Industrial wastewater presents significant challenges due to high Chemical Oxygen Demand (COD) and stringent regulatory requirements.

Titanium anodes offer an advanced electrochemical solution for efficient and sustainable COD degradation.

These anodes utilize powerful direct and indirect oxidation mechanisms, including hydroxyl radical generation, for superior pollutant removal.

Benefits include high efficiency, minimal sludge production, operational stability, and applicability across diverse industrial sectors.

Proper anode selection, system optimization, and routine maintenance are crucial for maximizing performance and longevity.

Embracing titanium anode technology delivers substantial environmental benefits and long-term economic advantages, ensuring regulatory compliance and a strong return on investment.

Key Industrial Applications for Titanium Anodes in Wastewater Treatment

Selecting the Right Titanium Anode: Technical Considerations

Proven Performance: Case Studies in Industrial COD Reduction

Operational Guidelines and Maintenance for Titanium Anode Systems

Sustainable Wastewater Treatment: Environmental and Economic Advantages

Frequently Asked Questions About Titanium Anodes for COD Removal

Industrial wastewater presents a complex and persistent environmental challenge. Its diverse composition, often characterized by high concentrations of organic pollutants, demands robust and effective treatment solutions. A primary indicator of organic pollution is Chemical Oxygen Demand (COD). High COD levels in discharged effluents pose significant threats to aquatic ecosystems and human health. They deplete dissolved oxygen, harming aquatic life, and can introduce toxic substances into water bodies. Consequently, environmental regulatory bodies worldwide impose increasingly stringent limits on industrial wastewater discharge.

Conventional wastewater treatment methods often struggle with these complex industrial effluents. Biological treatments can be inhibited by toxic compounds, while chemical coagulation may generate large volumes of sludge requiring further disposal. This necessitates the adoption of advanced technologies capable of achieving higher COD reduction efficiencies sustainably.

Chemical Oxygen Demand (COD): A measure of the total quantity of oxygen required to oxidize all organic material in a liquid sample into carbon dioxide and water. It serves as an indicator of the amount of organic pollutants in wastewater.

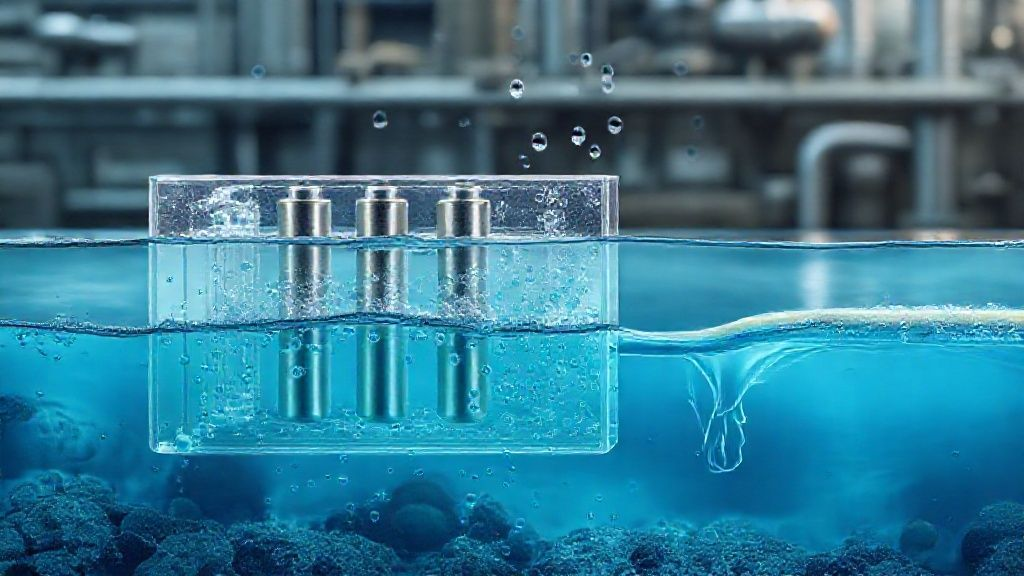

Electrochemical oxidation, particularly utilizing titanium anodes, represents a highly effective and sustainable approach to industrial wastewater treatment. These anodes serve as robust platforms for generating powerful oxidizing species directly within the wastewater stream. This process efficiently degrades a broad spectrum of organic pollutants. The fundamental principle involves applying an electric current across electrodes submerged in the wastewater. At the anode surface, water molecules and other species are oxidized, producing highly reactive radicals. These radicals then attack and mineralize organic compounds. Titanium, chosen for its exceptional corrosion resistance and mechanical strength, forms the substrate for these advanced electrodes. It is typically coated with electrocatalytically active materials, such as mixed metal oxides (MMO) or platinum group metals. These coatings significantly enhance the anode's efficiency and longevity.

