What is Heat Anodizing Titanium? Understanding the Process and Its Applications

Titanium, prized for its strength-to-weight ratio and corrosion resistance, often presents a muted, silvery-gray appearance. For many applications, this is perfectly adequate. However, what if a project demands both the superior mechanical properties of titanium and a striking aesthetic? The answer often lies in surface treatments.

One such method, heat anodizing, offers a transformative solution. It’s a process that alters the visual and, to some extent, the functional characteristics of titanium by precisely controlling heat. This technique creates a spectrum of vibrant colors without dyes or pigments, enhancing the material's appeal and utility.

This guide delves deep into the specifics of heat anodizing titanium. We'll explore the science, methodology, and diverse applications, providing a clear roadmap for engineers, designers, and enthusiasts looking to master this versatile surface treatment.

The Science Behind Titanium's Vibrant Hues: How Heat Creates Color

Heat anodizing titanium isn't about applying a colored coating. It’s a trick of light, literally. When titanium is exposed to controlled heat, it naturally forms a thin, transparent layer of titanium dioxide (TiO₂). This oxide layer acts as a prism, interacting with light in a fascinating way.

The phenomenon at play here is called thin-film interference. When white light strikes the surface, some light reflects off the very top of the oxide layer. The rest passes through, reflects off the underlying titanium metal, and then exits back through the oxide layer. These two sets of light waves interfere with each other.

Thin-Film Interference: A natural phenomenon where light waves reflecting off the top and bottom surfaces of a thin film (like titanium oxide) interfere with each other, either reinforcing or canceling out specific wavelengths. This selective cancellation and reinforcement produce the perception of color.

The thickness of this transparent TiO₂ layer dictates which wavelengths of light are amplified and which are canceled out. As the oxide layer grows thicker with increased heat and duration, the perceived color shifts across the spectrum—think a rainbow. This is why precise temperature control is not just recommended, but absolutely critical for predictable results.

Understanding this fundamental principle is the first step in mastering titanium color formation through thermal processes.

Heat Anodizing vs. Electrochemical Anodizing: A Comparative Analysis

While both heat and electrochemical anodizing yield colorful titanium surfaces, their mechanisms and optimal applications differ significantly. It's not a matter of one being inherently "better," but rather which method suits the specific project requirements.

Heat Anodizing (Thermal Oxidation):

Process: Involves heating titanium in air or an oxygen-rich environment. No electricity or liquid electrolytes are required.

Oxide Layer: Forms a natural, somewhat less dense TiO₂ layer. Thickness is controlled by temperature and time.

Color Range: Typically produces a spectrum of browns, golds, blues, purples, and greens. Achieving vibrant, consistent blues and purples is common.

Control: Primarily temperature-dependent. Can be harder to achieve extremely fine, repeatable gradients compared to electrochemical methods, but offers unique "organic" color shifts.

Equipment: Relatively simple: heat source (oven, torch, hot plate), temperature gauge.

Applications: Jewelry, artistic pieces, small components where aesthetics are primary, or when a "burnished" look is desired.

Electrochemical Anodizing:

Process: Uses an electrical current passed through an electrolyte solution with titanium as the anode.

Oxide Layer: Forms a denser, more uniform oxide layer. Thickness is precisely controlled by voltage.

Color Range: Can achieve a broader, often brighter and more consistent spectrum of colors, including very vivid blues, purples, and greens.

Control: Voltage-dependent, offering very precise and repeatable color control. Gradients are easier to manage.

Equipment: More complex: power supply, electrolyte bath, cathodes, precise voltage meter.

Applications: Medical implants, aerospace components, precise custom titanium parts, high-volume manufacturing.

While electrochemical anodizing offers finer control and a broader palette, thermal oxidation excels in simplicity and can impart a unique character. Many choose it for its accessibility and distinct visual effects.

Preparing Titanium for Heat Anodizing: Essential Steps for Optimal Results

A flawless finish begins with meticulous preparation. Skipping steps here is a rookie mistake, leading to inconsistent coloring, splotches, or poor adhesion. Think of it as laying a foundation; a shaky start guarantees a shaky outcome.

