MMO Coatings are Critical: Mixed Metal Oxide (MMO) coatings are essential for enhancing substrate performance and longevity in electrochemical applications.

Verification Prevents Failure: Rigorous verification of coating thickness and adhesion prevents premature failure, operational inefficiencies, and increased costs.

Diverse Thickness Methods: Both non-destructive (Eddy Current, XRF) and destructive (Cross-Sectional Microscopy, Coulometric Stripping) techniques are employed for accurate thickness measurement.

Adhesion is Paramount: Adhesion is assessed through standard tests like Cross-Cut, Pull-Off, and Tape tests, alongside advanced methods such as Scratch and Ultrasonic testing.

Accuracy Depends on Factors: Surface preparation, equipment calibration, environmental control, and operator proficiency are critical for reliable verification results.

Robust QC is Essential: Implementing comprehensive quality control protocols, including proper sampling, documentation, and training, ensures coating integrity.

Mixed Metal Oxide (MMO) coatings represent a cornerstone of modern industrial electrochemistry, providing enhanced performance and extended service life to various metallic substrates. These specialized coatings are integral to applications ranging from cathodic protection and chlor-alkali production to wastewater treatment and various industrial processes.

The integrity of an MMO coating is paramount for its intended function. Ensuring both its thickness and adhesion properties meet stringent specifications is not merely a best practice; it is a critical requirement for operational reliability, safety, and economic viability. This comprehensive guide details the essential methodologies for verifying MMO coating thickness and adhesion, offering insights for engineers and quality control professionals.

Mixed Metal Oxide (MMO) coatings are advanced catalytic layers applied to valve metal substrates, most commonly titanium. These coatings consist of a precise blend of noble metal oxides, such as ruthenium dioxide (RuO₂) and iridium dioxide (IrO₂), often combined with other non-noble metal oxides.

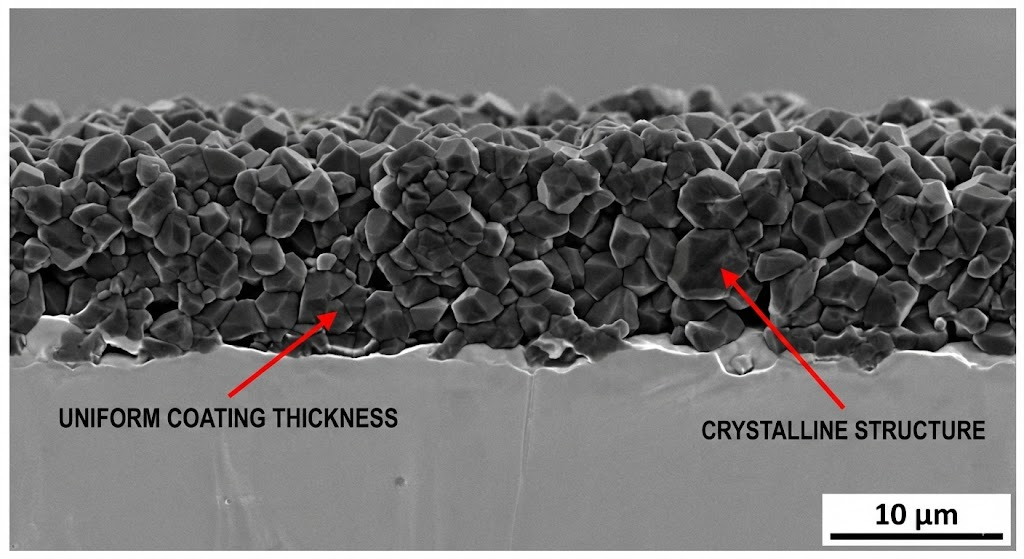

The manufacturing process typically involves applying a precursor solution containing metal salts onto a meticulously prepared titanium substrate. This is followed by high-temperature thermal decomposition, which converts the salts into a crystalline oxide layer. This method allows for precise control over the coating composition and microstructure.

MMO coatings are highly valued for their exceptional electrocatalytic activity, stability, and corrosion resistance in aggressive electrochemical environments. Their diverse applications include dimensionally stable anodes (DSAs) for chlorine and oxygen evolution, as well as anodes for impressed current cathodic protection (ICCP) systems.

