Navigating Titanium Anode Technical Data Sheets: A Comprehensive Guide

Industrial processes requiring electrochemical reactions demand precise material specification. Titanium anodes are foundational to these operations. Their performance, longevity, and efficiency directly impact system economics and output quality. Engineers and procurement specialists routinely face the challenge of selecting the optimal anode from a myriad of options.

The primary tool for this critical decision-making is the titanium anode technical data sheet (TDS). This document is more than a mere specification list; it is a blueprint for performance and reliability. Misinterpreting a TDS can lead to suboptimal system design, premature anode failure, and significant operational costs. Our objective here is to demystify the titanium anode TDS, providing a comprehensive framework for its interpretation and application.

Understanding these sheets is not just about reading numbers. It's about translating technical data into tangible operational advantages. At China Titanium Factory, we recognize that a well-understood TDS is the first step toward a successful electrochemical project.

Understanding Titanium Anodes: Fundamentals and Types

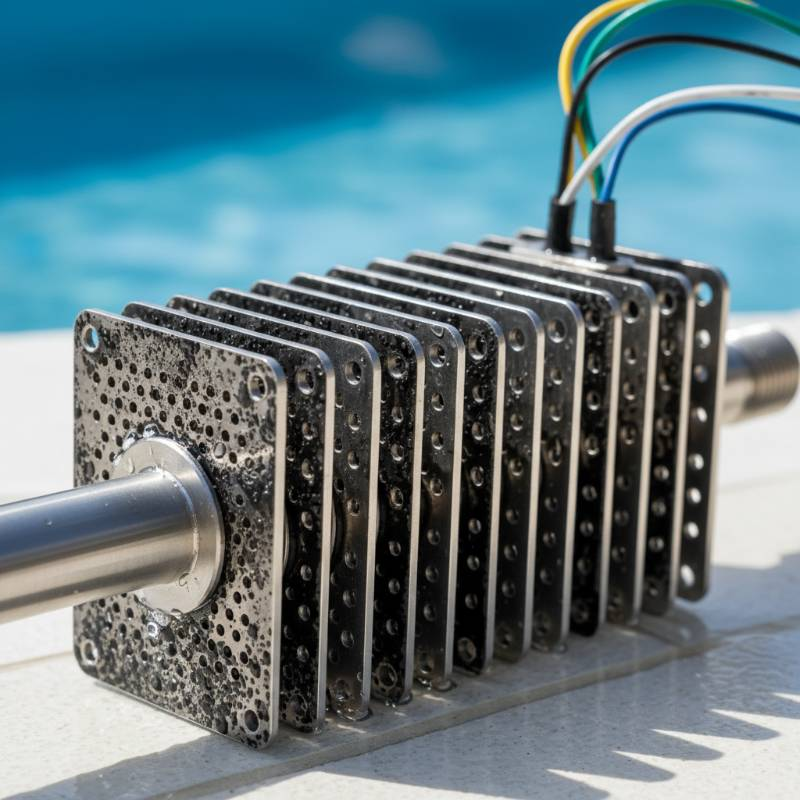

Titanium anodes serve as critical components in various electrochemical systems. They facilitate electron transfer, driving reactions such as chlor-alkali production, electroplating, and cathodic protection. Their success hinges on exceptional corrosion resistance and catalytic activity.

We define an electrochemical anode as an electrode where oxidation reactions occur, releasing electrons into the external circuit. Titanium is favored as a substrate due to its inherent passivity and high strength-to-weight ratio.

The core function of these anodes remains consistent: to provide a stable, conductive surface for electrochemical processes. However, their specific design and coating vary widely based on application demands.

Material Composition and Substrate Properties

The foundation of any high-performance titanium anode is its substrate. Pure titanium, specifically grades like ASTM B338 Grade 1 and Grade 2, offers unparalleled corrosion resistance in aggressive environments. Grade 1 provides maximum ductility and formability; Grade 2 offers slightly higher strength with excellent corrosion resistance. These properties are non-negotiable for long-term operational stability.

