Titanium, a remarkable metal known for its strength, lightness, and corrosion resistance, possesses another fascinating characteristic: its ability to display a spectrum of vibrant colors when anodized. These anodized titanium colors are not due to dyes or pigments, but rather a unique optical phenomenon created through a controlled electrochemical process. From dazzling blues and purples to subtle bronzes and greens, the versatility of anodized titanium has made it a popular choice across various industries, including jewelry, medical implants, and aerospace components. This article delves into the science behind these captivating hues, exploring the anodizing process, the factors influencing color, and its diverse applications. Understanding the intricacies of titanium anodizing is key to appreciating the beauty and functionality of this extraordinary material.

Anodized titanium refers to titanium metal that has undergone an electrolytic passivation process to increase the thickness of the natural oxide layer on its surface. This enhanced oxide layer is what gives rise to the array of colors. Unlike painted or coated surfaces, the color in anodized titanium is integral to the material itself, making it highly durable and resistant to fading or chipping. The process not only adds aesthetic appeal but also improves the material's wear resistance and biocompatibility, making it suitable for a wide range of demanding applications.

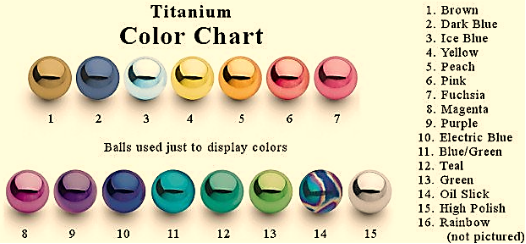

The aesthetic appeal of titanium color plays a crucial role in its application, particularly in consumer-facing products. In jewelry, for instance, the ability to produce a wide titanium color spectrum allows designers to create unique and eye-catching pieces without relying on traditional plating methods that can wear off. In medical and dental fields, different anodized titanium colors can be used for identification purposes, such as distinguishing between various implant sizes or types. Furthermore, the visual differentiation provided by anodizing colors can enhance brand identity and product recognition in competitive markets. The vibrant and durable colors offer both functional and decorative advantages, expanding titanium's utility beyond its inherent mechanical properties.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. While commonly associated with aluminum, titanium also undergoes a unique anodizing process that results in its distinctive coloration. The term "anodizing" comes from the fact that the part to be treated forms the anode electrode of an electrolytic cell. This process is fundamentally different from plating, where a layer of metal is deposited onto the surface. Instead, anodizing grows a layer of oxide from the base metal itself, making it an integral part of the material.

The titanium anodizing process is a relatively straightforward yet precise procedure that involves immersing the titanium part in an electrolytic solution and applying an electric current. The thickness of the resulting oxide layer directly correlates with the voltage applied, and it is this varying thickness that causes the interference colors we observe. This phenomenon is known as thin-film interference, similar to how oil slicks on water or soap bubbles display colors.

Cleaning: The titanium piece must be thoroughly cleaned to remove any oils, dirt, or surface contaminants. This step is crucial for ensuring uniform anodization and consistent color. Any impurities can lead to uneven coloration or defects in the oxide layer.

Etching (Optional but Recommended): Sometimes, the titanium is etched in an acid solution to create a uniform surface texture. This can improve the adhesion of the oxide layer and enhance the vibrancy of the colors.

Rinsing: After cleaning and etching, the titanium is rinsed thoroughly with distilled water to remove any residual chemicals.

Electrolyte Preparation: The titanium is then immersed in an electrolytic bath. Common electrolytes include TSP (trisodium phosphate) solutions or various acid solutions (e.g., phosphoric acid, sulfuric acid). The choice of electrolyte can influence the quality and consistency of the oxide layer.

Anodizing: A DC power supply is connected, with the titanium acting as the anode (positive electrode) and an inert material (like stainless steel or lead) as the cathode (negative electrode). As voltage is applied, oxygen ions from the electrolyte combine with the titanium surface to form a transparent titanium dioxide (TiO2) layer. The voltage is gradually increased until the desired color is achieved. The higher the voltage, the thicker the oxide layer, and thus a different color is produced. This is where the titanium anodizing voltage chart comes into play, guiding the operator to achieve specific colors.

