What is Black Titanium Anodizing? A Foundational Understanding

Black titanium anodizing isn't just a fancy coating; it's a sophisticated surface treatment that fundamentally alters the metal's outer layer. Many folks wonder if it's truly durable or if that sleek black finish is just skin deep. Good question.

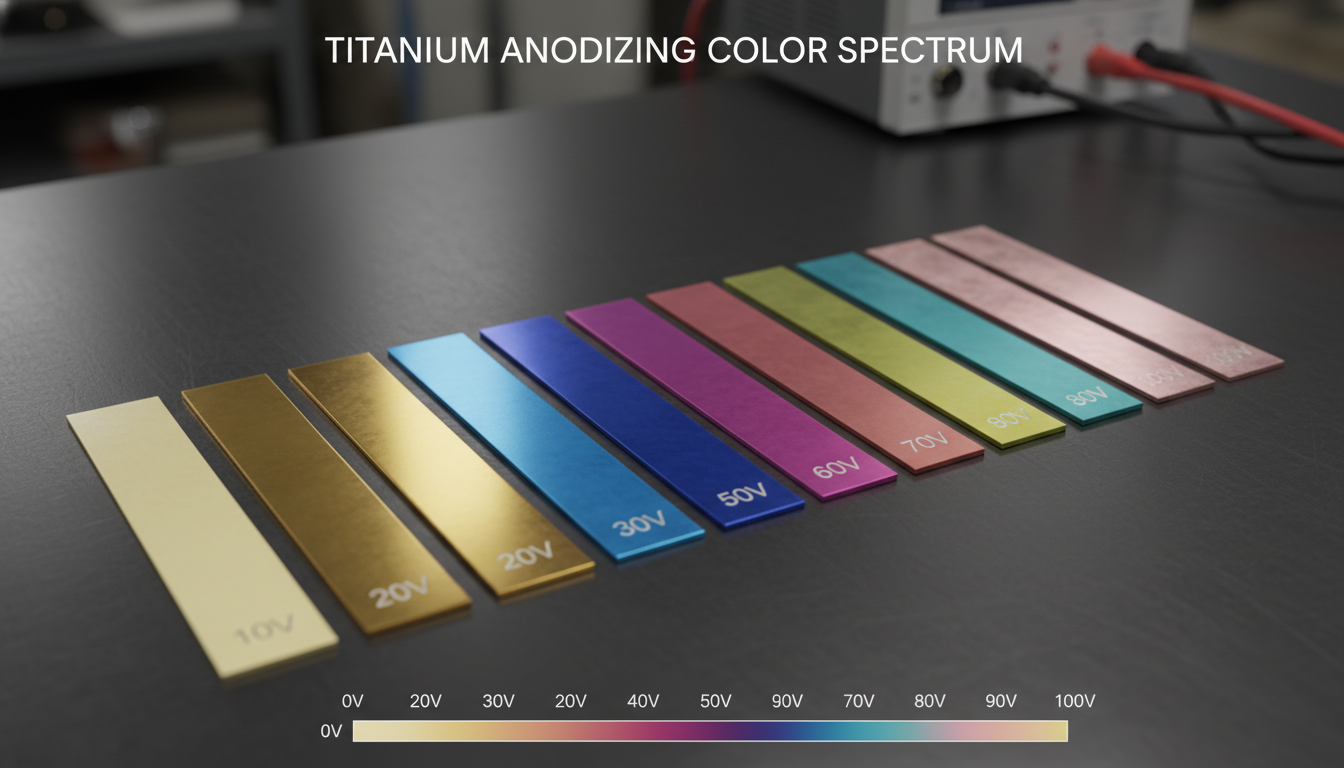

Simply put, anodizing is an electrochemical process. It intentionally grows an oxide layer on the titanium surface. For black anodizing, specific techniques, often involving thicker oxide layers and light interference principles, create that deep, dark hue.

This process enhances titanium's natural properties, making it even more robust. It's not paint. It's not a dip. It's a transformation.