Definition: Mixed Metal Oxide (MMO) coatings are electrochemically active and corrosion-resistant layers, typically composed of noble metal oxides, thermally applied to valve metal substrates to enhance their performance in electrolytic processes.

Rigorous verification of MMO coating thickness and adhesion is not merely a quality control measure; it is a fundamental requirement for ensuring the functional performance and longevity of coated components. Inadequate coating properties can lead to a cascade of detrimental outcomes.

Premature component failure is a significant risk. If an MMO coating is too thin, it may not provide sufficient catalytic activity or corrosion protection, leading to rapid degradation of the underlying substrate. Conversely, excessive thickness can introduce internal stresses, reducing adhesion and increasing material costs unnecessarily.

Poor adhesion, regardless of thickness, allows for delamination, exposing the substrate to corrosive environments and rendering the coating ineffective. Such failures can result in substantial operational efficiency losses, requiring costly downtime for repairs and replacements.

The economic impact of MMO coating failure extends beyond immediate repair costs. It encompasses lost production, environmental risks from material release, and potential safety hazards. Investing in robust verification protocols mitigates these long-term financial and reputational risks.

For industrial applications where titanium anodes are critical, consistent coating quality is directly linked to process stability and product purity. Manufacturers like China Titanium Factory emphasize stringent quality control to ensure optimal performance and reliability of their coated products.

Accurate measurement of MMO coating thickness is crucial for ensuring the coating's performance and cost-effectiveness. A range of techniques, both non-destructive and destructive, are available, each with specific advantages and application limits.

The selection of a method depends on factors such as the substrate material, coating thickness range, required accuracy, and whether the component can tolerate destructive testing. Understanding the principles behind each technique is essential for effective quality control.

Non-destructive methods are preferred when the component must remain intact after testing. They are typically faster and suitable for in-line process control or final product inspection.

The Eddy Current method is widely used for non-conductive coatings on non-ferrous conductive substrates, such as MMO coatings on titanium. It operates by inducing eddy currents in the substrate; the coating thickness affects the impedance of the probe coil, which is then correlated to thickness. This method requires calibration against known standards.

Magnetic Induction is less applicable for MMOs on titanium as it requires a ferrous substrate. However, it is a common non-destructive method for other coating systems.

X-ray Fluorescence (XRF) is a highly accurate method capable of measuring the thickness and elemental composition of coatings, including MMOs. XRF works by exciting the coating materials with X-rays, causing them to emit characteristic fluorescent X-rays. The intensity of these emitted X-rays is proportional to the coating thickness. XRF is versatile but requires specialized equipment and safety precautions.

| Technique | Principle | Advantages | Limitations |

|---|---|---|---|

| Eddy Current | Measures impedance changes from induced eddy currents. | Fast, portable, suitable for non-ferrous substrates. | Requires calibration, sensitive to substrate conductivity variations. |

| X-ray Fluorescence (XRF) | Analyzes characteristic X-rays emitted by excited coating elements. | Highly accurate, measures composition, wide thickness range. | Expensive equipment, radiation safety, sample size limitations. |

For further details on XRF principles and applications, authoritative sources such as Thermo Fisher Scientific's technical resources provide comprehensive information.

Destructive methods offer high precision and detailed microstructural information, often used for research, failure analysis, or when non-destructive methods are insufficient. These methods involve damaging or destroying the sample.

Cross-Sectional Microscopy involves cutting a small section of the coated material, mounting it in resin, polishing the cross-section, and then observing it under an optical or scanning electron microscope (SEM). This technique provides a direct visual measurement of the coating thickness and allows for detailed examination of the coating layers, interface with the substrate, and any defects.

Coulometric Anodic Stripping is an electrochemical method where a small area of the coating is dissolved layer by layer. The time required to strip the coating at a constant current is directly proportional to its thickness. This method is highly precise for thin coatings and can often distinguish between multiple layers, but it requires careful electrolyte selection and can be slow.

The adhesion of an MMO coating to its substrate is a critical property that dictates its long-term durability and performance. A strong bond prevents delamination and ensures the coating functions as intended throughout its service life. Various methods are employed to quantify this bond strength, each with distinct advantages and limitations.