Here’s the rundown for proper titanium surface preparation:

1. Thorough Cleaning and Degreasing

Any oil, grease, fingerprints, or machining lubricants will prevent the oxide layer from forming evenly. This is non-negotiable.

Soap and Water: Start with a good scrub using dish soap and hot water. Use a clean, non-abrasive cloth or brush.

Acetone/Isopropyl Alcohol: Follow with a solvent wipe. Acetone or isopropyl alcohol (IPA) are excellent for removing residual oils. Ensure proper ventilation.

Ultrasonic Cleaner (Optional but Recommended): For small, intricate parts, an ultrasonic cleaner with a suitable degreasing solution can reach crevices manual cleaning misses.

2. Rinsing and Drying

Rinse thoroughly with distilled water to remove any cleaning agent residue. Tap water can leave mineral deposits. Pat dry with a lint-free cloth or use clean compressed air. Avoid touching the cleaned surface with bare hands thereafter; wear clean gloves.

3. Surface Abrasion (Optional, but Influences Finish)

While not strictly necessary for color formation, the surface finish directly impacts the final appearance. A highly polished surface will show bright, reflective colors, while a matte or brushed finish will produce more subdued, satin hues.

Sanding/Brushing: Use progressively finer grit sandpaper or Scotch-Brite pads for a brushed finish.

Polishing: For a mirror finish, use polishing compounds and buffing wheels.

Acid Etching (Advanced): Some professionals use mild acid etching to create a more uniform micro-texture, enhancing color adherence and consistency. This requires specialized handling and safety protocols.

Remember, consistency in surface texture across the part ensures consistency in color. A patchy finish will yield patchy colors.

Mastering the Process: Methods and Parameters for Heat Anodizing Titanium

With a pristine surface ready, it's time to apply the heat. The core principle is simple: controlled heating. The execution, however, demands attention to detail. Different heating methods suit different scales and desired effects.

Common Heating Methods

Oven Heating: This is arguably the most controlled method for uniform coloring on multiple pieces or larger items. A kiln or heat-treating oven provides stable temperatures. Place parts on a clean, non-reactive surface (e.g., ceramic tile, stainless steel mesh).

Torch Anodizing: Best for localized coloring, small parts, or creating gradients. A propane or butane torch works. The key is a steady hand and even heat application. Keep the flame moving; lingering in one spot causes overheating and dull, gray patches.

Hot Plate/Electric Skillet: Suitable for flat pieces or creating patterns by selectively heating areas. Ensure even heat distribution across the plate.

Induction Heating (Advanced): Offers rapid, precise heating for industrial applications, allowing for very localized and controlled thermal coloring.

Critical Parameters

Success hinges on managing these variables:

Temperature: This is the prime driver of color. Higher temperatures yield thicker oxide layers and different colors. A good thermometer or thermocouple is essential for oven work. For torch work, experience and visual cues become your guide.

Duration: Time at temperature also plays a role, especially at lower temperatures where oxide growth is slower. For torch work, it's about the speed of application. For oven work, it's the soak time once the target temperature is reached.

Atmospheric Conditions: Generally, heating in ambient air is sufficient. An oxygen-rich environment promotes faster oxide growth. Avoiding contaminants in the air (like smoke or dust) is crucial.

Cooling: Rapid cooling can sometimes shock the oxide layer, though generally, air cooling is sufficient. Avoid quenching in water unless specifically trying to achieve a particular effect, as it can cause warping or cracking in some cases.

Trial and error, especially with torch anodizing, is part of the learning curve. Start with scrap pieces to dial in your technique and build a reference.

Achieving the Spectrum: Temperature-Color Correlation in Heat Anodizing

The beauty of heat anodizing lies in its predictable, albeit delicate, relationship between temperature and color. As the titanium heats, the oxide layer thickens, shifting the perceived color through a distinct sequence. This isn't an exact science in terms of universal temperature readings, as factors like titanium alloy, surface finish, and heating rate influence results. However, a general progression holds true.

