stability of the electrodes employed within the electrolytic cell.

At the heart of this process are titanium anodes, which serve as the primary site for oxidation reactions. These specialized electrodes are designed to withstand aggressive acidic environments while maintaining optimal electrocatalytic activity.

Their selection is paramount for maximizing current efficiency and minimizing energy consumption in the copper electrowinning process. The electrochemical principles governing these reactions dictate the need for robust and highly conductive anode materials in metallurgy.

Definition: Copper electrowinning is an industrial process that uses electrolysis to recover copper from a solution containing dissolved copper salts. An electric current is passed through the solution, causing copper ions to deposit onto a cathode, while oxidation reactions occur at the anode.

Historically, lead-based anodes were common, but their limitations regarding environmental impact and performance have led to a widespread adoption of advanced titanium-based alternatives. These modern anode materials in metallurgy offer a superior balance of properties. For further reading on the fundamentals of electrowinning, consult authoritative metallurgical resources such as those provided by ScienceDirect.

Titanium itself is a highly stable and corrosion-resistant metal, forming a passive oxide layer that protects it from aggressive acidic electrolytes. This inherent stability makes it an ideal substrate for the active catalytic coatings.

Without this protective base, the active coatings would quickly degrade, leading to rapid anode failure and significant operational disruptions. The structural integrity of titanium ensures a long-lasting foundation for the electrochemical reactions.

The adoption of advanced titanium anodes in copper electrowinning facilities yields a multitude of operational and economic advantages. These benefits directly translate to improved productivity and reduced long-term costs.

Key among these are enhanced energy efficiency in electrowinning and significantly extended operational lifespans. The inherent design and material properties of these anodes contribute directly to these gains.

Exceptional Corrosion Resistance: The robust nature of titanium, especially when paired with specialized coatings, provides superior corrosion resistance anodes in highly aggressive acidic electrolytes. This minimizes material degradation and contamination.

Significant Energy Savings: Titanium anodes exhibit lower overpotentials for oxygen evolution compared to conventional materials. This translates directly to reduced power consumption and substantial reduced operational costs over time.

Extended Operational Lifespan: With proper design and maintenance, titanium anodes can operate effectively for several years. This drastically reduces the frequency of anode replacement and associated downtime.

Production of High Purity Copper: The inert nature of the coatings prevents metallic impurities from leaching into the electrolyte. This ensures the production of high purity copper production, often exceeding LME Grade A standards.

Dimensional Stability: Unlike consumable anodes, titanium anodes maintain their shape and dimensions throughout their operational life. This ensures consistent cell geometry and optimized current distribution.

The initial investment in high-quality titanium anodes is quickly offset by substantial long-term savings. These savings stem from reduced energy bills, lower maintenance requirements, and the superior value of consistently produced high-purity copper. Strategic selection of anode type and coating is crucial for optimal return on investment.

These collective titanium anode benefits underscore their position as the preferred choice for modern, efficient, and sustainable copper electrowinning operations.

