Understanding Custom Anode Shapes: A Foundation for Marine Protection

Marine environments are relentless. Saltwater, oxygen, and dissimilar metals combine to create a perfect storm for corrosion. This isn't just an aesthetic issue; it compromises structural integrity, leads to costly repairs, and can even pose safety risks for vessels and offshore structures.

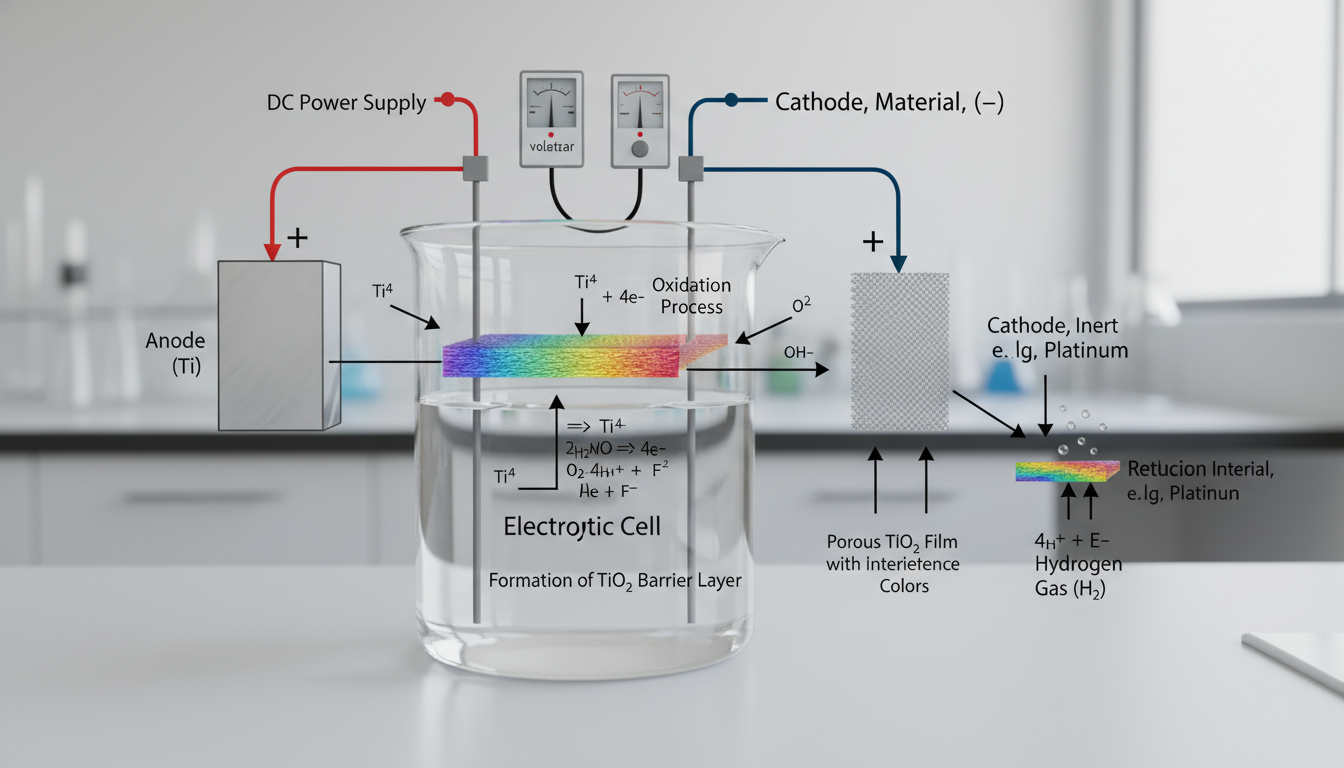

At the heart of mitigating this problem lies cathodic protection. It's a proven method to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. Often, this means employing sacrificial anodes.

But what happens when standard, off-the-shelf anodes just don't cut it? That's where custom anode shapes come into play. These specialized anodes are engineered precisely for unique applications, offering protection where generic options fall short.

What is Galvanic Corrosion?

Galvanic corrosion occurs when two dissimilar metals are in electrical contact with each other in the presence of an electrolyte (like seawater). The more "active" metal corrodes preferentially, protecting the more "noble" metal.

Think of it as a battery. The anode is the negative terminal, the cathode is positive, and the seawater acts as the conductor. The active metal, or anode, "sacrifices" itself to protect the less active cathode.

The Role of Sacrificial Anodes

A sacrificial anode is a highly active metal that is deliberately corroded to protect a more valuable, less active metal structure from electrochemical corrosion. It literally sacrifices itself.

