Superior Corrosion Prevention: Mixed Metal Oxide (MMO) tubular anodes offer exceptional protection for critical infrastructure in deep well groundbeds.

Extended Lifespan & Efficiency: Engineered for longevity and high current output, ensuring cost-effective, low-maintenance cathodic protection.

Versatile Applications: Ideal for pipelines, storage tanks, power plants, and marine structures, especially in challenging environments.

Strategic Deep Well Advantage: Optimally designed for limited surface areas, high soil resistivity, and urban settings where traditional methods fall short.

Technical Precision: Manufactured with a robust titanium substrate and precise mixed metal oxide coatings for consistent, reliable performance.

Corrosion represents a significant threat to the integrity and operational lifespan of critical infrastructure, particularly buried or submerged metallic structures. Mitigating this degradation is paramount for industries ranging from oil and gas to municipal water systems. Cathodic protection (CP) stands as a highly effective method for preventing such corrosive processes. Deep well groundbeds, a specialized configuration within impressed current cathodic protection (ICCP) systems, offer a robust solution where surface area is restricted or soil conditions are challenging. Within these systems, Mixed Metal Oxide (MMO) tubular anodes demonstrate exceptional performance.

Definition: Cathodic Protection (CP)

Cathodic protection is an electrochemical technique used to prevent corrosion of a metal surface by making it the cathode of an electrochemical cell. This is achieved by supplying an external current to the structure, forcing it to remain in a passive state, or by connecting it to a more easily corroded "sacrificial" metal.

The deployment of MMO tubular anodes in deep well groundbeds ensures a consistent and uniform current distribution, safeguarding assets from premature failure. Their design optimizes current output while minimizing anode consumption, leading to superior long-term reliability.

Deep well groundbeds are a critical component of modern cathodic protection strategies, particularly when conventional shallow groundbeds are impractical or ineffective. These systems involve installing anodes at significant depths, often hundreds of feet below the surface. This approach offers distinct operational and environmental benefits. One primary advantage is their suitability for environments with limited surface area. Urban centers, industrial complexes, and densely populated regions often lack the expansive land required for conventional groundbed installations. Deep wells allow for effective corrosion protection without extensive surface disruption. Additionally, deep well groundbeds are highly effective in areas characterized by high soil resistivity. Deeper soil layers often exhibit lower and more stable resistivity, facilitating better current distribution and reducing overall system resistance. This enhances the efficiency of the cathodic protection system.

Strategic placement of deep well groundbeds can significantly reduce interference with adjacent structures and minimize stray current issues. Their vertical orientation allows for a concentrated current discharge point, optimizing protection over vast areas of buried infrastructure. This makes them ideal for large-scale pipeline networks and extensive tank farms.

The deep placement also offers superior isolation from surface disturbances and environmental factors. This contributes to more stable system performance and reduced maintenance requirements over the long term.

