What Are Titanium Anodes and Why Do They Need Recoating?

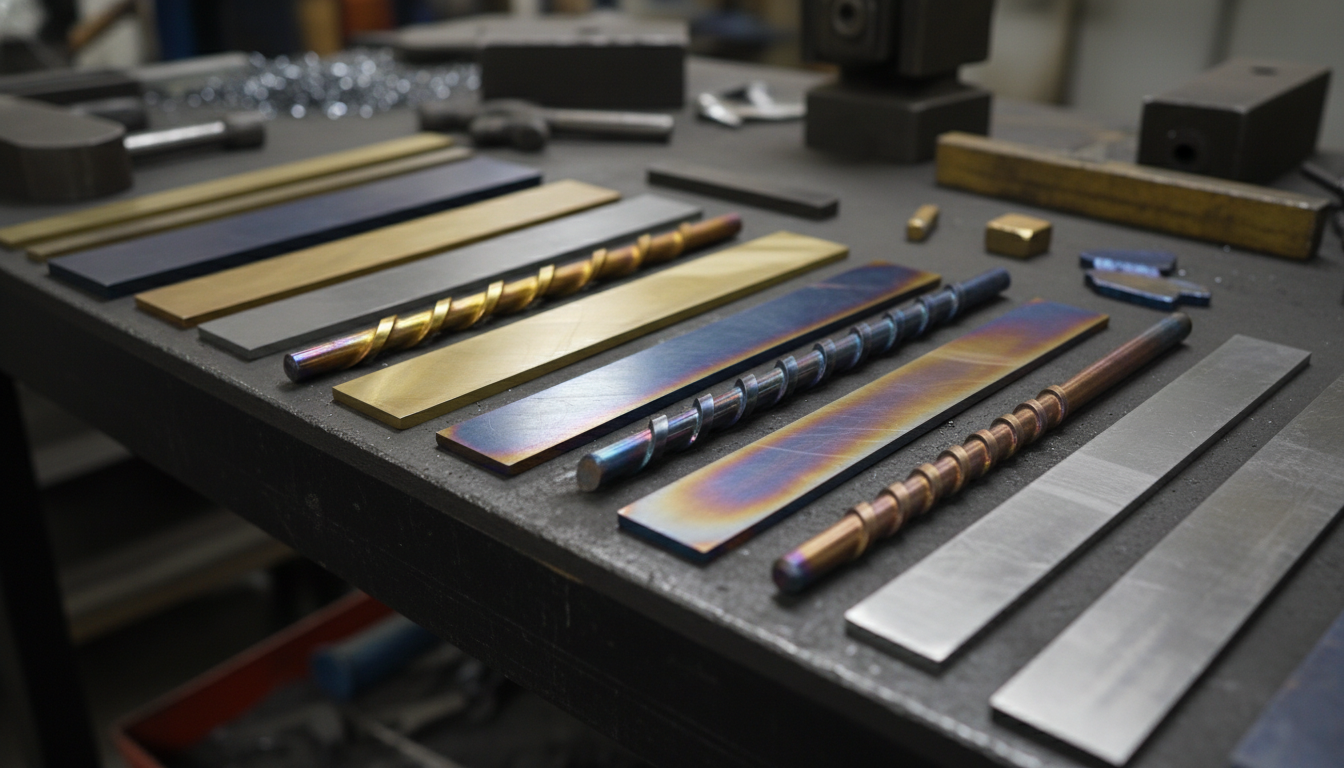

In countless industrial processes, from water treatment to chemical production, titanium anodes are the silent workhorses. These specialized electrodes facilitate electrochemical reactions, playing a critical role in efficiency and product quality. They aren't just bare titanium; they feature an active coating, often a Mixed Metal Oxide (MMO) or platinum, that makes the magic happen.

These active coatings, applied to a robust titanium substrate, are what make them "Dimensional Stable Anodes" (DSA). They offer superior conductivity and corrosion resistance. But even the toughest coatings have a shelf life. Over time, constant exposure to harsh electrochemical environments takes its toll. The active layer degrades, current efficiency drops, and your energy bills go through the roof. This isn't just a minor hiccup; it can bring an entire production line to a grinding halt.

This degradation isn't a mystery; it's a fact of life for these hardworking components. The active coating thins, delaminates, or gets poisoned by impurities in the electrolyte. When that happens, the underlying titanium starts to passivate, or worse, corrode, rendering the anode useless. Replacing them outright can be a significant capital expense, a real pinch in the budget. This is where recoating enters the picture – a smart, sustainable solution to breathe new life into your critical assets.