These anodes are typically made from zinc, aluminum, or magnesium. They're designed to corrode steadily over time, drawing the corrosive attack away from the vessel's hull, propellers, rudders, or other critical components.

For specialized needs, however, the standard blocks and disks simply won't cut it. Customization becomes the answer.

Why Standard Anodes Aren't Always Enough: The Case for Customization

You wouldn't put a square peg in a round hole, right? The same logic applies to marine corrosion protection. Generic anodes, while effective for many applications, hit a wall when faced with unique challenges.

Modern vessel designs are intricate. Hull shapes vary wildly. Propulsion systems are complex. Offshore platforms have specific structural requirements. These scenarios often demand more than a one-size-fits-all approach.

Limitations of Off-the-Shelf Solutions

Standard anodes have several drawbacks in specialized applications:

Inefficient Coverage: They might not provide uniform current distribution across complex surfaces, leaving vulnerable spots exposed.

Hydrodynamic Drag: Poorly shaped or placed standard anodes can increase drag, impacting fuel efficiency and vessel speed.

Installation Challenges: Mounting generic anodes on irregular surfaces can be difficult, leading to weak attachments or improper contact.

Premature Depletion: If the surface area or material isn't optimized, the anode might deplete faster than expected, requiring more frequent replacements.

The Tangible Benefits of Custom Anodes

This is where custom solutions shine. Tailored anodes offer a host of advantages:

Enhanced Protection: Precisely designed shapes ensure optimal current spread, covering every inch of the protected surface.

Optimized Performance: Anodes can be shaped to minimize hydrodynamic drag, maintaining vessel efficiency without compromising protection.

Extended Longevity: Engineered with the exact mass and alloy composition needed, custom anodes last longer, reducing maintenance cycles and costs.

Seamless Integration: They fit perfectly into the existing structure, often becoming an integral, almost invisible part of the design.

For operations where reliability is non-negotiable, custom anodes are not a luxury, but a necessity. They are a strategic investment that pays dividends in reduced downtime and prolonged asset life.

The Science of Sacrifice: How Marine Cathodic Protection Works

Understanding cathodic protection isn't rocket science, but it does require a grasp of basic electrochemistry. The principle is elegant in its simplicity: divert corrosion away from your valuable assets.

Principles of Galvanic Corrosion

When different metals are submerged in an electrolyte, they develop different electrical potentials. This is quantified by the galvanic series. The metal higher on the series (more active) will act as the anode and corrode, while the metal lower on the series (more noble) will act as the cathode and be protected.

In marine applications, the steel hull of a ship is relatively noble compared to zinc or aluminum. By attaching a sacrificial anode made of these more active metals, the hull becomes the cathode, and the anode corrodes instead.

Sacrificial Anode Materials and Their Applications

The choice of anode material is critical. It depends on the electrolyte (freshwater, brackish, seawater) and the metal being protected.

| Material | Primary Application | Key Characteristics |

|---|---|---|

| Zinc Anodes | Seawater applications (steel hulls, rudders, propellers). | Consistent performance, reliable in saltwater, less effective in freshwater. |

| Aluminum Anodes | Seawater and brackish water (aluminum hulls, large vessels, offshore structures). | Higher current capacity per pound than zinc, versatile for various salinities. |

| Magnesium Anodes | Freshwater applications (inland vessels, water heaters, pipelines). | Most active metal, highest driving voltage, can overprotect in saltwater. |

For specific requirements, particularly with unique vessel designs or specialized environments, the expert team at China Titanium Factory can guide you through the ideal anode material selection to ensure robust, long-lasting protection.

Beyond Sacrifice: Impressed Current Cathodic Protection (ICCP)

While sacrificial anodes are common, another method exists: Impressed Current Cathodic Protection (ICCP). This system uses an external power source to drive a current through inert anodes, providing controlled protection. ICCP is often used on larger vessels or structures where sacrificial anodes might be impractical due to sheer size or high current demands. Sometimes, both systems are used in tandem for comprehensive defense.

For more detailed technical insights into marine corrosion and cathodic protection standards, refer to resources from organizations like NACE International (now AMPP), a leading authority in corrosion control.

From Concept to Creation: The Custom Anode Design and Manufacturing Process

Crafting a custom anode isn't a shot in the dark. It's a meticulous process, blending client needs with advanced engineering. The goal is pinpoint precision and flawless performance.

The Anode Customization Process Unveiled

It starts with a conversation. We delve deep into your vessel's specifications, operational environment, and specific corrosion challenges. Every detail matters.