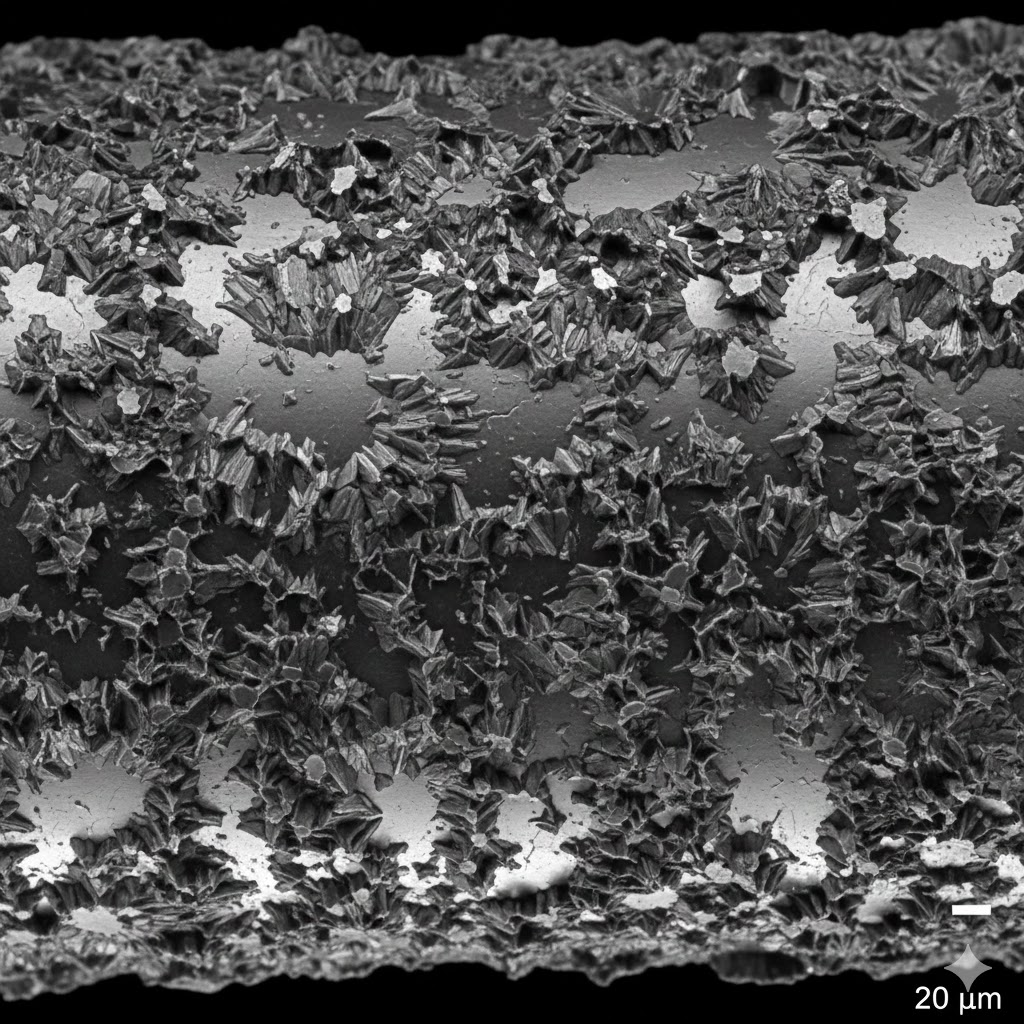

Mixed Metal Oxide (MMO) tubular anodes represent a pinnacle in impressed current cathodic protection technology. Their design and material composition are engineered for maximum efficiency and durability in demanding subsurface environments. These anodes are typically constructed from a titanium substrate, renowned for its excellent mechanical properties and corrosion resistance. The titanium substrate is then coated with a thin layer of mixed metal oxides, primarily iridium oxide and ruthenium oxide. These noble metal oxides are highly electrocatalytic, meaning they efficiently facilitate the electrochemical reaction required for current discharge without significant degradation of the anode material itself. This results in an exceptionally low consumption rate. The precise manufacturing process ensures a uniform and adherent coating, which is crucial for consistent performance and extended service life. The electrochemical properties of these oxides enable high current output densities, making them highly effective even with relatively compact anode dimensions.

| Component | Primary Function/Property |

|---|---|

| Titanium Substrate | Mechanical strength, electrical conductivity, corrosion resistance. |

| Mixed Metal Oxide Coating | Electrocatalytic activity, low consumption rate, high current density. |

| Ruthenium Oxide (RuO₂) | Enhances conductivity and reaction kinetics. |

| Iridium Oxide (IrO₂) | Improves stability and durability, especially in aggressive environments. |

For further technical insights into anode materials and their applications, authoritative resources like those provided by AMPP (Association for Materials Protection and Performance) offer extensive documentation.

The adoption of MMO tubular anodes from ChinaTitaniumFactory.com delivers a compelling array of benefits for critical infrastructure protection. These advantages translate directly into enhanced operational reliability and significant lifecycle cost savings. A primary benefit is their extended lifespan. Due to the extremely low consumption rate of the mixed metal oxide coating, these anodes are designed to operate effectively for decades. This longevity drastically reduces the frequency and cost of anode replacement. Furthermore, MMO tubular anodes provide high current output efficiency. Their electrocatalytic properties allow them to deliver substantial protective current from a relatively small surface area. This efficiency ensures robust cathodic protection even in challenging soil conditions.

Minimal Maintenance Requirements: The durable design and low consumption rate translate to less frequent inspection and servicing.

Cost-Effective CP Solutions: Long operational life and high efficiency contribute to a lower total cost of ownership over the system's lifetime.

Versatile Adaptability: Consistent performance across diverse environmental conditions, including varying soil resistivities and temperatures.

Enhanced System Stability: Reliable current output ensures continuous and stable protection for assets.

These combined attributes underscore why MMO tubular anodes are considered a superior choice for long-term, critical cathodic protection applications. Explore our full range of cathodic protection services and products.