The Strategic Advantages of Recoating Titanium Anodes

Choosing to recoat your titanium anodes isn't just a maintenance task; it's a strategic business decision. Think of it as getting a new car for a fraction of the price, but with the same performance. The most immediate benefit? Cost savings. Recoating can be significantly less expensive than purchasing brand-new anodes, often cutting costs by 50% or more. This isn't pocket change; it's a substantial reduction in capital expenditure that frees up funds for other critical investments.

Beyond the budget, recoating offers a lifeline to your operational efficiency. A freshly recoated anode performs just like a new one, restoring optimal current density and energy consumption. This means your processes run smoother, faster, and with less power draw. It's a win-win: better performance for less money. This approach also extends the overall lifespan of your anode inventory, pushing out replacement cycles and reducing the headache of frequent procurement.

Then there's the environmental angle. In an era where sustainability isn't just a buzzword but a business imperative, anode recoating shines. By reusing the titanium substrate, you significantly reduce waste and conserve valuable raw materials. This practice embodies the principles of a circular economy, cutting down on the energy and resources needed for new manufacturing. It's a responsible choice that bolsters your company's green credentials and helps keep valuable materials out of the landfill. For a deeper dive into sustainable industrial practices, consider resources from the Environmental Protection Agency (EPA).

When is Recoating the Right Choice? Assessing Anode Condition

Not every old anode is a candidate for a facelift. Knowing when to recoat is just as crucial as knowing how. The golden rule? Substrate integrity. The underlying titanium structure must be sound, free from significant deformation, severe corrosion, or excessive pitting. Think of it like a house: you can repaint the walls and fix the roof, but if the foundation is crumbling, it's time for a new build.

A thorough visual inspection is your first line of defense. Look for signs of mechanical damage, severe pitting, or warping. Beyond what meets the eye, consider the remaining coating thickness and its uniformity. Historical operational data—how long the anode has been in service, the type of electrolyte, current densities—also provides valuable clues. If the anode has been working in extremely aggressive conditions, its substrate might be compromised even if it doesn't look terrible.

It's smart to consult with specialists who possess the right tools and expertise for anode assessment. Companies like China Titanium Factory can provide detailed evaluations, using techniques like eddy current testing or ultrasonic checks to gauge substrate health. This isn't guesswork; it's a data-driven decision. A proper assessment ensures you're not throwing good money after bad, and that your recoated anodes will deliver the performance you expect.

Here's a quick decision matrix for anode suitability:

| Criterion | Good Candidate for Recoating | Consider Replacement |

|---|---|---|

| Substrate Integrity (Visual) | Minimal pitting, no severe warping or cracks. | Extensive pitting, severe deformation, or cracks. |

| Coating Adhesion | Coating wear, but no major delamination (prior to stripping). | Widespread delamination or bare spots exposing compromised titanium. |

| Operational History | Standard operating conditions, expected wear patterns. | Extreme overcurrent, highly corrosive electrolytes, repeated short circuits. |

| Cost-Benefit Analysis | Recoating offers significant savings over new anode purchase. | Recoating cost approaches new anode cost due to extensive repairs needed. |