These tests are often standardized by organizations such as ASTM International and ISO, providing consistent methodologies for comparison and quality assurance. Selecting the appropriate adhesion test depends on the coating system, substrate, and the specific application requirements.

Cross-Cut (X-cut/Lattice) Test (ASTM D3359 / ISO 2409): This qualitative test involves cutting a lattice pattern through the coating into the substrate. A pressure-sensitive tape is then applied over the cuts and rapidly removed. The adhesion is rated based on the amount of coating removed, providing a quick assessment of the coating's cohesive strength and adhesion to the substrate.

Pull-Off Test (ASTM D4541 / ISO 4624): This quantitative method measures the tensile stress required to detach a dolly (test fixture) that has been glued to the coating surface. The test provides a numerical value for adhesion strength in psi or MPa. It is highly effective for thick and durable coatings like MMOs, providing precise data on bond strength.

Tape Test (ASTM D3359): Similar to the cross-cut test but without the lattice pattern. A specific adhesive tape is applied to the coated surface and then pulled off. The amount of coating removed indicates the adhesion level. This test is generally used for evaluating adhesion of coatings to metallic substrates and is a simpler, qualitative assessment.

These standard tests are crucial for routine quality control and for validating coating processes. Adherence to ASTM International standards ensures comparability and reliability of results across different testing environments.

For more detailed analysis or specific research and development applications, advanced adhesion testing techniques are employed.

Scratch Testing: This method involves drawing a stylus across the coated surface under increasing load until the coating delaminates or fractures. The critical load at which failure occurs is a measure of adhesion and scratch resistance. It is particularly useful for thin, hard coatings and can reveal different failure modes.

Indentation Testing: While primarily used for hardness measurements, indentation can also provide insights into adhesion by observing the behavior of the coating around the indentation mark. Delamination or cracking patterns can indicate poor adhesion or internal stresses.

Ultrasonic Testing: This non-destructive technique utilizes high-frequency sound waves to detect discontinuities or delaminations within the coating or at the coating-substrate interface. Changes in the ultrasonic signal characteristics can indicate areas of poor adhesion or voids, offering a way to inspect large areas without damage.

The accuracy and reliability of MMO coating thickness and adhesion measurements are influenced by a multitude of factors. Overlooking any of these can lead to erroneous data, potentially resulting in product failures or unnecessary rework.

Surface Preparation: Inadequate cleaning or preparation of the substrate before coating application can severely impact adhesion. Similarly, improper surface preparation of the coated sample prior to testing (e.g., presence of oils, dirt, or uneven surfaces) can skew measurement results.

Equipment Calibration: All measurement instruments, whether for thickness or adhesion, must be regularly calibrated against certified standards. Uncalibrated equipment is a primary source of inaccurate data. Calibration frequency should align with manufacturer recommendations and industry standards.

Environmental Conditions: Temperature, humidity, and airborne contaminants can affect both the coating properties and the performance of testing equipment. For instance, extreme temperatures can alter coating elasticity, while high humidity can affect adhesive bond strength in pull-off tests.

For critical measurements, performing tests in a controlled laboratory environment (e.g., stable temperature and humidity) significantly enhances the reproducibility and reliability of results. This minimizes external variables that could introduce measurement uncertainty.

Operator Proficiency: The skill and experience of the operator performing the tests are paramount. Proper training in equipment usage, adherence to standard operating procedures, and correct data interpretation are essential to minimize human error and ensure consistent results.

Substrate and Coating Properties: Variations in substrate metallurgy, surface roughness, or the inherent properties of the MMO coating formulation (e.g., internal stress, porosity) can directly influence measurement outcomes. These material characteristics must be accounted for during planning and interpretation.

Establishing and maintaining effective quality control (QC) protocols for MMO coatings is fundamental to delivering high-performance and reliable products. A systematic approach ensures consistency and mitigates risks throughout the production lifecycle.

Comprehensive Sampling Plans: Implement statistically sound sampling plans that define the number, location, and frequency of tests. This ensures representative data collection without over-testing or under-testing production batches. Sampling should cover different stages of the coating process.

