What Happens When Your Sacrificial Anode is Fully Consumed? A Comprehensive Guide

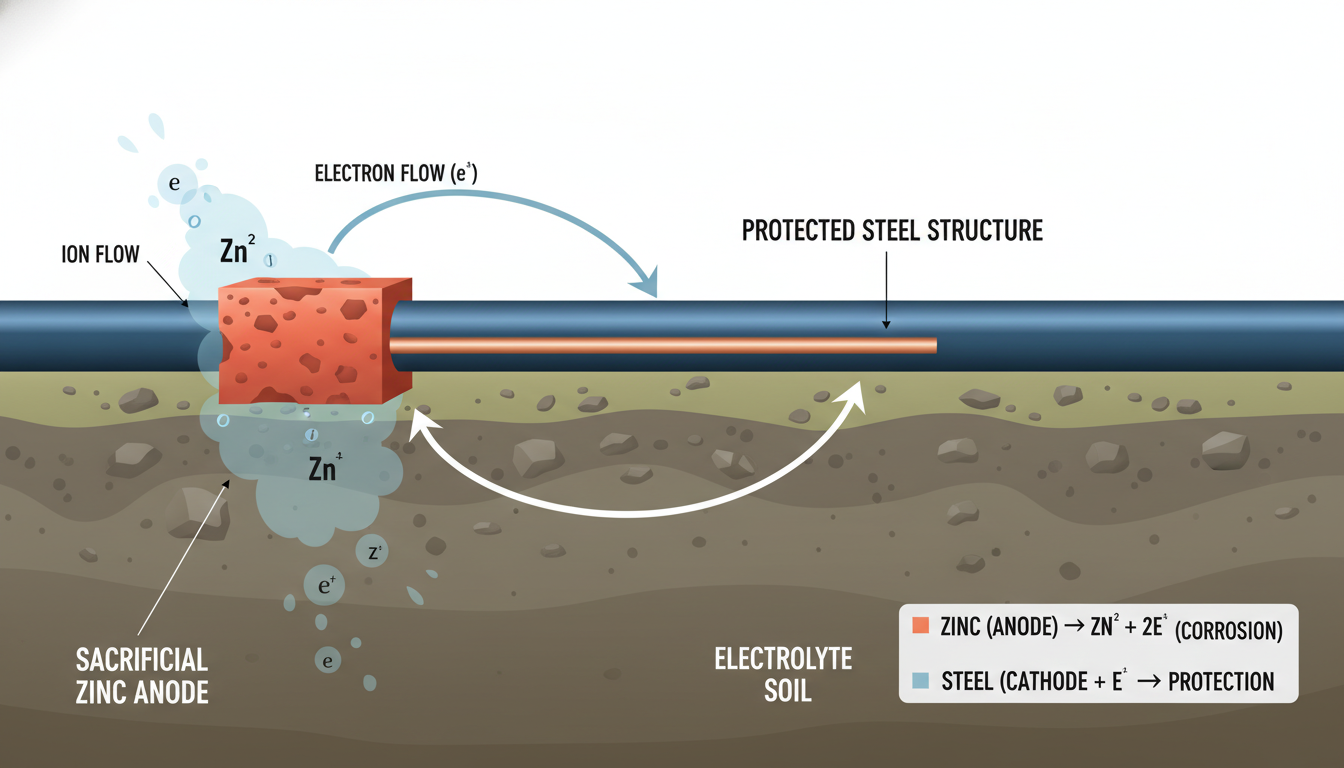

Imagine a tiny, unsung hero silently protecting your most valuable metal assets from an invisible enemy: corrosion. That hero is the sacrificial anode. It’s a workhorse, giving its own life to save your equipment. But what happens when this selfless protector is gone, completely consumed?

The answer is stark: your assets become vulnerable. The very problem the anode was designed to prevent—metal degradation—begins, often with costly and catastrophic results. Understanding this critical point is key to effective cathodic protection systems and preventing premature system failure.

Understanding Sacrificial Anodes: Your First Line of Defense Against Corrosion

Corrosion is a relentless foe, constantly seeking to degrade metals through electrochemical reactions. Think of rust on an old car or pitting on a boat hull. Sacrificial anodes are a straightforward, yet incredibly effective, weapon against this destructive process.

They are core components of passive cathodic protection systems, specifically designed to be more electrochemically active than the metal they protect. This means they corrode first, "sacrificing" themselves to shield the more vital component.

It's a clever trick of chemistry, ensuring your expensive equipment stays intact.