The material science behind titanium's passivity is fundamental. A stable, tenacious oxide layer forms instantly upon exposure to oxygen, protecting the underlying metal. This layer is crucial for preventing substrate degradation, even under potent anodic polarization. According to a study by ASTM International, compliance with B338 standards ensures consistent material quality.

Advanced Anode Coatings: MMO, Platinized, and Beyond

While the titanium substrate provides structural integrity and corrosion resistance, the active coating dictates the anode's electrochemical performance. This coating is the true workhorse.

Mixed Metal Oxide (MMO) Anodes: These are the industry standard. MMO coatings, typically composed of iridium-tantalum or iridium-ruthenium oxides, offer superior catalytic activity and extended service life. Iridium-tantalum coatings excel in oxygen evolution reactions, while iridium-ruthenium is preferred for chlorine evolution.

Platinized Titanium Anodes: A thin layer of platinum is electrodeposited onto the titanium substrate. Platinized anodes are known for their high catalytic activity and suitability for specific applications, particularly those requiring precise potential control or operation in high-purity solutions. However, platinum's cost can be a factor.

Other specialized coatings exist, tailored for niche applications requiring unique catalytic properties or enhanced durability in extreme conditions. Each coating type is designed to optimize specific electrochemical reactions, making coating selection a critical design parameter. You can explore various coating options and their applications on our services page.

Interpreting Your Titanium Anode Technical Data Sheet

A titanium anode technical data sheet is a dense document. It consolidates all vital information required for proper anode selection, integration, and operation. Understanding its structure is the first step toward effective utilization. Don't gloss over the details; they matter.

The TDS typically presents data in a structured format, covering material properties, electrochemical performance, mechanical specifications, and quality assurances. Each section holds critical information that directly impacts project viability and long-term success.

Key Performance Parameters and Electrochemical Properties

This section is the heart of the TDS. It quantifies the anode's operational capabilities under specific conditions. Ignoring these parameters is like flying blind.

Current Density (A/m²): This specifies the maximum current an anode can sustain per unit of active surface area without excessive degradation. Higher current densities typically mean faster reaction rates but can also accelerate coating wear.

Overpotential (V): The extra voltage required beyond the theoretical equilibrium potential to drive an electrochemical reaction at a certain rate. Lower overpotential indicates higher energy efficiency.

Anode Consumption Rate (mg/Ah or µg/Ah): This measures how much of the active coating is consumed per ampere-hour of operation. A lower consumption rate equates to a longer service life and reduced replacement costs.

Operating Voltage (V): The typical voltage range under which the anode is designed to operate efficiently. Exceeding this range can lead to accelerated degradation.

Expected Service Life (Hours/Years): An estimate of the anode's operational lifespan under specified conditions. This figure is critical for budgeting and maintenance planning.

Electrolyte Composition and Temperature Range: Defines the chemical environment and thermal limits within which the anode performs optimally. Deviation can severely compromise performance.

These figures are not isolated. They are interconnected and must be evaluated holistically. A low consumption rate at a specific current density, for instance, implies robust coating stability.

Mechanical Specifications and Quality Standards

Beyond electrochemical performance, the physical attributes and adherence to standards are equally important. These details ensure compatibility and reliability.

Physical Dimensions (Length, Width, Thickness, Diameter): Essential for mechanical integration into existing or new systems. Precise measurements prevent costly rework.

Weight (kg): Important for structural support and handling considerations.

Connection Types (Cable, Bolt, Stud): Specifies how the anode connects to the power supply. Compatibility with rectifier systems is paramount.

Substrate Material Grade (e.g., ASTM B338 Grade 1 or 2): Confirms the quality and type of titanium used, impacting corrosion resistance and mechanical strength.

Quality Standards and Certifications (ISO 9001, ASTM, NACE): These certifications guarantee that the manufacturing process and materials meet international benchmarks. For example, NACE International standards are vital for cathodic protection applications.