How Black Titanium Anodizing Works: The Science Behind the Finish

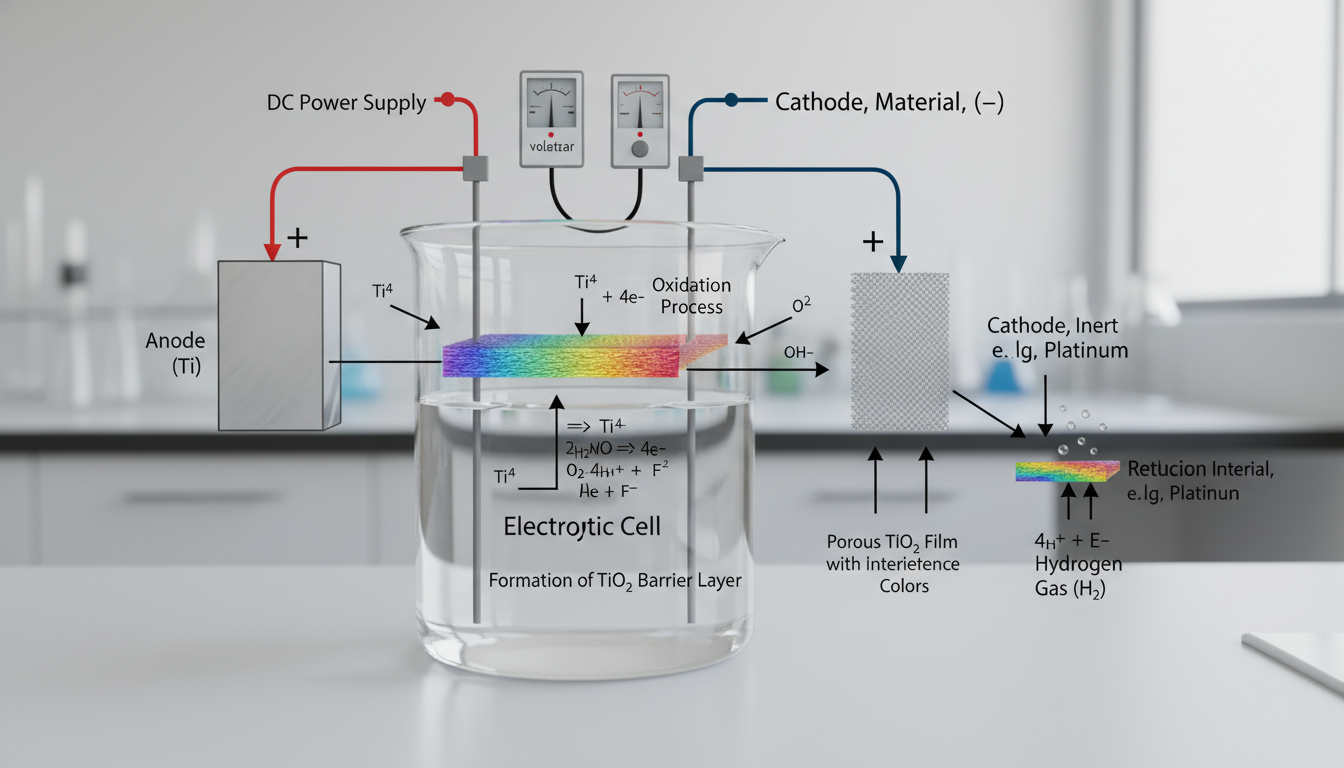

The magic happens in an electrolytic bath. We submerge the titanium part, connecting it as the anode (positive electrode). An electric current passes through an electrolyte solution.

This current causes oxygen ions to bond with the titanium atoms on the surface. What forms? A controlled, uniform titanium oxide layer. This isn't just any oxide; it's an incredibly stable, integral part of the titanium itself. It literally grows out of the base metal.

Achieving a true black finish with titanium anodizing is a bit more nuanced than other colors. It often involves either specific electrolyte compositions, higher voltages to achieve a thicker film that absorbs most light, or post-anodizing dyeing processes. The goal is a uniform, deep black that doesn't just sit on the surface but is part of it.

Anodizing: An electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts, typically aluminum or titanium. This process enhances corrosion resistance, wear resistance, and allows for decorative finishes.