Initial Consultation and Data Gathering

This phase involves understanding the protected structure's material, dimensions, desired lifespan of the anode, and environmental factors like water salinity and temperature. Photos, blueprints, and 3D models of the vessel are invaluable.

Design Considerations for Custom Anodes

Here's where the rubber meets the road. Key factors include:

Material Selection: Zinc, aluminum, or magnesium, chosen based on the application.

Size and Shape: Optimized for surface area, weight, and hydrodynamic efficiency.

Weight and Mass: Calculated to provide the required current output and lifespan.

Attachment Methods: Bolt-on, weld-on, flush-mounted – designed for secure and effective electrical contact.

Current Distribution: Modeling to ensure even protection across the target surface.

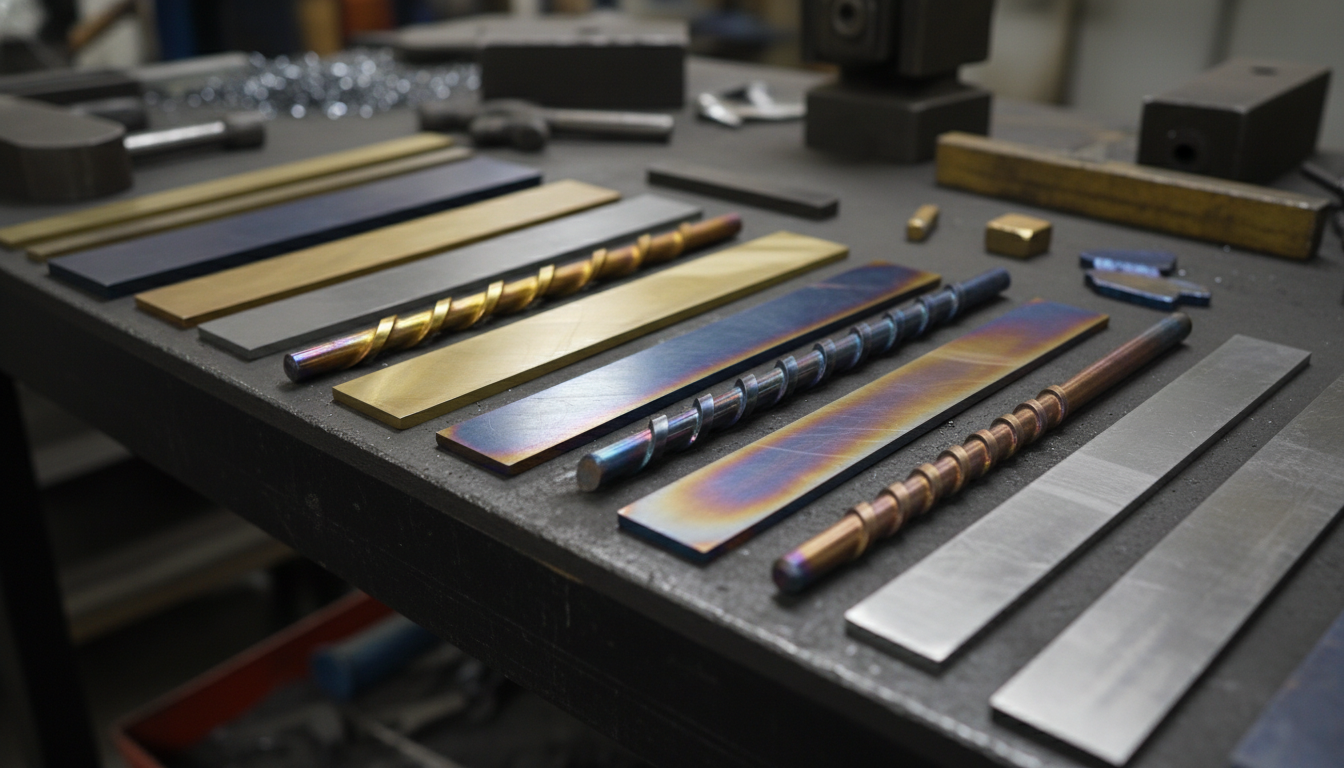

Advanced Manufacturing Techniques

Modern anode production leverages cutting-edge technology. CAD/CAM software is indispensable. It allows engineers to create precise 3D models, simulate performance, and generate toolpaths for manufacturing.

Precision casting and machining ensure that every custom anode meets stringent specifications. Prototyping allows for real-world testing and validation before full-scale production begins. This iterative process guarantees that the final product is not just good, but perfect for its intended purpose.

At China Titanium Factory, our custom anode design stages prioritize accuracy and client trust. We're not just making anodes; we're crafting solutions.