The Science Behind the Sacrifice: How Anodes Protect Your Assets

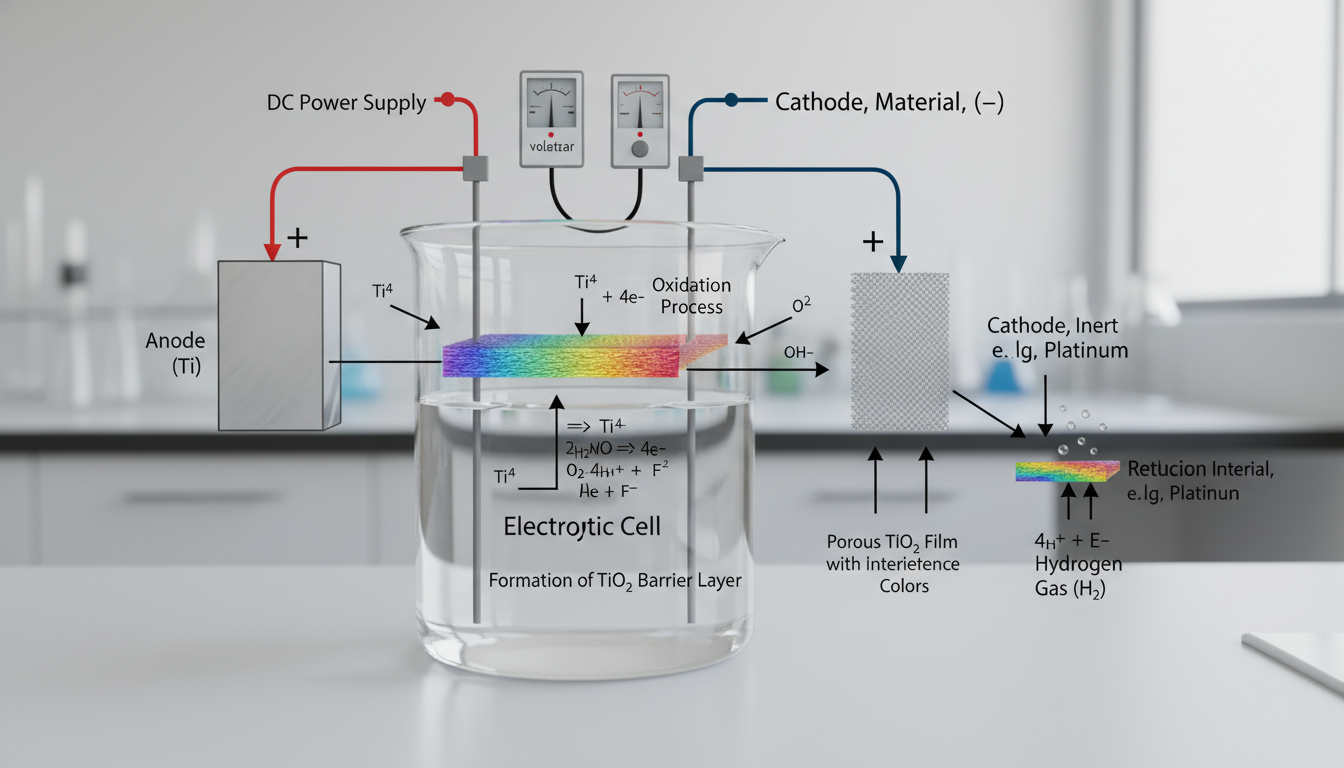

At its heart, corrosion is an electrochemical process. Metals naturally want to return to their more stable oxidized state. When two different metals are in electrical contact and submerged in an electrolyte (like water or soil), a tiny battery forms.

Galvanic Corrosion: An electrochemical process where one metal corrodes preferentially when it is in electrical contact with another, more noble metal, and both metals are immersed in an electrolyte.

The more active metal (the anode) becomes the negative terminal, losing electrons and corroding. The less active metal (the cathode) becomes the positive terminal, gaining electrons and remaining protected. Sacrificial anodes exploit this natural phenomenon.

They are deliberately chosen from the "more active" end of the galvanic series, ensuring they become the anode in the circuit and draw the corrosive attack away from your valuable assets. This electron flow is what keeps your critical components safe. For industrial applications requiring specific material properties, custom titanium fabrication can be crucial in ensuring optimal galvanic compatibility.