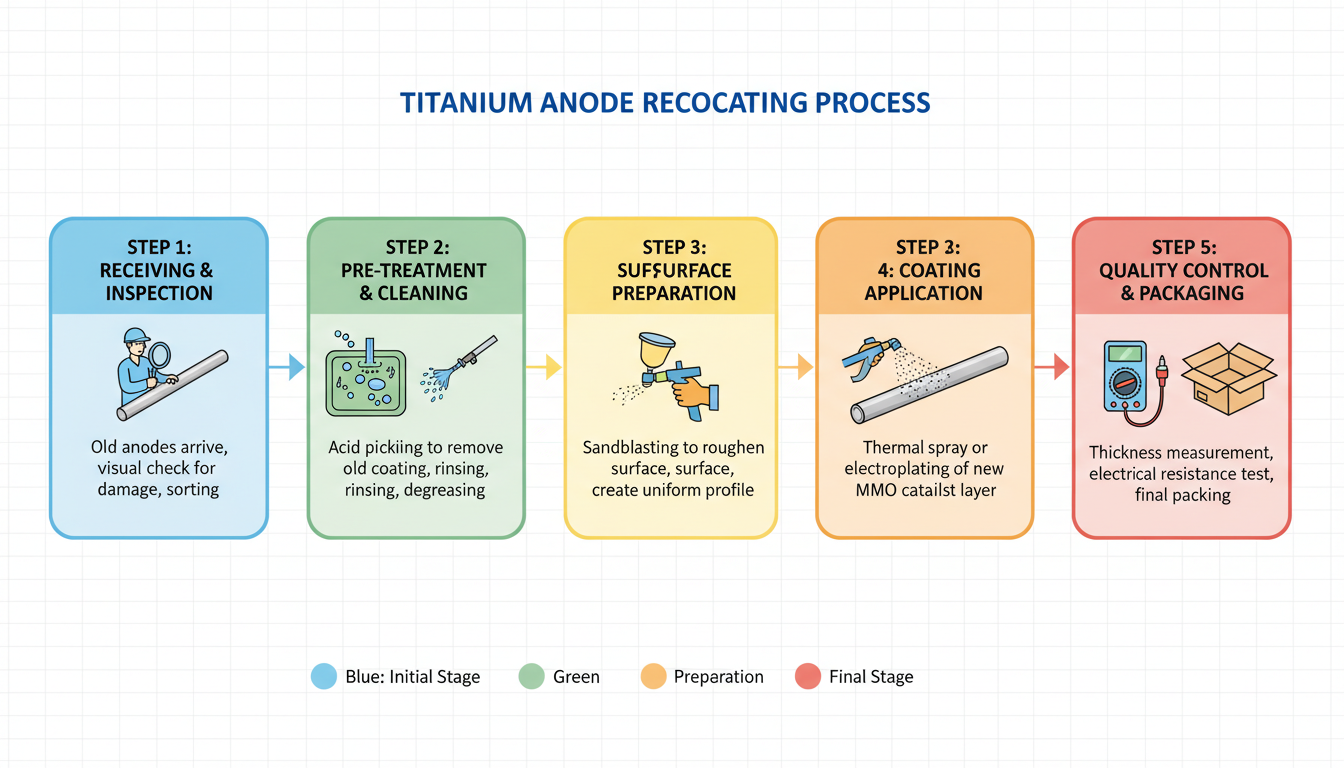

The Comprehensive Process of Recoating Titanium Anodes

Recoating a titanium anode is far from a simple paint job. It's a precise, multi-stage engineering process demanding meticulous attention to detail and specialized equipment. Each step is crucial, building upon the last to ensure the new coating adheres perfectly and performs flawlessly. Skipping a step or cutting corners inevitably leads to premature failure and wasted investment. Let's walk through the journey an anode takes from worn-out to like-new.

Step 1: Stripping the Old Coating

First things first: the old, exhausted coating has to go. This isn't just about getting it off; it's about doing so without harming the underlying titanium. Chemical stripping, typically involving acids, is a common method. It dissolves the spent active layer, leaving the titanium largely untouched. The choice of chemical and precise control over temperature and exposure time are critical here to prevent substrate damage.

For some applications, mechanical abrasion might be used, but this requires extreme care to avoid pitting or scratching the titanium. The goal is a clean slate, a substrate ready for its next life. Any remnants of the old coating or corrosion products can compromise the adhesion of the new layer, setting the stage for early failure.

Step 2: Surface Preparation and Cleaning

This stage is arguably the most crucial for coating longevity. A pristine, active titanium surface is paramount for optimal adhesion. After stripping, anodes undergo rigorous cleaning. This usually involves degreasing to remove any oils or organic contaminants, followed by multiple rinses.

Next comes surface roughening, often through sandblasting with specialized media or controlled acid etching. This creates a microscopic texture, giving the new coating something to "grip" onto. The prepared surface isn't just clean; it's activated, ready to form a strong metallurgical bond with the new coating. Think of it as preparing a canvas for a masterpiece – the foundation has to be perfect.