These advanced anode materials exhibit superior performance compared to traditional graphite or lead-based electrodes. They offer higher stability, increased current efficiency, and a reduced tendency for passivation. This results in more consistent and effective COD reduction.

The efficacy of titanium anodes in COD removal stems from several powerful electrochemical mechanisms. These include direct oxidation, where pollutants react directly on the anode surface, and indirect oxidation, involving the generation of highly reactive species. A key aspect of indirect oxidation is the generation of hydroxyl radicals (•OH). These are extremely potent, non-selective oxidizers capable of mineralizing a wide range of organic compounds into carbon dioxide and water. Other generated oxidants include active chlorine species (ClO⁻) in chloride-containing wastewaters.

The immense oxidizing power of hydroxyl radicals (•OH), with a redox potential of approximately 2.8 V, makes them exceptionally effective. They rapidly break down even recalcitrant organic molecules, leading to high mineralization rates and efficient COD reduction.

These mechanisms contribute to several significant benefits for industrial wastewater treatment. Titanium anode systems demonstrate high efficiency in COD reduction, often achieving over 90% removal rates. They also exhibit high selectivity for organic pollutants. Furthermore, electrochemical oxidation with titanium anodes leads to minimal sludge production. This drastically reduces the costs and environmental impact associated with sludge handling and disposal. Operational stability and adaptability to varying wastewater compositions are additional advantages.

| Feature | Titanium Anode Electrochemical Oxidation | Conventional Biological Treatment | Chemical Coagulation/Flocculation |

|---|---|---|---|

| COD Removal Efficiency | High (often >90%), effective for recalcitrant organics | Variable, sensitive to toxicity, less effective for non-biodegradable COD | Moderate, primarily removes suspended/colloidal COD, not dissolved organics |

| Sludge Production | Minimal (often reduced by >50%) | Significant biological sludge (biosolids) | High chemical sludge volume |

| Chemical Consumption | Low (primarily electrolytes if needed, no bulk chemical addition for oxidation) | Low (nutrients, pH adjustment) | High (coagulants, flocculants, pH adjusters) |

| Footprint | Compact, modular systems | Large (aeration tanks, clarifiers) | Moderate (mixing tanks, clarifiers) |

| Operational Complexity | Relatively simple, automated control | High (microorganism health, aeration control) | Moderate (chemical dosing, mixing) |

The versatility and robust performance of titanium anodes make them suitable for a wide array of challenging industrial wastewater streams. Their ability to degrade persistent organic pollutants is invaluable across various sectors. In the chemical manufacturing industry, effluents often contain complex, non-biodegradable organic compounds. Titanium anodes effectively break down these substances, ensuring compliance with discharge regulations. Similarly, the textile dyeing industry benefits from the decolorization and COD reduction capabilities, tackling recalcitrant dyes.

The pharmaceutical industry, known for its highly concentrated and specific organic contaminants, finds titanium anode technology particularly effective. It offers a reliable method for degrading active pharmaceutical ingredients (APIs) and other complex intermediates. The pulp and paper industry also utilizes these anodes for treating high-COD effluents and bleach plant filtrates. Other sectors include food and beverage processing, oil and gas, and landfill leachate treatment. These applications underscore the technology's adaptability and efficacy in handling diverse and challenging wastewater compositions. For more detailed insights into specific industry solutions, explore the services offered by China Titanium Factory.

Optimizing an electrochemical wastewater treatment system hinges on selecting the appropriate titanium anode. Several critical technical factors must be meticulously evaluated to ensure peak performance and longevity. Key considerations include the substrate material and its specific coating type. Mixed Metal Oxide (MMO) anodes, often based on iridium or ruthenium oxides, are highly favored for their excellent electrocatalytic activity and durability in various wastewater matrices. Platinum-coated titanium anodes also offer high performance, particularly in applications requiring extreme corrosion resistance.

Substrate Material: Ensure high-purity titanium (e.g., Grade 1 or 2) for optimal corrosion resistance.

Coating Type: Select between MMO (IrO₂/Ta₂O₅, RuO₂/TiO₂) or Platinum, depending on wastewater pH, halide concentration, and target pollutants.

Coating Thickness/Loading: Directly impacts anode lifespan and initial cost; thicker coatings generally last longer.

Anode Geometry: Plates, meshes, rods, or tubes are chosen based on reactor design and desired surface area.

Current Density: Optimization is crucial to balance treatment efficiency, energy consumption, and anode wear rate.

Wastewater Characteristics: pH, conductivity, temperature, and specific pollutant types dictate the most effective anode choice.