Types of Titanium Anodizing and Their Characteristics

Not all anodizing is created equal. With titanium, we generally talk about a few key types:

Type I (Chromic Acid Anodizing): Thinner, more corrosion-resistant, typically used for aerospace components where fatigue resistance is critical. Not for color.

Type II (Sulfuric Acid Anodizing): The most common for aluminum, but for titanium, variations can produce a range of interference colors, including the sought-after black. This is where most decorative and many functional titanium anodizing services come into play.

Type III (Hardcoat Anodizing): Produces a much thicker, denser, and harder oxide layer, primarily for maximum wear resistance. While it can be dyed black, the natural color is often a dark gray.

For a vibrant black, Type II variations are often used, sometimes followed by a specialized dye or a process that creates a thicker, light-absorbing oxide. The experts at China Titanium Factory understand these distinctions, ensuring you get the right finish for your needs.

Unpacking the Durability of Black Anodized Titanium

Now, the million-dollar question: how tough is black anodized titanium? Many believe it's indestructible, a finish that can take anything you throw at it. That's not quite the whole enchilada. While incredibly durable, it's essential to set realistic expectations.

The anodized layer significantly boosts corrosion resistance and hardness compared to raw titanium. This means it stands up well to harsh environments, chemicals, and general wear. The longevity of an anodized titanium black surface is often impressive, making it a solid choice for many applications.

However, "durable" doesn't mean "bulletproof." Understanding its limits is key to appreciating its strengths.

Is Black Anodized Titanium Scratch Resistant? Real-World Expectations

Here's where the rubber meets the road. Is black anodized titanium scratch resistant? Yes, to a degree. Is it scratch-proof? Absolutely not. That's a common misconception.

The oxide layer is much harder than the base titanium metal. It provides excellent resistance against minor abrasions, scuffs, and everyday handling. Think about a titanium watch or a medical instrument; they see a lot of action. The anodized layer helps them look good longer.

But if you take something sharp, like a knife or a coarse abrasive, and really go at it, the anodized layer will scratch. It's like a hard shell; it protects, but it can be breached. The darker the finish, the more noticeable a scratch might appear, revealing the lighter titanium underneath. It's not a deal-breaker, but it's something to keep in mind, especially for consumer goods.

Does Black Anodized Titanium Fade Over Time? Understanding Color Stability

Color stability is another hot topic. Does black anodized titanium fade? Generally, it holds its color exceptionally well. The color is integral to the oxide layer itself (for interference colors) or deeply absorbed by the porous structure (for dyed films).

However, extreme conditions can play a role. Prolonged, intense UV exposure, like leaving a black anodized part in direct sunlight for years on end, can cause subtle lightening or shifting in hue. Similarly, exposure to very aggressive chemicals outside its intended operating environment could degrade the finish.

For most applications, though, you won't see a significant fade. Think of it this way: a well-made black anodized part should retain its striking appearance for a good long while, provided it's not abused. It's designed to go the distance.

Factors Affecting the Lifespan of Anodized Titanium Black Finishes

Several variables determine how long your black anodized titanium piece will look its best and perform optimally. It's not just a roll of the dice.

Quality of Anodizing: This is huge. A properly executed process, with the right electrolyte, voltage, and sealing, makes all the difference. Subpar work leads to a weaker, less stable finish. Working with experienced manufacturers like China Titanium Factory ensures a high-quality finish from the get-go.

Environmental Exposure: Constant exposure to salt spray, corrosive chemicals, or extreme temperatures will naturally challenge any finish.

Mechanical Stress: Heavy impacts, constant rubbing, or high-friction environments will wear down the oxide layer faster than gentle use.

Base Material Quality: Even the grade of titanium matters. Different titanium grades can react slightly differently to the anodizing process, affecting final finish properties.

Maintaining Your Black Anodized Titanium: Tips for Longevity

Taking care of black anodized titanium isn't rocket science, but a little effort goes a long way. Here's the lowdown:

Cleaning: Use mild soap and warm water. A soft cloth is your best friend. Gently wipe down the surface. Rinse thoroughly and dry immediately to prevent water spots.