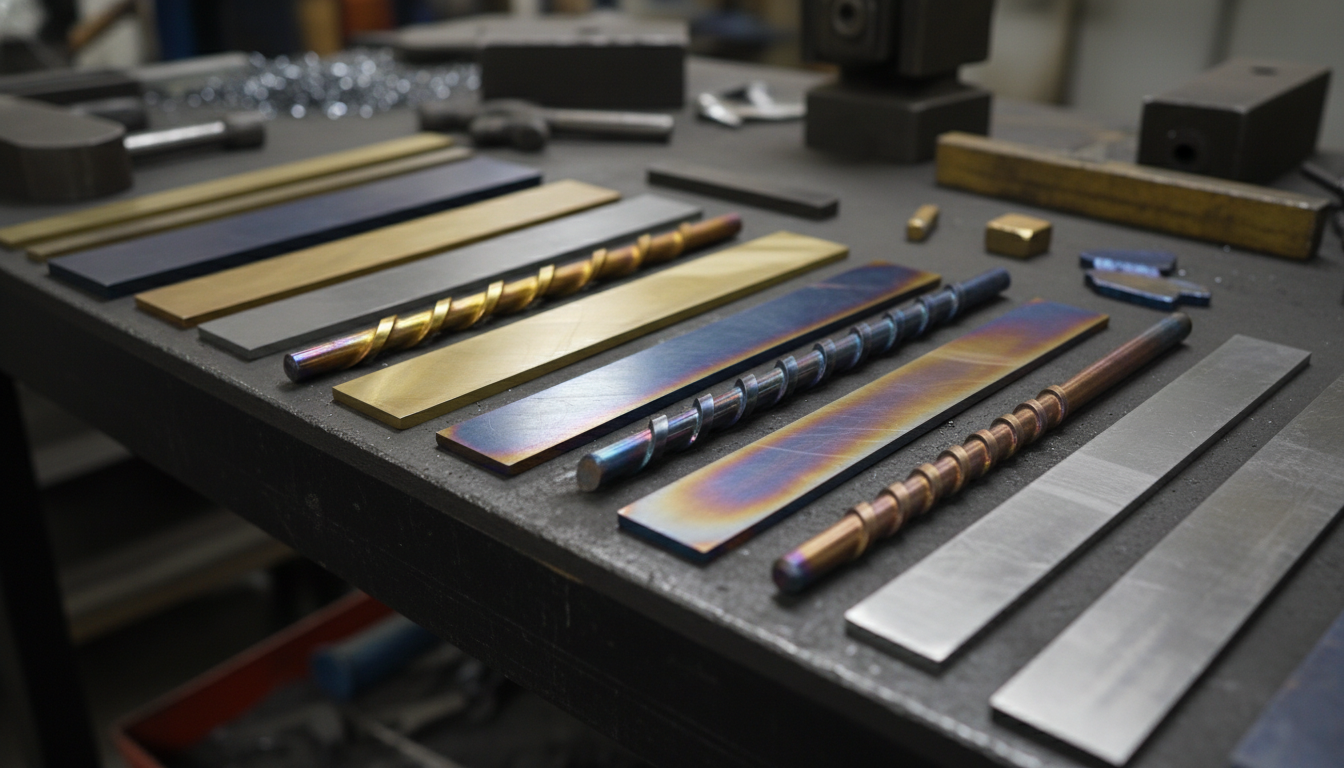

Types of Sacrificial Anodes: Choosing the Right Material for the Job

Not all anodes are created equal. The right material depends heavily on the environment and the metal being protected. Three common types dominate the market:

Magnesium Anodes: These are the most active, providing the highest driving voltage. They're ideal for freshwater applications like water heaters or underground pipelines where resistivity is higher.

Aluminum Anodes: A versatile choice, aluminum anodes are primarily used in saltwater. They offer a good balance of protection and lifespan. They're often alloyed with other elements (like indium) to prevent passivation.

Zinc Anodes: Less active than magnesium, zinc anodes are excellent for saltwater environments and brackish water. They provide a lower driving voltage, making them suitable for protecting steel hulls and propellers.

Selecting the wrong type can lead to insufficient protection or, conversely, overprotection which can damage coatings. Consulting with experts, like those at China Titanium Factory, can help determine the optimal material for your specific application, especially for systems involving specialized metals.

Here's a quick comparison:

| Anode Type | Primary Environment | Typical Applications | Key Characteristics |

|---|---|---|---|

| Magnesium | Freshwater, Soil | Water heaters, underground pipelines | Highest driving voltage, fast consumption |

| Aluminum | Saltwater, Brackish Water | Boat hulls, offshore structures, heat exchangers | Good balance of lifespan and output, often alloyed |

| Zinc | Saltwater | Boat hulls, propellers, rudders, stern drives | Reliable, consistent output, best for immersed applications |

The Dire Consequences of a Completely Consumed Sacrificial Anode

The problem is simple: when the sacrificial anode is gone, its job stops. There’s nothing left to sacrifice. This immediate lack of protection kicks off a cascade of serious issues, directly impacting the longevity and safety of your metal assets.

