Iridium oxide titanium anodes are workhorses in modern industry. They drive essential electrochemical processes, from purifying water to producing chlorine. But like any high-performance component, their active coating eventually wears down. When efficiency dips, replacing these expensive anodes feels like a necessary evil. There's a better way: professional recoating.

This comprehensive guide dives into why iridium oxide titanium anodes degrade, how recoating restores them to their prime, and why it’s a smart move for your bottom line and the planet. We'll cut through the noise and give you the facts you need to make an informed decision.

The Science Behind Iridium Oxide Titanium Anodes

Iridium oxide titanium anodes are a marvel of material science. They combine the robust, corrosion-resistant properties of titanium with the exceptional electrocatalytic activity of iridium oxide. This synergy makes them indispensable in harsh electrochemical environments.

The core of the anode is typically a titanium substrate, chosen for its excellent mechanical strength and ability to form a passive oxide layer that prevents further corrosion. On this substrate, a thin, multi-layered coating of iridium oxide (IrO₂) is applied. This coating acts as the catalyst, facilitating the desired electrochemical reactions with high efficiency and selectivity.

Electrocatalysis: The acceleration of electrochemical reactions at an electrode surface due to the presence of a catalyst. In the case of iridium oxide anodes, IrO₂ significantly lowers the overpotential required for reactions like oxygen evolution or chlorine evolution, making the process more energy-efficient.

Key Properties and Applications of Iridium Oxide Anodes

What makes these anodes so good? It boils down to a few critical properties:

High Catalytic Activity: They promote specific reactions with minimal energy input, crucial for cost-effective operations.

Exceptional Corrosion Resistance: The iridium oxide coating stands up to aggressive chemical environments, extending the anode's life.

Good Electrical Conductivity: Efficient electron transfer means less energy waste.

Mechanical Stability: They maintain structural integrity under operational stress.

These properties make iridium oxide anodes the go-to choice for a wide array of industrial applications:

| Industry/Process | Primary Use |

|---|---|

| Chlor-Alkali Production | Chlorine and caustic soda generation. |

| Water Treatment | Electrolytic disinfection, wastewater purification. |

| Electroplating/Electrowinning | Metal recovery and surface finishing. |

| Cathodic Protection | Preventing corrosion in pipelines, marine structures. |

| Organic Synthesis | Driving specific chemical reactions. |

For more specific requirements or custom anode designs, consider consulting experts in custom titanium anode manufacturing.

Understanding Anode Degradation: Why Recoating Becomes Essential

Even the best anodes don't last forever. Over time, the active iridium oxide coating degrades. This isn't a sudden failure; it's a gradual decline in performance, often unnoticed until it hits your bottom line. Think of it like tread on a tire – it wears down with use.

Several factors contribute to this anode degradation:

Electrochemical Corrosion: The very reactions the anode facilitates can slowly erode the coating. High current densities and aggressive electrolytes accelerate this.

Mechanical Abrasion: Particulates in the electrolyte or physical handling can wear away the coating.

Poisoning: Impurities in the electrolyte can deposit on the anode surface, blocking active sites and reducing efficiency.

Passivation of the Titanium Substrate: If the coating is compromised, the titanium substrate can oxidize, leading to increased resistance.

Thermal Stress: Fluctuations in temperature can cause stress within the coating layers, leading to cracking and delamination.

Understanding these mechanisms is key to predicting anode lifespan and planning for maintenance. A study published in Electrochimica Acta often delves into these degradation pathways.