Optimizing current density is crucial for balancing treatment efficiency with energy consumption and anode lifespan. Higher current densities generally lead to faster reaction rates but can accelerate anode wear. Therefore, a careful balance must be struck. The design configuration of the electrode system, including inter-electrode gap and flow dynamics, also plays a vital role. Collaborating with experienced providers like China Titanium Factory ensures access to tailored solutions and expert guidance for specific wastewater treatment needs.

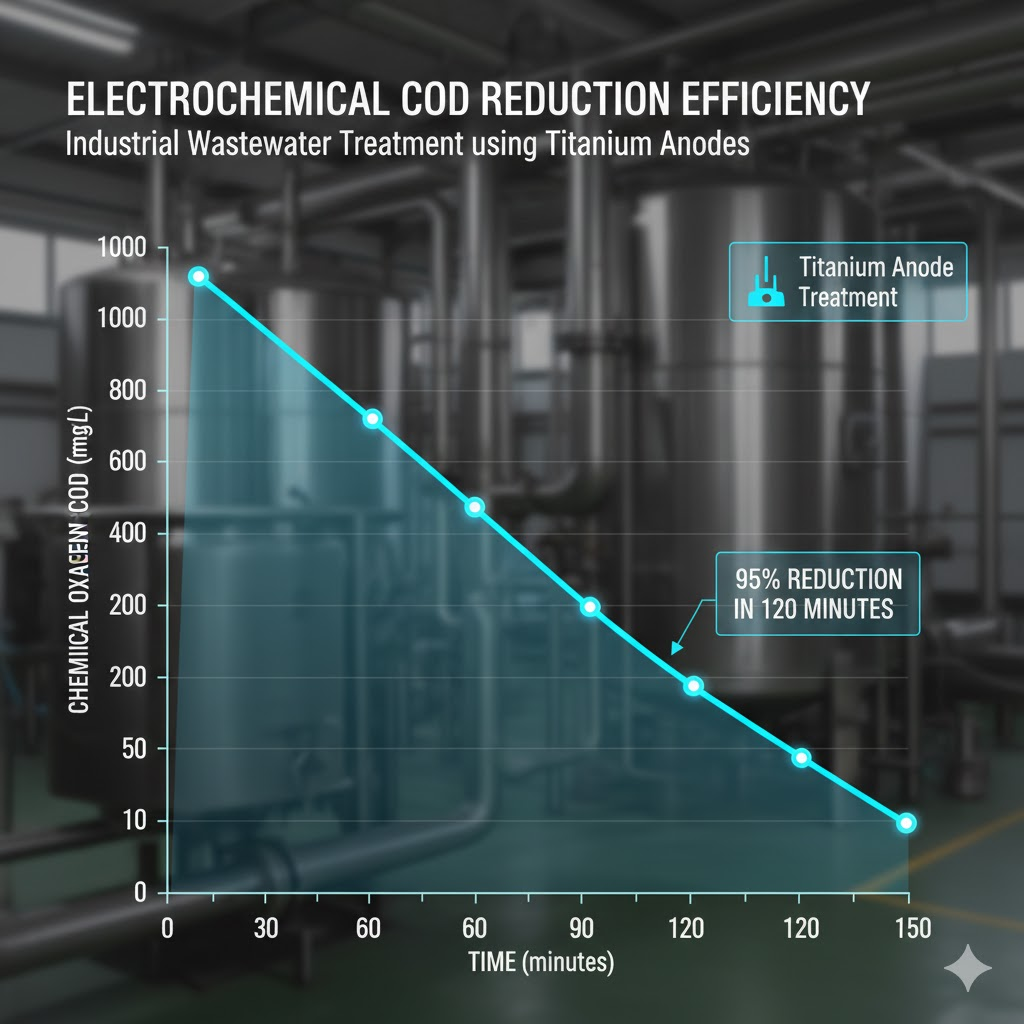

The effectiveness of titanium anodes in industrial wastewater treatment is well-documented through numerous successful implementations. These case studies provide quantifiable proof of their ability to achieve significant COD reduction and meet stringent environmental standards. For instance, a chemical plant processing complex organic dyes in its effluent achieved a COD reduction of over 95% using an MMO-coated titanium anode system. This led to discharge water quality consistently below regulatory limits, avoiding hefty penalties. The operational costs were also significantly lower compared to previous chemical oxidation methods due to reduced reagent consumption.

Another notable case involved a pharmaceutical manufacturing facility struggling with high COD and specific drug residues. After implementing a titanium anode-based electrochemical reactor, the facility reported a consistent COD removal efficiency of 88-92% and complete degradation of target pharmaceutical compounds. This ensured full compliance and enhanced the company's environmental profile.