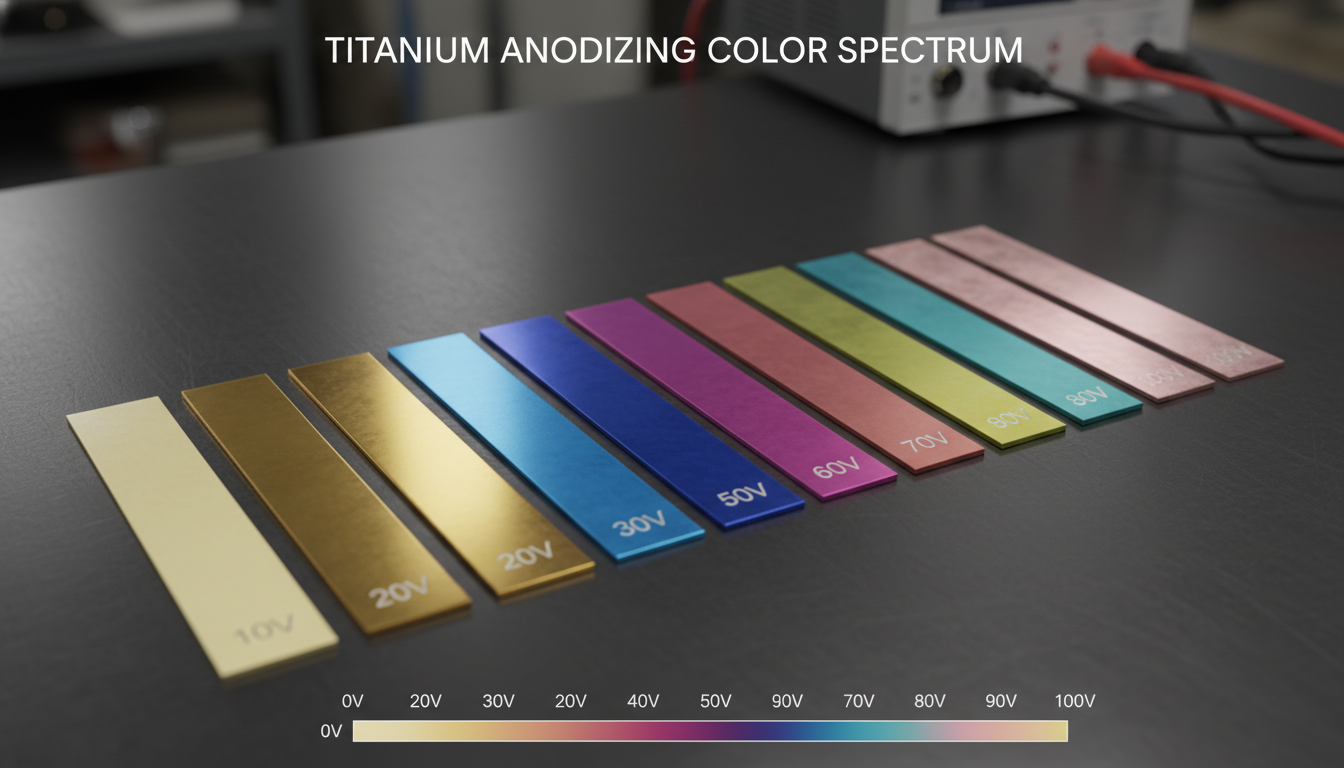

Below is a typical, approximate titanium color chart temperature guide for heating in air:

| Approx. Temperature (°F / °C) | Resulting Color | Oxide Layer Thickness (approx.) |

|---|---|---|

| 500-600°F (260-315°C) | Light Straw, Pale Yellow | 10-20 nm |

| 600-700°F (315-370°C) | Darker Gold, Bronze | 20-30 nm |

| 700-800°F (370-425°C) | Purple, Magenta | 30-40 nm |

| 800-900°F (425-480°C) | Dark Blue, Royal Blue | 40-50 nm |

| 900-1000°F (480-540°C) | Sky Blue, Light Blue | 50-60 nm |

| 1000-1100°F (540-590°C) | Greenish Blue, Green | 60-70 nm |

| 1100-1200°F (590-650°C) | Green, Yellow-Green | 70-80 nm |

Going beyond these temperatures can lead to thicker, less stable oxide layers that appear dull gray or brown, losing the vibrant interference colors. It's a fine line. Experience will teach you the subtle shifts. When using a torch, observe the color change in real-time and stop heating immediately upon reaching the desired hue.

