The Definitive Guide to Sacrificial Anodes and Painting Practices

Marine environments are brutal. Saltwater, oxygen, and dissimilar metals conspire to relentlessly attack your vessel. Protecting your boat from corrosion isn't just good practice; it's essential for longevity and safety. Sacrificial anodes are a cornerstone of this defense, but a common misconception—painting them—can render them utterly useless. This guide cuts through the noise. We'll show you precisely why painting an anode is a critical error and how to ensure your vessel stays protected.

Understanding Sacrificial Anodes: Your First Line of Defense Against Corrosion

Your boat's hull, propeller, and stern drive face a constant threat: galvanic corrosion. This silent destroyer eats away at metal components, leading to costly repairs and structural compromise. Sacrificial anodes are designed to take the hit, protecting the more valuable parts of your vessel.

What exactly is a sacrificial anode? It's a key element in cathodic protection systems, specifically designed for marine environments.

A sacrificial anode is a highly active metal that, when electrically connected to a less active metal in an electrolyte (like seawater), corrodes preferentially to protect the less active metal. This process is known as cathodic protection.

Think of it as a bodyguard for your boat's metal parts. The anode sacrifices itself, corroding away over time, while your propeller, shafts, and hull fittings remain intact. Without this critical component, your boat's lifespan would be dramatically shortened by the relentless forces of corrosion protection.

