For pool owners and commercial facilities, maintaining pristine water quality is a constant battle. Traditional chlorination methods often involve handling harsh chemicals, leading to inconsistent chlorine levels and potential health concerns. The solution lies in advanced saltwater chlorination systems, and at the core of their efficiency is the titanium anode for pool chlorinator.

This guide cuts through the noise. We'll explore why a high-performance titanium anode isn't just a component but the linchpin for a safer, healthier, and more cost-effective pool environment. Investing in the right anode translates directly into superior water quality, reduced maintenance, and peace of mind.

Understanding Titanium Anodes in Saltwater Pool Systems

A saltwater pool chlorinator operates on a simple yet powerful principle: electrolysis. It takes mildly salted water and converts it into a potent, natural sanitizer. The star player in this conversion? The titanium anode.

We define a titanium anode as an electrode, typically made from a titanium substrate, coated with noble metals (like ruthenium and iridium oxides). Its primary function in a pool chlorinator is to facilitate the electrochemical reactions that transform dissolved sodium chloride (salt) into hypochlorous acid (free chlorine), the active sanitizing agent.

These anodes are specifically engineered to withstand the aggressive electrochemical environment inside a chlorinator cell. Without a robust, efficient anode, your saltwater system is dead in the water. It's that critical.

The Science Behind Saltwater Chlorination: How It Works

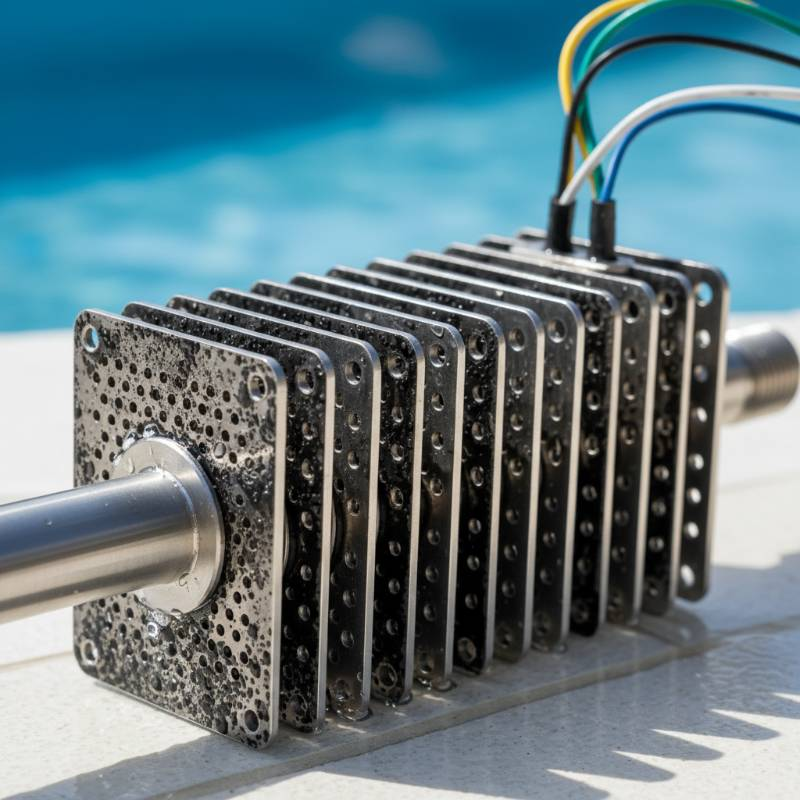

Demystifying the process clarifies the anode’s role. Saltwater chlorination begins when pool water, containing a low concentration of dissolved sodium chloride (NaCl), flows through the chlorinator cell. This cell houses multiple titanium plates, functioning as anodes and cathodes.

When an electrical current is applied across these plates, a series of electrochemical reactions unfolds:

At the anode (the positively charged electrode), chloride ions (Cl-) are oxidized to form chlorine gas (Cl2).

Simultaneously, at the cathode (the negatively charged electrode), water (H2O) is reduced, forming hydrogen gas (H2) and hydroxide ions (OH-).

The chlorine gas rapidly reacts with water, forming hypochlorous acid (HClO) and hydrochloric acid (HCl). Hypochlorous acid is the active sanitizer.

The hydrochloric acid then reacts with the hydroxide ions from the cathode, regenerating the chloride ions and water, completing the cycle.