Seamless Integration: Optimizing Anodes for Your Hull Design

An anode, no matter how perfectly crafted, is only as effective as its placement. Strategic integration into your hull design is paramount. It’s about more than just sticking them on; it’s about making them part of the ship’s very being.

Anode Placement Strategies on Hulls

Different hull materials and vessel types demand varied approaches. A yacht's needs differ wildly from an oil rig's.

Anodes for Steel Hulls

Steel hulls are robust but highly susceptible to corrosion in saltwater. Zinc or aluminum anodes are typically welded or bolted directly onto the hull, concentrated around areas of high turbulence or dissimilar metals, like propellers, shafts, and rudder assemblies. Even distribution is key to prevent localized corrosion.

Anodes for Aluminum Hulls

Aluminum requires careful consideration. While aluminum itself can act as a sacrificial anode, it's best to use specifically formulated aluminum alloys or zinc anodes. Magnesium is generally avoided due to its high driving voltage, which can overprotect and potentially damage aluminum in saltwater. Anodes must be electrically isolated from the aluminum hull if made of a different material to prevent localized corrosion at the connection point.

Anodes for Fiberglass Hulls

Fiberglass itself doesn't corrode, but metal components attached to it (struts, shafts, thru-hulls) do. Anodes are typically bolted to these components or mounted to the hull with internal wiring ensuring electrical continuity. Magnesium anodes might be suitable for freshwater fiberglass boats.

Hydrodynamic Impact and Efficiency

Anodes shouldn't just protect; they should do so without hindering performance. Large, bulky anodes can create drag, increasing fuel consumption and reducing speed. Custom shapes, meticulously designed, can be flush-mounted or streamlined to blend seamlessly with the hull's contours. This minimizes turbulence and preserves the vessel's hydrodynamic efficiency.

The goal is a symbiotic relationship: maximum corrosion protection with minimal impact on performance. This balance is a hallmark of expertly integrated custom anode solutions, something we excel at here at China Titanium Factory.

Navigating the Market: Choosing a Custom Anode Manufacturer

Selecting the right partner for your custom anode needs is crucial. It’s not just about buying a product; it’s about investing in expertise, reliability, and peace of mind. A bad anode means bad news down the line.

Critical Factors for Supplier Selection

Don't just pick the first name that pops up. Do your homework. Look for these key attributes:

Demonstrated Technical Expertise: Does the manufacturer truly understand electrochemistry, metallurgy, and marine engineering? Can they speak your language, or do they just parrot buzzwords?

Adherence to Quality Standards: Are they certified? Look for compliance with international standards like ISO 9001. Do their products meet specific marine classification society requirements (e.g., DNV, ABS, Lloyd's Register)? These certifications aren't just fancy plaques; they signify a commitment to quality and safety.

Customization Capabilities: Can they actually produce complex shapes with precision, or are they limited to minor modifications of standard designs? This is where true custom manufacturers like China Titanium Factory stand out.

Responsive Customer Support: Can you get answers when you need them? Clear communication throughout the design and manufacturing process is invaluable.

Track Record and References: Ask for case studies or client testimonials. A history of successful projects speaks volumes.

The Custom Order Process: What to Expect

A typical custom order involves several stages:

Inquiry & Consultation: You provide your requirements, and the manufacturer offers initial guidance.

Design & Quotation: Engineers develop a detailed design and provide a comprehensive quote.

Approval & Prototyping (if needed): You review and approve the design. Prototypes may be created for complex orders.

Manufacturing: Production begins, adhering to strict quality control.

Delivery: Your custom anodes are shipped.

Regarding cost of custom anode manufacturing, it varies significantly based on material, complexity, size, and quantity. Lead times also depend on these factors and the manufacturer's current workload. Always get a clear timeline upfront.

For more on marine anode certifications and standards, you can consult organizations like DNV (Det Norske Veritas), a global leader in maritime assurance.

Success Stories: Custom Anodes in Action

Seeing is believing. While specific client projects are often under wraps due to proprietary information, we can illustrate the impact of custom anodes through common scenarios.

Case Study: Offshore Platform Leg Protection

An aging offshore oil platform faced severe corrosion on its support legs, particularly at the splash zone and submerged sections. Standard anodes couldn't be effectively installed due to complex structural nodes and existing marine growth, leaving critical areas vulnerable.

The Custom Solution: Engineers designed ring-shaped aluminum anodes, precisely molded to fit around the tubular legs. These were segmented for easier installation underwater by divers. Specific attachment points were engineered to ensure optimal electrical contact despite the challenging environment.