Equipment and Safety: Essential Tools and Precautions for Heat Anodizing

You don't need a state-of-the-art laboratory for heat anodizing, but having the right tools makes a world of difference. More importantly, understanding and implementing safety protocols is paramount. Working with heat and potentially chemicals is no joke; cutting corners here is a recipe for trouble.

Essential Equipment List

Heat Source:

Propane/Butane Torch (for small parts, localized heating)

Electric Oven/Kiln (for uniform, larger batches)

Hot Plate (for flat items)

Temperature Measurement:

Infrared Thermometer (for surface temperature)

Thermocouple with digital readout (for oven accuracy)

Cleaning Supplies:

Dish soap, distilled water

Acetone or Isopropyl Alcohol (IPA)

Lint-free cloths, clean gloves (nitrile or latex)

Handling Tools:

Heat-resistant tongs or pliers

Non-combustible work surface (fire brick, ceramic tile)

Crucial Safety Precautions

Prioritize safety above all else. A momentary lapse can have lasting consequences.

Ventilation: Always work in a well-ventilated area. Heating metals, especially if there are residual contaminants, can produce fumes.

Personal Protective Equipment (PPE):

Safety Glasses: Protect your eyes from heat, glare, and potential sparks.

Heat-Resistant Gloves: Crucial for handling hot titanium and heat sources.

Respirator (Optional, but Recommended): If using strong solvents or working in a less-than-ideal ventilation setup, a respirator with appropriate filters is a wise choice.

Fire Safety: Keep a fire extinguisher (Class D for metal fires, or Class ABC for general fires) readily accessible. Ensure no flammable materials are near your work area.

Stable Work Surface: Work on a sturdy, non-combustible surface. Hot titanium can easily scorch or ignite flammable materials.

Chemical Handling: If using solvents, follow their specific safety data sheets (SDS). Wear appropriate gloves and ensure good ventilation.

Never rush. Double-check your setup. Being safe is the only way to ensure a successful project without a hitch.