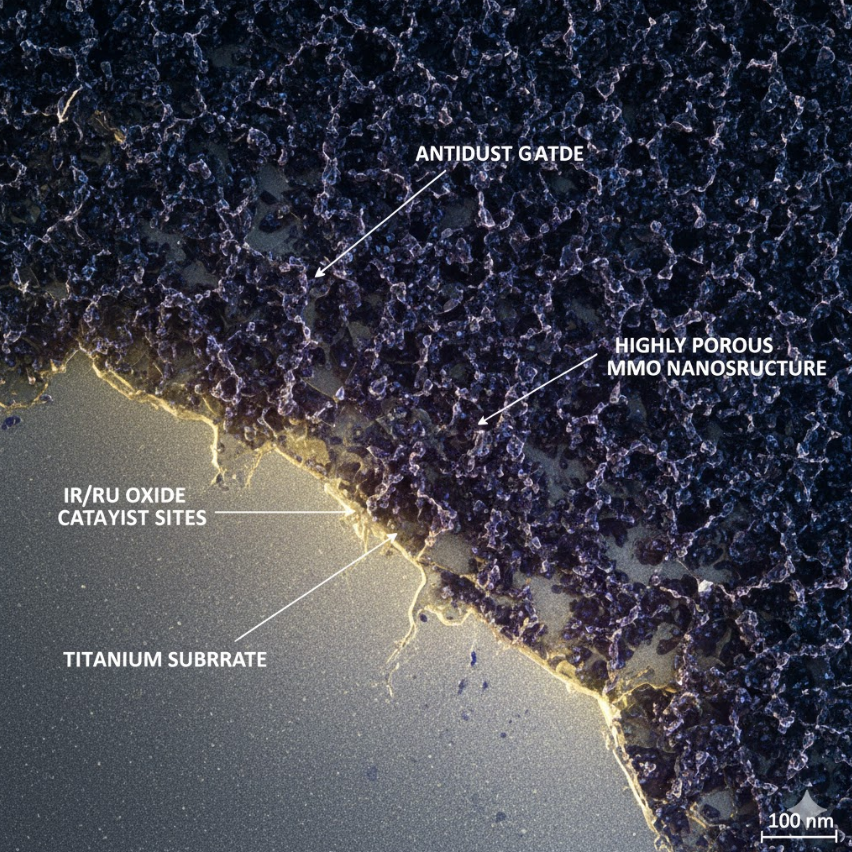

The performance of titanium anodes is profoundly influenced by the specialized coatings applied to their surface. These coatings are engineered to enhance electrocatalytic activity, improve durability, and optimize the overall efficiency of the electrowinning process.

The selection of the appropriate coating depends on the specific electrolyte composition, current density requirements, and desired operational lifespan. Two primary types of coatings dominate the industrial electrochemical landscape.

MMO anodes (Mixed Metal Oxide) and DSA anodes (Dimensionally Stable Anodes) are essentially synonymous terms referring to titanium anodes coated with noble metal oxides. These coatings are typically composed of iridium oxide and ruthenium oxide, often mixed with other metal oxides.

These anode coating types provide exceptional electrocatalytic activity for the oxygen evolution reaction, which is the primary anodic reaction in copper electrowinning. The precise composition of the coating is crucial for optimizing performance.

| Coating Type | Primary Components | Key Advantages | Typical Application |

|---|---|---|---|

| Iridium Oxide Coating | IrO2, Ta2O5 | High stability in acidic media, low oxygen overpotential. | Copper electrowinning, chlor-alkali, electrogalvanizing. |

| Ruthenium Oxide Coating | RuO2, TiO2 | Excellent electrocatalytic activity, cost-effective. | Chlor-alkali, wastewater treatment, some electrowinning. |

| Mixed Metal Oxide (MMO) | Combinations of IrO2, RuO2, TiO2, Ta2O5 | Optimized balance of activity, stability, and cost for specific applications. | Widely used across various electrochemical processes, including copper electrowinning. |

The precise formulation of an iridium oxide coating or ruthenium oxide coating is a proprietary process, enabling manufacturers like Chinatitaniumfactory.com to deliver anodes optimized for specific electrowinning parameters. For more information on MMO anode technology, refer to specialized literature such as articles available on Taylor & Francis Online.

Optimizing copper electrowinning performance necessitates a precise alignment between anode specifications and operational demands. Understanding critical technical parameters is essential for selecting the most effective anode solution.

Chinatitaniumfactory.com offers comprehensive titanium anode specifications and extensive custom anode design capabilities to meet diverse industrial requirements.

Current Density: The amount of current applied per unit area of anode surface (A/m²). This directly impacts reaction rates and energy consumption. Optimized current density in electrowinning is crucial.

Voltage Requirements: The cell voltage necessary to drive the electrochemical reactions, influenced by anode overpotential and electrolyte conductivity.