Avoid Harsh Chemicals: Stay clear of abrasive cleaners, strong acids, alkalis, or solvents like acetone. These can etch or degrade the oxide layer.

No Abrasive Tools: Steel wool, scouring pads, or stiff brushes are a big no-no. They will scratch the finish.

Protection: For items prone to impact, consider protective cases or sleeves. Common sense goes a long way here.

If a minor scratch occurs, sometimes it can be less noticeable if cleaned properly. Major damage to the anodized layer typically requires professional re-anodizing, which isn't always practical or cost-effective depending on the item.

Black Titanium Finishes Compared: Anodizing vs. PVD vs. DLC

Anodizing is one way to get a black titanium finish, but it's not the only game in town. Other common methods, PVD and DLC, offer different characteristics. Let's break down how they stack up.

| Feature | Anodizing | PVD (Physical Vapor Deposition) | DLC (Diamond-Like Carbon) |

|---|---|---|---|

| Process | Electrochemical conversion of surface metal to oxide. | Vacuum deposition of thin film coating (e.g., TiN, ZrN). | Vacuum deposition of amorphous carbon coating. |

| Hardness/Scratch Resistance | Good; harder than base titanium but can scratch. | Very good to excellent; harder than anodizing. | Exceptional; significantly harder than PVD and anodizing. |

| Corrosion Resistance | Excellent; integral oxide layer. | Very good; barrier coating. | Excellent; very dense and inert. |

| Thickness | Microns to tens of microns. | Sub-micron to a few microns. | Nanometers to a few microns. |

| Biocompatibility | Excellent. | Good, depending on materials. | Excellent. |

| Cost | Moderate. | Moderate to High. | High. |

Each method has its sweet spot. Anodizing offers a great balance of aesthetics, corrosion resistance, and good scratch resistance for many applications, often at a more palatable price point. PVD and DLC shine when extreme hardness and wear resistance are non-negotiable, though they come with a higher price tag. Choosing the right finish is like picking the right tool for the job – it depends on what you're trying to achieve.

Applications of Black Anodized Titanium: Where Durability Matters

The unique blend of properties that black anodized titanium brings to the table makes it a standout material in a surprising array of industries. It’s not just about looking good; it's about performance and reliability.

From high-fashion accessories to life-saving medical devices, its combination of strength, lightness, corrosion resistance, and that striking black finish makes it an attractive choice. It's a material that truly punches above its weight.

Black Titanium in Jewelry and Watches: Style Meets Resilience

Walk into any high-end jewelry store, and you're likely to see black titanium. It's a game-changer for designers. Its lightweight nature makes for comfortable wear, while its hypoallergenic properties mean even those with sensitive skin can enjoy it.

The black anodized finish adds a sleek, modern aesthetic that's both bold and understated. Think about watch cases, wedding bands, or statement earrings. The durability of the anodized layer means these pieces can stand up to daily knocks and still look sharp for years. It's truly a win-win: exceptional style without sacrificing resilience.