Successful implementation of titanium anode systems often yields benefits beyond just COD reduction. This includes significant color removal, reduction of toxicity, and even disinfection, providing a multi-faceted approach to wastewater purification.

These examples highlight the robust capabilities of titanium anode technology. They deliver not only environmental compliance but also substantial operational efficiency gains and a strong return on investment for industrial clients. For further reading on electrochemical advanced oxidation processes, refer to publications from reputable sources such as ScienceDirect or the American Chemical Society.

Ensuring the long-term efficiency and reliability of titanium anode systems requires adherence to specific operational and maintenance protocols. Proper management extends anode lifespan and optimizes treatment performance. Installation should be performed by qualified personnel, following manufacturer specifications for electrical connections, electrode spacing, and reactor integration. The power supply must be stable and appropriately sized for the system's current density requirements. Routine maintenance primarily focuses on electrode cleaning to prevent passivation or fouling. Depending on wastewater characteristics, this may involve periodic acid washing, mechanical brushing, or polarity reversal. Monitoring key operational parameters such as current, voltage, pH, and temperature is also essential.

Troubleshooting common issues, such as decreased current efficiency or increased cell voltage, typically involves checking electrode cleanliness, power supply integrity, and effluent composition. Adopting these best practices ensures sustained system longevity and consistent COD reduction.

The adoption of titanium anodes for industrial wastewater treatment aligns perfectly with modern sustainability goals. This technology offers a compelling combination of environmental stewardship and robust economic benefits. Environmentally, these systems significantly reduce the reliance on bulk chemical reagents for oxidation processes. This translates to a lower chemical footprint, safer operations, and reduced transportation impacts. Furthermore, the minimal sludge production drastically decreases the volume of hazardous waste requiring disposal, contributing to a circular economy. The energy footprint can also be optimized through efficient system design and operation. While electrochemical processes require electricity, the overall lifecycle impact is often favorable due to reduced chemical manufacturing, transport, and sludge management. The United States Environmental Protection Agency (EPA) provides extensive resources on sustainable water management practices, which can be explored further on their website. Economically, the long lifespan of high-quality titanium anodes translates to reduced replacement costs. Lower chemical consumption and minimized sludge disposal expenses contribute to substantial operational cost savings over time. Achieving consistent regulatory compliance avoids potential fines and enhances corporate reputation. Ultimately, investing in titanium anode technology provides a strong return on investment. It delivers a future-proof solution for industrial wastewater challenges, balancing stringent environmental demands with cost-effective and sustainable operations.

This section addresses common inquiries regarding the application, performance, and maintenance of titanium anodes in industrial wastewater treatment for COD reduction.

The lifespan of a titanium anode varies significantly based on its coating type, operating current density, and the specific characteristics of the wastewater. High-quality MMO-coated anodes can typically operate effectively for 3 to 7 years, with some specialized coatings exceeding 10 years under optimal conditions.

Titanium anodes, particularly with MMO coatings, generate highly reactive hydroxyl radicals that are non-selective oxidizers. This allows them to effectively degrade a very broad range of organic compounds, including recalcitrant and non-biodegradable pollutants that challenge conventional methods. However, efficiency can vary with molecular structure and concentration.

Unlike chemical precipitation or biological treatments that generate significant volumes of sludge, electrochemical oxidation directly mineralizes organic pollutants into carbon dioxide and water. This process minimizes the formation of solid byproducts, substantially reducing the volume of sludge that requires costly handling and disposal.

Primary maintenance involves periodic cleaning of the anode surfaces to prevent fouling or scaling, which can reduce efficiency. This may include chemical washes (e.g., with dilute acid), mechanical cleaning, or occasional polarity reversal. Regular monitoring of operational parameters like current, voltage, and effluent quality is also crucial.

Yes, titanium anode systems are highly adaptable and can be integrated as a pre-treatment, post-treatment, or standalone unit within existing wastewater treatment plants. They often serve as an effective polishing step for effluents that require further COD reduction to meet stringent discharge limits, or as a primary treatment for specific challenging streams.

Addressing the complexities of industrial wastewater treatment requires specialized expertise and cutting-edge technology. China Titanium Factory stands as a leading provider of high-performance titanium anodes, engineered for superior Chemical Oxygen Demand (COD) removal and sustainable environmental compliance. The team offers comprehensive support, from initial consultation and customized system design to anode manufacturing and ongoing technical assistance. A collaborative approach ensures that solutions are precisely tailored to the unique characteristics of each industrial wastewater stream.

Partnering with an experienced provider ensures access to the latest advancements in electrochemical technology. This commitment to innovation and quality guarantees optimal performance and long-term cost-effectiveness for industrial clients. Learn more about our approach and capabilities by visiting our blog, or explore our range of advanced titanium anode products.