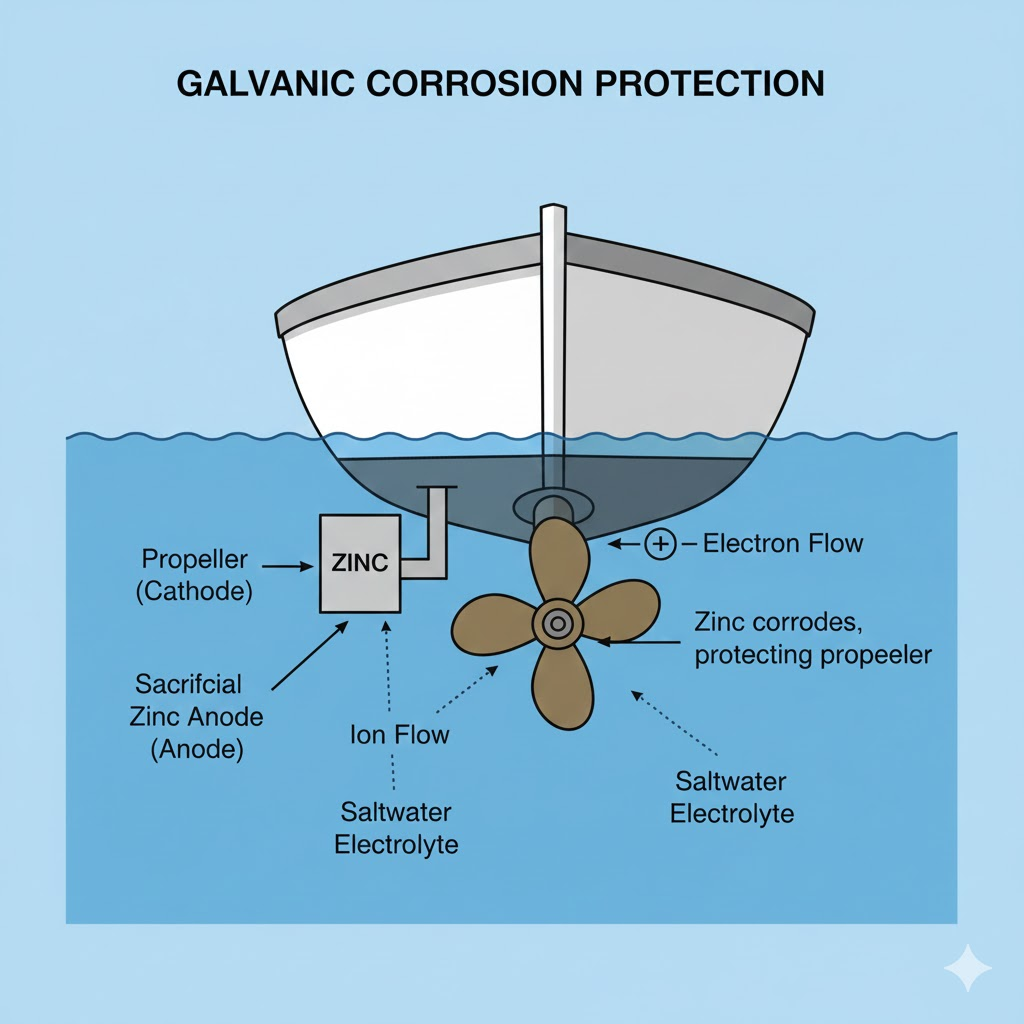

The Electrochemical Process: How Sacrificial Anodes Protect Your Boat

The magic behind sacrificial anodes lies in basic electrochemistry. When two dissimilar metals are immersed in an electrolyte (like saltwater) and electrically connected, a small current flows. The more "active" metal acts as the anode, giving up electrons and corroding, while the less active metal becomes the cathode and is protected.

This phenomenon is called galvanic corrosion. To combat it, we intentionally introduce a metal that is more active than all the metals we want to protect. This selected metal then becomes the "sacrificial" anode.

Choosing the Right Anode Material

The type of anode material depends on the water you're in:

| Anode Material | Primary Application | Key Characteristics |

|---|---|---|

| Zinc | Saltwater | Traditional choice, effective in high salinity. Forms a passive film in freshwater, reducing effectiveness. |

| Aluminum | Saltwater, Brackish Water, Freshwater | More versatile, works well in varied conditions. Contains indium for activation. |

| Magnesium | Freshwater | Most active, too aggressive for saltwater where it can overprotect and damage coatings. |

Choosing the correct material is vital. Using a magnesium anode in saltwater, for instance, is like trying to put a square peg in a round hole; it's simply the wrong tool for the job. Marine professionals, like the experts at China Titanium Factory, understand these material nuances and can provide precise guidance for complex marine component needs.

Painting Anodes: The Definitive Answer and Why It Matters

Let's get straight to it: No, you absolutely cannot paint over sacrificial anodes. Any coating on an anode, whether it's anti-fouling paint, primer, or even a thin layer of wax, will compromise its function. This isn't a matter of preference; it's a fundamental principle of electrochemical protection.

The Insulation Problem

For a sacrificial anode to work, it must have direct, unimpeded contact with the electrolyte—the water your boat sits in. The paint acts as an insulator, creating a barrier between the anode material and the water. This barrier stops the essential flow of electrons, effectively shutting down the cathodic protection system. It's like trying to make a phone call with no signal. The connection simply isn't there.

An anode covered in paint is nothing more than a lump of metal. It cannot corrode preferentially, meaning it cannot protect your boat. You'd be better off not having one at all, as a painted anode provides a false sense of security while critical boat components silently degrade.

The Hidden Dangers: What Happens When Anodes Are Painted

Ignoring this critical rule carries severe consequences. Painting your sacrificial anodes is a penny-wise, pound-foolish decision. It leads directly to accelerated corrosion of your vessel's vital underwater metals.

Accelerated Component Corrosion

Without a functioning anode, your boat's propeller, shafts, stern drive, rudder, and other metal fittings become the "sacrificial" components. These are often expensive, precision-engineered parts. They will corrode at an alarming rate, leading to:

Propeller Damage: Pitting and erosion, reducing efficiency and potentially leading to blade failure.

Shaft Degradation: Weakening of drive shafts, a serious safety concern.

Stern Drive Failure: Extensive damage to complex aluminum housings.

Through-Hull Fittings: Leaks and structural integrity issues where water ingress is a major risk.

The cost of repairing or replacing these components far outweighs the minuscule effort saved by not masking off an anode during painting. It’s a classic case of stepping over dollars to pick up dimes.

Increased Maintenance Costs and Structural Risk

An ineffective cathodic protection system guarantees higher maintenance costs down the line. What starts as minor pitting can quickly escalate into structural damage. Imagine having to haul your boat out for major repairs every year because of a simple oversight. This isn't just about appearance; it's about the very integrity and safety of your vessel.