Rinsing: Once the desired color is reached, the titanium is removed from the electrolyte and rinsed again with distilled water to stop the anodizing reaction and remove any remaining electrolyte.

Drying: The anodized titanium is then dried, revealing its new, vibrant color.

While there are various types of anodizing processes for different metals, for titanium, the most common type used to achieve decorative colors is Type II (or often referred to as color anodizing). This type focuses on creating a thin, aesthetically pleasing oxide layer that produces interference colors. Other types of anodizing, like Type III (hardcoat anodizing) primarily for aluminum, aim for thicker, harder, and more wear-resistant coatings, which are generally not used for decorative titanium coloring.

The magic of anodized titanium colors lies in the precise control of voltage during the anodizing process. As the voltage increases, the thickness of the titanium dioxide layer grows, causing different wavelengths of light to interfere and produce a distinct color. This relationship is so consistent that a reliable titanium anodizing chart can be created, mapping specific voltages to specific colors. This chart is an invaluable tool for artisans and manufacturers aiming for predictable and repeatable results.

The titanium anodizing voltage color chart is a practical guide that illustrates the approximate colors achieved at various voltage levels. It's important to note that these values can vary slightly depending on the electrolyte used, the purity of the titanium, and the surface finish. However, the general progression of colors remains consistent. Below is a typical representation of a titanium voltage color chart:

| Voltage (V) | Approximate Color |

|---|---|

| 9-15 | Tan/Brown |

| 15-20 | Bronze |

| 20-25 | Dark Blue/Purple |

| 25-30 | Blue |

| 30-35 | Light Blue/Sky Blue |

| 35-40 | Gold/Yellow |

| 40-45 | Rose Gold/Pink |

| 45-50 | Magenta/Purple |

| 50-55 | Green |

| 55-60 | Teal/Blue-Green |

| 60-65 | Light Green/Lime Green |

| 65-70 | Yellow-Green |

| 70-75 | Orange |

| 75-80 | Red-Orange |

| 80-85 | Pink-Red |

| 85-90 | Violet/Deep Purple |

| 90-100 | Multi-color/Rainbow |

This anodizing colors chart serves as a fundamental reference for anyone working with titanium anodization. It allows for precise color selection and replication, which is critical for both artistic and industrial applications.

The titanium color spectrum is a continuous range of colors produced by the varying thickness of the oxide layer. Unlike pigments that absorb certain wavelengths of light and reflect others, anodized titanium colors are structural colors. This means the color arises from the interference of light waves reflecting off the surface of the titanium and the surface of the oxide layer. As the oxide layer thickens, the path difference for the light waves changes, leading to the cancellation of some colors and the enhancement of others. This phenomenon explains why the color can appear to shift slightly depending on the viewing angle.

Certain anodized titanium colors are particularly popular due to their aesthetic appeal and ease of production. Blues, purples, and golds are frequently seen in jewelry and decorative items. The vibrant blue, often achieved around 25-30 volts, is a classic and widely recognized titanium color. Gold, appearing around 35-40 volts, offers a warm and luxurious alternative. Purple, typically seen at 45-50 volts, provides a rich and deep hue. These colors are relatively stable and consistent, making them favorites for various applications.

While the standard voltage chart provides a good guide, achieving certain rare or unique anodized titanium colors can be more challenging and often requires specialized techniques or precise control. For instance, true reds are notoriously difficult to achieve consistently and often appear as red-orange or pink-red. Multi-color or rainbow effects, often seen at higher voltages (90-100V) or through specific anodizing methods, are also considered unique. These effects are often created by carefully manipulating the voltage during the process or by using specialized masking techniques to create distinct colored areas on a single piece. The pursuit of these unique hues pushes the boundaries of titanium anodizing artistry.

The unique combination of aesthetic appeal and enhanced material properties makes anodized titanium highly desirable across a multitude of practical applications. Its biocompatibility, corrosion resistance, and lightweight nature, coupled with the ability to produce a wide array of colors, open up diverse possibilities.