The catalytic coating on the titanium anode is paramount. It dramatically lowers the energy required for these reactions, increases chlorine output, and protects the titanium substrate from corrosion and degradation. Our expert insights detail the intricate chemistry, underscoring why coating quality isn't just a feature; it's the performance differentiator.

Unrivaled Benefits of Titanium Anodes for Your Pool

Choosing a high-grade titanium anode for pool chlorinator applications isn't merely a purchase; it's an investment in superior pool management. The advantages are clear and compelling.

Exceptional Durability and Corrosion Resistance

Titanium, inherently robust, gains its true electrochemical resilience from the precious metal oxide coatings. These coatings, often ruthenium-iridium blends, prevent the titanium from oxidizing prematurely, even in the highly corrosive environment of electrolysis. This translates to an anode that stands the test of time, unlike lesser materials that quickly degrade.

High Efficiency in Chlorine Production

The specialized coatings act as powerful catalysts. They ensure that chlorine generation is not only consistent but also highly efficient. This means less energy consumption for a given output of chlorine, leading to lower utility bills. Consistent chlorine generation also prevents the "chlorine roller coaster" of highs and lows that can stress pool equipment and swimmers.

Long-Term Cost Savings

When you account for reduced chemical purchases, lower energy consumption, and significantly extended anode lifespan, the initial investment in a quality titanium anode pays dividends. Less frequent replacements mean less downtime and fewer service calls. It's a classic case of "penny wise, pound foolish" to skimp on this critical component.

Reduced Chemical Handling and Environmental Impact

Saltwater chlorination systems, powered by reliable titanium anodes, virtually eliminate the need for manual chlorine dosing. This reduces exposure to harsh chemicals for pool operators and homeowners. From an environmental standpoint, it minimizes the transportation and storage of hazardous substances. It’s a win-win for safety and sustainability.

Selecting the Right Titanium Anode: Types and Compatibility

Not all titanium anodes are created equal. Making the right selection involves understanding the nuances of their construction and ensuring perfect compatibility with your existing chlorinator system.

Coating Matters: Ruthenium-Iridium Oxide

The performance of any titanium anode for pool chlorinator systems hinges on its coating. The most prevalent and effective coatings are mixed metal oxides (MMO), primarily composed of ruthenium and iridium oxides. These noble metals offer exceptional electrocatalytic activity and stability.

Ruthenium Oxide (RuO2): Primarily contributes to chlorine evolution efficiency.

Iridium Oxide (IrO2): Enhances the coating's stability and resistance to corrosion, especially under high current densities and varying pH levels.

The precise ratio and application method of these oxides directly impact the anode's lifespan and chlorine output. Inferior coatings wear down quickly, leading to premature anode failure and diminished chlorine production.

Size, Design, and Compatibility

Anodes come in various configurations: plates, meshes, or rods. The physical dimensions and electrical connections must precisely match your chlorinator cell's specifications. A mismatch can lead to poor performance, damage to the cell, or even safety hazards. Always consult your chlorinator's manual or a trusted supplier. For high-quality titanium products, including custom anode solutions, understanding these specifications is key.

At China Titanium Factory, we emphasize that the First Principle of Saltwater Chlorination is this: The integrity of the titanium anode's catalytic coating dictates the efficiency and lifespan of your entire pool sanitation system.

The Electro-Catalytic Optimization (ECO) Method for Anode Longevity

Maximizing the lifespan and performance of your titanium anode for pool chlorinator systems isn't guesswork. It's a science. We introduce the Electro-Catalytic Optimization (ECO) Method, a unique framework designed to unlock peak efficiency and extend anode life far beyond typical expectations.

Phase 1: Precision Installation

Secure Fit: Ensure the anode fits snugly within the chlorinator cell. Loose connections cause arcing, damaging both the anode and the cell.

Proper Orientation: Follow manufacturer guidelines for anode orientation. Incorrect placement can lead to uneven wear.

Electrical Integrity: Verify all electrical connections are clean, tight, and corrosion-free to minimize resistance and heat generation.

Phase 2: Routine Operational Checks

Salt Level Vigilance: Maintain salt levels within the manufacturer's recommended range. Too low, and the cell works harder; too high, and it can accelerate scaling.

Flow Rate Stability: Ensure consistent water flow through the cell. Insufficient flow leads to localized overheating and reduced efficiency.

Visual Inspection: Periodically remove and visually inspect the anode for scaling, discoloration, or coating degradation. Early detection is key.