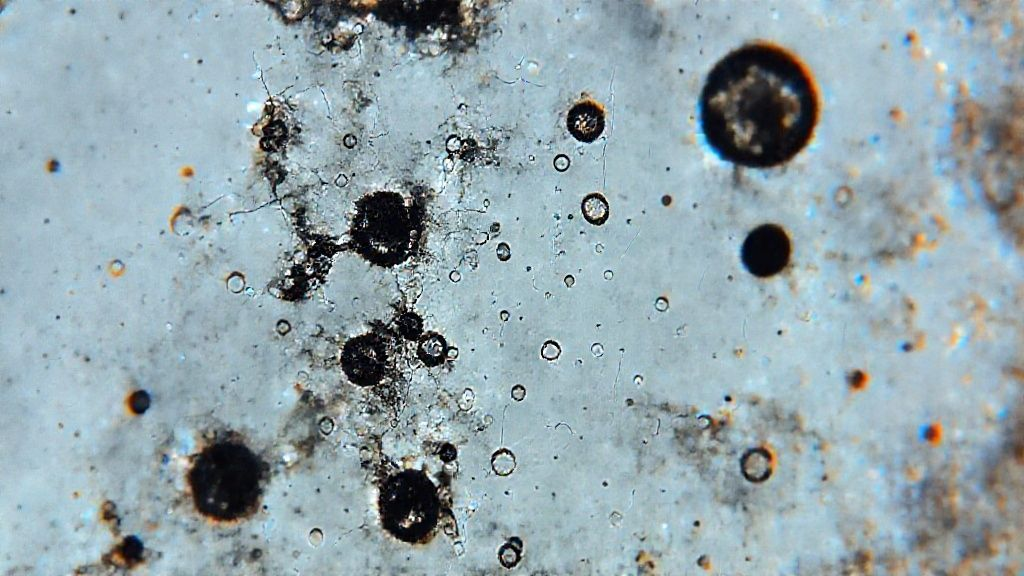

Common Signs of Anode Coating Degradation

How do you know when your anodes are calling it quits? Watch out for these red flags:

Increased Cell Voltage: This is often the most noticeable sign. As the coating degrades, resistance increases, requiring more voltage to maintain the same current. More voltage means higher energy consumption and bigger electricity bills.

Reduced Product Yield or Purity: If your electrochemical process is producing less of the desired product, or if its quality drops, anode degradation could be the culprit.

Visual Changes: A healthy anode has a uniform, dark coating. Look for discoloration, bare titanium spots, blistering, or flaking. These are clear indicators of coating wear.

Shortening Maintenance Cycles: If you're cleaning or adjusting your cell more frequently to maintain performance, your anodes might be losing their edge.

Catching these signs early can save you a bundle. Ignoring them only leads to escalating operational costs and potential system failures. That's where recoating steps in.

The Recoating Process: Revitalizing Your Iridium Oxide Titanium Anodes

Recoating isn't just a patch job. It's a precise, multi-stage restoration that brings depleted anodes back to life. Think of it as a full factory reset for your industrial workhorses. The goal? To deliver performance on par with, or even exceeding, a brand new anode.

A professional recoating service, like those offered by China Titanium Factory, follows a rigorous protocol to ensure optimal results. It’s a delicate dance of chemistry and engineering, performed by seasoned experts.

Detailed Stages of Professional Anode Recoating

The process typically breaks down into these critical stages:

Initial Assessment and Receiving: Anodes arrive and undergo a thorough visual inspection and preliminary testing. We document their condition and identify any structural damage to the titanium substrate.

Stripping the Old Coating: This is where the magic begins. The old, depleted iridium oxide coating is carefully removed using specialized chemical and mechanical methods. The aim is to strip the active layer without damaging the underlying titanium. Clean slate, literally.

Surface Preparation: The bare titanium substrate needs meticulous cleaning and activation. This often involves acid etching, degreasing, and sandblasting to create a perfectly clean and roughened surface. This texture is vital for strong adhesion of the new coating.

New Coating Application: This is the heart of the recoating process. A fresh, proprietary solution containing iridium oxide precursors is applied to the titanium substrate. Methods can vary, including brush coating, spray coating, or dip coating, depending on anode geometry and desired thickness. Multiple layers are typically applied.

Thermal Treatment (Curing): After each coating layer, the anode is carefully dried and then subjected to high-temperature thermal treatment. This converts the precursor solution into the active, crystalline iridium oxide coating, bonding it firmly to the titanium. This step ensures durability and performance.

Final Inspection and Quality Control: Once the full coating process is complete, the anode undergoes stringent quality checks. This includes visual inspection, coating thickness measurements, adhesion tests, and electrochemical performance testing. Only anodes that meet strict specifications are approved for return.

Technologies and Quality Control in Anode Recoating

Modern recoating facilities leverage advanced technologies to ensure superior results. Precision matters here. Techniques like X-ray fluorescence (XRF) spectroscopy measure coating composition and thickness with high accuracy. Scanning electron microscopy (SEM) reveals surface morphology and adhesion quality.

Rigorous quality control isn't just a buzzword; it’s baked into every step. Performance testing, often simulating real-world operating conditions, confirms that the recoated anodes will perform as expected. This commitment to quality is what distinguishes a top-tier provider.

Recoating vs. New Anodes: A Strategic Comparison for Your Operations

When your iridium oxide titanium anodes show signs of wear, you face a choice: buy new ones or have your existing units recoated. It's not always an obvious decision, but for many, recoating is the smarter play. Let's break down the implications.