One of the most prominent applications of anodized titanium colors is in the jewelry industry. Jewelers and artisans are drawn to titanium for its hypoallergenic properties, making it an excellent choice for individuals with sensitive skin who cannot wear traditional metals like gold or silver. The ability to create vibrant, permanent colors without dyes or plating means that titanium jewelry is not only beautiful but also extremely durable and resistant to tarnishing. From rings and earrings to pendants and bracelets, the titanium color spectrum allows for creative designs that stand out. The colors can range from subtle earth tones to brilliant blues, greens, and purples, offering a modern and distinctive alternative to conventional jewelry materials. Furthermore, the lightweight nature of titanium makes large, intricate pieces comfortable to wear.

While less common than in jewelry, anodized titanium cookware is gaining traction, particularly in high-performance outdoor and camping gear. The anodization process enhances the surface hardness and corrosion resistance of titanium, making it more durable and easier to clean. The non-reactive nature of titanium ensures that it does not impart any metallic taste to food, and the anodized layer further reinforces this property. Although the primary focus for cookware is functionality, the subtle coloration that can result from anodization can also add to the aesthetic appeal of these specialized items. This application leverages titanium's strength-to-weight ratio, making for lightweight yet robust cooking solutions for adventurers.

Beyond consumer goods, anodized titanium finds critical applications in various industrial sectors where its enhanced properties are paramount. In the aerospace industry, for example, titanium components are often anodized to improve their corrosion resistance and wear characteristics, especially in harsh environments. The ability to color-code parts through anodization can also aid in assembly and maintenance, ensuring that the correct components are used in specific applications. Similarly, in the medical and dental fields, where biocompatibility is crucial, anodized titanium is widely used for surgical implants, prosthetics, and dental devices. The anodized layer further enhances titanium's already excellent biocompatibility and can be used for identification purposes, as mentioned earlier. For instance, different sizes of dental implants might be anodized to different colors to facilitate quick and accurate selection during surgery. The durability and inertness of the anodized surface also contribute to the long-term success of these implanted devices. Furthermore, in chemical processing and marine environments, the superior corrosion resistance offered by anodized titanium makes it an ideal material for components exposed to aggressive chemicals or saltwater.

In summary, the captivating world of anodized titanium colors is a testament to the fascinating interplay of science and aesthetics. We've explored how titanium, a metal celebrated for its strength and corrosion resistance, can be transformed into a vibrant palette through a precise electrochemical process known as anodizing. This process creates a thin, transparent layer of titanium dioxide on the metal's surface, and it is the varying thickness of this layer, controlled by the applied voltage, that produces the interference colors. The titanium anodizing voltage chart serves as a crucial guide, demonstrating the predictable relationship between voltage and the resulting hue, from subtle tans to brilliant blues, greens, and purples. These structural colors, unlike those produced by dyes, are integral to the material, offering exceptional durability and resistance to fading. The applications of anodized titanium are diverse and impactful, ranging from the hypoallergenic and visually stunning jewelry industry to critical components in aerospace, medical implants, and even specialized cookware, where its enhanced properties provide both functional and aesthetic benefits.

The field of titanium anodizing continues to evolve, with ongoing research and innovation pushing the boundaries of what's possible. Future trends are likely to focus on achieving even greater control over color consistency and expanding the titanium color spectrum to include hues that are currently difficult to produce, such as true reds. Advancements in nanotechnology and surface engineering may lead to novel anodizing techniques that allow for more complex patterns, gradients, and even dynamic color-changing effects. Furthermore, as sustainability becomes an increasingly important consideration, research into more environmentally friendly electrolytes and energy-efficient anodizing processes will undoubtedly gain traction. The integration of artificial intelligence and machine learning could also play a role in optimizing anodizing parameters for precise color replication and quality control. As our understanding of thin-film interference and material science deepens, the future of anodized titanium colors promises even more breathtaking possibilities, further solidifying titanium's place as a material of both exceptional utility and unparalleled beauty.