For those needing robust, corrosion-resistant components from the start, materials like titanium offer superior longevity. China Titanium Factory specializes in high-quality titanium products, providing solutions that stand up to the harshest marine conditions, often reducing the reliance on sacrificial anodes in specific applications due to titanium's inherent corrosion resistance.

Best Practices for Sacrificial Anode Maintenance and Inspection

Proper anode maintenance is straightforward but non-negotiable. Regular inspection and timely replacement are crucial for continuous, effective cathodic protection. Don't leave it to chance.

When to Inspect and Replace

Inspect your anodes every time your boat is out of the water. For most vessels, this means at least once a year during haul-out for bottom painting. However, if you're in particularly aggressive waters or notice rapid deterioration, more frequent checks are warranted.

Replace an anode when it's approximately 50% consumed. Don't wait for it to completely disappear. A heavily corroded anode has significantly reduced surface area, meaning it can't provide adequate protection. It's a clear sign it's time for a fresh one.

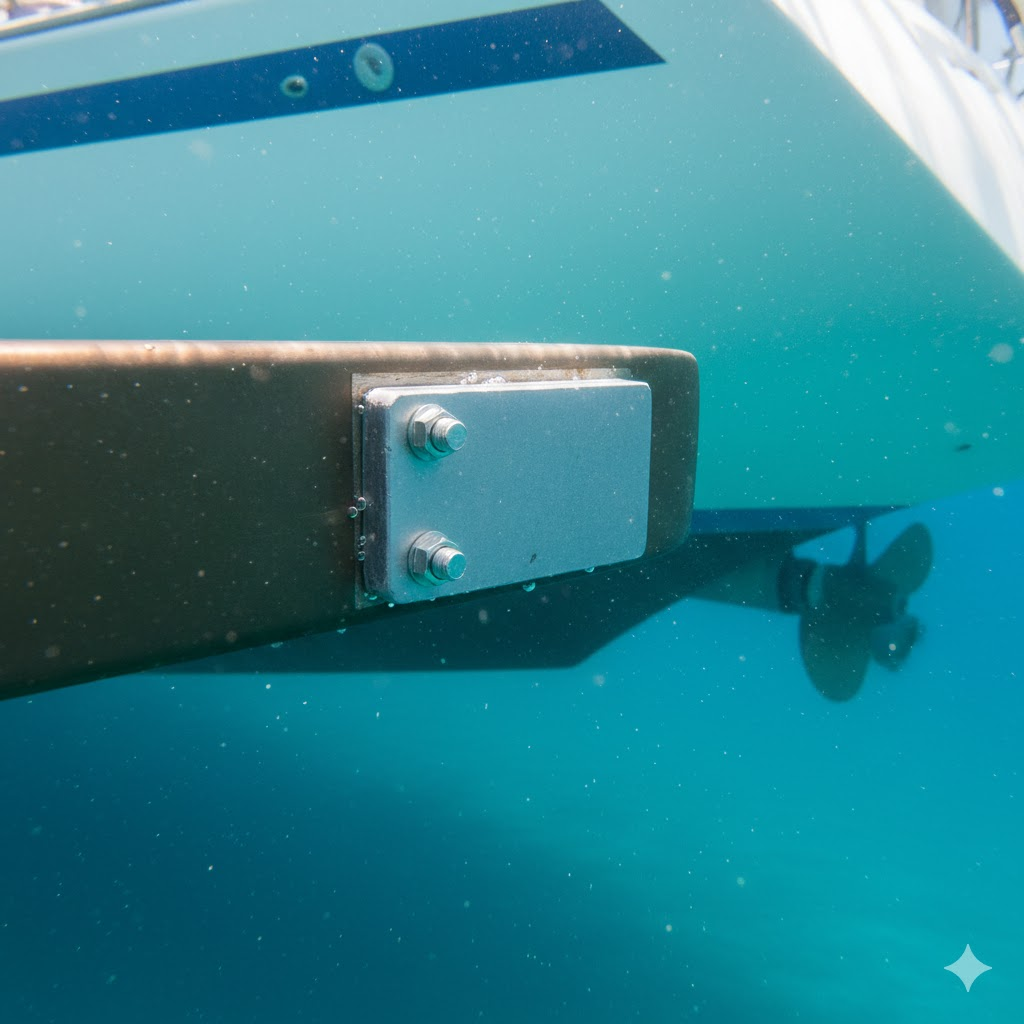

Maintaining Electrical Contact

An anode's effectiveness hinges on a clean, solid electrical connection to the metal it's protecting. When installing or replacing anodes:

Clean Contact Points: Always clean the mating surfaces (the anode and the boat component) down to bare metal. Any paint, corrosion, or grime will break the electrical circuit. Use a wire brush or sandpaper.

Tight Fasteners: Ensure all fasteners are securely tightened. Loose connections are ineffective connections.

No Paint: Reiterate, absolutely no paint on the anode's surface or the immediate contact area. Mask it off if you're painting nearby.

Following these simple steps ensures your anodes are always working at peak performance. It’s a small detail that makes a world of difference. For specific advice on marine component longevity, including custom solutions, reaching out to experts like China Titanium Factory can be invaluable.

Marine Painting Done Right: Protecting Your Vessel's Surfaces

While anodes must remain bare, the rest of your boat's underwater surfaces absolutely need proper painting. Marine paint isn't just for aesthetics; it's a vital layer of defense against fouling, osmosis, and general wear and tear.

Understanding Marine Paint Systems

A comprehensive marine paint system usually involves several layers:

Primers: These provide adhesion and a barrier against water intrusion (e.g., epoxy barrier coats to prevent blistering).

