The Critical Role of IrO2 Coated Anodes: Understanding Service Life in Acidic Environments

Iridium oxide (IrO2) coated anodes are foundational in numerous electrochemical industries. They enable critical processes from chlor-alkali production to water electrolysis. These titanium anodes offer exceptional electrocatalytic activity and corrosion resistance. However, their performance in acidic environments presents a significant challenge.

Acidic conditions can severely limit the service life and durability of IrO2 anodes. Understanding these challenges is paramount for industrial applications. This guide explores the factors affecting anode durability. It also outlines strategies to enhance their performance and lifespan.

What Are IrO2 Coated Anodes? A Foundational Overview

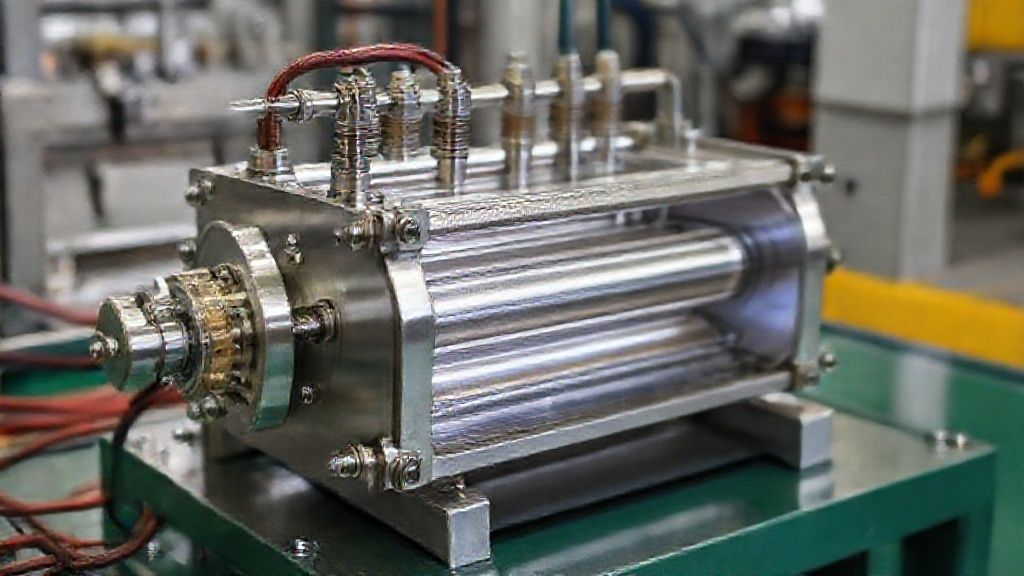

IrO2 coated anodes are a type of Dimensionally Stable Anode (DSA). They feature an active iridium oxide layer on a titanium substrate. This design combines the strength of titanium with the catalytic properties of IrO2. These anodes are prized for their efficiency and stability.

"Dimensionally Stable Anodes (DSAs) are electrodes used in industrial electrochemistry. They consist of a non-consumable substrate, typically titanium, coated with precious metal oxides. DSAs maintain their shape and catalytic activity over long periods."

They are essential in environments requiring high oxygen evolution overpotential. This makes them crucial for many demanding electrochemical processes. China Titanium Factory specializes in producing high-performance IrO2 anodes tailored for diverse industrial needs.

The Science Behind IrO2 Anodes: Composition and Structure

The manufacturing of IrO2 anodes involves several precise steps. First, a titanium substrate undergoes thorough cleaning and surface preparation. This ensures optimal adhesion of the active coating. Next, iridium salt solutions are applied, often through thermal decomposition. This forms a robust iridium oxide layer.

The resulting microstructure is critical. It influences the anode's electrochemical activity and stability. Factors like coating thickness, crystal structure, and porosity are carefully controlled. These elements dictate the anode's resilience in harsh operating conditions.

Key Characteristics and Electrochemical Applications

IrO2 anodes exhibit unique electrochemical characteristics. They possess high oxygen evolution overpotential. This makes them ideal for processes like water electrolysis and chlor-alkali production. Their excellent corrosion resistance also ensures long-term performance.

Key applications include:

Chlor-alkali process: For chlorine and caustic soda production.

Water electrolysis: Generating hydrogen and oxygen.

Electrowinning: Extracting metals from solutions.

Wastewater treatment: Oxidizing pollutants.

These anodes provide superior efficiency and reliability in these critical industrial sectors. Their robust nature supports continuous operation under demanding conditions.