It's like removing a goalie mid-game. The net is wide open for attack.

Increased Risk of Galvanic Corrosion and System Failure

Without its designated protector, the formerly cathodic (protected) metal component becomes vulnerable. It now has to fend for itself. If other, more active metals are present in the system, the protected component can suddenly become the anode in a new galvanic couple, leading to its rapid corrosion.

This isn't just slow decay; it’s accelerated degradation. Structural integrity is compromised. For critical infrastructure, pipelines, or marine vessels, this can quickly escalate to system failure, putting operations, safety, and investments at grave risk. According to AMPP (formerly NACE International), the global cost of corrosion is staggering, reinforcing the need for robust prevention strategies. [1]

Damage to Protected Components: From Water Heaters to Boat Hulls

The consequences are tangible and costly across various applications:

Water Heater Tanks: A common household example. Without an anode, the steel tank starts corroding, leading to leaks, foul-smelling water (from bacteria thriving on corrosion byproducts), and ultimately, complete tank failure and water damage.

Boat Hulls & Marine Equipment: Saltwater is a highly aggressive electrolyte. A depleted anode means propellers, rudders, outdrives, and the hull itself are susceptible to pitting and structural damage. This can lead to expensive repairs or even sinkings.

Pipelines & Storage Tanks: Industrial systems face immense pressure. Corrosion of pipelines or storage tanks can result in leaks, environmental contamination, operational shutdowns, and severe safety hazards.

Industrial Machinery: Components exposed to harsh chemicals or demanding environments rely on anodes. Their failure can lead to equipment breakdown, production losses, and exorbitant replacement costs.

The damage is not always immediately apparent, but it's always progressing. Think of small leaks turning into floods, or minor pitting becoming structural weakness. For robust industrial solutions, exploring titanium-based corrosion solutions might be a smarter long-term investment.

Visible Signs of Anode Depletion and Impending Damage

While often hidden, a depleted anode leaves clues. Keep an eye out for these red flags:

Rust Spots: The most obvious indicator. Rust appearing on a previously protected metal surface means the anode is no longer doing its job.

Water Leaks: For tanks or pipelines, unexplained drips or puddles are a serious warning sign.

Reduced Efficiency: Fouling or corrosion on heat exchanger surfaces can reduce thermal transfer efficiency.

Unusual Odors: Sulfurous or rotten egg smells from water (especially in water heaters) often indicate anaerobic bacteria thriving on corrosion byproducts in an unprotected tank.

Pitting or Roughness: Visual inspection of accessible metal components might reveal localized corrosion, appearing as small holes or an uneven surface.

Catching these signs early can save you a bundle. Don't sweep them under the rug.

Impact on Lifespan, Performance, and Maintenance Costs

Let's not mince words: a depleted anode is a ticking time bomb for your budget. The initial cost of an anode is peanuts compared to the repairs it prevents.

When corrosion sets in, equipment lifespan plummets. A water heater designed to last 10-15 years might fail in 5-7. A boat hull meant for decades of service could require major patch-ups much sooner. Performance degrades as components weaken or become clogged.

Ultimately, neglecting anode replacement leads to significantly higher maintenance costs, frequent repairs, and premature replacement of entire systems. It's a classic example of being penny-wise and pound-foolish.

Proactive Anode Maintenance: Protecting Your Investment

The good news? Preventing these dire outcomes is often simple and cost-effective. Regular inspection and timely replacement of sacrificial anodes are the cornerstones of a robust corrosion prevention strategy. It's not rocket science; it's just good practice.

Treat your anodes like oil changes for your car – essential, routine maintenance that pays dividends.

How to Inspect Your Sacrificial Anode: A Step-by-Step Guide

Inspection methods vary by application, but the core idea remains: visually assess the anode's remaining material. Safety first, always!

For Water Heaters:

Shut off power/gas and water supply to the heater.

Drain a few gallons from the tank to reduce pressure and hot water level.

Carefully unscrew and remove the anode rod (usually located on top).

Inspect: If it's less than half its original diameter, heavily pitted, or has exposed core wire, it's time for replacement.

Reinstall or replace, ensuring a tight seal.

For Marine Vessels:

This typically requires hauling the boat out of the water.

Visually check all external anodes (hull, trim tabs, shafts, propellers, outdrives).

If an anode is reduced by more than 50% of its original size, replace it. Don't wait until it's completely gone.

For Industrial Systems:

Follow specific shutdown and lockout/tagout procedures.

Access internal components or external burial sites as per system design.

Measure remaining anode mass or dimensions against original specifications.