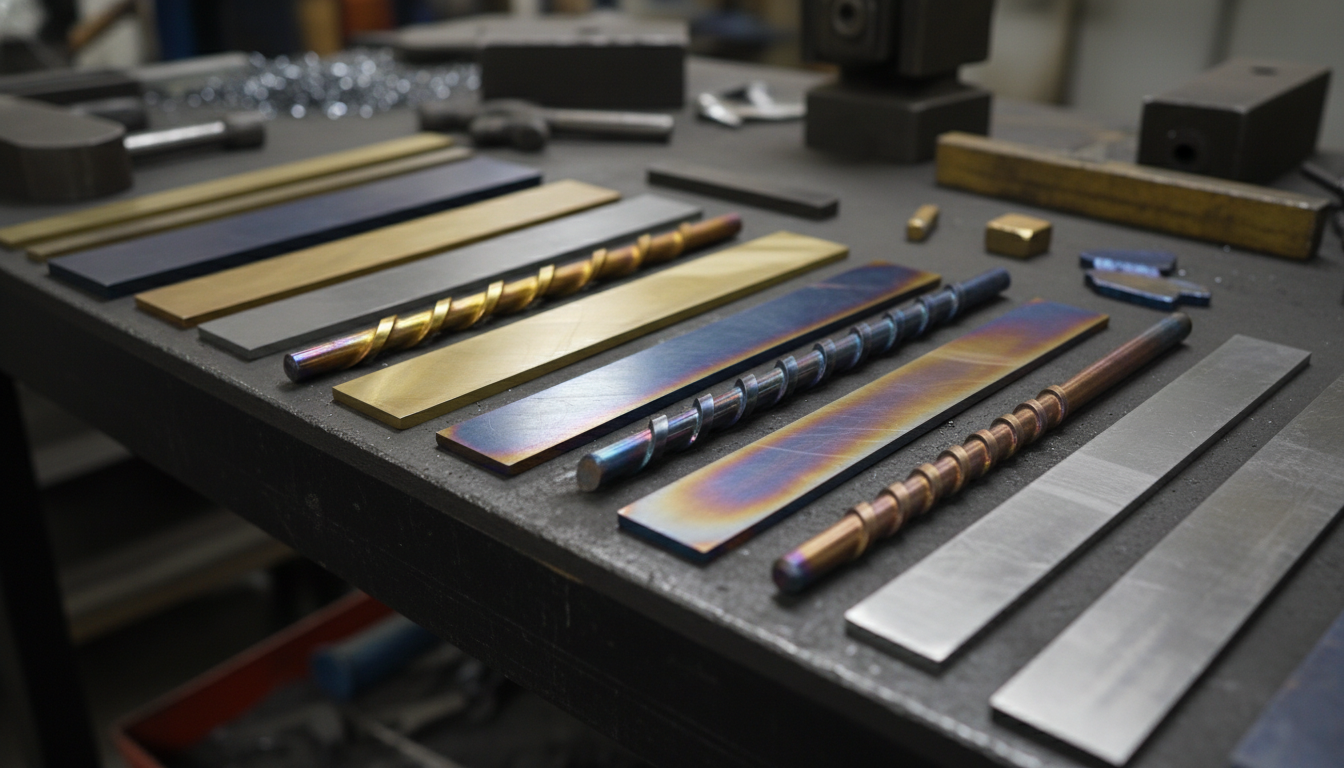

Industrial and Aerospace Applications: Performance Under Pressure

In demanding sectors like aerospace and industrial manufacturing, performance isn't just a bonus; it's a necessity. Black anodized titanium components are right at home here.

Its high strength-to-weight ratio is critical for aircraft components, reducing overall mass and improving fuel efficiency. The enhanced corrosion resistance provided by anodizing protects parts exposed to harsh atmospheric conditions, jet fuel, and various chemicals. From structural brackets to specialized fasteners, these components need to perform without fail, often in extreme conditions. The dark finish can also be beneficial for reducing reflectivity or for identification purposes.

Medical and Biomedical Uses: Biocompatibility and Sterilization

The medical field relies heavily on titanium's inherent biocompatibility. Anodizing takes this a step further. The oxide layer is inert and non-toxic, making black anodized titanium perfect for implants, surgical instruments, and prosthetic components. It plays well with the human body, which is a big deal.

Beyond biocompatibility, these instruments face rigorous sterilization cycles. The anodized finish can withstand repeated autoclave sterilization without degradation, maintaining its integrity and appearance. This ensures patient safety and extends the lifespan of expensive equipment. It's a testament to the finish's robust nature.

For more on the rigorous standards for materials in these fields, check out resources like ASTM International's standards for titanium.

Beyond Durability: Cost-Benefit, Sustainability, and Future Outlook

Durability is a big piece of the puzzle, but it's not the only one. When considering black titanium anodizing, it makes sense to look at the bigger picture. What about the cost? What about its impact on the planet? And where is this technology headed?

These questions matter. They help paint a complete picture, ensuring you're making a truly informed decision, not just one based on surface-level appeal.