Phase 3: Advanced Maintenance Protocols

Acid Washing (Diligent): When scaling occurs, use a diluted acid solution (e.g., muriatic acid at a 10:1 water-to-acid ratio) to gently remove calcium deposits. Aggressive or frequent acid washing can strip the catalytic coating, so proceed with caution.

Brush Cleaning (Soft): For light deposits, a soft brush can be effective. Never use metal brushes or abrasive tools, which will damage the precious coating.

Water Chemistry Optimization: As per our analysis, the single greatest factor in anode longevity is stable water chemistry. Specifically, pH, alkalinity, and calcium hardness must remain in optimal ranges to prevent scaling and reduce stress on the anode.

Identifying a Failing Titanium Anode: Signs and Symptoms

A failing titanium anode for pool chlorinator can lead to cloudy water, algae growth, and increased chemical consumption. Knowing the signs prevents extended pool downtime and costly fixes.

Visual Cues

Flaking or Peeling Coating: The most obvious sign. The dark, often black, catalytic coating should be intact. If it's peeling, chipping, or exposing the shiny metallic titanium underneath, the anode is losing its effectiveness.

White or Green Deposits: While some scaling is normal, excessive, hard white (calcium) or green (copper) deposits indicate poor water chemistry or a struggling anode.

Damaged Plates: Bent, warped, or cracked plates compromise the entire cell's function.

Performance Drops

Decreased Chlorine Output: Your pool consistently tests low for free chlorine, even with the chlorinator running at full capacity. This is the primary indicator.

Increased Run Time: The chlorinator needs to run longer and more frequently to maintain target chlorine levels.

Cell Error Messages: Many modern chlorinators display "Inspect Cell," "Low Flow," or "Service Required" warnings when the anode is failing or severely scaled.

The average lifespan for a quality titanium anode is typically 3-7 years, depending on usage and water chemistry. Regular inspection is a small price to pay for consistent sanitation.

Step-by-Step Guide: Installing Your Titanium Anode

Replacing a titanium anode for pool chlorinator systems isn't overly complex, but precision is critical. Always prioritize safety.

Safety First

Power Off: Crucially, turn off all power to the chlorinator and the pool pump at the breaker.

Gloves and Eye Protection: Always wear appropriate personal protective equipment.

Necessary Tools

Wrench or pliers (for unions)

Screwdriver (if applicable for electrical terminals)

New titanium anode replacement cell

O-ring lubricant (silicone-based)

The Installation Process

Bypass or Shut Off Water: If your system has a bypass valve, use it. Otherwise, shut off the main pump and close valves to isolate the chlorinator cell.

Disconnect Cell: Loosen the union nuts on both ends of the chlorinator cell. Carefully remove the cell from the plumbing.

Disconnect Electrical: Detach the electrical cable from the old cell. Note the orientation if multiple connections exist.

Inspect & Clean: Clean the housing if necessary. Inspect the unions and O-rings for wear. Replace O-rings if they appear cracked or flattened, and apply a thin layer of O-ring lubricant.

Connect New Anode: Connect the electrical cable to the new titanium anode cell, ensuring a secure and correct connection.

Install New Cell: Insert the new cell into the plumbing, ensuring the O-rings are properly seated. Hand-tighten the union nuts, then use a wrench for a final snug fit – avoid overtightening.

Restore Power & Check: Reopen valves, turn on the pump, and check for leaks. Finally, restore power to the chlorinator and verify operation.

If you encounter any issues, don't hesitate to contact our team for assistance.

Maintaining Optimal Pool Water Chemistry with Your Salt Chlorinator

The Golden Rule of Anode Performance: Unwavering water chemistry is the bedrock upon which titanium anode longevity and peak chlorine generation are built. A quality titanium anode for pool chlorinator systems performs best in a balanced chemical environment. Neglecting water chemistry shortens anode life and reduces chlorinator efficiency.

Critical Parameters

Salt Levels: Maintain within the manufacturer's specified range (typically 3,000-4,000 ppm). Low salt stresses the cell; high salt can cause issues with other equipment.

pH: Keep pH between 7.4-7.6. High pH encourages scale formation on the anode. The CDC emphasizes proper pH for effective chlorine sanitization.

Total Alkalinity (TA): Aim for 80-120 ppm. TA buffers pH, preventing drastic swings.