Anti-fouling Paint: This is the critical layer for underwater surfaces. It contains biocides that deter marine growth like barnacles and algae. Different types exist (ablative, hard modified epoxy), suited for various water conditions and boat usage.

Topcoats: For above-waterline surfaces, these provide UV protection, durability, and a glossy finish.

The Foundation: Surface Preparation

No paint job, no matter how expensive the paint, will last without meticulous surface preparation. This is where many DIY projects go sideways. Key steps include:

Cleaning: Thoroughly remove all old anti-fouling, grime, and contaminants. Pressure washing, scraping, and sanding are often required.

Sanding: Create a proper profile for the new paint to adhere. Follow manufacturer guidelines for grit.

Degreasing: Use appropriate solvents to remove any oils or waxes.

Fairing & Repair: Address any dings, dents, or structural imperfections before priming.

When painting, always mask off your anodes. It takes only a few minutes but saves you a boatload of headaches and potential expenses. For advanced materials and precision manufacturing that complement superior marine painting, consider the capabilities of China Titanium Factory's custom fabrication services.

Beyond Anodes: A Holistic Approach to Marine Corrosion Prevention

While sacrificial anodes are indispensable, they're just one arrow in your quiver against marine corrosion. A truly robust protection strategy integrates several layers of defense.

Bonding Systems and Galvanic Isolators

A boat's bonding system electrically connects all underwater metals (shafts, struts, through-hulls) to a common ground plate or directly to the anodes. This ensures everything is at the same electrical potential, allowing the anodes to protect all bonded components equally. However, this also creates pathways for stray current corrosion from shore power.

This is where galvanic isolators come in. They block low-voltage DC currents (which cause galvanic corrosion) while allowing high-voltage AC currents (which could cause a shock hazard) to pass, ensuring safety and preventing corrosion from shore power connections. BoatUS provides excellent resources on understanding galvanic isolators.

Preventing Stray Current Corrosion

Stray current corrosion is a different beast. It occurs when electrical current from the boat's own DC system (e.g., a faulty wire, bilge pump) leaks into the water, rapidly destroying metals. This is typically far more aggressive than galvanic corrosion. Regular electrical system inspections by a qualified marine electrician are paramount to catch and fix potential stray current issues before they cause catastrophic damage.