Detailed Data Documentation: Maintain meticulous records of all verification results, including instrument settings, environmental conditions, operator details, and calibration certificates. This documentation is vital for traceability, trend analysis, and addressing any future performance issues.

Continuous Personnel Training: Regularly train and certify personnel involved in coating application and verification. This ensures a consistent understanding of procedures, equipment operation, and interpretation of results, fostering a culture of quality.

Integration with Continuous Improvement: Utilize verification data not just for pass/fail decisions but as feedback for process optimization. Identifying trends or recurring issues can lead to adjustments in coating parameters, substrate preparation, or post-treatment processes, driving continuous improvement.

Organizations like China Titanium Factory adhere to these best practices, integrating advanced quality control measures into every stage of their product manufacturing to guarantee the highest standards for their MMO-coated products.

Despite robust protocols, challenges can arise during MMO coating verification. Addressing these issues systematically is key to maintaining reliable quality control.

Inconsistent Readings: If thickness measurements vary significantly across a seemingly uniform surface, check for irregular substrate roughness, localized coating defects, or inconsistent probe pressure during non-destructive testing. Re-calibration of the instrument or using a different measurement technique may be necessary.

Unexpected Adhesion Test Results: Low adhesion values might indicate insufficient substrate preparation, incorrect coating application parameters (e.g., curing temperature), or contamination. Investigate the entire coating process for deviations. Ensure the adhesive used for pull-off tests is appropriate and fully cured.

Challenges in Data Interpretation: When results are ambiguous, consult relevant industry standards (e.g., ASTM, ISO) for acceptance criteria. For complex failures, destructive methods like cross-sectional microscopy can provide visual evidence of interfacial issues or internal coating defects not detectable otherwise.

Systematic root cause analysis, involving a review of process parameters, material certifications, and equipment maintenance logs, is crucial for effective troubleshooting. Regular cross-validation between different testing methods can also help confirm findings.

The verification of MMO coating thickness and adhesion is an indispensable aspect of ensuring the reliability and performance of coated components in demanding industrial applications. Through a combination of non-destructive and destructive techniques, rigorous quality control protocols are maintained.

From eddy current and XRF for thickness to pull-off and scratch tests for adhesion, each method plays a vital role in validating coating integrity. The accuracy of these verifications is heavily dependent on meticulous surface preparation, precise equipment calibration, and highly trained personnel.

Looking forward, the field of coating verification is poised for significant advancements. Emerging technologies, such as advanced sensor integration, artificial intelligence for data analysis, and enhanced automation, promise to revolutionize quality assurance processes.

These innovations will lead to faster, more accurate, and more comprehensive non-destructive testing capabilities, further securing the performance of critical industrial components. For more insights into future trends and technological developments, readers are encouraged to explore the China Titanium Factory blog.

The primary purpose of an MMO coating is to enhance the electrocatalytic activity, corrosion resistance, and operational lifespan of a substrate, typically titanium, in demanding electrochemical environments. This makes them ideal for applications such as industrial anodes and cathodic protection systems.

Coating thickness verification is crucial because it directly impacts the coating's performance and durability. A coating that is too thin may fail prematurely due to insufficient protection or catalytic material, while an overly thick coating can lead to internal stresses, reduced adhesion, and unnecessary material costs.

Non-destructive testing (NDT) methods, such as Eddy Current and XRF, measure coating properties without damaging the component, making them suitable for production line checks. Destructive testing (DT) methods, like cross-sectional microscopy and coulometric stripping, require sacrificing a sample but provide highly detailed or microstructural information.

Adhesion is commonly measured using standard tests such as the Cross-Cut test (qualitative assessment of cohesive strength), Pull-Off test (quantitative measurement of tensile adhesion strength), and Tape test (qualitative assessment). More advanced methods like Scratch and Ultrasonic testing are used for specialized analysis.

Common causes of poor adhesion include inadequate substrate surface preparation (e.g., insufficient cleaning or roughening), improper application parameters (e.g., incorrect temperature or solution concentration), post-coating contamination, or inherent stresses within the coating layer itself.

Trust in precision and reliability for your critical industrial applications. Partner with China Titanium Factory for MMO-coated titanium products that meet the most stringent quality standards.

Contact Our Experts Today