Step 3: Advanced Coating Application Methods

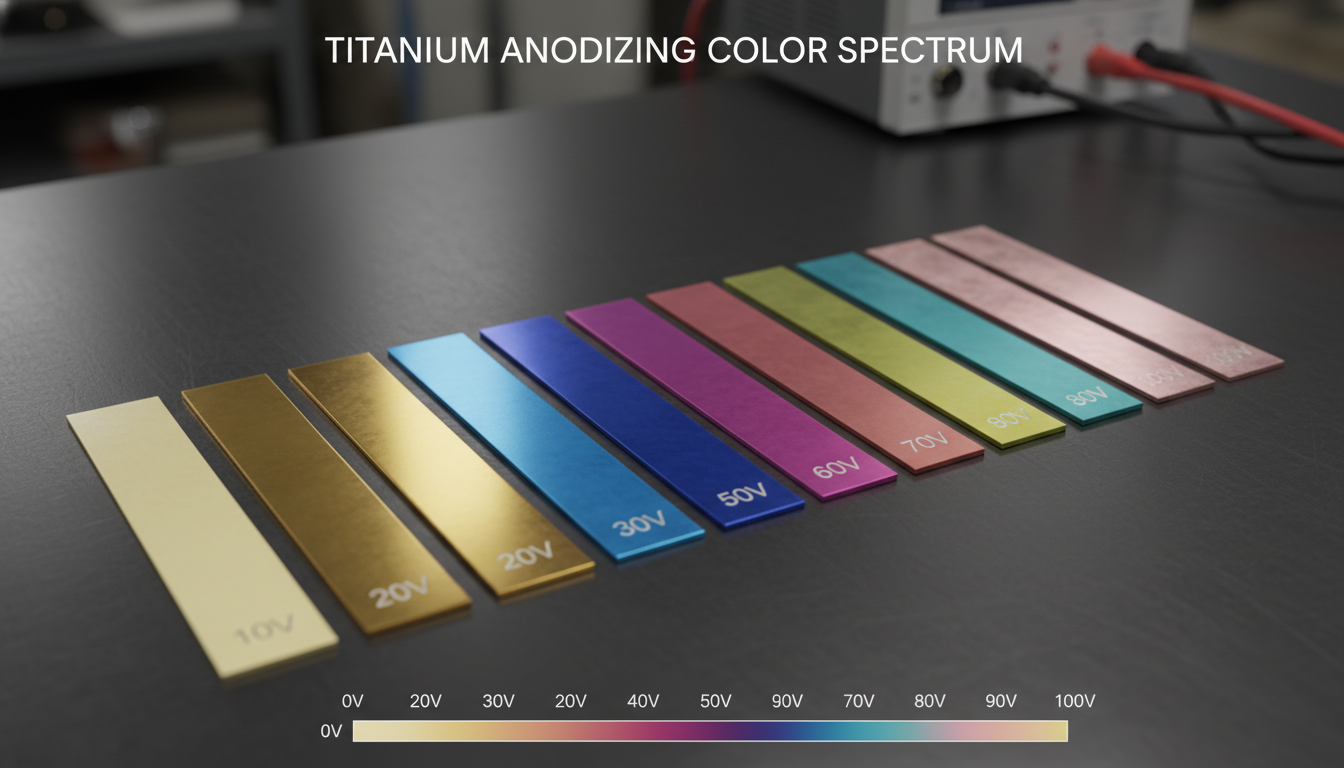

With the substrate prepped, it's time for the new active coating. Various sophisticated techniques are employed, each suited for different coating materials and anode geometries. Thermal spraying, including plasma or flame spraying, deposits a molten coating onto the titanium surface. It's fast, but requires careful temperature control.

Electroplating and brush plating involve depositing a metal layer (like platinum or ruthenium) from an electrolyte using an electric current. This offers precise thickness control. For MMO coatings, a solution containing precious metal salts (e.g., ruthenium oxide, iridium oxide) is typically applied in multiple layers, often through painting or spraying. The choice of method depends on the specific requirements, desired coating properties, and the expertise of the anode manufacturing and coating service provider.

Mixed Metal Oxide (MMO) Coating: A composite coating consisting of various metal oxides, often including precious metals like ruthenium and iridium. These coatings are highly conductive, catalytically active, and provide excellent corrosion resistance, making them ideal for many electrochemical applications.

Step 4: Curing and Post-Treatment

Once applied, the coating isn't fully ready. It needs to be cured. For MMO coatings, this typically involves high-temperature heat treatment in specialized ovens. This process transforms the applied metal salts into their stable oxide forms, developing the desired crystal structure and electrochemical properties. Precise temperature profiles and dwell times are critical for optimal performance and durability. It's during this stage that the coating truly "activates."

Some coatings may also undergo additional post-treatment steps, such as annealing or surface conditioning, to further enhance their adhesion, reduce internal stresses, or fine-tune their catalytic activity. These steps ensure the coating is robust enough to withstand the rigors of its operational environment.

Step 5: Rigorous Quality Control and Testing

The final step, but by no means the least important, is comprehensive quality control. Every recoated anode undergoes a battery of tests to confirm it meets specifications and will perform as expected. This starts with visual inspection for any defects, followed by precise coating thickness measurements using non-destructive methods like X-ray fluorescence (XRF) or eddy current gauges. Adhesion testing, often involving destructive peel tests on samples or pull-off tests, verifies the bond strength between the new coating and the substrate.