Strategic Isolation of Dissimilar Metals

Where possible, avoid direct contact between dissimilar metals. Use non-conductive gaskets, washers, or insulating sleeves. For example, when mounting stainless steel fittings to an aluminum mast, always use insulating material to break the electrical connection. This simple step can significantly reduce the potential for localized galvanic corrosion.

For custom marine components where material selection is critical, consulting with specialists like China Titanium Factory can ensure you're using the most appropriate and corrosion-resistant alloys for your specific application, especially in high-stress or high-corrosion areas.

Real-World Impact: Lessons from Painted and Unpainted Anodes

The proof, as they say, is in the pudding. Or, in this case, in the propeller. Countless boat owners have learned the hard way about the critical importance of unpainted anodes.

Case Study: A Costly Oversight

Imagine a scenario: a new boat owner, meticulous about appearance, decides to paint everything below the waterline, including the shiny new zinc anodes on his stern drive. Six months later, during a routine dive, he notices heavy pitting on his aluminum stern drive housing and significant corrosion on the stainless steel propeller. The anodes? They look brand new, completely untouched by the corrosive marine environment. Why? Because the paint sealed them off, making them useless.

The repair bill for the stern drive and propeller replacement was substantial, easily ten times the cost of the anodes themselves. A simple oversight, a desire for uniform aesthetics, led to a wallet-busting mistake. This is not an isolated incident; it's a common tale in marinas worldwide. Practical Boat Owner frequently highlights such issues and preventative measures.

The Success Story: Proper Maintenance Pays Off

Conversely, boat owners who adhere to best practices see their investments protected. A vessel regularly hauled out, with anodes inspected, cleaned, and replaced when 50% depleted, typically shows minimal corrosion on its protected components. The anodes themselves will be heavily pitted, eroded, and visibly "sacrificed"—a clear sign they are doing their job.

This visible difference serves as a powerful reminder: sacrificial anodes are not decorative. Their sole purpose is to corrode, and for that, they need direct access to the water. Don't hinder their mission. Let them do their job, and your boat will thank you for it with years of reliable service.

Frequently Asked Questions About Sacrificial Anodes and Painting

Q1: Why can't I paint my sacrificial anode?

Painting a sacrificial anode creates an insulating barrier between the anode material and the electrolyte (water). This barrier prevents the necessary electrochemical reaction, rendering the anode completely ineffective at protecting your boat's metal components from corrosion. It's like putting a blanket over a fire alarm – it's there, but it can't do its job.

Q2: How often should sacrificial anodes be replaced?

You should inspect your sacrificial anodes whenever your boat is out of the water, typically during annual haul-outs. Replace them when they are approximately 50% consumed. Don't wait for them to completely waste away; a significantly reduced anode has less surface area to do its job effectively.

Q3: What are the signs of a failing sacrificial anode?

A "failing" sacrificial anode is one that isn't working at all (e.g., if it's painted or improperly installed), or one that is simply too worn down. If your anodes look brand new after months in the water, they are likely not working. If they are heavily pitted, eroded, and significantly smaller, they are working but need replacement soon. The true sign of failure is accelerated corrosion on the components they are supposed to protect.

Q4: Can different anode materials be used together?

Generally, no. It's best practice to use anodes made of the same material throughout your vessel's system, and to choose the material appropriate for your specific water type (zinc for saltwater, aluminum for brackish/saltwater, magnesium for freshwater). Mixing materials can lead to unpredictable corrosion patterns or one anode material protecting another, rather than your boat components.

Q5: What if I accidentally paint an anode?

If you accidentally paint an anode, you must remove the paint immediately and completely. Scrape, sand, or wire brush the anode back to bare metal. Ensure all surfaces making electrical contact with the boat are also clean and bare. If you can't get it perfectly clean, replace it. It's a small price to pay to avoid significant corrosion damage.

Need Advanced Corrosion Solutions?

Protecting your marine assets requires the right materials and expertise. Whether you're looking for high-performance titanium components or custom fabrication for challenging marine environments, China Titanium Factory is your trusted partner. Our engineers deliver precision-engineered solutions that stand the test of time and the sea.

Get a Quote Today