The Challenge of Acidic Environments: Impact on Anode Performance

Acidic media present considerable challenges for IrO2 anodes. These environments are particularly aggressive. They significantly accelerate anode degradation. This leads to reduced efficiency and shorter service life. Understanding these impacts is crucial for effective anode deployment.

The low pH values promote undesirable electrochemical reactions. These reactions compromise the integrity of the active coating. Robust anode design and strategic operational approaches become essential. They mitigate these harsh environmental effects.

Understanding Acidic Media in Electrochemistry

Electrochemical processes often involve various acidic solutions. These include sulfuric acid, hydrochloric acid, and phosphoric acid. Each presents unique corrosive properties. The pH value is a primary indicator of acidity. Lower pH values signify higher acidity.

In acidic environments, materials are prone to proton-induced corrosion. This process can dissolve metal oxides. For IrO2 anodes, this means the active coating can slowly degrade. This degradation mechanism impacts overall electrode stability.

Specific Degradation Pathways for IrO2 in Acid

IrO2 coatings degrade through several distinct mechanisms in acidic conditions. One primary pathway is oxide dissolution. Iridium oxide can react with acidic electrolytes, forming soluble iridium species. This leads to a loss of the active material. Research highlights the vulnerability of IrO2 to dissolution under highly acidic and anodic potentials.

Mechanical erosion also contributes to degradation. High current densities can generate gas bubbles. These bubbles physically abrade the coating. Furthermore, the formation of less active species can occur. This reduces the anode's catalytic efficiency over time. Understanding these failure modes is crucial for mitigation.

Factors Governing IrO2 Anode Service Life and Durability

The lifespan of IrO2 coated anodes depends on many factors. These include operational parameters, material properties, and environmental conditions. A comprehensive analysis of these influences is vital. It allows for accurate prediction and extension of anode durability. Optimizing these factors maximizes performance and return on investment.

Operational Parameters: Current Density and Temperature

Current density significantly impacts anode degradation. Higher current densities accelerate oxygen evolution. This can increase mechanical stress and dissolution rates. Operating within optimal current windows is essential. It balances efficiency with anode longevity.

Temperature also plays a critical role. Elevated temperatures often increase reaction rates. This includes both desired electrochemical reactions and degradation processes. Careful control of operating temperature extends anode service life. It prevents premature failure mechanisms.

Material and Manufacturing Influences

The quality of the anode's components is paramount. Substrate choice, like high-purity titanium, affects mechanical stability. Coating thickness directly correlates with active material availability. Thicker coatings generally offer longer life. However, optimal thickness balances cost and performance.

IrO2 purity and the presence of dopants are also critical. Mixed metal oxides (MMOs) often enhance durability. Reputable manufacturers, like China Titanium Factory, employ stringent quality controls. They ensure superior anode manufacturing for enhanced resistance to acidic attack.

Electrolyte Composition and Impurities

The electrolyte's chemistry profoundly affects anode performance. Specific ions can accelerate or mitigate degradation. For example, chloride ions might influence degradation pathways. pH fluctuations directly impact the stability of the IrO2 coating. Maintaining a stable, controlled pH is vital.

Common impurities in the electrolyte can also poison the anode surface. This reduces catalytic activity. Effective electrolyte management, including filtration and purification, is crucial. It ensures an extended and consistent anode life. This proactive approach safeguards investment.

Advanced Strategies for Extending IrO2 Anode Service Life

Extending the service life of IrO2 anodes in acidic environments is crucial. It ensures operational efficiency and cost-effectiveness. Innovative solutions and best practices are continuously evolving. These strategies aim to enhance durability and longevity. They provide practical approaches for industry professionals.

Innovative Coating Technologies and Mixed Metal Oxides

Advancements in coating formulations are significantly improving anode durability. Mixed Metal Oxides (MMOs) are a prime example. Combining RuO2 with IrO2 creates a synergistic effect. This enhances both corrosion resistance and catalytic activity. Such custom anode designs are engineered for specific, challenging conditions.

Novel materials and multi-layer coatings are also under development. These innovations aim to create more robust anode surfaces. They resist dissolution and mechanical wear more effectively. Studies demonstrate the superior performance of RuO2-IrO2 coatings in aggressive media. This extends service life substantially.

Operational Best Practices and Maintenance

Optimizing operational parameters is essential for anode longevity. This includes careful control of current density and temperature. Implementing effective monitoring systems allows for real-time performance tracking. Early detection of anomalies can prevent premature failure.