Calcium Hardness (CH): Maintain 200-400 ppm. Low CH can corrode equipment; high CH leads to scaling.

Cyanuric Acid (CYA): Essential for outdoor pools, 30-50 ppm helps stabilize chlorine against UV degradation. Too much CYA can make chlorine less effective.

Testing Frequency

Test salt and free chlorine levels weekly. Test pH, TA, and CH bi-weekly or monthly, adjusting as needed. This proactive approach is a cornerstone of the ECO Method, ensuring your titanium anode for pool chlorinator operates under ideal conditions.

Troubleshooting Common Saltwater Chlorinator Issues

Even with a top-tier titanium anode for pool chlorinator, issues can arise. Here's a quick rundown of common problems and their solutions.

| Problem | Symptom(s) | Potential Cause | Solution |

|---|---|---|---|

| Low Chlorine Output | Cloudy water, algae, low FC readings. | Low salt, scaled cell, worn anode, low water temp, high CYA. | Check salt, clean cell, replace anode, adjust run time/temp, check CYA. |

| "Inspect Cell" / Error Light | Indicator light on control panel. | Scaled cell, low salt, faulty flow switch, aging anode. | Clean cell, verify salt, check flow sensor, inspect anode. |

| Excessive Scaling | White, crusty deposits on anode plates. | High calcium hardness, high pH, improper acid washing. | Balance water chemistry, gentle acid wash (per ECO Method). |

| No Chlorine Production | Zero FC, chlorinator running. | Complete anode failure, power supply issue, main board failure. | Test power supply, inspect anode (replace if necessary), professional diagnosis. |

For more detailed diagnostics, refer to your chlorinator's user manual. Sometimes, a simple adjustment can prevent a bigger headache. Additional troubleshooting resources can also be helpful.

Where to Purchase High-Quality Titanium Anodes Globally

Sourcing a reliable titanium anode for pool chlorinator systems is fundamental to long-term pool health. The global market offers numerous options, but quality varies wildly. Always prioritize manufacturers with a proven track record in material science and electrochemical applications.

Look for suppliers who:

Provide detailed specifications on anode coatings (e.g., ruthenium-iridium content).

Offer material certifications and quality assurance protocols.

Have robust manufacturing capabilities and a global supply chain.

Stand behind their products with warranties and technical support.

At China Titanium Factory, we specialize in advanced titanium solutions, including custom-engineered anodes for various industrial applications, including pool chlorinators. Our commitment to material integrity and performance ensures you receive anodes built to last. Explore our custom anode solutions and discover the difference true quality makes. For insights into quality standards, consider sources like NACE International (now AMPP), a leading authority on corrosion engineering.

Frequently Asked Questions About Titanium Anodes

What is the average lifespan of a titanium anode?

A well-maintained titanium anode with a quality coating typically lasts 3 to 7 years. Factors like water chemistry, run time, and salt levels significantly influence this lifespan. Following the ECO Method can help extend it.

Can I recoat my titanium anode?

While technically possible in specialized facilities, recoating is generally not practical or cost-effective for individual pool owners. The process requires industrial-grade cleaning, precise application of noble metal oxides, and high-temperature curing. Most pool owners opt for a new replacement anode cell when their existing one fails.

Is it normal for my anode to have some white deposits?

Yes, some calcium scale (white deposits) can form on the anode plates over time, especially in hard water areas. Regular, gentle cleaning with a diluted acid solution (following the ECO Method guidelines) is necessary. Excessive scaling indicates poor water chemistry, particularly high pH or calcium hardness.

What happens if I don't replace a failing anode?

Ignoring a failing anode leads to insufficient chlorine production, resulting in cloudy water, algae growth, and an unhealthy pool environment. It also stresses other components of your chlorinator system, potentially leading to more expensive repairs down the line. It’s a false economy to delay replacement.

Does the salt level affect anode performance?

Absolutely. The chlorinator cell requires a specific salt concentration for efficient electrolysis. Too low, and the cell works harder, reducing anode life and chlorine output. Too high, and while it might produce chlorine, it can also cause premature wear on the anode and other pool equipment.

Ready for Peak Pool Performance?

Don't compromise on your pool's health or your chlorinator's efficiency. A premium titanium anode for pool chlorinator systems is the cornerstone of crystal-clear, safe water.

At China Titanium Factory, we engineer durable, high-performance anodes designed for longevity and optimal chlorine generation. Upgrade your system with confidence.