We advocate for a "by the book" approach to these specifications. Cutting corners here invariably leads to problems down the line.

The "AnodeSelect™" Evaluation Framework: Optimizing Your Choice

Selecting the ideal titanium anode is a complex task. To streamline this process and ensure optimal outcomes, we introduce the AnodeSelect™ Evaluation Framework. This proprietary methodology provides a structured, three-step approach for technical professionals.

According to our analysis, successful anode deployment hinges on a rigorous, systematic evaluation. The AnodeSelect™ Framework ensures no critical aspect is overlooked. This is our Golden Rule: Never compromise on a thorough, data-driven selection process.

Step 1: Application Profiling

Define the operational environment and performance requirements with utmost precision. This includes:

Electrolyte Composition: pH, concentration of specific ions (e.g., chloride, sulfate), presence of organic contaminants.

Temperature and Pressure: Operating range and potential fluctuations.

Desired Reaction: Chlorine evolution, oxygen evolution, metal deposition, etc.

Current Requirements: Total current, desired current density, and potential for current reversals.

Service Life Expectancy: Target operational duration before replacement.

Step 2: TDS Cross-Referencing and Performance Modeling

With the application profile established, systematically compare available titanium anode technical data sheets. Focus on matching the anode's electrochemical and mechanical specifications to your requirements.

Match Current Density: Ensure the anode's rated current density aligns with or exceeds your operational needs.

Verify Overpotential: Prioritize anodes with lower overpotential for energy efficiency.

Estimate Service Life: Correlate the anode consumption rate with your target service life under the specified operational current density.

Mechanical Compatibility: Confirm dimensions, weight, and connection types fit your system.

This stage often involves basic performance modeling to predict real-world behavior based on TDS data.

Step 3: Cost-Benefit and Vendor Evaluation

Beyond raw technical data, a comprehensive evaluation includes economic and logistical factors.

Total Cost of Ownership (TCO): Factor in initial purchase price, energy consumption (driven by overpotential), and replacement frequency (driven by service life).

Supplier Reliability: Assess the manufacturer's reputation, quality control processes, and technical support capabilities. China Titanium Factory maintains strict adherence to quality and provides comprehensive support.

Lead Times and Customization: Evaluate the vendor's ability to meet delivery schedules and offer custom solutions if required.

The AnodeSelect™ Framework ensures a balanced decision, moving beyond just price to encompass true value and performance.

Real-World Applications and Industry-Specific Guidance

Titanium anodes are not a one-size-fits-all solution. Their design and coating are specifically engineered for diverse industrial applications. Understanding these specific contexts is paramount for correct anode selection.

From large-scale chemical production to delicate electroplating operations, the right anode can make all the difference. Incorrect selection can lead to inefficiency, product contamination, or premature system failure.

Case Studies: Quantifiable Performance in Action

Real-world examples underscore the importance of precise anode selection based on TDS parameters.

Case Study 1: Chlor-Alkali Production

A major chemical plant sought to reduce energy consumption in its chlor-alkali cells. By switching from graphite anodes to advanced iridium-ruthenium MMO coated titanium anodes, as specified in their TDS for low overpotential in chloride solutions, they achieved a 12% reduction in energy draw. The anode consumption rate, detailed in the TDS, indicated a projected service life of over 8 years, significantly extending maintenance cycles.

Case Study 2: Cathodic Protection for Offshore Structures

An offshore oil rig required a robust cathodic protection system. Utilizing platinized titanium anodes, selected for their stability in seawater and high current output, minimized corrosion on critical steel components. The TDS for these anodes guaranteed a minimum current density output of 100 A/m² at 3V, ensuring adequate protection over a vast surface area. This prevented costly structural damage and downtime.

These cases are not outliers. They are direct results of meticulous application of TDS information and expertise. For tailored solutions, consider reaching out to the experts at China Titanium Factory.