Substrate Material Composition: Typically pure titanium (ASTM B265 Grade 1 or 2), ensuring structural integrity and corrosion resistance. This forms the anode substrate material.

Dimensional Specifications: Precise length, width, thickness, and hole patterns are critical for proper fitment and uniform current distribution within the electrolytic cells.

Coating Thickness and Loading: Directly impacts anode lifespan and electrochemical performance. Higher loading generally equates to longer life but also higher cost.

These parameters are meticulously considered during the design and manufacturing process. Tailored solutions ensure maximum efficiency and longevity for each specific application.

Off-the-shelf anodes may offer initial cost savings, but they rarely provide optimal performance for unique plant configurations. Custom-designed anodes, precisely engineered for specific electrolyte compositions and operational parameters, deliver superior efficiency, extended lifespan, and ultimately, a lower total cost of ownership.

Clients are encouraged to engage with our technical team to discuss their specific electrowinning parameters and requirements. Further details on our bespoke manufacturing capabilities can be found on our Services page.

The efficacy of titanium anodes is best demonstrated through quantifiable results from real-world industrial applications. Numerous operations have transitioned from traditional lead-based anodes to advanced titanium solutions, achieving significant improvements.

These improvements span across various key performance metrics, showcasing the tangible benefits of modern anode technology. Examples highlight efficiency gains, cost reductions, and enhanced product quality.

<img src="https://image.pollinations.ai/prompt/chart%20showing%20ROI%20and%20efficiency%20gains%20from%20titanium%20anode%20implementation%20in%20a%20copper%20mine,%20data%20visualization,%20industrial%20setting?width=1024&height=576&nologo=true" alt="Performance chart demonstrating the ROI and operational efficiency improvements achieved through the implementation of titanium anodes in copper electrowinning" style="width: 100%; height: auto; border-radius: 12px; margin-top: 24px; margin-bottom: 24px; box-shadow: 0 4px 6px -1px rgba="0, 0, 0, 0.1);">While specific client data remains confidential, representative outcomes from various industrial anode applications illustrate the consistent advantages:

| Performance Area | Typical Improvement with Titanium Anodes | Impact |

|---|---|---|

| Energy Consumption | 10-20% reduction per ton of copper | Significant reduced operational costs, lower carbon footprint. |

| Anode Lifespan | 3-5 times longer than lead anodes | Reduced maintenance, less downtime, lower replacement costs. |

| Copper Purity | Consistently 99.99% or higher | Meets LME Grade A standards, enhanced market value. |

| Environmental Impact | Elimination of lead sludge, reduced emissions | Improved regulatory compliance, safer workplace. |

These copper electrowinning case studies underscore the substantial ROI titanium anodes provide. The operational efficiency improvements are a direct result of advanced material science and engineering.

Proper anode installation guide, optimal operational procedures, and routine maintenance are paramount for maximizing the lifespan and performance of titanium anodes. Adherence to best practices ensures consistent output and prevents premature failure.

These guidelines are designed to help facilities achieve peak efficiency and minimize downtime in electrowinning maintenance scenarios. Proactive measures are always more cost-effective than reactive repairs.

Installation:

Handle anodes with care to prevent damage to the active coating.

Ensure proper electrical contact and uniform spacing within the cell.

Verify anode alignment to prevent short-circuiting and uneven current distribution.

Operation:

Maintain stable current density and electrolyte temperature within recommended ranges.

Avoid sudden power surges or shutdowns that can stress the anode coating.

Monitor cell voltage and current distribution regularly for anomalies.

Maintenance:

Periodically inspect anodes for scaling, damage, or signs of coating wear.

Clean anodes as needed to remove deposits that can hinder performance.

Implement a scheduled rotation or replacement program to maximize anode lifespan extension.

Adhering to these operational best practices is critical for preventing common anode problems and ensuring consistent performance. For detailed troubleshooting guides and support, clients can refer to Chinatitaniumfactory.com's blog on electrowinning best practices.