Crucially, electrochemical performance evaluations are carried out. These include accelerated life testing, measuring electrode potential, and assessing current efficiency to simulate real-world operating conditions. Only anodes that pass these stringent checks are cleared for return to service. This rigorous approach ensures reliability and gives you peace of mind. For more on quality assurance in manufacturing, refer to standards from organizations like the International Organization for Standardization (ISO).

Understanding Coating Wear and Preventing Common Issues

Even with the best recoating job, coatings will eventually wear down. It's the nature of the beast. But understanding why they degrade and what problems can pop up during refurbishment helps you get more mileage out of them. A little foresight can save a lot of heartache and downtime.

Mechanisms of Anode Coating Degradation

Anode coatings face a constant barrage of challenges. Electrochemical degradation is a prime culprit, where side reactions or localized overpotentials slowly consume the active material. Passivation, the formation of a non-conductive oxide layer, can occur on the titanium substrate if the active coating is compromised, effectively shutting down the anode. It's like rust on steel, but for an electrode.

Physical erosion from high flow rates or abrasive particles in the electrolyte also grinds away at the coating. Chemical attack from aggressive species within the electrolyte can dissolve or destabilize the active oxides. Understanding these mechanisms helps in selecting the right coating for specific applications and optimizing operating parameters to extend anode life. Every process is unique, so tailoring your approach is key.

Troubleshooting Adhesion Problems in Recoated Anodes

Poor adhesion is a nightmare scenario for recoated anodes. If the new coating doesn't stick, you've got a dud on your hands. The most common culprit? Inadequate surface preparation. Any residual contaminants—oils, old coating particles, or even invisible oxides—will act as a barrier, preventing a strong bond. It's like trying to glue something to a greasy surface; it just won't hold.

Incorrect surface roughening, either too smooth or too aggressive, can also lead to issues. Over-etching can weaken the substrate, while insufficient etching won't provide enough mechanical interlock. The wrong coating material for the substrate or improper curing temperatures are also major players in adhesion failure. It all boils down to precision and following the process to the letter. A reputable recoating service provider, like China Titanium Factory, understands these nuances and has robust protocols to prevent these headaches.

Preventing Substrate Damage During Refurbishment

The titanium substrate is the bedrock of your anode. Damage it during recoating, and you might as well throw the whole thing out. The stripping phase is particularly risky. Aggressive chemical solutions or prolonged exposure can thin the titanium or induce hydrogen embrittlement. Mechanical methods, if not precisely controlled, can gouge or pit the surface, creating weak points.

Best practices include using inhibitors in chemical baths, carefully monitoring etching times, and employing highly skilled technicians for any abrasive cleaning. The goal is to strip the old coating while preserving the titanium's integrity for future recoating cycles. A good substrate means more life cycles, more savings, and less waste. It's about playing the long game.

Industry Standards, Leading Providers, and Material Innovations

Navigating the world of titanium anode recoating means understanding the benchmarks of quality, knowing who to trust, and keeping an eye on what's new. It's not just about getting a service; it's about making an informed investment that pays dividends in performance and longevity.

Key Industry Standards and Certifications

When dealing with industrial anodes, standards aren't just suggestions; they're critical for safety, performance, and compatibility. Look for providers who adhere to relevant international standards such as ISO 9001 for quality management systems. Specific ASTM standards might govern material properties, testing methods, and performance criteria for various electrochemical applications. These certifications are your assurance that the provider's processes are vetted and meet rigorous global benchmarks.

Understanding these standards helps you specify your requirements clearly and ensures that the recoated anodes integrate seamlessly into your existing systems. It's the difference between a reliable component and a constant headache. Don't be shy about asking for proof of compliance.

Selecting a Trusted Titanium Anode Recoating Service Provider

Choosing the right recoating partner is paramount. This isn't a commodity purchase; it's a specialized service. Look for providers with a proven track record, extensive experience in your specific industry, and a deep understanding of various coating chemistries (MMO, platinum, etc.). Check their technical capabilities: Do they have the necessary equipment for advanced surface preparation, precise coating application, and comprehensive quality control? Ask about their quality assurance protocols, their testing methodologies, and if they offer warranties on their work.

Don't just take their word for it. Request case studies, customer testimonials, and references. A reputable provider will be transparent about their processes and eager to demonstrate their expertise. Companies like China Titanium Factory, with years of experience in titanium anode manufacturing and recoating, often stand out for their comprehensive approach and commitment to quality.