Manufacturing Excellence and Sustainability Considerations

The quality of a titanium anode begins with its manufacturing. Precision engineering, stringent quality control, and adherence to international standards are non-negotiable. Substandard manufacturing can lead to coating delamination, premature failure, and inefficient operation.

Modern manufacturing processes for titanium anodes involve sophisticated coating technologies, often utilizing thermal decomposition or electrodeposition. Each step is carefully monitored to ensure coating uniformity, adhesion, and optimal crystal structure. This meticulous approach directly translates to the performance data presented in the TDS.

Sustainability is also moving to the forefront. Manufacturers are increasingly focusing on reducing the environmental footprint of anode production. This includes optimizing energy consumption during manufacturing, minimizing waste, and exploring strategies for anode recycling or refurbishment. Long-life anodes inherently contribute to sustainability by reducing material consumption and waste generation.

Frequently Asked Questions (FAQs) About Titanium Anodes

What is the most critical parameter on a titanium anode TDS?

While many parameters are vital, the anode consumption rate (or coating loss rate) and the associated expected service life are often considered the most critical. These directly impact the anode's operational lifespan and total cost of ownership. A low consumption rate indicates superior coating stability and longevity under specified operating conditions.

How does current density affect anode performance?

Current density directly influences the rate of the electrochemical reaction and the anode's wear rate. Operating an anode below its optimal current density might lead to inefficient reactions. Conversely, exceeding the maximum rated current density can significantly accelerate coating consumption, increase overpotential, and drastically shorten the anode's service life.

Can titanium anodes be recoated or repaired?

Yes, in many cases, titanium anodes can be recoated. This process involves stripping the old, depleted coating and applying a new one to the titanium substrate. Recoating can be a cost-effective alternative to purchasing new anodes, extending their useful life and reducing material waste. The feasibility depends on the integrity of the original titanium substrate. Consult your supplier for specific recoating services.

What are the advantages of MMO anodes over platinized anodes?

MMO (Mixed Metal Oxide) anodes generally offer better cost-effectiveness and versatility for many industrial applications. They are designed for specific reactions (e.g., chlorine or oxygen evolution) and often exhibit lower overpotential and longer service life for those applications compared to platinized anodes. Platinized anodes, while highly catalytic, are typically more expensive and might be preferred in applications requiring very high purity, precise potential control, or where platinum's specific catalytic properties are indispensable.

Why is substrate grade important for titanium anodes?

The substrate grade, typically ASTM B338 Grade 1 or 2, defines the mechanical strength, ductility, and fundamental corrosion resistance of the titanium base. While the active coating performs the electrochemical work, the substrate provides the structural integrity and protects against general corrosion. Using the correct grade ensures the anode can withstand the physical and chemical stresses of its operating environment without compromising the coating's adhesion or the anode's overall structural stability.

Glossary of Essential Electrochemical and Material Science Terms

Navigating titanium anode technical data sheets requires familiarity with specific terminology. This glossary provides concise definitions.

Anode: The electrode where oxidation occurs; electrons are released.

Cathode: The electrode where reduction occurs; electrons are consumed.

Current Density: Electric current per unit of electrode surface area (A/m² or mA/cm²).

Electrolyte: A substance containing free ions that conducts electricity.

Mixed Metal Oxide (MMO): A catalytic coating composed of various noble metal oxides (e.g., IrO₂, RuO₂, Ta₂O₅) applied to a titanium substrate.

Overpotential: The difference between the actual potential and the theoretical (equilibrium) potential required for an electrochemical reaction.

Passivity: The state of a metal that makes it highly resistant to corrosion in an environment where it should theoretically be active. Titanium forms a passive oxide layer.

Platinized Titanium: A titanium anode coated with a thin layer of platinum.

Substrate: The underlying material onto which an active coating is applied; in this case, titanium.

Technical Data Sheet (TDS): A document providing detailed technical specifications and characteristics of a product.