The robust performance characteristics of MMO tubular anodes make them indispensable across a wide spectrum of industrial applications requiring reliable corrosion control. Their ability to deliver consistent current output over extended periods, particularly in deep well groundbeds, positions them as a preferred solution for safeguarding vital infrastructure. Key sectors that benefit significantly from these advanced anodes include:

Oil and Gas Pipelines: Protecting extensive networks of buried pipelines from external corrosion, ensuring safe and uninterrupted transport of hydrocarbons.

Storage Tanks: Safeguarding the integrity of underground and aboveground storage tanks used for petroleum products, chemicals, and water.

Power Generation Facilities: Protecting critical components such as cooling water systems, buried conduits, and foundations at power plants.

Chemical Processing Plants: Providing corrosion control for complex piping systems, vessels, and reactors exposed to aggressive environments.

Marine Structures: While deep wells are less common here, the underlying MMO technology is vital for jetties, piers, and offshore platforms when adapted.

Municipal Water and Wastewater Systems: Protecting buried water mains, sewer lines, and treatment plant infrastructure.

These anodes are specifically engineered to address the unique challenges presented by each application, ensuring long-term asset integrity and operational continuity.

Selecting the appropriate MMO tubular anode configuration is critical for optimizing cathodic protection system performance and achieving desired design life. This process involves a detailed assessment of project-specific demands and environmental parameters. Key technical specifications guide this selection. Typical anode dimensions, current output capabilities, and expected operational parameters are essential considerations. Anodes are available in various lengths and diameters, each designed to deliver specific current densities and total current output.

| Parameter | Typical Range/Consideration |

|---|---|

| Anode Diameter | 1" to 2" (25mm to 50mm) |

| Anode Length | 2 ft to 10 ft (0.6m to 3m) per segment |

| Current Output (per ft) | 0.5 to 5 Amps/ft (depending on coating and environment) |

| Design Life | 20 to 50+ years (application-dependent) |

| Coating Thickness | Typically 6-12 microns (for industrial applications) |

The selection process also considers the required current density for the protected structure, the resistivity of the surrounding soil, and the desired design life of the CP system. Comprehensive resistance calculations are performed to ensure the chosen anode string can deliver the necessary current effectively.

Rigorous quality assurance (QA) and quality control (QC) procedures are paramount in MMO anode manufacturing. These protocols ensure the integrity of the titanium substrate, the uniformity and adhesion of the mixed metal oxide coating, and the overall electrical performance of each anode. Reputable suppliers adhere to strict industry standards for product consistency and reliability.

For custom solutions and detailed technical consultations, clients are encouraged to contact ChinaTitaniumFactory.com directly.

The successful deployment and long-term efficacy of MMO tubular anodes in deep well groundbeds are heavily dependent on adherence to meticulous installation best practices. Proper installation ensures optimal system integrity, uniform current distribution, and maximum operational lifespan. The process begins with precise borehole preparation. This involves drilling a borehole to the specified depth and diameter, ensuring stability and proper alignment. Geological surveys are crucial to identify suitable strata for anode placement. Next, the anode string assembly involves connecting individual tubular anode segments, typically using robust, corrosion-resistant cable connections. Each connection must be watertight and mechanically secure to prevent premature failure.

Borehole Drilling and Logging: Drill to design depth, log soil strata, and ensure borehole stability.

Anode String Preparation: Assemble anode segments, secure cable connections (e.g., using heat-shrink sleeves and epoxy encapsulation).

Lowering the Anode String: Carefully lower the anode string into the borehole, ensuring no damage to anodes or cables.

Backfill Material Selection and Placement: Utilize specialized carbonaceous backfill (e.g., coke breeze) to reduce anode-to-earth resistance and ensure even current discharge. The backfill must be compacted properly.

Vent Pipe Installation: A vent pipe is typically installed alongside the anodes to allow for the escape of gases (primarily oxygen) generated during the electrochemical reaction, preventing gas blocking and ensuring consistent performance.

Surface Termination and Connection: Securely terminate the anode cables at the surface, connecting them to the rectifier and test stations.

CP System Commissioning: Conduct thorough testing and adjustments to ensure the system is operating at optimal parameters.

Adherence to these guidelines, often detailed in standards from organizations like ISO or ASTM International, is paramount for a successful deep well groundbed installation.