Measurable Benefits: Within months, monitoring confirmed stable cathodic protection across the entire leg structure. The custom anodes provided uniform current density, significantly extending the lifespan of the platform's legs and preventing potential structural failures. The tailored fit also reduced drag in strong currents, a bonus for stability.

Case Study: Luxury Yacht Propeller and Shaft Protection

A high-performance luxury yacht, with its polished bronze propellers and stainless steel shafts, was experiencing accelerated pitting corrosion around these critical areas. Standard "doughnut" anodes were too bulky, causing cavitation and vibration, which was unacceptable for a vessel of its caliber.

The Custom Solution: Sleek, low-profile zinc anodes were designed to perfectly match the hydrodynamic contours of the propeller hub and shaft housing. These anodes were flush-mounted, eliminating turbulence and maintaining the yacht's aesthetic and performance. The alloy composition was fine-tuned for the specific saltwater conditions it operated in.

Measurable Benefits: The yacht's owners reported zero signs of corrosion after a full season. Performance metrics showed no increase in drag or vibration. The custom anodes provided discreet, yet powerful, protection, preserving both the function and beauty of the vessel's propulsion system. This is an example of successful anode applications in a demanding sector.

Interactive Tools and Resources for Anode Planning

Planning for optimal corrosion protection requires data and precision. Thankfully, various resources and tools can assist in preliminary design and material selection. These aids help narrow down options before engaging with a manufacturer for a bespoke solution.

Anode Calculators and Material Selectors

Many reputable cathodic protection suppliers offer online anode calculators. These tools typically ask for details like the wetted surface area of your vessel, the type of water (fresh, brackish, salt), and the expected lifespan. They then suggest an approximate number and type of standard anodes needed.

Similarly, anode material selectors can guide you on the best alloy based on your specific environment and the metals you need to protect. While these tools provide good starting points, remember they are generalized. Custom applications will always require direct consultation.

Technical Guides and Industry Standards

For those who like to dive deep, a wealth of technical resources exists. Industry associations like AMPP (formerly NACE International and SSPC) publish extensive standards and best practices for cathodic protection. Classification societies (e.g., ABS, DNV, Lloyd's Register) also have detailed rules for anode placement and material quality on classed vessels.

These guides offer invaluable information on everything from current density requirements to installation guidelines. For specific technical questions or to explore advanced cathodic protection strategies, contacting a specialist at China Titanium Factory can provide tailored insights and solutions.

Frequently Asked Questions About Custom Anode Shapes

Q1: What are the main advantages of custom anodes over standard ones?

Custom anodes offer superior protection tailored to specific structural geometries, optimizing current distribution and minimizing vulnerable spots. They can be designed to reduce hydrodynamic drag, enhance longevity, and integrate seamlessly into complex designs, providing a more efficient and cost-effective long-term solution.

Q2: How long do custom anodes typically last?

The lifespan of a custom anode depends heavily on factors like material, size, environmental conditions (water salinity, temperature), and the specific current demand of the protected structure. However, because they are precisely engineered for the application, custom anodes often have an optimized lifespan, usually ranging from 1 to 5 years before requiring replacement. Regular inspections are always recommended.

Q3: Is the cost of custom anodes significantly higher than standard anodes?

Initially, the per-unit cost of a custom anode might be higher due to design, tooling, and specialized manufacturing. However, this upfront investment often leads to significant long-term savings. Custom anodes offer more effective protection, reduce the frequency of replacements, minimize maintenance costs, and prevent costly corrosion damage, making them a more economical choice over the lifespan of the asset.

Q4: What information do I need to provide for a custom anode quote?

To get an accurate quote, you should provide detailed information about the structure to be protected, including its material, dimensions, desired anode lifespan, operating environment (water type, temperature), and any existing blueprints or 3D models. Specifying preferred attachment methods and quantity also helps streamline the quoting process.

Q5: Can custom anodes be used with Impressed Current Cathodic Protection (ICCP) systems?

While ICCP systems use inert anodes (often titanium-based with mixed metal oxide coatings) rather than sacrificial ones, custom shapes are still highly relevant. Custom-designed ICCP anodes can optimize current distribution, minimize hydrodynamic impact, and fit precisely into complex vessel or structure designs, maximizing the efficiency and effectiveness of the impressed current system. China Titanium Factory specializes in various anode types, including those for ICCP applications.

Ready for Unmatched Marine Protection?

Don't let corrosion eat away at your valuable marine assets. Experience the peace of mind that comes with precision-engineered, custom anode solutions.

Get a Custom Anode Quote Today