Innovations in Anode Coating Materials and Technology

The field of electrochemical coatings isn't stagnant. Researchers and manufacturers are constantly pushing the envelope, developing new formulations that offer enhanced performance and durability. We're seeing innovations in Mixed Metal Oxide (MMO) blends, incorporating novel catalysts and dopants that improve current efficiency, reduce overpotential, and extend lifespan in challenging environments. Think of coatings designed specifically for high-salinity water treatment or harsh chlor-alkali production.

Advancements in coating application techniques are also making recoating more precise and efficient. These innovations mean that today's recoated anodes can often outperform their predecessors, sometimes even surpassing the performance of older "new" anodes. Staying informed about these developments can help you make future-proof decisions for your anode management strategy. It’s an exciting time to be in the industry.

Frequently Asked Questions About Recoating Titanium Anodes

Got questions? You're not alone. Here are some common queries we hear about titanium anode recoating, offering practical insights for engineers and decision-makers.

How many times can a titanium anode be recoated?

The number of recoating cycles primarily depends on the integrity of the titanium substrate. If the substrate remains sound—free from significant corrosion, warping, or deep pitting—it can often be recoated multiple times, typically 3 to 5 times. Some well-maintained anodes have even seen more cycles. The quality of previous refurbishments also plays a role; a poorly stripped or prepped anode might not make it through another cycle.

What is the typical turnaround time for anode recoating?

Turnaround times can vary significantly based on the anode's condition, type, complexity, and the service provider's workload. Generally, the entire process—from receipt and assessment to stripping, preparation, coating application, curing, and quality control—can take anywhere from 4 to 8 weeks. It's crucial to discuss lead times with your chosen provider and factor them into your maintenance schedule to avoid unexpected downtime.

Does recoating affect the anode's original performance?

When done by an experienced and reputable provider, recoating aims to restore or even enhance the anode's original electrochemical performance. Modern recoating techniques and advanced coating materials mean that a properly refurbished anode should exhibit equivalent or superior current efficiency, operating voltage, and lifespan compared to a new anode. The key is meticulous surface preparation and precise coating application.

What are the environmental benefits of choosing recoating?

Recoating offers substantial environmental advantages. By reusing the titanium substrate, you significantly reduce the demand for virgin raw materials, which are energy-intensive to extract and process. It also minimizes waste generation by keeping old anodes out of landfills. This aligns perfectly with circular economy principles, lowering your carbon footprint and promoting sustainable industrial operations. It's a win for both your business and the planet.

How do I know if my anodes are suitable for recoating?

The primary indicator for recoating suitability is the integrity of the titanium substrate. Look for minimal physical damage, such as severe bending, deep pitting, or cracks. The substrate should not be significantly corroded. A reputable recoating service will perform a thorough assessment, including visual inspection and potentially non-destructive testing, to determine if your anodes are good candidates. When in doubt, let the experts take a look.

Is recoating cheaper than buying new anodes?

Yes, almost always. Recoating titanium anodes is significantly more cost-effective than purchasing new ones. While costs vary based on anode size, complexity, and coating type, recoating typically offers savings of 30% to 70% compared to new anode procurement. This massive reduction in capital expenditure makes it an attractive option for budget-conscious operations looking to maintain high performance.

What industries benefit most from titanium anode recoating?

Industries heavily reliant on electrochemical processes stand to gain the most. This includes the chlor-alkali industry for chlorine and caustic soda production, electroplating for metal finishing, water treatment (for disinfection and purification), electrowinning for metal recovery, and cathodic protection systems. Essentially, any industry using titanium anodes that undergo coating degradation will find immense value in recoating programs.

Conclusion: Embracing the Future of Anode Management

Recoating titanium anodes isn't just a maintenance task; it's a strategic pillar for operational excellence and environmental stewardship. When your anodes start to falter, don't automatically reach for the replacement catalog. Consider the proven benefits of professional recoating: substantial cost savings, restored or enhanced performance, and a significant reduction in your ecological footprint. It's a smart business move, plain and simple.

The key lies in understanding the process, assessing your anodes diligently, and partnering with a provider who truly knows their stuff. With meticulous surface preparation, advanced coating techniques, and rigorous quality control, a recoated anode can be every bit as effective as a new one, often for a fraction of the cost. By embracing this sustainable approach, you're not just extending the life of your equipment; you're building a more efficient, resilient, and responsible operation. It's time to make informed decisions about your long-term anode management strategy.