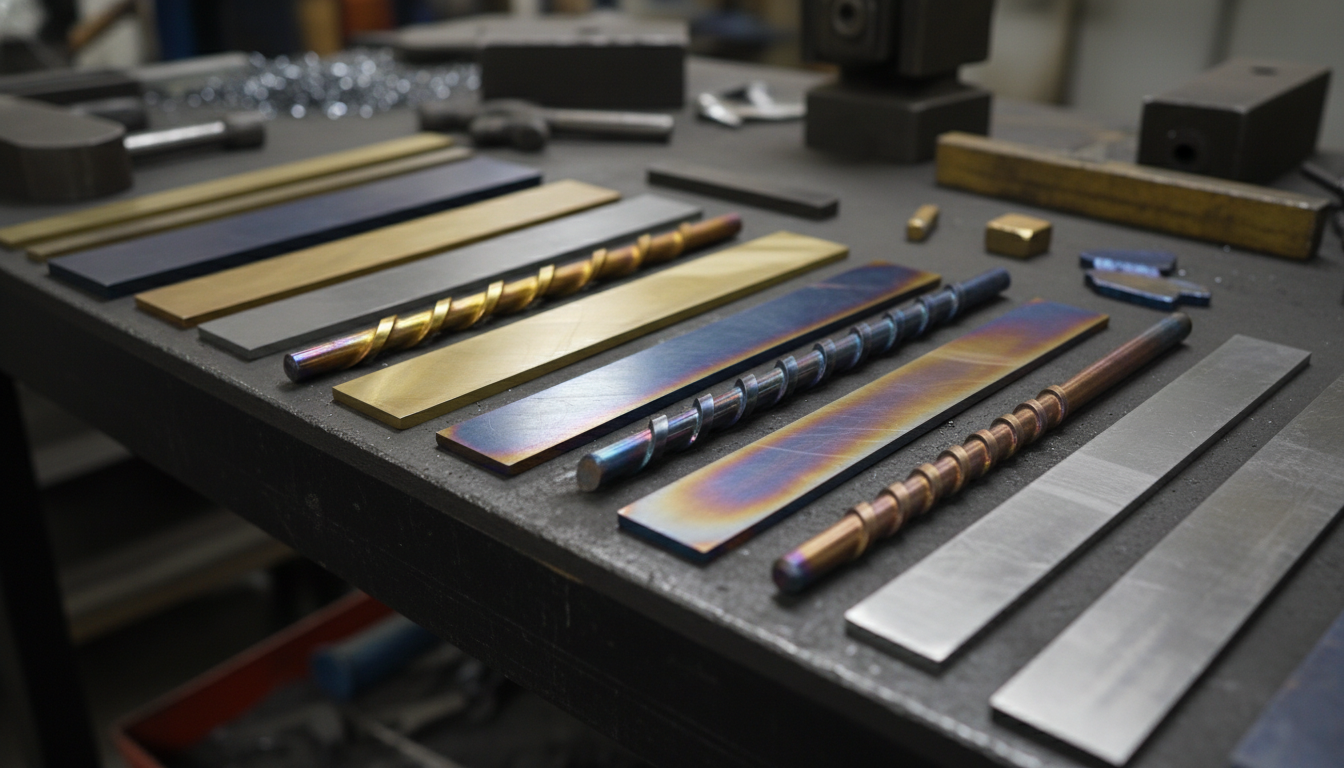

Applications of Heat Anodized Titanium: Beyond Aesthetics

While the visual appeal of heat-anodized titanium is undeniable, its utility extends far beyond mere decoration. The surface modification imparts properties that are highly valued across various industries. It’s not just a pretty face; it's a functional enhancement.

Medical Implants

Titanium is already a biocompatible champion, ideal for prosthetics, dental implants, and surgical instruments. Heat anodizing enhances this. The oxide layer further improves biocompatibility and corrosion resistance in the harsh biological environment. Additionally, the ability to color-code implants can assist surgeons in identifying different sizes or types during complex procedures. This is a big deal in the operating room. Research suggests that anodized titanium surfaces can promote cell adhesion and growth, which is critical for successful integration into the body.

Aerospace Components

In aerospace, every ounce and every property matters. Heat anodizing can improve the wear resistance and fatigue life of titanium components. The oxide layer provides a harder surface, reducing friction and extending the lifespan of critical parts in demanding environments. Identifying different titanium aerospace components by color also helps with assembly and maintenance.

Jewelry and Decorative Arts

This is where heat anodizing truly shines aesthetically. Artists and jewelers use the technique to create stunning, iridescent pieces—rings, pendants, sculptures—that harness the unique optical properties of titanium. The ability to produce a full spectrum of colors without dyes offers unparalleled creative freedom.

Consumer Electronics and Sporting Goods

From high-end phone cases to bicycle frames, heat-anodized titanium adds a premium, customized look. Its durability ensures the color stands up to daily wear and tear, providing both function and flair. Manufacturers like China Titanium Factory can produce custom titanium products with these aesthetic finishes.

The versatility of heat-anodized titanium ensures its continued relevance across a wide array of specialized and everyday items. It’s a testament to how material science can elevate both form and function.

Enhanced Properties: Corrosion Resistance, Biocompatibility, and Hardness

Beyond the visual spectacle, the thermally grown oxide layer significantly impacts titanium's inherent properties. This isn't just skin deep; it's a fundamental alteration that benefits performance.

Corrosion Resistance: Titanium naturally forms a passive oxide layer that grants it exceptional corrosion resistance. Heat anodizing thickens and densifies this protective barrier. This enhanced layer provides even greater resistance to chemical attack and environmental degradation, making it ideal for marine, chemical processing, and other harsh environments.

Biocompatibility: For medical applications, maintaining or improving biocompatibility is paramount. The TiO₂ layer formed during heat anodizing is non-toxic and inert, further reducing the risk of adverse reactions in biological systems. This makes heat-anodized titanium even more suitable for long-term implantation.

Surface Hardness and Wear Resistance: The titanium dioxide layer is significantly harder than the underlying pure titanium. This increased surface hardness can improve wear resistance, crucial for parts subjected to friction or abrasion. While not a replacement for specialized hard coatings, it offers a measurable improvement.

These property enhancements underscore why heat anodizing is considered a functional surface treatment, not just a cosmetic one.