Developing robust maintenance schedules is also critical. Regular cleaning and inspection prevent fouling and damage. Proactive measures, rather than reactive repairs, ensure sustained performance. This approach maximizes the useful life of each anode. China Titanium Factory offers expertise in electrochemical solutions and support.

Predictive Modeling and Testing for Durability

Various testing methodologies evaluate anode durability. Accelerated life tests simulate long-term operation in compressed timeframes. Electrochemical characterization techniques assess surface changes. These methods provide valuable insights into degradation kinetics. They help predict an anode's expected service life.

The development of predictive models is also advancing. These models use empirical data and theoretical principles. They estimate anode lifespan under specific operating conditions. This allows for informed decision-making in anode selection and process design. It ensures optimal performance and reliability.

Real-World Applications and Economic Considerations

The performance of IrO2 anodes directly impacts industrial efficiency. Understanding their service life is key to cost-effectiveness. This section connects theoretical knowledge to practical applications. It highlights the economic benefits of extended anode durability. Case studies and comparative analyses provide tangible proof.

Case Studies: IrO2 Anodes in Industrial Processes

Industries worldwide rely on IrO2 anodes. In chlor-alkali production, they maintain high current efficiency. This is crucial for profitability. For instance, a major chemical plant significantly extended anode life. They implemented advanced MMO coatings and rigorous pH control.

Water treatment facilities also benefit. IrO2 anodes effectively oxidize pollutants in acidic wastewater. Strategies like pulsed current application have shown promise. They reduce degradation rates and improve overall system stability. These real-world examples underscore the importance of durability.

Cost-Benefit Analysis: IrO2 vs. Alternative Anode Materials

Selecting the right anode material involves a careful cost-benefit analysis. IrO2 anodes offer high initial performance and good corrosion resistance. However, iridium is a precious metal, impacting initial cost. Mixed metal oxide (MMO) anodes, like RuO2-IrO2, often provide a superior balance. They offer enhanced durability at a competitive price point.

Platinum-iridium alloys are another option. They are highly stable but significantly more expensive. The return on investment (ROI) for IrO2 or MMO anodes often outweighs cheaper alternatives. This is due to reduced downtime and lower replacement costs. Long-term operational savings are a key consideration.

| Material | Initial Cost | Corrosion Resistance (Acid) | Catalytic Activity | Typical Service Life |

|---|---|---|---|---|

| Pure IrO2 | High | Good | Excellent | Moderate-Long |

| RuO2-IrO2 MMO | Moderate-High | Excellent | Very Good | Longer |

| Platinum-Iridium Alloy | Very High | Superior | Good | Very Long |

Frequently Asked Questions about IrO2 Anode Service Life

This section addresses common inquiries regarding IrO2 coated anodes. It focuses on their performance and maintenance in acidic environments. These answers provide concise, authoritative guidance for practical challenges.

How does pH affect IrO2 anode degradation?

Lower pH (more acidic) environments significantly accelerate IrO2 degradation. Highly acidic conditions promote the dissolution of the iridium oxide coating. This leads to a loss of active material. Maintaining optimal pH ranges helps extend anode service life.

What are the typical signs of IrO2 anode failure?

Observable indicators include increased cell voltage and decreased current efficiency. Visual signs might involve coating delamination or substrate exposure. A decline in product quality or increased energy consumption also signals failure. Monitoring these parameters is crucial.

Can IrO2 anodes be refurbished or recoated?

Yes, refurbishment and recoating are often feasible. This process involves stripping the old coating and applying a new one. It can significantly extend the anode's useful life. This practice reduces operational costs and promotes sustainability. China Titanium Factory provides expert anode refurbishment services.

What are the key differences between IrO2 and RuO2-IrO2 mixed metal oxide anodes?

Pure IrO2 anodes excel in highly oxidative, acidic conditions. RuO2-IrO2 MMO anodes combine iridium and ruthenium oxides. They often offer enhanced stability and catalytic activity. This makes them suitable for a broader range of applications. MMOs typically provide better cost-performance balance.

What is the average service life of an IrO2 anode in a typical acidic application?

The average service life varies significantly. It depends on operating conditions, coating quality, and electrolyte composition. Lifespans can range from several months to several years. High-quality anodes with optimized operation achieve longer durations. Consulting with expert manufacturers ensures realistic expectations.

Optimize Your Electrochemical Processes

Partner with a global leader in titanium and anode manufacturing. Ensure unparalleled reliability and efficiency for your operations. Our technical expertise delivers durable, high-performance solutions.

Contact Our Experts Today