The choice of anode material is a critical decision in designing an impressed current cathodic protection system. While various anode types exist, MMO tubular anodes offer distinct advantages, particularly in deep well groundbed applications, when compared to traditional alternatives such as graphite and high silicon cast iron (HSCI).

| Feature | MMO Tubular Anodes | Graphite Anodes | High Silicon Cast Iron (HSCI) Anodes |

|---|---|---|---|

| Consumption Rate | Extremely low (mg/A-yr) | Moderate (kg/A-yr), prone to degradation | Low to moderate (kg/A-yr), brittle |

| Current Output Density | High (Amps/m²) | Low to moderate | Moderate |

| Lifespan | Very long (20-50+ years) | Short to moderate (5-15 years) | Moderate (10-25 years) |

| Mechanical Strength | High (titanium substrate) | Brittle, susceptible to damage | Brittle, heavy |

| Environmental Impact | Minimal (low waste, energy efficient) | Can produce CO₂ (if consumed) | Heavy, requires more material |

This comparative analysis highlights the superior performance and economic benefits of MMO tubular anodes, especially for long-term, high-current deep well applications.

The selection of cathodic protection solutions increasingly incorporates environmental stewardship as a key criterion. MMO tubular anodes contribute significantly to sustainable corrosion control practices through several inherent advantages. Their exceptional longevity directly translates to reduced material consumption and waste generation. By operating effectively for decades, MMO anodes minimize the need for frequent replacement, thereby lessening the environmental footprint associated with manufacturing, transportation, and disposal. This extended operational life is a cornerstone of their sustainability profile. Furthermore, the high current output efficiency of MMO anodes allows for optimal protection with minimal energy input. This energy efficiency reduces the overall power consumption of the cathodic protection system, contributing to lower greenhouse gas emissions over the system's operational tenure.

The inert nature of the mixed metal oxide coating also ensures that no harmful byproducts are released into the surrounding soil or water during operation. This aligns with stringent environmental regulations and promotes ecological preservation. Information on environmentally friendly industrial practices can be found on reputable environmental agencies' websites. For more information on sustainable practices in cathodic protection, refer to the ChinaTitaniumFactory.com blog.

The efficacy and reliability of MMO tubular anodes in deep well groundbeds are substantiated by numerous successful deployments across various challenging industrial environments. Documented case studies consistently illustrate their ability to deliver robust, long-term corrosion protection. These examples often highlight significant reductions in maintenance costs and extended asset lifespans. For instance, a major pipeline operator implemented MMO tubular anodes in a deep well configuration for a critical section traversing high-resistivity terrain. Post-installation monitoring confirmed stable current distribution and effective protection, exceeding initial performance targets. This resulted in averted potential failures and substantial savings from deferred asset replacement. Client testimonials frequently underscore the consistent performance and durability of the anodes provided by ChinaTitaniumFactory.com. Project managers and corrosion engineers commend the technical support and the long-term value delivered by these advanced solutions. Such feedback reinforces the confidence in MMO technology for critical infrastructure. For detailed project outcomes and references, please contact our technical team.

MMO tubular anodes offer an exceptionally low consumption rate, leading to a significantly longer operational lifespan compared to graphite or high silicon cast iron anodes. They also provide high current output efficiency and superior mechanical strength due to their titanium substrate.

With proper design and installation, MMO tubular anodes can have a design life of 20 to 50 years or even longer. Their longevity is a key factor in reducing the overall lifecycle cost of cathodic protection systems.

MMO tubular anodes are highly versatile and perform well across a wide range of soil conditions, including those with high resistivity. Their deployment in deep well groundbeds is particularly advantageous in challenging geological or urban environments where surface space is limited.

Due to their low consumption rate and robust design, MMO anode deep well systems require minimal maintenance. Routine monitoring of rectifier output, current, and potential readings is standard to ensure continuous optimal performance. Physical intervention is rarely needed over their long lifespan.

Yes, ChinaTitaniumFactory.com specializes in providing tailored cathodic protection solutions. The technical team can assist with anode selection, system design, and custom configurations to meet specific project demands and environmental considerations.

Ensuring the long-term integrity and operational reliability of critical infrastructure demands advanced cathodic protection solutions. Mixed Metal Oxide (MMO) tubular anodes, particularly when deployed in deep well groundbeds, represent the pinnacle of this technology. Their superior performance, extended lifespan, and environmental advantages make them an unparalleled choice for demanding applications.

Request a Consultation for Your CP Project

The experts at ChinaTitaniumFactory.com are prepared to provide comprehensive technical support, custom solution development, and a partnership approach to address your specific corrosion control needs. Engage with a team dedicated to delivering optimal cathodic protection for your assets.