ASTM F136 is the standard specification for Wrought Titanium-6Aluminum-4Vanadium Extra Low Interstitial (Ti-6Al-4V ELI) alloy, designated for use in **surgical implant applications**. It is a high-strength, low-density, and highly biocompatible material, often referred to as **Titanium Grade 23**. The "ELI" designation signifies strict control over interstitial elements (Oxygen, Carbon, Nitrogen, Iron) to ensure superior ductility and fracture toughness, which are essential for long-term implant performance [1] [2].

The chemical purity of ASTM F136 is paramount. The "Extra Low Interstitial" limits distinguish it from standard Grade 5 titanium (Ti-6Al-4V), making it suitable for implantation. The table below provides the maximum allowable limits for key elements as per the standard:

| Element | Maximum Weight % (ASTM F136) | Key Difference from Grade 5 |

|---|---|---|

| Aluminum (Al) | 5.5 – 6.75 | Same |

| Vanadium (V) | 3.5 – 4.5 | Same |

| Oxygen (O) | 0.13 (max) | Lower (Grade 5 max is 0.20) |

| Iron (Fe) | 0.25 (max) | Same |

| Carbon (C) | 0.08 (max) | Same |

| Nitrogen (N) | 0.05 (max) | Same |

| Hydrogen (H) | 0.0125 (max) | Same |

| Titanium (Ti) | Remainder | Base metal |

Source: ASTM F136 Standard Specification [1]

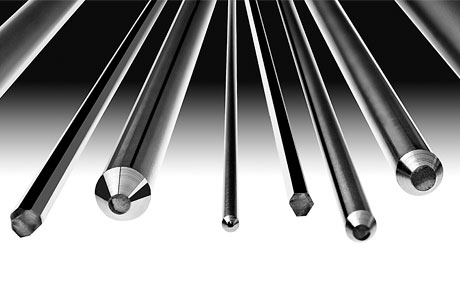

To ensure the structural integrity of surgical implants, ASTM F136 mandates specific minimum mechanical properties. These values are typically for the annealed condition and vary based on the product form (e.g., bar, sheet, wire) and diameter/thickness. The values below represent typical minimum requirements for bar stock:

| Property | Minimum Requirement | Unit |

|---|---|---|

| Tensile Strength (UTS) | 860 (125) | MPa (ksi) |

| Yield Strength (0.2% Offset) | 795 (115) | MPa (ksi) |

| Elongation at Break | 10 | % |

| Reduction of Area | 25 | % |

The high strength and low elastic modulus of Ti-6Al-4V ELI make it ideal for orthopedic devices, dental implants, and spinal fixation components [3].

For global procurement and compliance, it is important to recognize the equivalent international standard:

ISO Equivalent: ISO 5832-3 (Implants for surgery — Metallic materials — Part 3: Wrought titanium 6-aluminium 4-vanadium alloy). This standard is functionally identical to ASTM F136, ensuring consistency across international markets [4].

Orthopedic Implants (e.g., bone plates, screws, rods)

Spinal Fixation Devices

Dental Implants and Prosthetics

Surgical Instruments

Piercing Jewelry (due to its high biocompatibility)

If your intent is to source certified medical-grade titanium, you require a manufacturer with proven expertise in ELI material production and strict quality control. We specialize in producing Ti-6Al-4V ELI mill products (bar, plate, wire) that meet the latest ASTM F136 and ISO 5832-3 standards. Our materials are fully traceable and supplied with comprehensive mill test reports.

Contact Our Certified ASTM F136 Sales Team for a Quote Today.