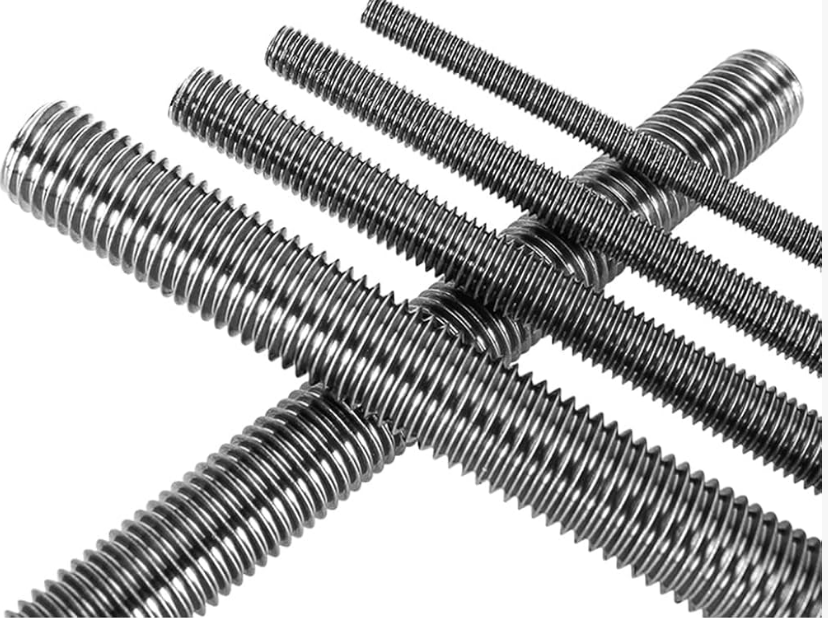

When you are building something that needs to last—especially in tough conditions—the materials you choose matter a lot. That is where the titanium threaded rod comes in. These rods are long metal bars with threads all along their length, making them perfect for fastening things together securely. Unlike regular steel, titanium offers a unique mix of strength, low weight, and amazing resistance to rust and corrosion.

From airplanes and spacecraft to deep-sea equipment and medical implants, the threaded titanium rod is the go-to choice for engineers who cannot compromise on quality. In this guide, we will break down why titanium is so powerful, explore the different types of titanium fasteners, and show you where to find the best quality products.

Titanium is famous for its incredible properties. It is not just strong; it is smart. Here are the three main reasons why a titanium threaded bar outperforms most other metals:

Imagine a metal that is as strong as many types of steel but weighs about 45% less. That is titanium. This light weight is crucial in industries like aerospace and automotive, where every gram saved boosts performance and fuel efficiency. When you use a titanium bar or rod, you get maximum strength without the heavy bulk.

Rust and corrosion destroy most metals over time, especially in saltwater, chemical plants, or high-humidity areas. Titanium naturally forms a protective oxide layer that makes it fully resistant to these harsh environments. This means your titanium hardware will maintain its strength and look great for decades, saving you money on maintenance and replacement.

Titanium is non-toxic and is well-tolerated by the human body. This makes it the only choice for medical applications like surgical implants, dental work, and prosthetics. This unique property ensures patient safety and comfort.

While the titanium threaded rod is a key product, titanium is used across a huge range of connecting parts. When you are building a system, you often need a complete set of titanium fasteners to ensure every connection is as strong as the rod itself.

The family of titanium connecting parts includes:

Titanium Bolts: Used with nuts to create a strong, non-permanent joint.

Titanium Screws: Used to fasten objects by driving into a material.

Titanium Studs: Similar to rods, but often shorter and used for mounting or securing components.

Titanium Fittings: Used in piping and tubing systems, often alongside rods and bolts, especially in chemical processing.

Using these titanium components together ensures that your entire assembly—whether it is a piece of marine equipment or a high-performance engine—benefits from titanium's superior qualities.

Not all titanium is the same. The two most common grades for threaded rods are Grade 2 and Grade 5, and the right size depends entirely on your project's needs.

| Feature | Titanium Grade 2 (Commercially Pure) | Titanium Grade 5 (Ti-6Al-4V Alloy) |

|---|---|---|

| Strength | Good strength; highly ductile (easy to work with). | **Excellent strength** (much stronger than Grade 2). |

| Corrosion | Outstanding resistance, especially in chemical environments. | Excellent resistance; great for high-stress applications. |

| Best For | Chemical processing, architecture, non-critical parts. | Aerospace, medical implants, high-performance sports. |

The size of your rod is critical for a secure fit. Here are two examples of common, specialized sizes:

This smaller, precise size is widely used in electronics, instrumentation, and precision engineering. Its fine thread pitch (32 threads per inch) allows for very secure and accurate adjustments, making it a staple in high-tech machinery and delicate assemblies.

For heavy-duty construction and structural applications, larger sizes are needed. The 1/2 inch rod is a workhorse, offering significant load-bearing capacity. When you need a 1/2 inch titanium threaded rod allow load to support a structure in a marine or chemical environment, Grade 5 is often preferred for its maximum strength and reliability.

Choosing the right titanium threaded rod is only the first step. For optimal performance and safety, engineers must also consider the technical aspects of installation and the long-term value of the material.

Titanium fasteners are known for their high strength, but they require careful handling during installation to prevent a common issue called **galling** (cold welding). This happens when the threads seize up due to friction. To avoid this, always use a high-quality anti-seize lubricant and ensure you follow the correct torque specifications for the specific grade and size of your titanium studs or rods. Proper installation is key to ensuring the full load capacity, especially for items like the 1/2 inch titanium threaded rod allow load, is achieved.

When sourcing your titanium bar or finished fasteners, always look for products that meet international standards. For example, **ASTM B348** is a key standard for titanium bar and billet. Working with a certified titanium grade 2 threaded rod manufacturer ensures the chemical composition and mechanical properties of the material are guaranteed, giving you peace of mind in critical applications.

While the initial cost of titanium is higher than common materials like stainless steel, its extended lifespan and superior performance in harsh environments offer a better **Total Cost of Ownership (TCO)**. In marine, chemical, or high-temperature settings, a titanium component can last ten times longer than a stainless steel one, dramatically reducing maintenance, replacement costs, and downtime.

Finding a reliable supplier who can meet both standard and custom needs is essential for any major project.

We are proud to introduce **www.chinatitaniumfactory.com** as a leading manufacturer and supplier of high-quality titanium products. Whether you need standard sizes of titanium studs, a large volume of titanium bolts, or a highly customized threaded titanium rod, they are equipped to handle your request.

What they offer:

Standard Products: All common grades (Grade 2, Grade 5) and sizes.

Custom Solutions: They accept various conventional and custom product requirements, ensuring you get the exact titanium components needed for your unique application.

Welcome to contact us for consultation and quotes!