When in doubt, it's better to replace an anode a little early than too late. It’s cheap insurance.

Recommended Anode Replacement Schedules and Lifespan Factors

There’s no one-size-fits-all answer for anode lifespan. It's a moving target, influenced by several factors:

Water Quality/Soil Resistivity: More conductive environments (e.g., saltwater) will consume anodes faster. Hard water in water heaters can also accelerate wear.

Temperature: Higher temperatures often increase electrochemical reaction rates, shortening anode life.

Usage Patterns: A frequently used boat in saltwater will consume anodes faster than one stored mostly on a trailer.

Original Anode Size & Material: Larger anodes last longer. Magnesium anodes generally deplete faster than zinc or aluminum due to their higher driving voltage.

Coating Integrity: If the protected metal's coating is damaged, the anode has to work harder, shortening its life.

As a general rule of thumb, inspect water heater anodes annually and marine anodes at least once per season (or every 6 months for heavily used vessels). Pipelines and industrial equipment should follow manufacturer recommendations or engineered corrosion prevention strategy schedules. You can learn more about general corrosion rates from industry bodies like ASTM International. [2]

DIY vs. Professional Anode Replacement: What You Need to Know

For simple applications like household water heaters or easily accessible marine anodes, DIY replacement is often feasible. It requires basic tools, a bit of elbow grease, and strict adherence to safety protocols (shutting off power/water, proper draining).

However, for complex industrial systems, large marine vessels, or critical infrastructure, calling in a professional is a no-brainer. They possess the expertise, specialized tools, and safety certifications to ensure the job is done correctly. Improper installation can negate the anode's effectiveness, potentially voiding warranties and leading to catastrophic failures. When in doubt, seek expert consultation.

Beyond Replacement: Optimizing Your Cathodic Protection System

Anode replacement is just one piece of the puzzle. A truly robust cathodic protection system considers:

System Design: Proper sizing and placement of anodes for optimal current distribution.

Material Selection: Choosing the right anode material for the specific environment and protected metal.

Installation Quality: Ensuring good electrical contact and secure mounting.

Ongoing Monitoring: Periodic checks of current output and potential readings to verify effectiveness.

For specialized needs, like those involving high-strength or corrosion-resistant alloys, partnering with a manufacturer experienced in advanced manufacturing techniques ensures your components contribute to, rather than detract from, your overall corrosion strategy.

Frequently Asked Questions About Sacrificial Anodes

How long does a sacrificial anode typically last?

Anode lifespan varies significantly. For water heaters, it's typically 3-5 years, but can be shorter in areas with aggressive water chemistry. Marine anodes might last one season (6-12 months) in saltwater, or longer if the vessel is used less frequently. Industrial anodes are designed for specific durations, often inspected annually, with replacement cycles ranging from 1 to 10 years depending on the system and environment.

Can I tell if my anode is depleted without removing it?

For most applications, a physical inspection is the most reliable way. However, indirect signs like rust appearing on protected surfaces, foul-smelling water (in water heaters), or a sudden increase in localized corrosion elsewhere on a boat hull can strongly suggest a depleted anode. For complex industrial systems, monitoring equipment can measure electrochemical potential, indicating when an anode is no longer providing adequate protection.

Is it safe to operate a system with a completely consumed anode?

No, it is not recommended. A completely consumed anode means your system has lost its primary corrosion defense. This significantly increases the risk of accelerated galvanic corrosion, leading to structural damage, leaks, equipment failure, and potential safety hazards. Continued operation without an anode is akin to playing Russian roulette with your valuable assets. Replace it as soon as depletion is identified.

What are the different types of anodes and which one is right for me?

The main types are Magnesium, Aluminum, and Zinc. Magnesium is best for freshwater and soil (highest driving voltage). Aluminum is versatile for saltwater and brackish water. Zinc is ideal for pure saltwater applications. The right choice depends on the specific electrolyte (freshwater, saltwater, soil, etc.) and the type of metal you are protecting. Always match the anode material to your environment for optimal performance.

What happens if I don't replace my sacrificial anode?

If you don't replace a depleted sacrificial anode, the metal component it was protecting will become vulnerable to corrosion. This leads to accelerated degradation, structural weakening, leaks, reduced operational efficiency, and ultimately, premature failure of the equipment. Ignoring anode replacement will inevitably result in costly repairs or complete system replacement far sooner than anticipated.

Don't Let Corrosion Eat Away Your Investment!

Proactive corrosion prevention is not just maintenance; it's smart business. Ensure your critical assets are protected with high-quality components and expert solutions.

Connect with China Titanium Factory for Your Corrosion Solutions Today!