The two main coating types for Titanium Anodes (also known as Dimensionally Stable Anodes or DSA) are Mixed Metal Oxide (MMO) and Platinum (Platinized) [1]. The titanium substrate provides mechanical stability, while the coating provides the electrochemically active surface.

The choice depends entirely on the application's electrolyte and required reaction:

MMO Anodes: Ideal for Chlorine Evolution (Ruthenium-based) and Oxygen Evolution (Iridium-based) in high-current density environments like chlor-alkali production, electroplating, and cathodic protection [2].

Platinized Anodes: Preferred for specific applications requiring high purity or where the electrolyte is less aggressive, such as certain electroplating baths and water treatment processes.

The coating determines the anode's lifespan, efficiency, and suitability for a given electrochemical process. MMO coatings are the most common due to their versatility and cost-effectiveness.

| Coating Type | Primary Composition | Key Advantage | Typical Applications |

|---|---|---|---|

| MMO (Mixed Metal Oxide) | Ruthenium Oxide (RuO₂) / Iridium Oxide (IrO₂) mixed with Titanium Dioxide (TiO₂) and Tantalum Oxide (Ta₂O₅). | High catalytic activity, long lifespan, low cost compared to Platinum, and excellent stability in harsh chemical environments. | Chlor-Alkali, Seawater Desalination, Cathodic Protection (CP), Electroplating, Water Treatment. |

| Platinized Titanium | Thin layer of pure Platinum (Pt) applied to the titanium substrate. | High purity, excellent conductivity, and stability in specific acidic solutions (e.g., sulfuric acid). | Precious metal electroplating, specialized water electrolysis. |

MMO coatings are further specialized based on the primary metal oxide used, which dictates the electrochemical reaction they catalyze:

Ruthenium-Iridium Oxide (RuO₂/IrO₂): Optimized for Chlorine Evolution (Cl₂ production). Used extensively in the chlor-alkali industry and brine electrolysis.

Iridium-Tantalum Oxide (IrO₂/Ta₂O₅): Optimized for Oxygen Evolution (O₂ production). Used in acidic electrolytes, copper foil production, and wastewater treatment.

Iridium-Tin Oxide (IrO₂/SnO₂): Used in specific applications requiring high stability in certain organic electrolytes.

Selecting the correct anode coating is crucial for maximizing efficiency and lifespan. Follow this guide:

Identify the Electrolyte: Is it brine (high chloride), sulfuric acid, or fresh water?

High Chloride: Choose a Ruthenium-based MMO coating.

Acidic/Oxygen-rich: Choose an Iridium-based MMO coating.

Determine the Reaction: Are you generating Chlorine, Oxygen, or plating a metal?

Chlorine Gas: Ruthenium-based MMO.

Oxygen Gas: Iridium-based MMO.

Precious Metal Plating: Platinized Titanium or specialized MMO.

Consider Current Density: High current density requires a robust, highly active coating like MMO to prevent rapid wear and passivation.

Evaluate Lifespan and Cost: MMO generally offers a better balance of cost and lifespan (typically 5-10 years) compared to the higher initial cost of Platinum [3].

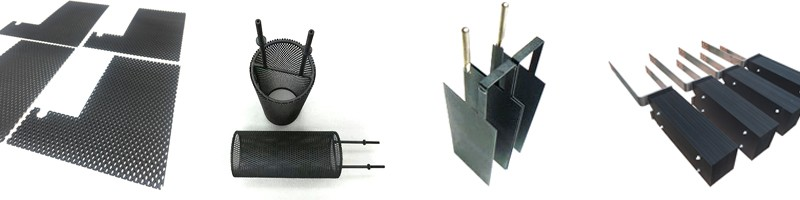

Choosing the right Titanium Anode coating for your specific industrial process is a complex decision. Our technical team specializes in manufacturing custom DSA and MMO anodes tailored for chlor-alkali, electroplating, and cathodic protection. We can help you select the optimal coating ratio and geometry to ensure maximum efficiency and lifespan for your application.