In an era of increasing environmental scrutiny, the industrial sector is continuously seeking more sustainable and eco-friendly operational methods. Titanium anodes offer significant advantages in this regard, contributing to a reduced ecological footprint in metallurgical processes.

Their inherent properties and operational efficiencies align with global initiatives for green metallurgy and responsible resource management. The environmental impact of anodes is a crucial consideration.

Reduced Energy Consumption: The lower oxygen overpotential of titanium anodes directly translates to less electricity usage per ton of copper produced. This contributes to a substantial reduced carbon footprint.

Minimized Waste Generation: Unlike lead anodes which produce toxic lead sludge, titanium anodes are dimensionally stable and do not corrode to form harmful byproducts. This leads to significantly minimized waste generation.

Compliance with Regulations: By eliminating lead and reducing energy intensity, operations using titanium anodes are better positioned to meet increasingly stringent environmental regulations and acquire necessary environmental certifications. For information on global environmental standards in mining, refer to resources like the U.S. EPA.

Resource Efficiency: The extended lifespan of these anodes means fewer raw materials are consumed for anode manufacturing and replacement over time.

These environmental benefits reinforce titanium anodes as a core component of sustainable electrowinning practices. Investing in these advanced solutions is an investment in both operational efficiency and environmental stewardship.

This section addresses common queries regarding the application, performance, and maintenance of titanium anodes in copper electrowinning. Understanding these aspects is crucial for optimizing their use and longevity.

The lifespan of a titanium anode, especially with MMO/DSA coatings, typically ranges from 3 to 7 years in copper electrowinning, depending on the current density, electrolyte conditions, and coating thickness. Proper maintenance and operational practices can extend this further. This is a key aspect of anode lifespan extension.

Yes, a significant advantage of titanium anodes is their recoatability. Once the active coating is depleted, the titanium substrate can be stripped and reapplied with a new coating, restoring the anode to nearly original performance at a fraction of the cost of a new anode. This process addresses common anode problems efficiently.

Primary causes of titanium anode troubleshooting include coating wear-out due to normal operation, mechanical damage, excessive current density leading to accelerated wear, and contamination of the electrolyte. Proper operational control and regular inspections minimize these risks.

Selecting the correct anode requires consideration of electrolyte composition, required current density, desired lifespan, and cell geometry. Consulting with an expert anode solutions provider, such as Chinatitaniumfactory.com, is recommended to ensure optimal anode selection questions are addressed for your specific needs.

Choosing the right supplier for industrial electrochemical equipment is as critical as selecting the equipment itself. Chinatitaniumfactory.com stands as a premier titanium anode supplier, committed to delivering unparalleled quality and technical expertise.

With extensive experience in the design and manufacturing of high-performance anodes, the company provides solutions engineered for durability, efficiency, and superior results in copper electrowinning. This commitment extends to every aspect of client engagement.

Chinatitaniumfactory.com's expertise is rooted in a deep understanding of electrochemical engineering and material science. The company offers:

Bespoke Customization: Leveraging advanced manufacturing capabilities for custom manufacturing services, anodes are precisely tailored to meet specific client operational parameters and cell configurations.

Rigorous Quality Control: Adherence to stringent quality standards ensures every anode delivers consistent, reliable performance and extended operational life.

Dedicated Technical Support: A team of experts provides comprehensive support, from initial consultation and anode selection to installation guidance and ongoing troubleshooting.

Sustainable Practices: A focus on energy-efficient and environmentally responsible solutions aligns with modern industrial sustainability goals.

Partnering with Chinatitaniumfactory.com ensures access to cutting-edge anode technology and a collaborative approach to achieving operational excellence. Learn more about our commitment to quality on our About Us page.

Ready to enhance efficiency, reduce costs, and achieve higher purity copper?

Request a Quote for Custom Titanium Anodes