Is Black Anodized Titanium Worth the Investment? A Cost-Benefit Analysis

Initial costs for black titanium anodizing can be higher than some alternative finishes or raw titanium. That's just the truth of it. However, you've got to look at the long game. This isn't just an expense; it's an investment.

Consider the extended lifespan of the product. Less frequent replacement. Reduced maintenance. Superior corrosion resistance means fewer failures in harsh environments. For applications where reliability is paramount, like medical or aerospace, the slightly higher upfront cost is often easily justified by the sheer reduction in long-term headaches and expenses.

It's often worth its weight in gold when you factor in the total cost of ownership. Durability pays dividends over time.

Environmental Impact and Sustainable Practices in Anodizing

In today's world, sustainability isn't just a buzzword; it's a responsibility. Anodizing, like any industrial process, has an environmental footprint. However, compared to some other coating methods, it can be relatively eco-friendly.

The process itself primarily uses water and acids, which can be treated and recycled. Many modern anodizing facilities, including those we work with at China Titanium Factory, employ closed-loop systems to minimize waste and conserve resources. The resulting oxide layer is inert and doesn't leach harmful chemicals.

Furthermore, the enhanced durability means products last longer, reducing the need for premature replacement and thus cutting down on material consumption and waste. It's a step in the right direction for responsible manufacturing. For deeper dives into industrial sustainability, resources like the EPA's sustainability initiatives can be informative.

Real-World Insights: Case Studies and Long-Term Performance

Talk is cheap, right? What really matters is how black anodized titanium performs when the chips are down. We see its long-term performance in various products every single day.

Consider high-end sporting goods, like bicycle components or specialized camping gear, subjected to mud, impacts, and varied weather. Black anodized finishes on these items hold up year after year, proving their mettle. Or look at architectural elements exposed to urban pollution and constant sunlight – they maintain their deep black hue and structural integrity. These aren't just theoretical benefits; they're proven results.

The data from countless applications speaks for itself: black anodized titanium is the real McCoy when it comes to combining aesthetics with enduring performance.

A recent study on the long-term corrosion resistance of anodized titanium in saline environments highlighted its superior performance compared to untreated titanium, reinforcing its value in marine and medical applications. This kind of scientific backing gives us confidence in the material's capabilities. You can often find such research through academic databases like Google Scholar by searching for "titanium anodizing corrosion long-term."

Frequently Asked Questions About Black Titanium Anodizing

How does black anodizing impact titanium's strength?

Black anodizing creates a thin, hard oxide layer on the surface. This layer doesn't significantly affect the bulk mechanical strength of the underlying titanium. It primarily enhances surface properties like hardness and corrosion resistance, without making the material more brittle or weaker overall.

Can black anodized titanium be re-anodized if damaged?

Yes, theoretically. The original anodized layer can be chemically stripped, and the part can then be re-anodized. However, this process requires specialized equipment and expertise. It's often more cost-effective for larger or high-value components. For smaller, less critical items, replacement might be the easier route.

Is black anodized titanium safe for skin contact?

Absolutely. One of titanium's standout features is its biocompatibility. The anodized oxide layer further enhances this. It's hypoallergenic, non-toxic, and widely used in medical implants and jewelry precisely because it's safe for prolonged skin contact without causing irritation or allergic reactions.

What's the difference between black anodizing and black paint on titanium?

It's night and day. Black paint is a surface coating that sits on the titanium. It can chip, peel, or scratch off relatively easily. Black anodizing, on the other hand, is an electrochemical process that grows an oxide layer out of the titanium itself. It's an integral part of the metal, offering far superior adhesion, durability, and corrosion resistance compared to paint.

Does the anodizing process add significant weight to titanium parts?

No. The anodized layer is extremely thin, typically in the range of a few microns (millionths of a meter). While it does add a minuscule amount of mass, it's negligible for almost all practical applications and won't impact the overall weight of the titanium part in any noticeable way.

Need Precision Black Titanium Anodizing?

When durability, aesthetics, and precision matter, trust the experts. China Titanium Factory offers state-of-the-art black titanium anodizing services, ensuring your components meet the highest standards. Get the robust, visually stunning finish your projects demand.

Get a Quote Today