Advantages and Limitations of Heat Anodizing Titanium

Every process has its strong suits and its Achilles' heel. Heat anodizing titanium is no different. Understanding both its benefits and its drawbacks helps in deciding if it's the right tool for the job.

Advantages of Thermal Coloring

Simplicity: Compared to electrochemical anodizing, the setup for heat anodizing is relatively straightforward. No electrolytes, no complex electrical circuits.

Cost-Effective: Lower equipment investment for small-scale operations or DIY projects.

No Chemical Waste: As it uses only heat and air, there are no hazardous chemical byproducts to dispose of, making it an environmentally friendlier option.

Enhanced Properties: Improves corrosion resistance, biocompatibility, and surface hardness.

Unique Aesthetic: The "burnished" or iridescent look created by thermal oxidation can be distinct and highly desirable for artistic applications.

Limitations of Heat Anodizing

Color Control: Achieving precise, repeatable colors across multiple batches or large surfaces can be challenging. Slight temperature variations lead to color shifts.

Limited Color Range: While vibrant, the color palette is dictated by the interference spectrum and can be less diverse or intense than electrochemically anodized titanium, especially for certain hues.

Uniformity: Achieving perfectly uniform color on complex geometries or very large parts can be difficult, particularly with torch methods.

Surface Finish Impact: The initial surface finish heavily influences the final color's appearance. Inconsistencies will be highlighted.

Durability: While the oxide layer is hard, it is still a thin film. Extreme abrasion can scratch or wear through it, though it generally holds up well under normal use. ASM International provides extensive data on titanium surface treatments, including their durability.

When considering heat anodizing, weigh these factors carefully against your project's specific needs for aesthetics, precision, and durability. For high-volume, precision CNC machining titanium components that need consistent coloring, electrochemical anodizing might be the better bet.

Troubleshooting Common Issues and Optimizing Your Heat Anodizing Results

Even seasoned pros hit snags sometimes. The difference is knowing how to diagnose and fix them. Here are some common problems and practical solutions to keep your heat anodizing projects on track, ensuring you don't throw good money after bad.

Inconsistent Coloring or Splotches

Problem: Colors vary across the surface, or specific areas are dull/discolored.

Solution: This is almost always a surface preparation issue. Re-clean and degrease meticulously. Ensure no fingerprints, oils, or residues remain. For oven heating, ensure even heat distribution; some ovens have hot spots. For torching, practice even passes.

Dull or Muddy Colors

Problem: Colors lack vibrancy or appear brownish/grayish instead of bright.

Solution: You likely overheated the titanium. The oxide layer became too thick or the surface oxidized beyond the interference spectrum. There's no coming back from this with heat anodizing alone. You'll need to sand or polish off the existing oxide layer and start fresh.

Colors Don't Match Expected Chart

Problem: You aimed for blue but got purple, or yellow instead of gold.

Solution: Temperature control is likely off. Calibrate your thermometer. Test on scrap pieces of the exact same alloy as your project piece. Different titanium alloys can react slightly differently. Adjust your target temperature up or down in small increments.

Optimizing for Repeatability and Quality

Keep a Log: Document every variable: titanium alloy, initial surface finish, cleaning method, specific temperature, heating time, and the resulting color. This builds invaluable institutional knowledge.

Test Pieces: Always use scrap pieces from the same batch and alloy as your final product to dial in parameters.

Controlled Environment: Minimize drafts if torching. Ensure stable oven temperatures. Consistency is your best friend.

Patience: Don't rush the heating or cleaning. Quality work takes time.

By systematically addressing these points, you'll improve your success rate dramatically. Even titanium fabrication experts leverage consistent processes for high-quality outcomes.

Cost Considerations and Equipment Investment for Heat Anodizing

Getting into heat anodizing doesn't have to break the bank, especially for hobbyists. However, scaling up to professional-grade or high-volume production requires a more significant investment. Let's break down the financial picture.

DIY / Hobbyist Costs (Low Investment)

For small projects, the entry barrier is quite low. You might already own some of the essentials.

Heat Source: Propane torch ($20-50), kitchen oven (already owned).

Temperature Measurement: Infrared thermometer ($30-70).

Cleaning Supplies: Dish soap, acetone/IPA ($10-20).