New anodes come with a hefty price tag. They require fresh raw materials, extensive manufacturing, and shipping. Recoating, on the other hand, reuses the titanium substrate, which often remains perfectly sound. This distinction holds significant economic and environmental weight.

Economic and Environmental Advantages of Anode Recoating

Let's talk brass tacks. The economic benefits of recoating are often the first thing that catches a plant manager's eye.

Significant Cost Savings: Recoating can be 30-70% cheaper than purchasing new anodes, depending on the anode's size and complexity. This isn't small change; it translates to substantial savings on your operational budget.

Reduced Lead Times: Often, recoating takes less time than manufacturing new anodes, minimizing downtime for your operations.

Optimized Resource Allocation: By extending the life of existing assets, you free up capital that would otherwise be tied up in new equipment purchases.

Beyond the ledger, recoating hits a home run for environmental responsibility:

Waste Reduction: Each anode recoated means one less anode sent to a landfill. This significantly reduces industrial waste.

Conservation of Raw Materials: Titanium, iridium, and other precious metals are finite resources. Recoating conserves these materials, lessening the demand for new mining and processing.

Lower Carbon Footprint: The energy expenditure for stripping and recoating is typically far less than that required for manufacturing a completely new anode from scratch. This translates to reduced greenhouse gas emissions. You can find more details on industrial sustainability practices from organizations like the U.S. Environmental Protection Agency (EPA).

Performance and Longevity: What to Expect from Recoated Anodes

Some might worry that a recoated anode can't measure up to a new one. That's simply not true, not with a reputable provider. Professionally recoated anodes are engineered to deliver equivalent, and often superior, performance. Why? Because the recoating process benefits from years of accumulated experience and refined techniques.

Expect recoated anodes to offer:

Restored Efficiency: Cell voltage drops back to optimal levels, reducing power consumption.

Extended Lifespan: A well-recoated anode can often achieve a lifespan comparable to its original design, effectively giving it a second life.

Consistent Performance: Rigorous quality control ensures uniform coating thickness and adhesion, leading to predictable and reliable operation.

Customization Opportunities: Sometimes, the recoating process allows for slight adjustments to the coating formulation, potentially optimizing the anode for specific process conditions that may have changed over time.

A good recoating provider stands by their work, often offering performance guarantees. This gives you peace of mind and validates the investment.

Selecting the Right Partner for Your Anode Recoating Needs

The success of your anode recoating project hinges on choosing the right service provider. This isn't a job for just anyone. You need a partner with deep expertise, state-of-the-art facilities, and a proven track record. Cutting corners here can cost you dearly in the long run.

When vetting potential partners, consider these key factors:

Specialized Expertise: Do they specialize in iridium oxide titanium anodes? Look for a company with years of experience and a strong understanding of electrochemistry and material science.

Technical Capabilities: Assess their facility. Do they have the equipment for precise stripping, application, and thermal treatment? What quality control measures are in place?

Quality Standards and Certifications: A reputable provider adheres to international quality standards (e.g., ISO certifications). Ask about their testing protocols and guarantees.

Customer Support and Communication: Good communication is vital. You want a partner who provides clear updates, understands your specific needs, and offers technical support.

Turnaround Time: While quality shouldn't be rushed, a transparent and reasonable turnaround time is important for minimizing your operational downtime.

Companies like China Titanium Factory bring extensive experience to the table, ensuring your anodes receive the best possible treatment.

Understanding the Quotation and Service Process

Getting a quote for anode recoating services should be straightforward. Here’s what to expect and what information you’ll typically need to provide:

Initial Inquiry: Reach out with your basic needs – type of anodes, quantity, approximate dimensions, and current application.

Anode Assessment: You may be asked to send photos or provide detailed specifications of your anodes. Sometimes, a preliminary in-person assessment is necessary for complex projects.

Detailed Quotation: The provider will issue a comprehensive quote outlining costs per anode, estimated turnaround time, and any specific terms. This should be transparent and easy to understand.

Shipping Logistics: Discuss the safest and most efficient way to ship your anodes to the recoating facility and back.

Project Execution: Once terms are agreed upon, the recoating process begins, with regular updates provided as needed.

Don’t hesitate to ask questions. A good partner will be happy to walk you through every step of the process. For expert advice on your anode refurbishment needs, a direct consultation can provide tailored solutions.

Real-World Impact: Successful Anode Recoating Case Studies

The proof is in the pudding, as they say. Countless companies across various industries have reaped significant benefits from professional anode recoating. These aren't just theoretical savings; they're tangible results impacting operational efficiency and financial health.