Safety Gear: Gloves, safety glasses ($15-30).

Total Estimated DIY: ~$75 - $170

This budget allows for experimentation and small-scale artistic endeavors. The main variable will be the cost of the titanium itself.

Professional / Small Business Costs (Moderate Investment)

For more consistent, higher-quality, and larger-scale production, upgrading equipment is necessary.

Heat Source: Dedicated heat-treating oven or kiln ($500 - $3,000+).

Temperature Control: High-precision thermocouple and controller ($100-300).

Cleaning: Ultrasonic cleaner ($100-500), industrial degreasers ($50-150).

Ventilation: Fume extractor hood ($200-1,000+).

Professional Tools: Quality tongs, non-contaminating racks ($50-200).

Total Estimated Professional Setup: ~$1,000 - $5,000+

This level of investment enables greater throughput, consistency, and safety, crucial for meeting client demands. For complex or large-scale titanium manufacturing and finishing, partnering with specialized providers is often more cost-effective than in-house setup.

Durability and Longevity: Heat Anodized vs. Electrochemically Anodized Titanium

When investing time and resources into surface finishing, durability is a major concern. How well does the color hold up? Does it scratch easily? Understanding the longevity of heat-anodized titanium, especially compared to its electrochemical cousin, helps set realistic expectations.

Wear and Scratch Resistance

Heat Anodized: The thermally grown oxide layer is hard, offering improved scratch resistance compared to bare titanium. However, it's a relatively thin layer. Deep scratches or heavy abrasion can penetrate the oxide, revealing the underlying metal and dulling the color. It holds up well to everyday handling but isn't impervious to abuse.

Electrochemical Anodized: Generally, electrochemically anodized layers can be grown thicker and often denser, potentially offering superior scratch and wear resistance. The precise control over voltage allows for very robust oxide layers.

Color Stability and Fade Resistance

Heat Anodized: The color in heat-anodized titanium comes from the oxide layer's physical interaction with light, not from pigments. This means the color itself cannot "fade" in the traditional sense from UV exposure like a dye might. However, prolonged exposure to extreme temperatures (re-heating) can cause the oxide layer to thicken further, changing the color. Chemical exposure can also etch or remove the layer.

Electrochemical Anodized: Similar to heat anodizing, the color is inherent to the oxide layer. It also doesn't fade from UV. However, some electrochemical processes might incorporate dyes, which can fade over time. For undyed electrochemical anodizing, color stability is excellent.

Overall, both anodizing methods create stable colors. The primary concern for both is physical abrasion or harsh chemical exposure. For applications requiring extreme durability, additional protective clear coatings might be considered, though this can alter the optical properties.

When considering functional titanium surface treatments, always match the process to the expected service environment. A piece of jewelry will face different challenges than an aerospace component.

Frequently Asked Questions About Heat Anodizing Titanium

Is heat anodizing titanium permanent?

The colored oxide layer formed during heat anodizing is permanent in the sense that it's part of the titanium's surface, not a coating that can peel. However, it can be removed by abrasion (scratching, sanding) or by strong chemical etching. It will not fade due to UV light.

Can you re-anodize heat-anodized titanium?

Yes, but you usually need to remove the existing oxide layer first for consistent results. This typically involves sanding, polishing, or a mild acid etch. Trying to re-anodize over an existing layer can lead to uneven or unpredictable colors.

What temperature do I need for blue titanium?

Achieving blue typically requires temperatures in the range of 800-1000°F (425-540°C). The exact shade of blue (dark royal to sky blue) depends on the precise temperature and duration. Always test on a scrap piece first.

Does heat anodizing affect titanium strength?

Generally, no. The temperatures used for heat anodizing are typically below the recrystallization or annealing temperatures for most common titanium alloys, so they do not significantly alter the bulk mechanical properties or strength of the underlying metal. The oxide layer itself is very thin and hard, slightly increasing surface hardness.

Is heat anodizing safe for food contact?

The titanium dioxide (TiO₂) layer formed is generally considered non-toxic and inert, commonly used in food products (e.g., as a white pigment). As long as no other contaminants are introduced during the process, heat-anodized titanium is generally considered safe for food contact. Always ensure a clean process and consult relevant regulations for specific applications.