Consider a large-scale chlor-alkali plant struggling with rising energy costs. Their old anodes were demanding higher voltage inputs, pushing electricity bills through the roof. After a full batch of iridium oxide titanium anodes underwent professional recoating, their cell voltage dropped back to optimal levels. The plant saw a 15% reduction in energy consumption for that cell line within the first quarter, representing hundreds of thousands of dollars in annual savings. This kind of proven performance is what makes recoating a no-brainer.

Another example: a municipal water treatment facility faced frequent downtime due to anode degradation in their electrolytic disinfection units. New anodes were always on backorder, causing operational headaches. By implementing a recoating program, they not only cut replacement costs by 40% but also established a reliable supply chain for refurbished anodes, virtually eliminating downtime related to anode availability. This strategic move kept the water flowing and the community safe, while also being environmentally responsible.

These stories underscore a simple truth: anode recoating isn't just about maintenance; it's about smart, sustainable business. It's about getting more mileage out of your assets and keeping your operations humming.

Maximizing Anode Lifespan: Maintenance and Future Innovations

Getting your anodes recoated is a big step, but maintaining them properly can push their lifespan even further. A little preventative care goes a long way. Think of it as keeping your car tuned up after a major overhaul.

Best practices for extending anode life include:

Optimal Operating Conditions: Stick to recommended current densities, temperatures, and electrolyte compositions. Deviating from these can accelerate wear.

Regular Cleaning: Periodically remove any deposits or fouling on the anode surface. This prevents active site blockage and maintains efficiency.

Electrolyte Purity: Minimize impurities in your electrolyte. Contaminants can poison the anode surface or lead to unwanted side reactions. A reputable resource like RSC Chemical Communications often features research on these topics.

Careful Handling: Anodes are robust but not indestructible. Avoid physical abrasion or dropping them during installation and removal.

Looking ahead, the field of anode technology isn't standing still. Researchers are constantly exploring new coating formulations and materials to enhance durability and efficiency. Innovations include:

Nanostructured Coatings: Creating coatings with more surface area at the nanoscale for improved catalytic activity.

Novel Alloys and Substrates: Exploring alternative materials that offer even greater corrosion resistance or conductivity.

Smart Anodes: Anodes with integrated sensors that monitor their own performance and alert operators to impending degradation.

These advancements promise even longer-lasting and more efficient anodes in the future, further solidifying their role in sustainable industrial processes. For cutting-edge titanium solutions, stay informed with leaders in the field, like China Titanium Factory.

Frequently Asked Questions About Anode Recoating

You've got questions, we've got answers. Here are some common inquiries about iridium oxide titanium anode recoating.

General Recoating Queries

What types of anodes can be recoated?

Most iridium oxide titanium anodes, regardless of their original manufacturer, can be successfully recoated, provided the titanium substrate is structurally sound. This includes mesh, plate, rod, and tubular designs.

How long does the recoating process take?

Turnaround times vary based on the anode type, quantity, and current workload of the facility. Typically, it can range from 2-6 weeks from receipt to shipment. Always confirm lead times with your specific service provider.

Is recoating always cheaper than buying new?

In almost all cases, yes. Recoating generally offers significant cost savings (30-70%) compared to purchasing new anodes. The primary cost is the precious metal coating, not the reusable titanium substrate.

Technical and Performance Questions

Will a recoated anode perform like a new one?

Yes, a professionally recoated anode is designed to deliver performance equivalent to, or in some cases even better than, its original state. This includes efficiency, lifespan, and chemical resistance. Reputable providers offer performance guarantees.

How is the quality of the recoating ensured?

Quality is ensured through a multi-stage process: thorough stripping, meticulous surface preparation, precise multi-layer coating application, controlled thermal treatment, and rigorous final quality control checks, including visual inspection, coating thickness measurements, and electrochemical performance testing.

Can the coating be customized for specific applications?

Often, yes. Experienced recoating partners can sometimes adjust the coating composition or thickness to optimize the anode's performance for particular operating conditions or electrochemical reactions, offering a tailored solution.

Ready to Revitalize Your Anodes?

Don't let degrading anodes drag down your operational efficiency and inflate costs. Extend the life of your valuable assets with professional iridium oxide titanium anode recoating services.

Partner with China Titanium Factory, a trusted name in high-performance anode solutions. We're committed to delivering quality, cost-effectiveness, and environmental responsibility.